CAMWorks Milling Features and Allowable Operations

In this article, we go over in detail each of the twelve CAMWorks milling features as well as all of their allowable operations.

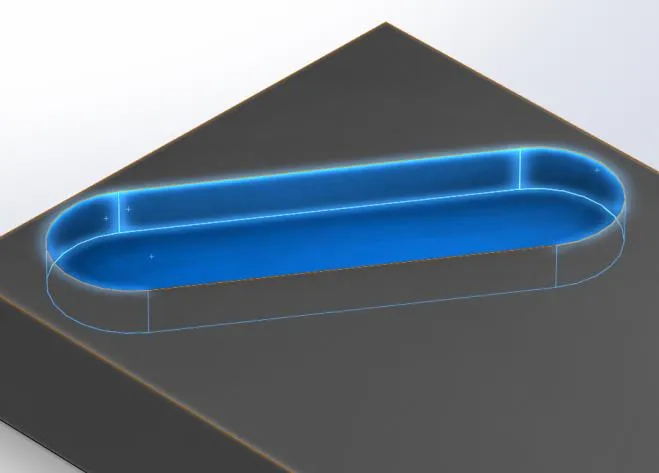

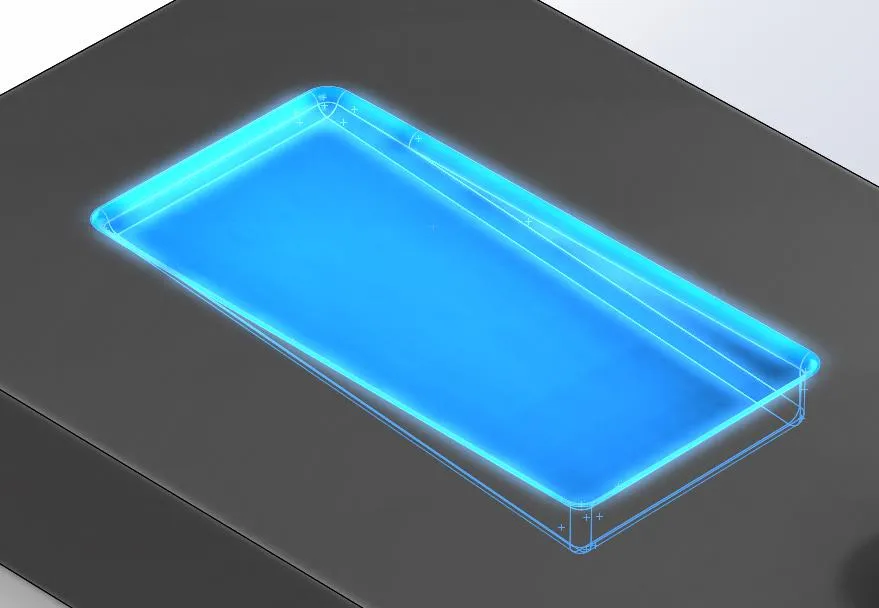

A Pocket is a recessed area surrounded by walls on all sides. CAMWorks distinguishes between Rectangular, Circular, Irregular, and Obround shaped pockets. The tool will stay within bounds of the feature. Pockets are defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill, Thread Mill, and all Hole Machining Operations

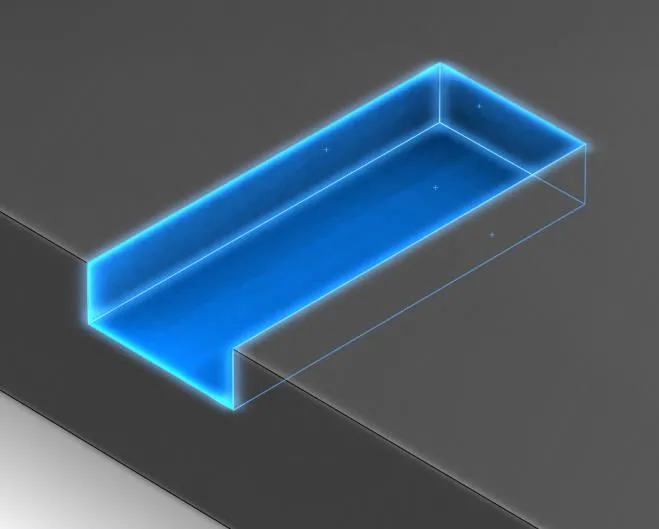

Slot

A Slot is a recessed area surrounded by walls on all sides but one. CAMWorks will identify the open side and allow the tool to travel beyond the bounds of the feature on that side to ensure the geometry of the feature is fully cut. CAMWorks distinguishes between Rectangular and Irregular shaped slots. Slots can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill

