STRATASYS ORIGIN TWO

Create High-Accuracy End-Use Parts for Low-Volume Manufacturing

Now Serving US & Canada

Now Serving US & Canada

Precision, Accuracy, Repeatability

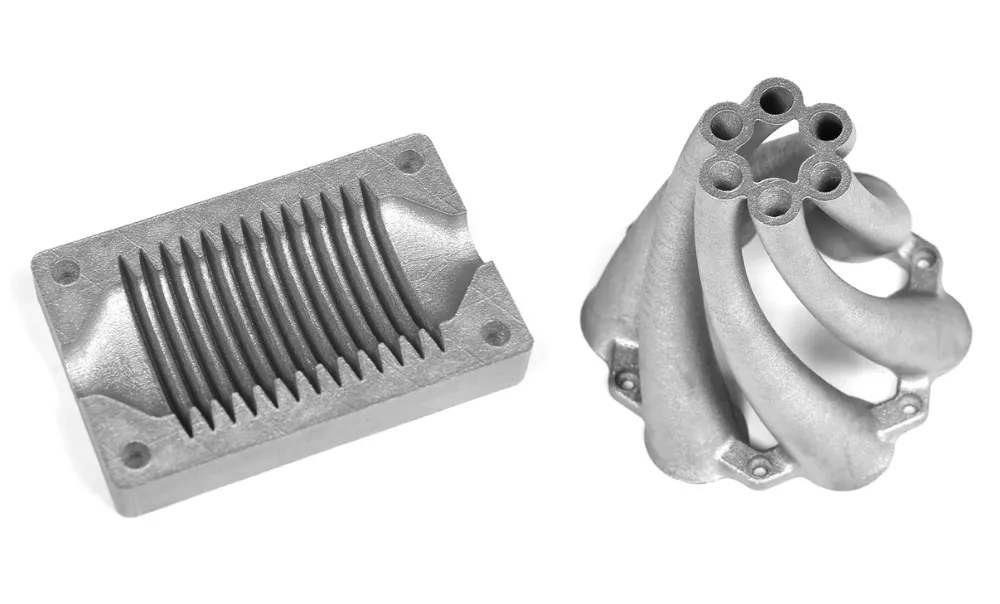

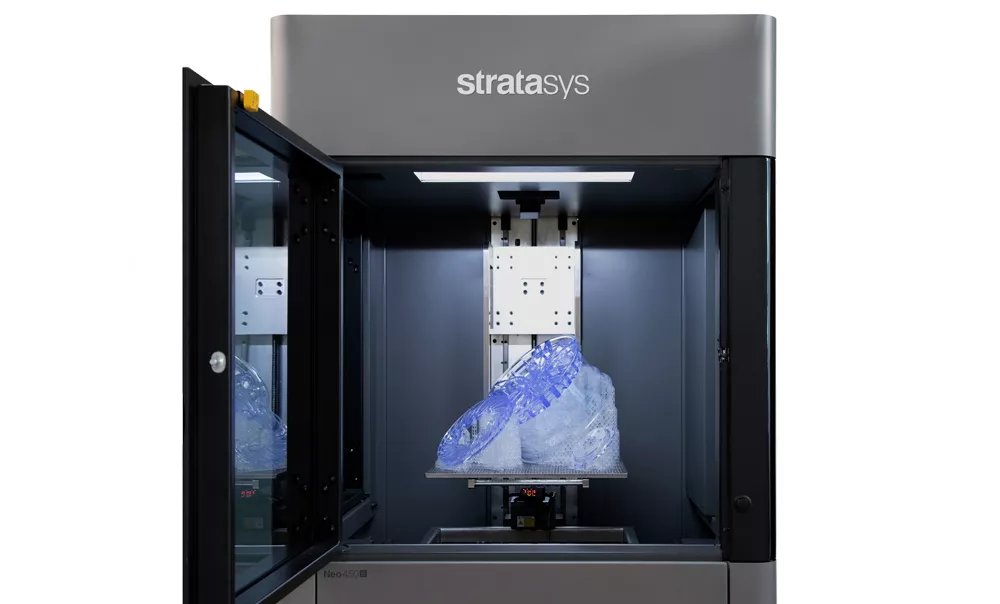

The Origin Two is an industrial 3D printer that enables high-accuracy 3D printing in a range of high-performance DLP materials. Programmable PhotoPolymerization P3™ technology delivers industry-leading precision, consistency, surface finish, and detail.

