CAMWorks Toolpath Doesn't Reach Bottom of Part

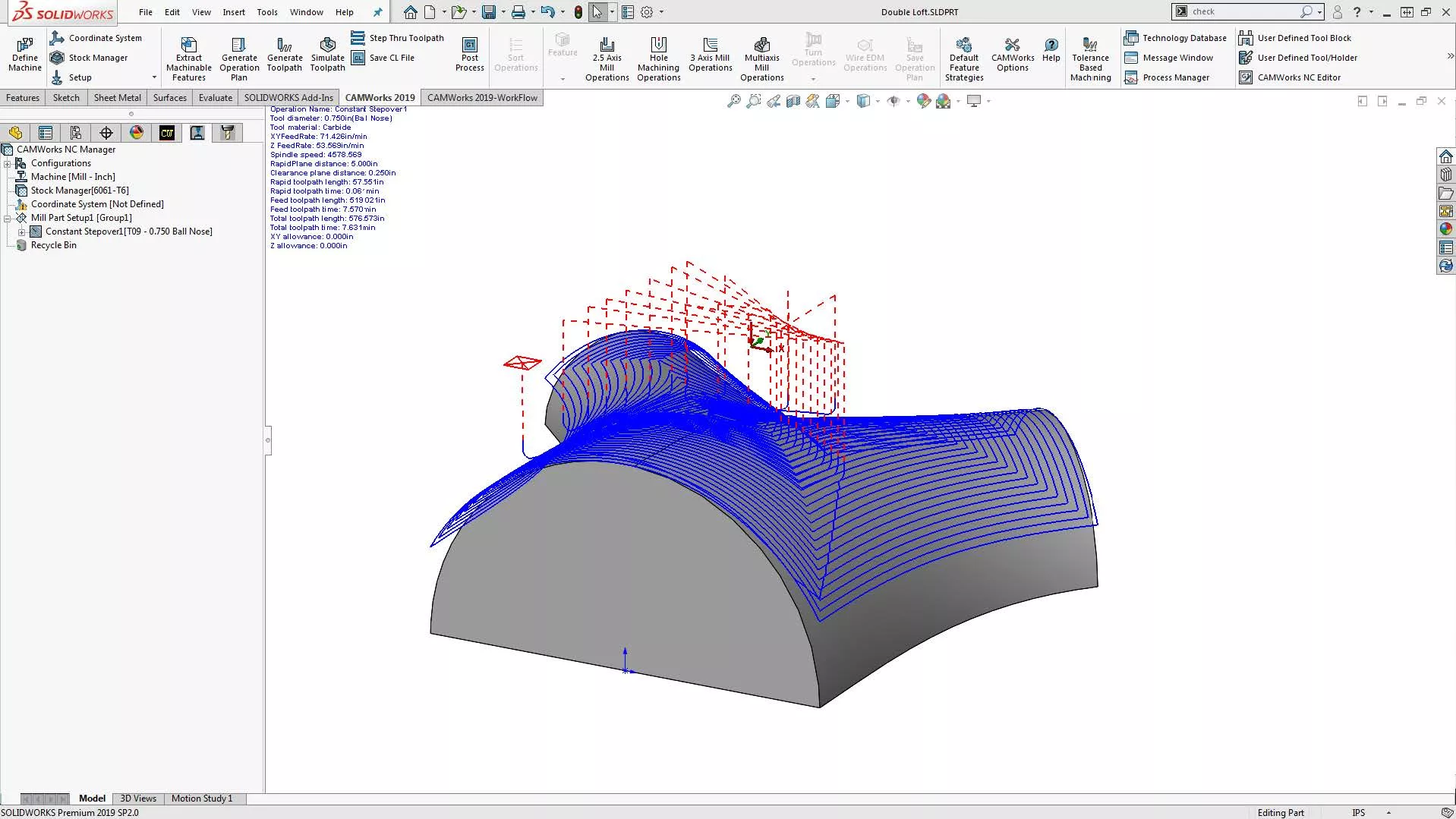

When performing a 3-axis finishing operation on the outer edges of a part in CAMWorks, the tool will not reach the full extent. (Figure 1)

Figure 1: Default setting

The issue might be interpreted that the tool is not going low enough, but that doesn’t tell the whole story. What is actually limiting the tool’s depth is the setting Automatic Contain Area which dictates how the tool’s center behaves with the model.

By default, the Automatic Contain Area tool condition is set to On Center, which limits the tool’s center axis from crossing the extents of the part. Changing this to Past will allow the tool to go further out and, therefore, further down as well.

