3DEXPERIENCE FACTORY OPERATIONS

Drive team meetings with lean principles and 3D data from the cloud

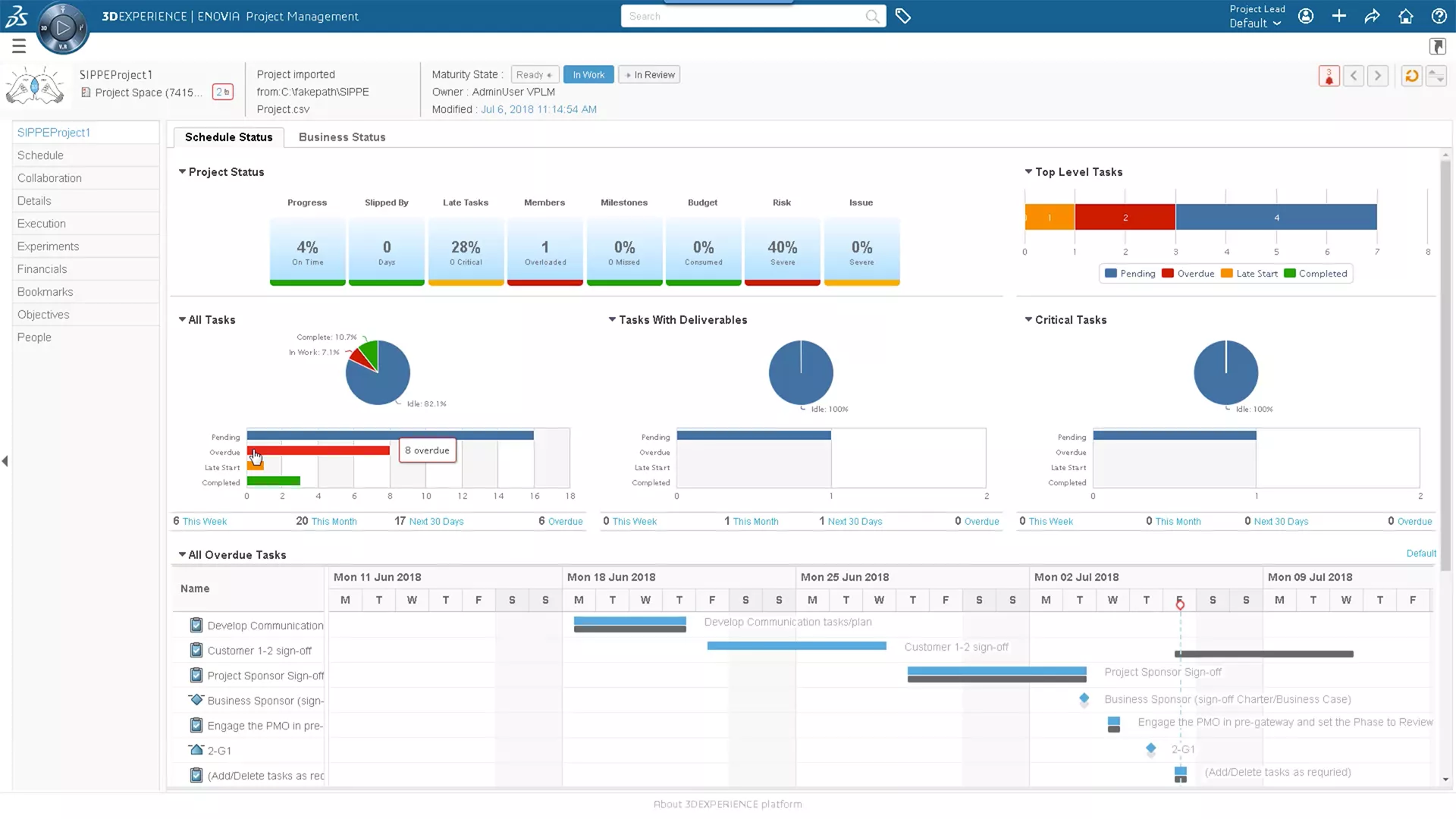