Features

High Accuracy, Smooth Surface Finish

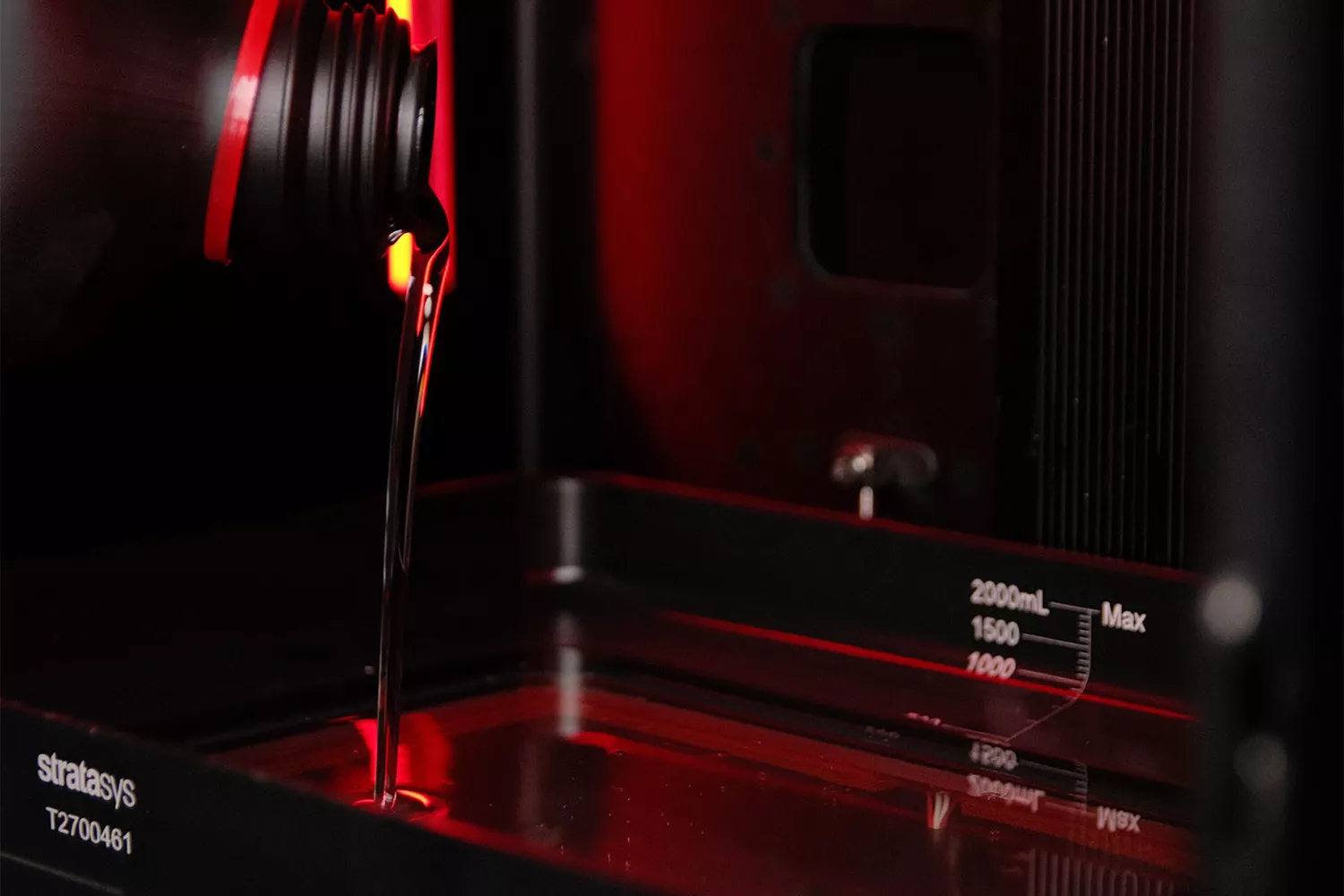

The state-of-the-art DLP projector at the heart of the Origin Two combines high-performance with expanded service life. At 5K resolution, it yields 38.5 µm pixels an injection-molded quality part surface finish. The enhanced resolution also brings geometry accuracies of up to +/-50 µm for selected applications. Its increased contrast ratio also ensures the sharpest feature detail, using industry-leading materials.