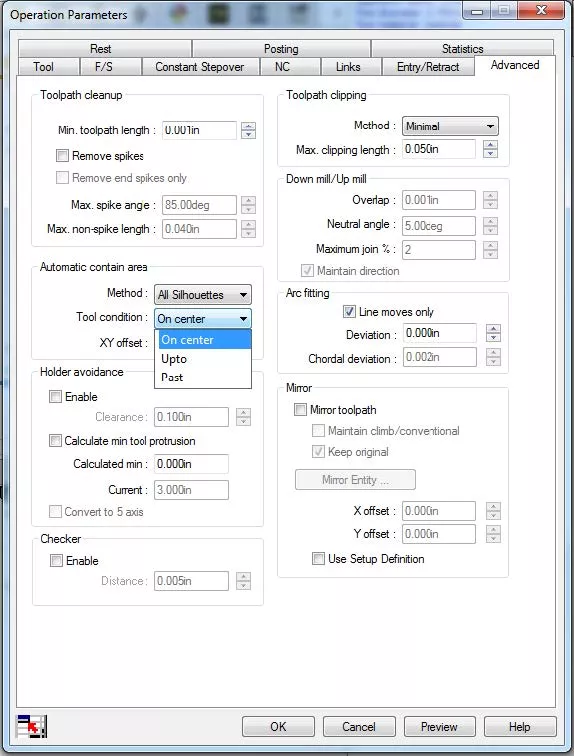

The tool condition setting can be found within the Automatic Contain Area section in the Operation Parameters dialogue box under the Advanced tab.

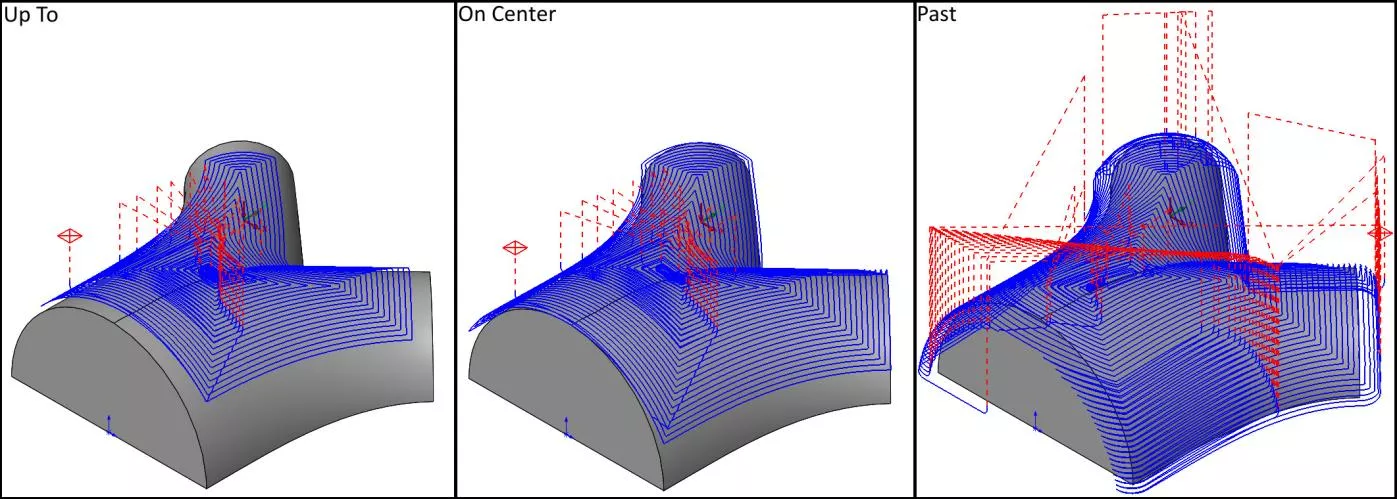

The three settings available are On center, Upto, and Past. (Figure 2)

