Metal 3D Printers

Functional Metal Parts and Prototypes for All Applications

Now Serving US & Canada

Now Serving US & Canada

Why Use Metal 3D Printing?

Traditional manufacturing methods have limitations for certain applications. By integrating 3D printing, you gain the freedom to design from multiple angles that conventional methods cannot achieve, while still maintaining the strength and durability of metals such as Inconel, Tungsten, Stainless Steel, and Titanium. For those in the injection molding industry, 3D printing offers a more precise and easier way to incorporate conformal channels into molds, leading to increased throughput.

Types of Metal 3D Printing

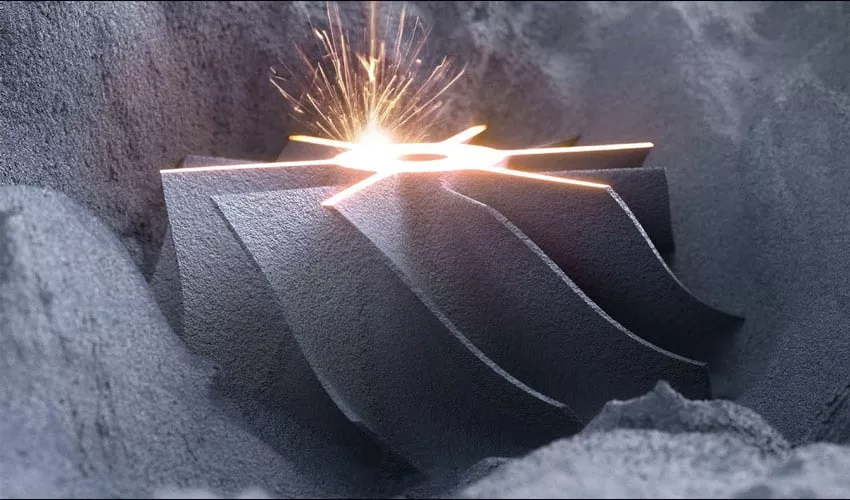

Laser Powderbed Fusion (LPBF)

The LPBF process begins by spreading a thin, even layer of metal powder over the build platform. Next, a high-powered laser comes into play, following a set pattern from a digital 3D model. The heat from the laser melts and fuses the powder particles together forming a solid layer. Once that layer is done, the platform lowers, and a fresh layer of powder is spread. This cycle continues until the entire part is built. When it's finished, any leftover powder is cleared away, and the part might need a bit of extra work, like removing supports or giving the surface a nice finish.

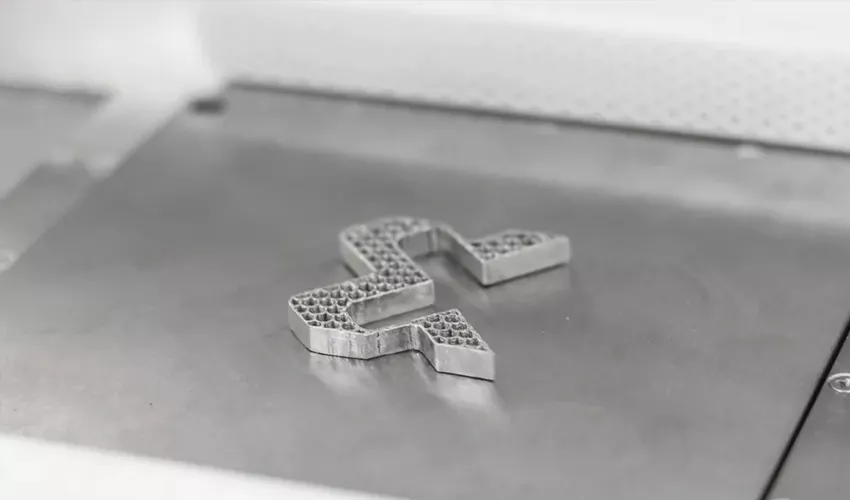

Binder Jet

Binder jet metal 3D printing begins by spreading a thin layer of metal powder on the build platform. A liquid binder is then sprayed over the powder, instead of a laser, sticking the particles together based on the 3D model. This process repeats layer by layer until the part is complete. Once done, the part is carefully removed and heated in a sintering process to fuse the metal particles.

DED (Directed Energy Deposition)

DED metal 3D printing works like high-tech welding. A nozzle feeds metal powder or wire, while a laser or electron beam melts it, building up the part layer by layer. The nozzle can move in different directions, making it great for repairs or new parts.

Our Partner:

BLT Metal 3D Printers

Bright Laser Technologies (BLT) is revolutionizing metal 3D printing with high-speed, multi-laser systems designed for both prototyping and large-scale production. Trusted by industries like aerospace, automotive, and medical, BLT's technology enhances design flexibility, reduces production cycles, and delivers superior part quality.BLT Metal 3D PrintersADDITIONAL 3D PRINTERS

POLYJET

3D print realistic prototypes and models with full-color elements, labels, and true-to-life textures in one operation. PolyJet 3D PrintersP3

Programmable PhotoPolymerization P3™ technology delivers industry leading accuracy, consistency, and details. Production P3 3D PrintersSAF

Selective Absorption Fusion™ SAF™ technology that delivers functional, production-grade parts with optimum consistency. Production SAF 3D PrintersFDM

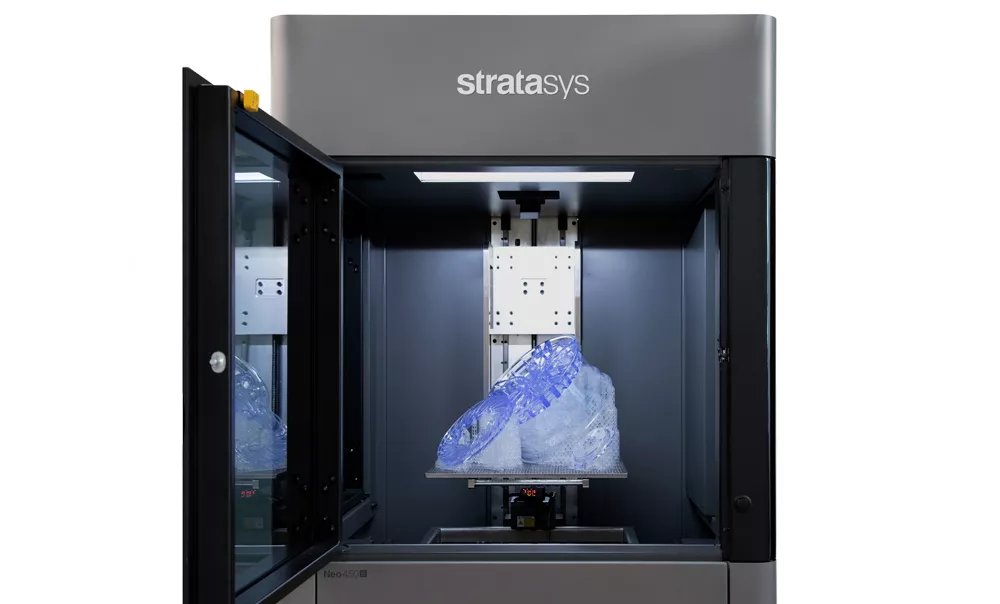

Stratasys FDM 3D printers streamline processes from design through manufacturing, reducing costs and eliminating traditional barriers along the way. Manufacturing FDM 3D PrintersStereolithography

Open-system Stereolithography (SL) technology delivers dependable, scalable fabrication at unprecedented speeds. Open-system Stereolithography 3D Printers

Additional 3D Printing Resources

AWARD WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services