CERTIFIED WORKFLOW

The Origin Two is equipped with a NRTL interlock on its door, providing enhanced operator and facility safety compliance. This safety feature complements a range of preferred and validated materials that are compatible with the Origin Two right out of the box, providing UL certifications for applications where flame resistance and ISO biocompatibility are critical.

Rapid Turnaround Time

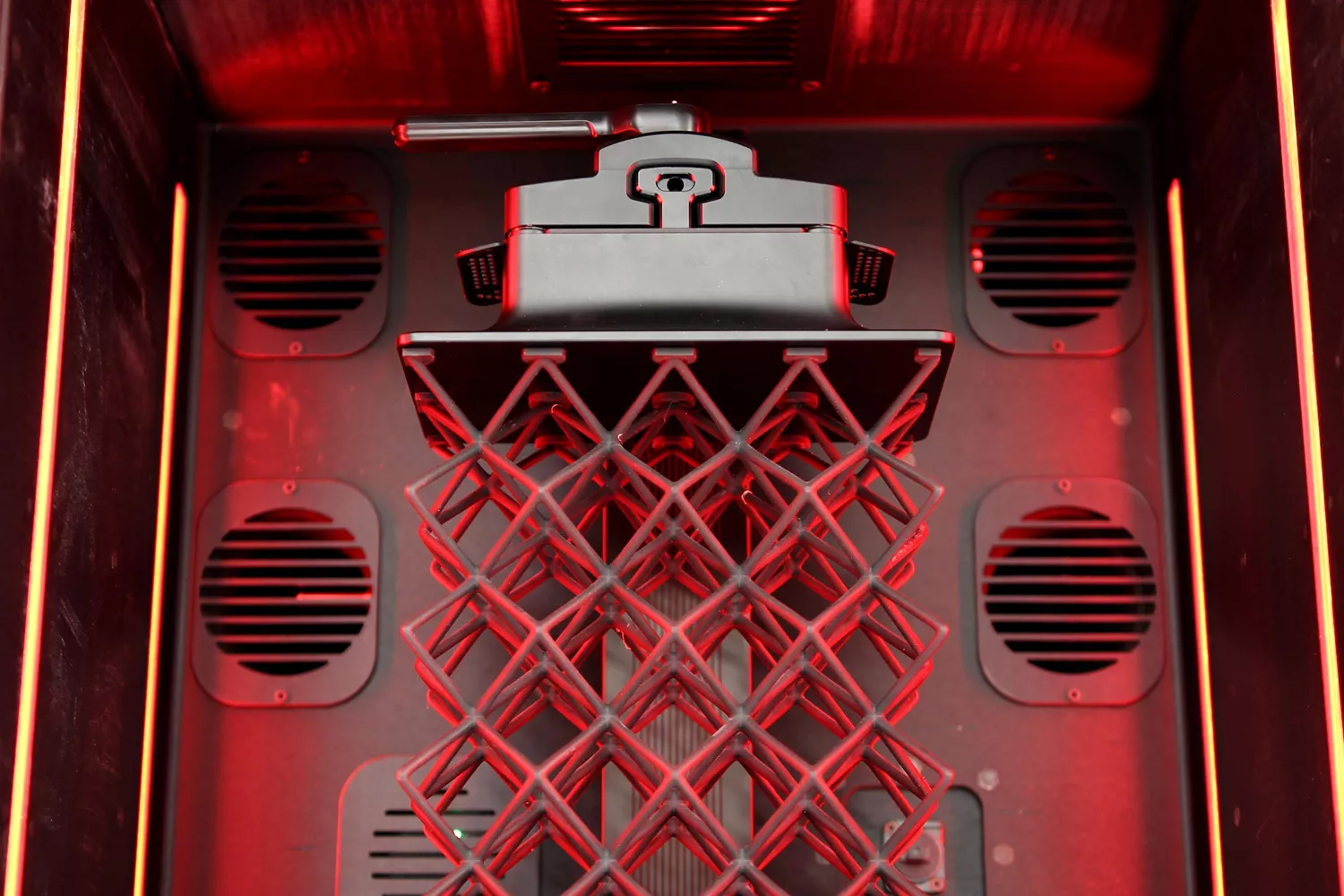

The Origin Two's next-generation build-head is designed with operator ergonomics in mind. Head calibration has been eliminated from the workflow, facilitating rapid turnaround between builds. Production applications will benefit from the streamlined process and empower the user to take their high-throughput production to the next level. The new head design is also optimized for automation solutions for truly lights-out production.