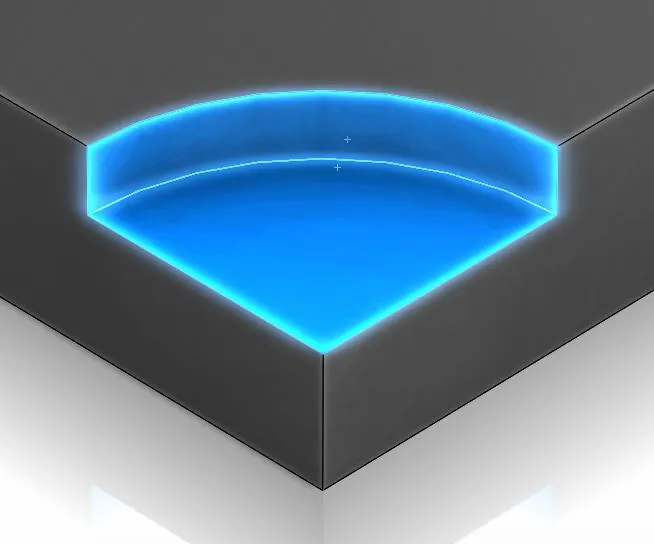

Corner Slot

A Corner Slot is a recessed area surrounded by walls on all sides but two. CAMWorks will identify the open sides and allow the tool to travel beyond the bounds of the feature on those sides to ensure the geometry of the feature is fully cut. CAMWorks distinguishes between Rectangular and Irregular shaped corner slots. Corner slots can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill

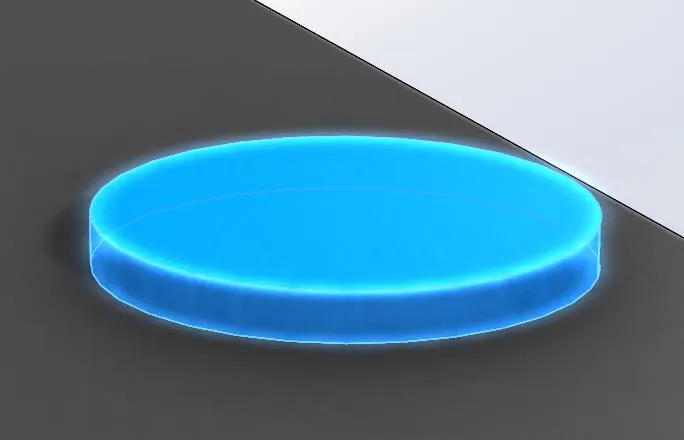

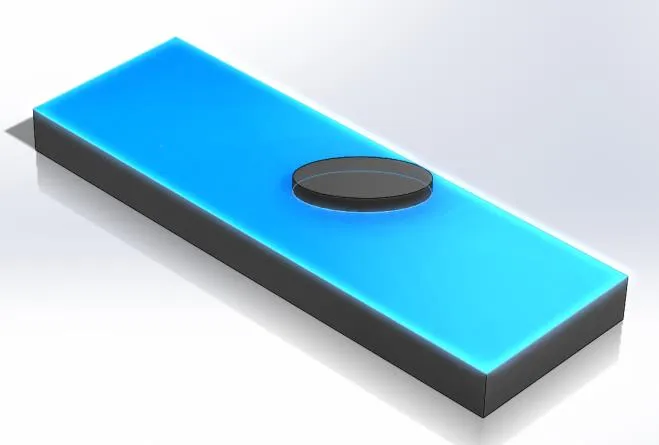

Boss

A Boss is a raised area to be cut around. CAMWorks distinguishes between Rectangular, Circular, Irregular, and Obround shapes. Bosses can be defined by faces, edges, or closed, non-intersecting sketches. If rough cuts are to be made around the boss, an Open Pocket feature should be used.

