CAM and CNC Post Processors

Convert toolpaths into machine-specific G-code

CAM and CNC Post Processor SERVICES AVAILABLE

Our technical experts can develop custom CAMWorks and SOLIDWORKS CAM post processors tailored to your company's specific needs. We draw from our extensive collection of customer-validated post processors as an initial starting point and customize the post processor based on your particular requirements. After development, this post processor will streamline your CNC workflow for years to come.

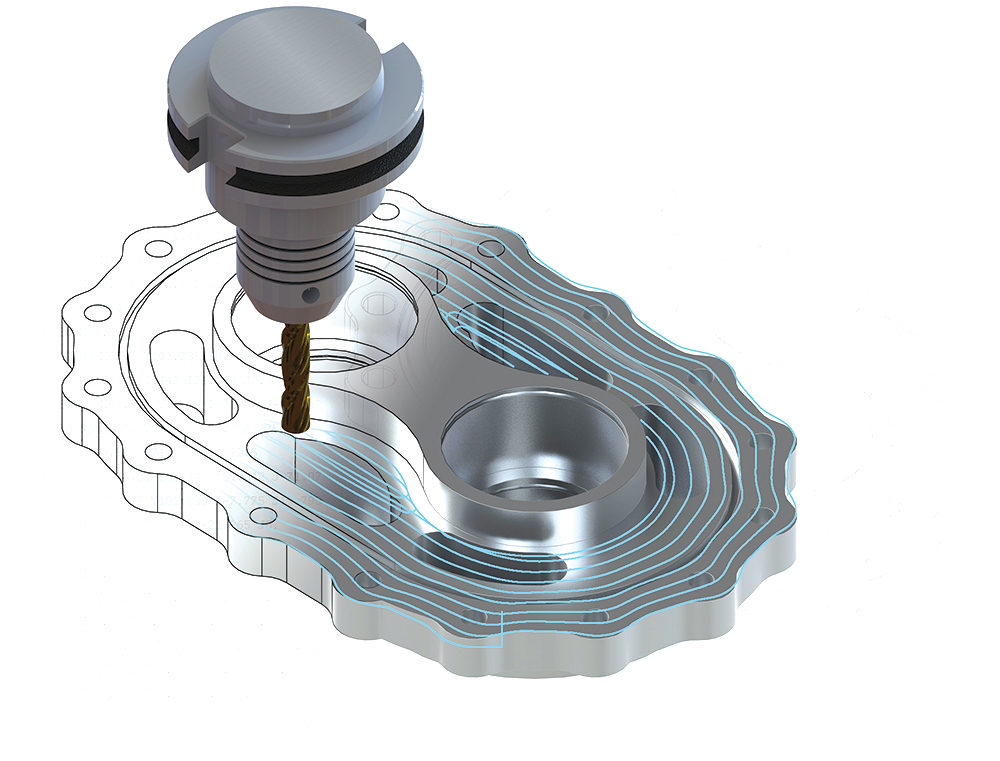

Post processors are a critical part of any CAM system

The role of the post-processor is critical – it acts as the translator between the CAM program's generic language and the language specific to your CNC machine's controller to convert toolpaths into machine-specific g-code.

The output of CAMWorks and SOLIDWORKS CAM is a g-code file. This file contains the instruction set for your parts program: the feeds, speeds, toolpath, tool changes, safety codes, and more.

Because the post processor is a translator, its g-code output is flexible. It is crucial the g-code matches your CNC machine parameters and takes advantage of the machine's full capabilities. We can also account for the preferences of CNC operators. Ultimately an excellent post processor means less hand-editing, more efficient programs, and faster setup and cycle times.

Both CAMWorks and SOLIDWORKS CAM install with a variety of basic post processors. Users can also create their post processors with the Universal Post Generator. However, most users find the best option is to rely on GoEngineer's expertise and experience to make a post processor specific to their needs and CNC equipment.

CUSTOM POSTS

REQUEST A QUOTE

With a custom post processor, you have control over the g-code output without the burden of learning to create post processors yourself. GoEngineer's experts can customize safety lines, tool changes, canned cycles, and m-codes within your post processor. We can even expand the capabilities of CAMWorks or SOLIDWORKS CAM with the post!

Our goal is to build a post processor that requires zero hand-editing and is tailored to your exact operator and machine requirements. We also commit to maintaining and supporting that post processor if your requirements change.

We have hands-on experience with most CNC machine tool vendors and control systems – in fact, we have written thousands of custom post processors over the years for our satisfied customers. There is no better way to squeeze the most power from CAMWorks or SOLIDWORKS CAM than with a custom post processor from GoEngineer.

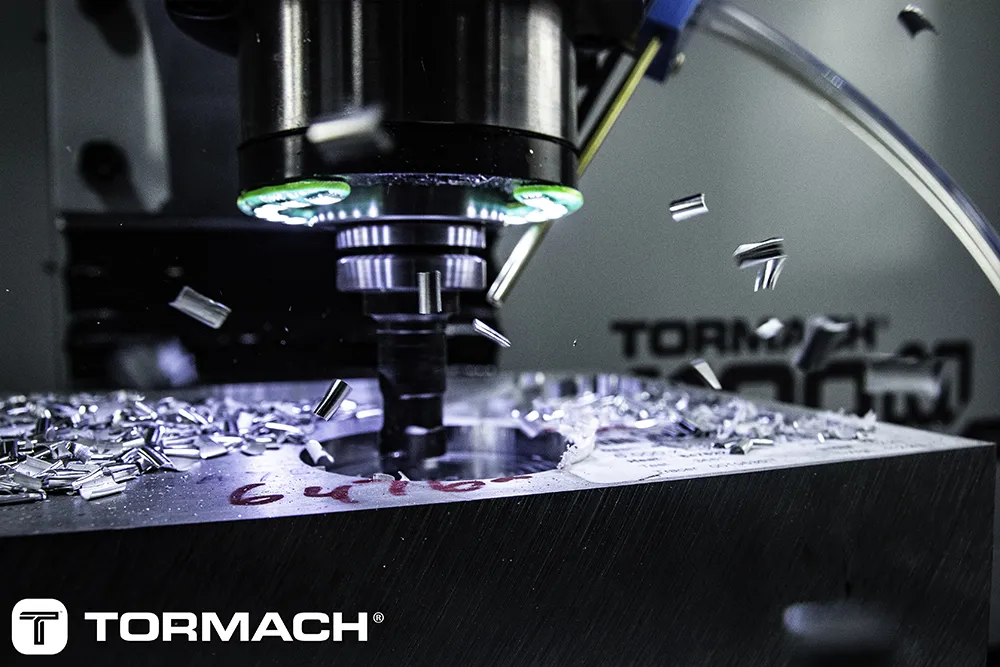

TORMACH POSTS

Tormach is the premier provider of small footprint, lab-friendly CNC machine tools. Their “personal-sized” selection of mills and lathes offer an affordable machining option without sacrificing accuracy or reliability.

At GoEngineer, we use Tormach as a test-bed for SOLIDWORKS CAM and CAMWorks g-code. We have also found them to be an excellent complement to our 3D printing and 3D scanning technologies!

We proudly provide a Tormach PathPilot post-processor for SOLIDWORKS CAM free of charge. Simply download the .zip, file here . Review the included PDF, and place the files in your Posts directory. If you have any comments or suggestions – feel free to share those with us at support@goengineer.com .

More SUPPORTED CNC TecHNOLOGY

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services