Materials

Available with: Stratasys Origin Two 3D Printers

LOCTITE 3D 3955 FST

- High-performance, high-modulus, engineering material

- Extremely high HDT exceeding 300° C

- Halogen-free and FST certified

- UL94 V-0 Flammability

- AITM2-0002, AITM2-0007, AITM3-0005

Potential applications:

- HVAC components

- Aerospace interior

- Automotive under the hood

- Precision connectors

- Electrical clips, plugs, housings

Available with: Stratasys Origin Two 3D Printers

P3 Deflect 120

- High HDT temperature of 121° C

- Extremely h igh yield strength of 100 MPa

- High stiffness and hardness

- Easy to print

Potential applications:

- Under-the-hood components

- Blow molds

- Clips and brackets

- Functional parts

Available with: Stratasys Origin Two 3D Printers

LOCTITE 3D IND403

- High HDT temperature of 80° C

- Machine and tappable

- Outstanding surface finish with minimal warping

- High yield strength of 70 MPa

Potential applications:

- Interior automotive components

- Tooling and molding

- Silicone molding and polyurethane casting

- Consumer products

Available with: Stratasys Origin Two 3D Printers

Ultracur3D ST 45

- Quick printing and post processing

- High strength, hardness, and impact strength

- Biocompatible to ISO 10993 (cytotoxicity, irritation, sensitization)

- Flammability certified to UL94 HB

Potential applications:

- Highly detailed or textured parts

- Rapid prototyping & production

- Medical devices & prosthetics

- Housings & enclosures

Available with: Stratasys Origin Two 3D Printers

LOCTITE 3D 3843

- High impact strength

- Semi-flexible

- Moderate HDT of 60 ° C

- Matte surface finish

- Biocompatible to ISO 10993-5/-23 (cytotoxicity, irritation, sensitization)

Potential applications:

- Consumer products

- Parts with Class A surfaces

- Automotive and industrial fabrication

- Medical device housing or parts

- Jigs & fixtures

Available with: Stratasys Origin Two 3D Printers

Dura56

- Extremely low cost per part

- High impact resistance

- High energy absorption

- Matte surface finish

- Specifically formulated by Henkel for Stratasys

Potential applications:

- Functional testing/prototyping

- Jigs & Fixtures

- Class A mating surfaces

- Gadgets, toys, novelty items

- End-use production parts

Available with: Stratasys Origin Two 3D Printers

LOCTITE 3D 3172

- Durable and tough

- Superior impact-resistance

- High energy absorption

- High elongation at break

- Machine, tap, and polish-able

Potential applications:

- Jigs & fixtures

- Sporting equipment

- Robotics & animatronics

- Insoles

- Topology oriented designs

Available with: Stratasys Origin Two 3D Printers

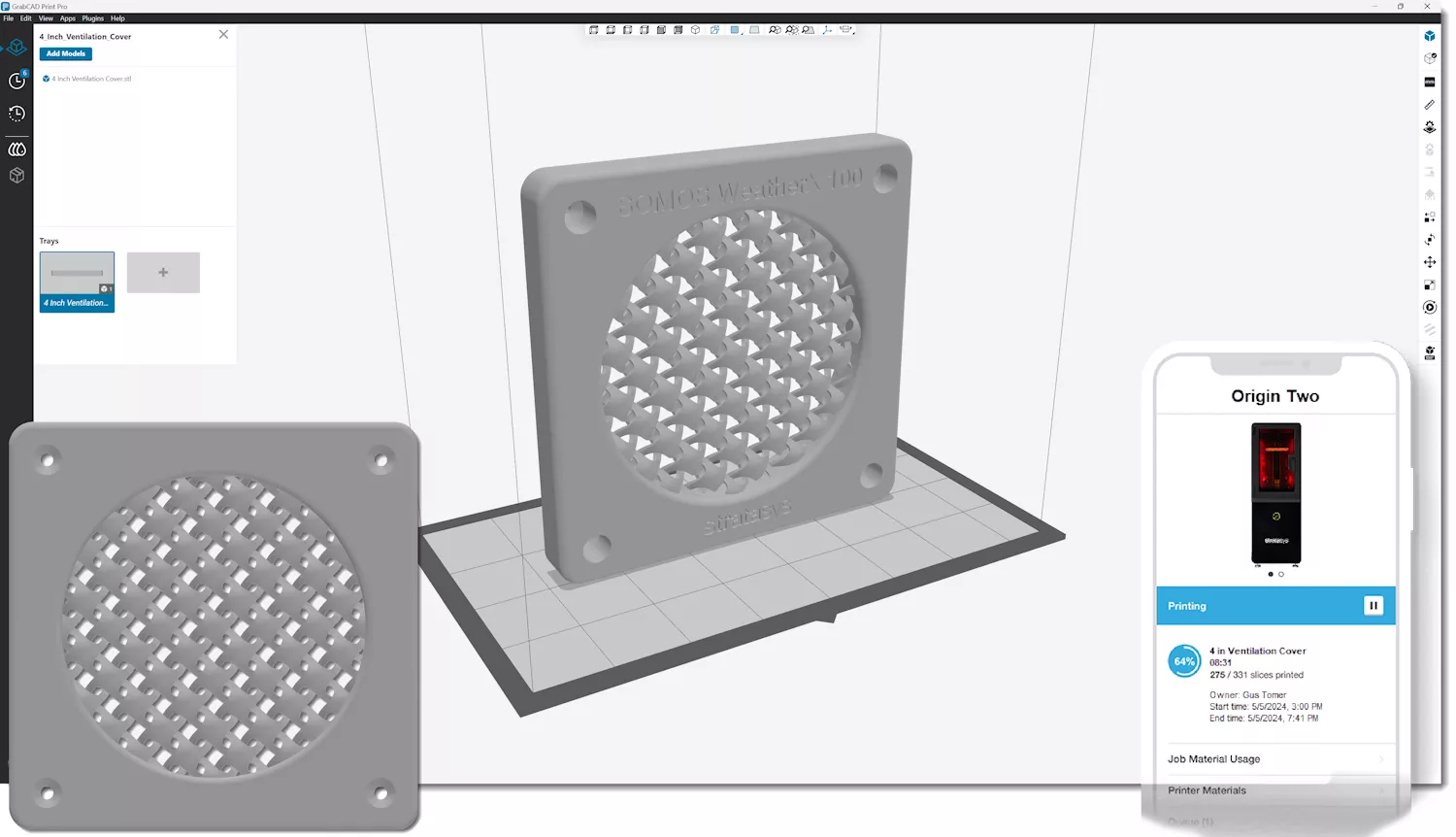

Somos Weatherx 100

- UV, Weather, Temperature, & Chemical Resistant

- Easy and Fast Post-Processing

- Isotropic

- Durability

- Suitable for Challenging Geometries

Potential applications:

- Transportation / Outdoor Vehicles

- Industrial Equipment

- Consumer Goods

- Applications Exposed to UV and/or Humid Environments

Available with: Stratasys Origin Two 3D Printers

LOCTITE 3D IND405

- High impact strength

- Over 125% elongation at break

- Excellent surface quality

- Optically transparent and clear

- Low UV degradation and yellowing

- Biocompatible options available

Potential applications:

- Mechanical guides

- Fluid ducts

- Microfluidic devices & guide overlays

- Light pipe and packaging prototypes

Available with: Stratasys Origin Two 3D Printers

LOCTITE 3D IND402

- True elastomeric behavior

- 230% elongation at UTS

- Shore hardness of 76A

- Excellent interlayer adhesion

- High energy absorption

- Minimal plastic deformation

Potential applications:

- Engineered lattice structures

- Sporting equipment

- Insoles and handgrips

- Gaskets, tubing, & hoses

- Ergonomic or soft touch items

Available with: Stratasys Origin Two 3D Printers

P3 Stretch IND475

- True elastomeric behavior

- 122 % elongation at UTS

- Shore hardness of 49 A

- 77% energy return

- Minimal shrinkage

- High resilience

- Easy to print and process

Potential applications:

- Air and dust gaskets

- Flexible seals and housings

- Cushioning pads

- Soft grippers for EOT

- Silicone-like parts

Available with: Stratasys Origin Two 3D Printers

LOCTITE 3D MED412

- Medical-grade certified

- Durable with flexibility

- Sterilizable

- Biocompatible to ISO 10993-5/-10 (cytotoxicity, irritation, sensitization)

Potential applications:

- Test swabs

- Single-use medical instruments

- Class I and II medical devices

- Lab equipment

- Covers and guards

Available with: Stratasys Origin Two 3D Printers

LOCTITE 3D MED413

- Medical-grade certified

- Stiff and tough

- Outstanding surface finish

- High HDT of 70° C

- Sterilizable

- Biocompatible to ISO 10993-5/-10 (cytotoxicity, irritation, sensitization)

Potential applications:

- Orthotics

- Durable and reusable medical components

- Hearing aids

- Respirator components

Specifications

TECHNOLOGY

- Programmable PhotoPolymerization P3 TM DLP (Digital Light Processing)

MATERIALS

Photocurable materials, single component:

- Validated materials developed by Stratasys and its material partners

- Any material, via the OpenAM™ License

- Changeover can be completed in under 10 min.

- Long shelf lives and re-usable

- Three starter materials included

BUILD ENVELOPE

- 192 x 108 x 370 mm / 7,672 cm 3

- (7.5 x 4.25 x 14.5 in. / 462 in 3 )

- Maximum length on the diagonal — 220mm (8.6 in.)

MINIMUM FEATURE SIZE

- Material and design dependent

Process ENERGY

- UV (385nm) and thermal

SOFTWARE

- GrabCAD Print

REGULATORY COMPLIANCE

- CE, UKCA, FCC, RCM, NRTL [pending]

SYSTEM SIZE AND WEIGHT

- Width: 50 cm (19.7 in.)

- Depth: 52 cm (20.5 in.)

- Height: 117 cm (46 in.)

- Weight: 86 kg (189.5 lbs.)

Power Requirements

- 100-120 VAC, 50/60Hz, 7.1A, 1 Ph; or

- 200-240 VAC, 50/60 Hz, 3.5 A, 1 Ph

OPERATING CONDITIONS

- Operating temperature in the range of 18 °C to 25°C (59°F to 86°F), with humidity range of 30% to 70%

RESIN TRAY CAPACITY

- 2L

RESIN STORAGE TEMP

- Typically 15°C to 30°C (59°F to 86°F)

Origin Cure

Enhance Post-processing

The Origin Cure offers an integrated workflow, finalizing the part post-cure process. It combines broad spectrum UV lights with a large volume, further facilitating high-throughput production, reducing time-to-part, and fully harnessing the capabilities of the Origin Two's broad material portfolio.

Software

GrabCAD Print for Origin

GrabCAD Print for Origin makes 3D printing easy, with thoughtful features:

- Automatically corrects files and reduces print time with automatic tray arrangement.

- Calculates the time and material resources needed for production before printing.

- 3MF file supported – significantly simplifies color assignment in your workflow.

- New feature alerts the user if there has been cross-contamination with a biocompatible material.

- Schedule and monitor the print job remotely from your mobile device or browser.

- Get automatic alerts remotely when the job is printing and finished.

Choose from pre-set print profiles for validated materials or adjust part accuracy using parameters from the OpenAM Material License (OpenAM) for added flexibility.

ADDITIONAL 3D PRINTERS

POLYJET

3D print realistic prototypes and models with full-color elements, labels, and true-to-life textures in one operation. PolyJet 3D PrintersMETAL

3D print functional metal parts and prototypes for industrial, commercial and private applications. Metal 3D PrintersSAF

Selective Absorption Fusion™ SAF™ technology that delivers functional, production-grade parts with optimum consistency. Production SAF 3D PrintersFDM

Stratasys FDM 3D printers streamline processes from design through manufacturing, reducing costs and eliminating traditional barriers along the way. Manufacturing FDM 3D PrintersStereolithography

Open-system Stereolithography (SL) technology delivers dependable, scalable fabrication at unprecedented speeds. Open-system Stereolithography 3D PrintersADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services