Allowable operations: Contour Mill, Thread Mill

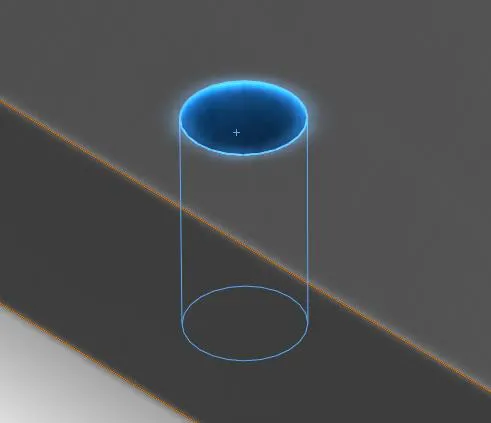

Hole

A Hole is a round recess to be cut using point-to-point tools. CAMWorks recognizes blind and through holes. Holes can be defined by faces, edges, or circular sketches.

Allowable operations: Centerdrill, Drill, Countersink, Bore, Ream, Tap, Rough Mill, Contour Mill, Thread Mill

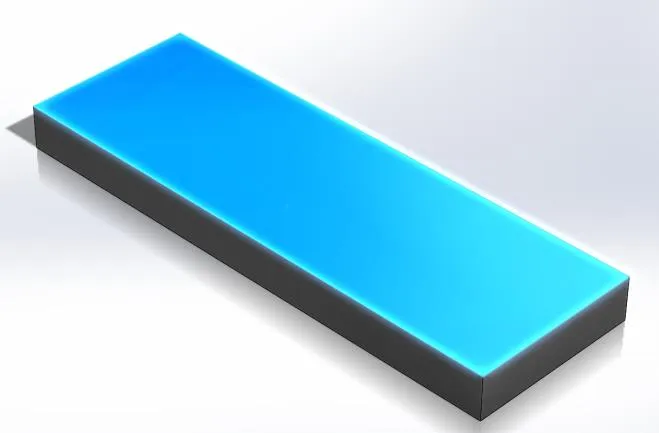

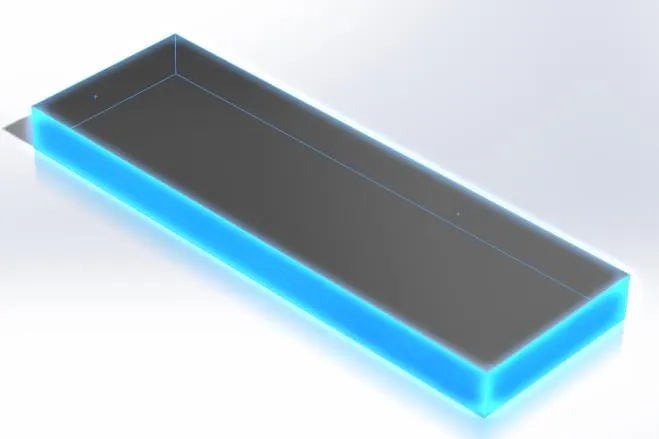

Open Pocket

An Open Pocket is an area to cut that is open on all sides. CAMWorks allows the tool to move beyond all boundaries of the feature. Islands are commonly associated with open pockets, especially when used to cut the part perimeter. This feature is a popular alternative to the Face feature due to the additional options it offers. Open pockets can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill

Face Feature

A Face Feature is an open area to be cut using a Facemill. CAMWorks allows the tool to move beyond all boundaries of the feature. Islands are commonly associated with open pockets, especially when used to cut the part perimeter. Face features can be defined by faces, edges, or closed, non-intersecting sketches.

Allowable operations: Rough Mill, Contour Mill

Open Profile

The Open Profile feature allows the tool to follow part edges or sketch lines. The tool will be offset from the edge or sketch line by the radius of the tool. This feature is commonly used to run a tool along the side of a part. This feature can be used on open, non-intersecting edges and sketches that are parallel to the current Mill Part Setup.