Figure 2: Tool condition settings

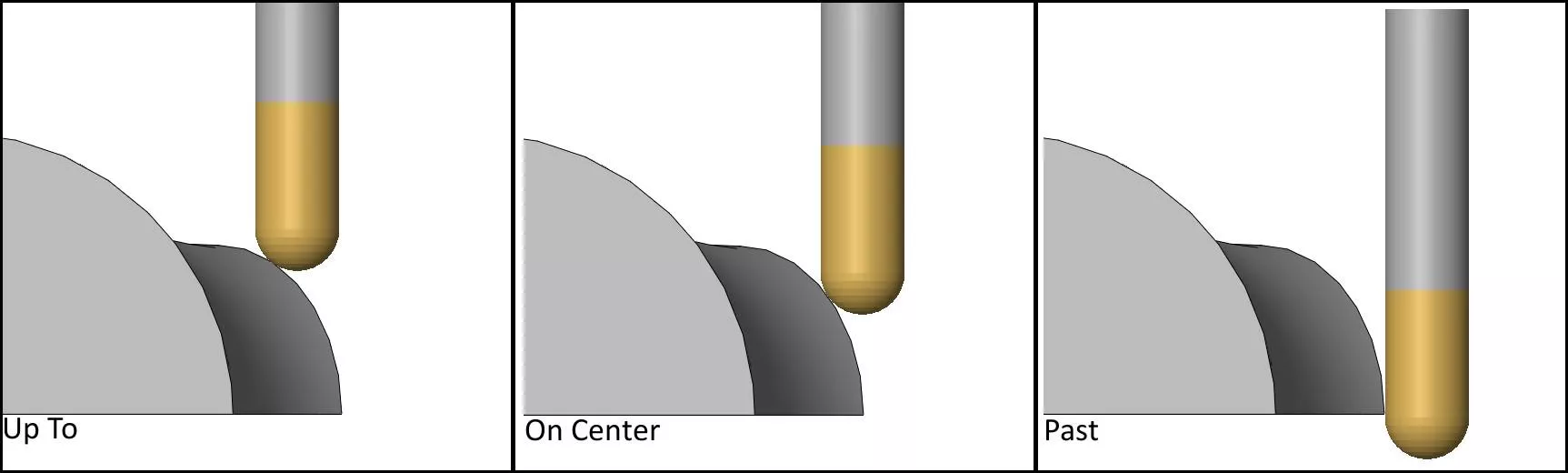

These settings affect the way the tool interacts with the part as follows:

- On center keeps the tool's center axis from crossing the part's extents.

- Upto limits the entirety of the tool from crossing the part's extents.

- Past will allow the tool to ride the outside of the part.

Figure 3: Tool condition settings visual

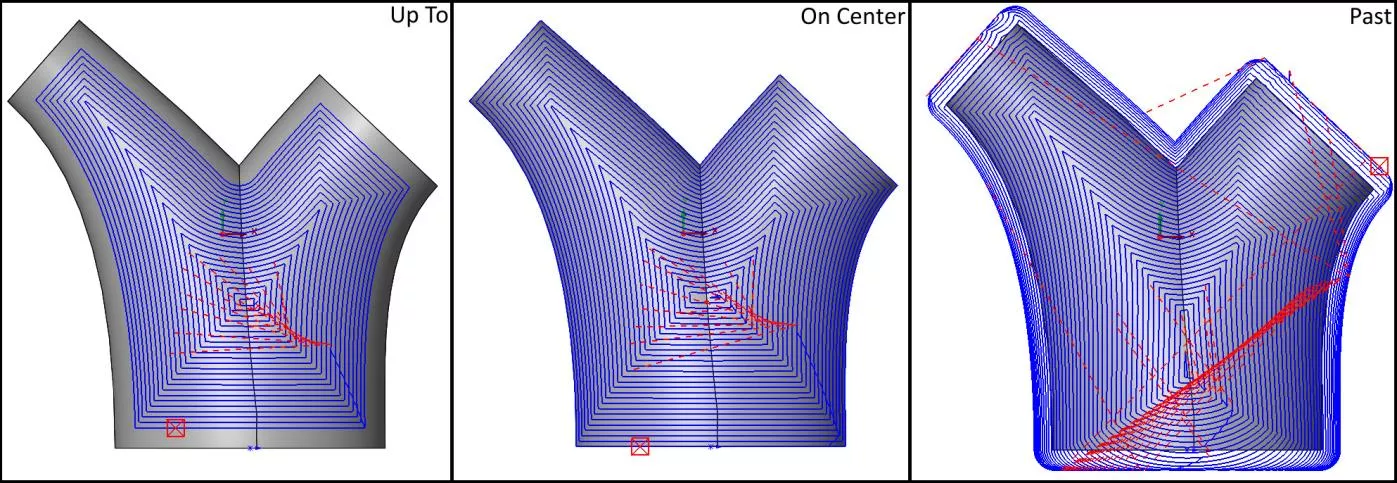

To allow our tool to reach the bottom of the part, the Past tool condition needs to be selected. Figures 4 and 5 show a top and isometric view of the tool path for each setting.

Figure 4: Past - Top View - Tool Path

Figure 5: Past - Isometric View - Tool Path

I hope you found this CAMWorks tutorial helpful. To learn more about CAMWorks, check out the articles below.

More CAMWorks Tutorials

How to Set Up a Firewall Exception for CAMWorks Teksoft.exe

Add Materials to CAMWorks Material Library

Creating a ThreadMill Feature in CAMWorks

CAMWorks Toolpath Allowances Explained

About Martin Hayes

Martin Hayes in an Elite Application Engineer at GoEngineer specializing in core functionality SOLIDWORKS products like surfacing and sheet metal as well as advanced tools including FEA/CFD Simulation, PDM, and CAMWorks. Martin earned his Mechanical Engineering degree from Mississippi State University.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.