Oryx Additive Support Removal

A Durable Support Removal System for 3D Printed Parts

Now Serving US & Canada

Now Serving US & Canada

Cost Effective support removal for 3D Printed Parts

Whether you desire a cost-effective semi-automated solution for your process, or a lights-out, fully automated system, Oryx has the experience and knowledge to develop streamlined and cost-effective solutions to meet your business’s unique needs. We innovate, design, develop and refine the tools, techniques and equipment that will further enable the future of additive manufacturing to compete with traditional manufacturing processes. Utilize our deep knowledge and connections within the additive manufacturing industry to yield increased efficiency and improved process scalability.

Oryx Systems

ScaWaterjet

Features:

- Large tilted clear-view operation

- LED-illuminated work area

- Dual filtration

- Easy access to pump & holding tank

- Direct plumbed water source or stand alone “recycle tank” operations

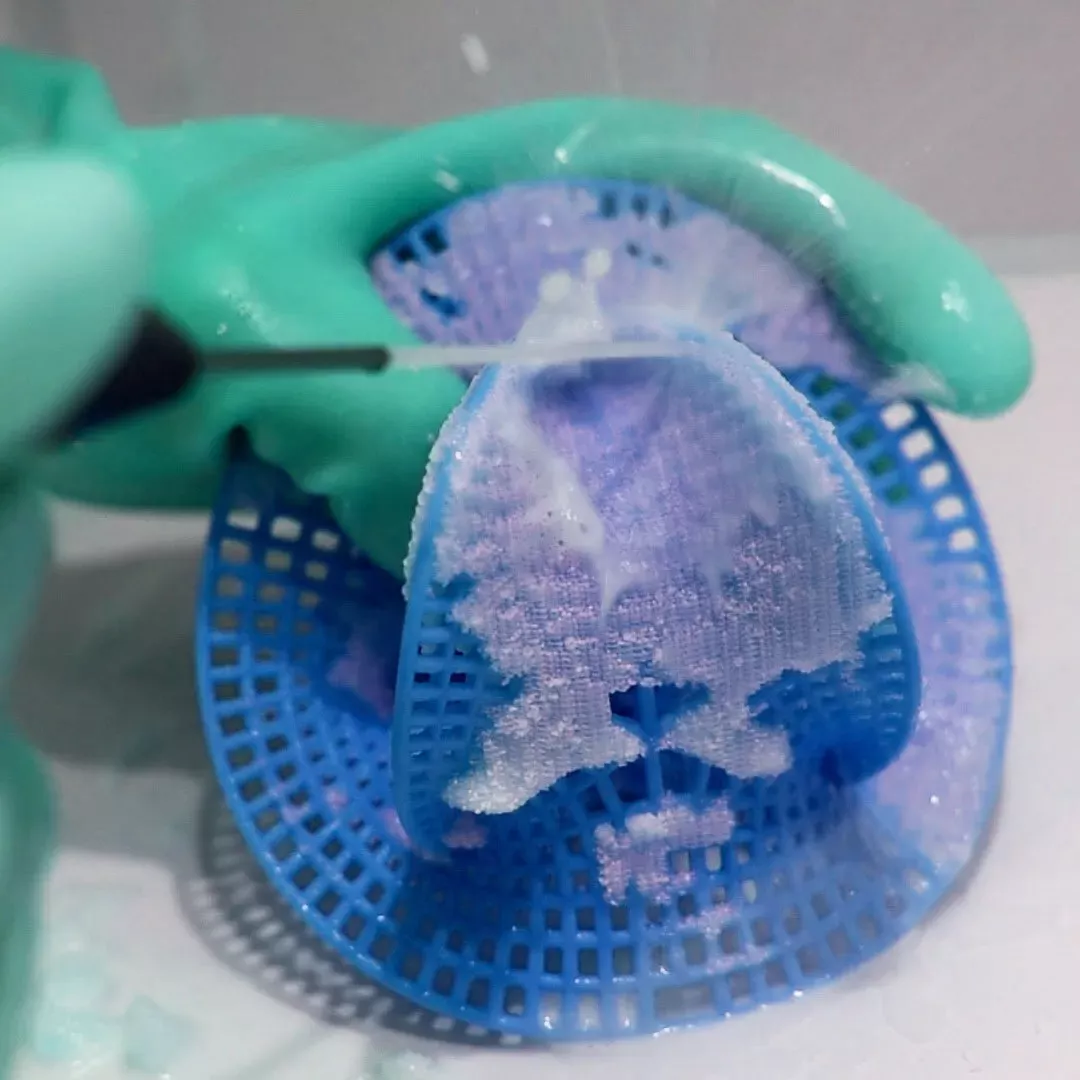

The scaWaterjet is a water jetting spray booth capable of coarse and fine support material removal for various AM processes. The capability to be plumbed direct or used stand-alone with an included mobile water tank allows for industrial uses or difficult-to-plumb situations such as offices.

It features a gasketed window with internal mount wiper blade assembly for clear view of the LED-illuminated work area, ergonomically-considered front cabinet design & gloved ports for operator part handling, with two water-jetting spray wands - both capable of high- and low-pressure operation to fit the needs of support removal for your delicate and rigid parts alike.

The covered mobile support frame minimizes collection of shop debris and dust inside the cabinet, while also allowing for a sit/stand option for operators, with easy access to the pump and holding tank. The scaWaterjet was specifically designed to meet your AM-based water spray & jetting needs.

Sca3600

Features:

- Proven Support Removal from FFF/FDM parts including ABS, ASA, PC, Nylon, PEEK, and others

- Unique Spray Nozzle & Pump Configuration

- Flow Reducer is included for delicate parts

- Whisper-quiet Operation for in-office use

- 1 Year Warranty & US-based Technical/Customer Support

The patented sca3600 is specifically designed for the removal of soluble support materials on 3D printed parts. The units are compatible with all all solvent-based and water soluble support materials as well as base modeling materials in conjunction with all recommended support removal concentrates – ABS, ASA, PC, Nylon, and PolyJet Resins.

The sca3600's versatility and efficient cleaning performance are built on the success of earlier models with all the features you have come to expect, in a larger and more capable model.

Common requests from desktop sca users were for a larger system for bigger parts, the ability to clean many parts at the same time, and the option to remove supports from PolyJet parts. The sca3600 is the answer: Faster, larger, and more capable.

Sca1200HT

Features:

- User-controlled Digital Timer

- Unique Spray Nozzle & Pump Configuration

- Flow Reducer is included for delicate parts

- Whisper-quiet Operation for in-office use

- 1 Year Warranty & US-based Technical/Customer Support with strong AM industry experience

sca1200ht is specifically designed for the removal of soluble support materials on 3D printed parts. The units are compatible with all all solvent-based and water soluble support materials as well as base modeling materials in conjunction with all recommended support removal concentrates – ABS, ASA, PC, Nylon, and PolyJet Resins.

The sca1200ht’s versatility and efficient cleaning was designed and built with the knowledge of years of 3D printing and distributor experience.

The most widely used agitation-based support removal system on the market, the highly rated sca1200ht has a well-earned reputation as a truly easy to use support removal solution.

The sca1200ht includes a "no-heat" option to use the device with the heater turned off, perfect for PolyJet parts. Older units can be upgraded with this option by contacting Oryx Additive.

Additional 3D Printing Resources

AWARD WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services