Allowable operations: Contour Mill

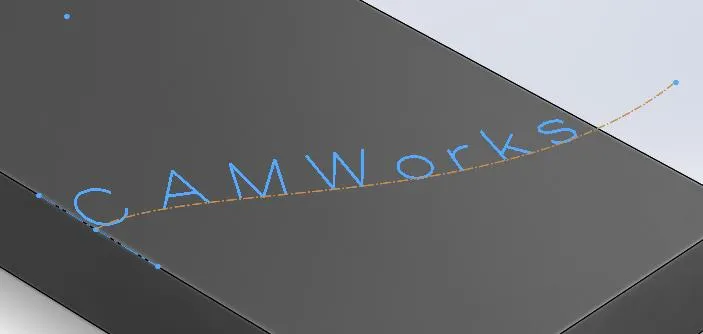

Engrave Feature

The Engrave Feature is intended to simplify the engraving of sketch text. The tool center will follow the selected sketch entities, which can include lines, arcs, splines, and text objects. Sketches can be open or closed and self-intersecting.

Allowable operations: Contour Mill

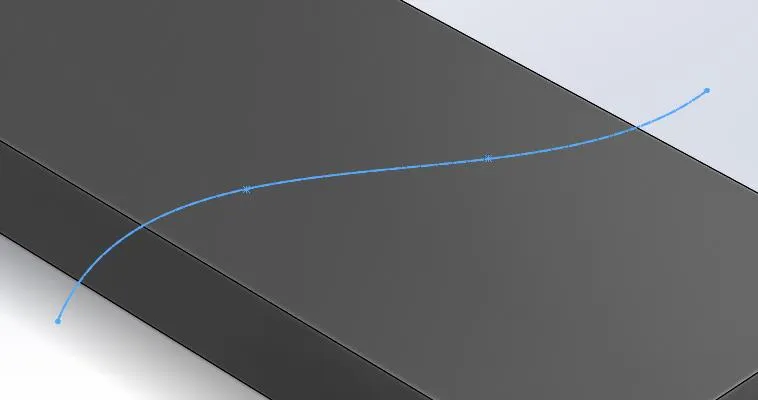

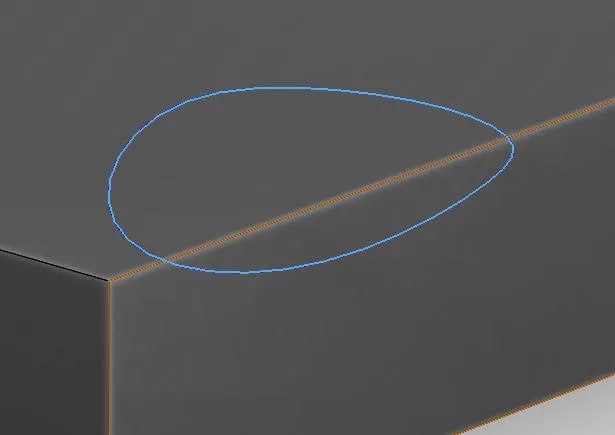

Curve Feature

The Curve Feature provides a way to guide a tool along a multidimensional path. The tool center will follow the selected 2D or 3D sketch, edge, or curve in 3 dimensions. Selected entities can be open or closed and self-intersecting.

Allowable operations: Contour Mill

Part Perimeter Feature

The Part Perimeter Feature is used to cut the perimeter of a part. It is a shortcut to creating an equivalent Boss or Open Pocket feature, as CAMWorks will automatically define the boundaries of the feature. A Boss-type feature should be selected if the tool is to carve out the part only. An Open Pocket-type should be used when all of the excess stock is to be removed.

Allowable operations: Rough Mill, Contour Mill

Multi-Surface Feature

The Multi-Surface Feature is used to define all multi-axis geometries to cut (3-, 4-, and 5-axis). Features are selected by choosing faces to cut, or using the ‘All Displayed’ option. Geometry that is not parallel to the Mill Part Setup will generally fall under this feature type.

Allowable operations: Area Clearance, Z Level, Flat Area, Pattern Project, Constant Stepover, Pencil Mill, Curve Project, Legacy Rough Mill, Legacy Finish Mill, Multiaxis Mill

Learn More About CAMWorks

CAMWorks: Best Practices for Updating Your Installation

About Tyler Reid

Tyler Reid is a CAD, CAM, and 3D printing expert. His early interest in machine tools led him to study Mechanical Engineering at the University of Utah, where he first learned to use SOLIDWORKS. Tyler has worked in the SOLIDWORKS VAR channel since 2010, making his way from technical support to application engineering to product management.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.