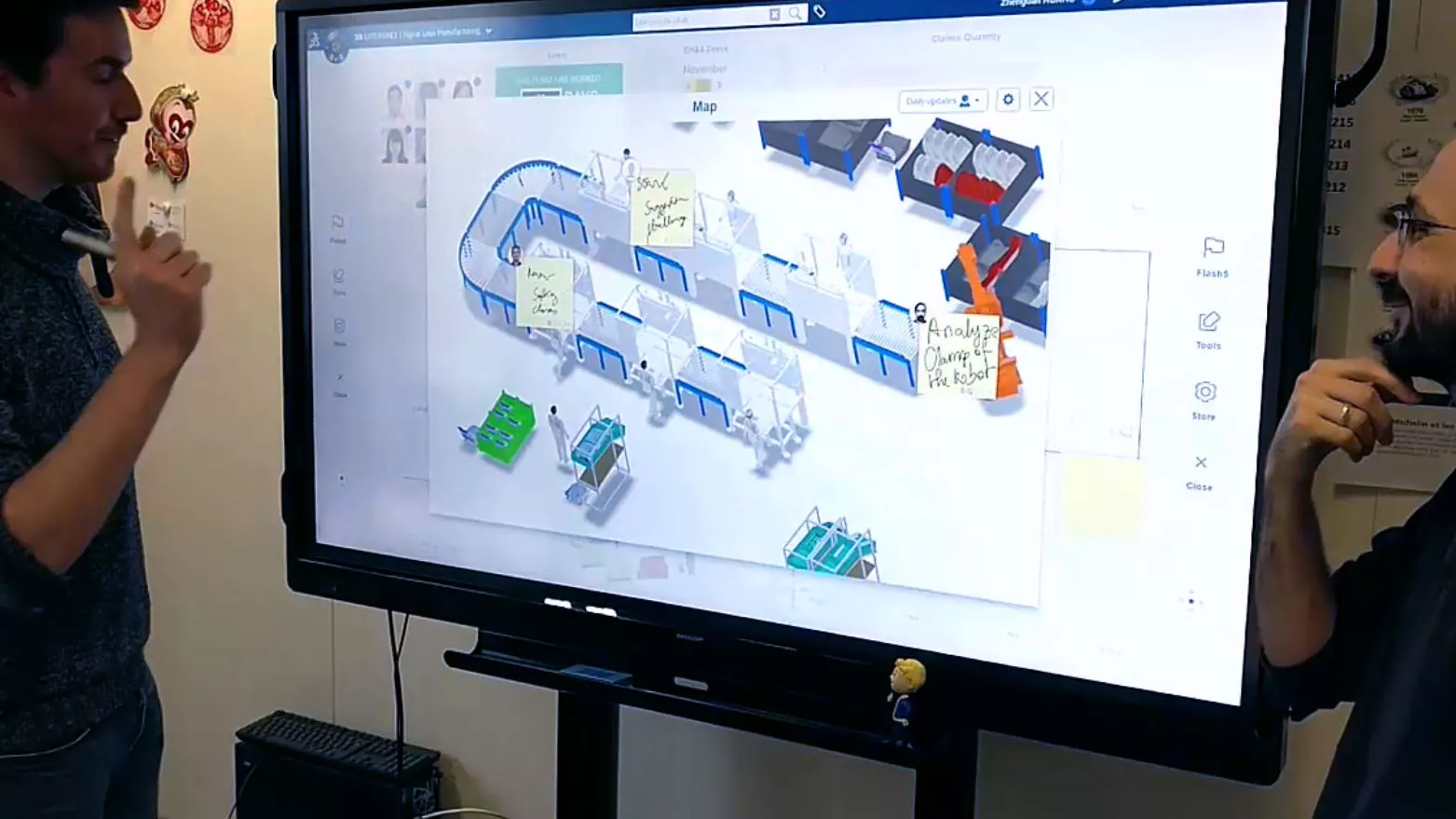

3DEXPERIENCE FACTORY OPERATIONS solutions guide team engagement and drive operational improvements with lean principles.

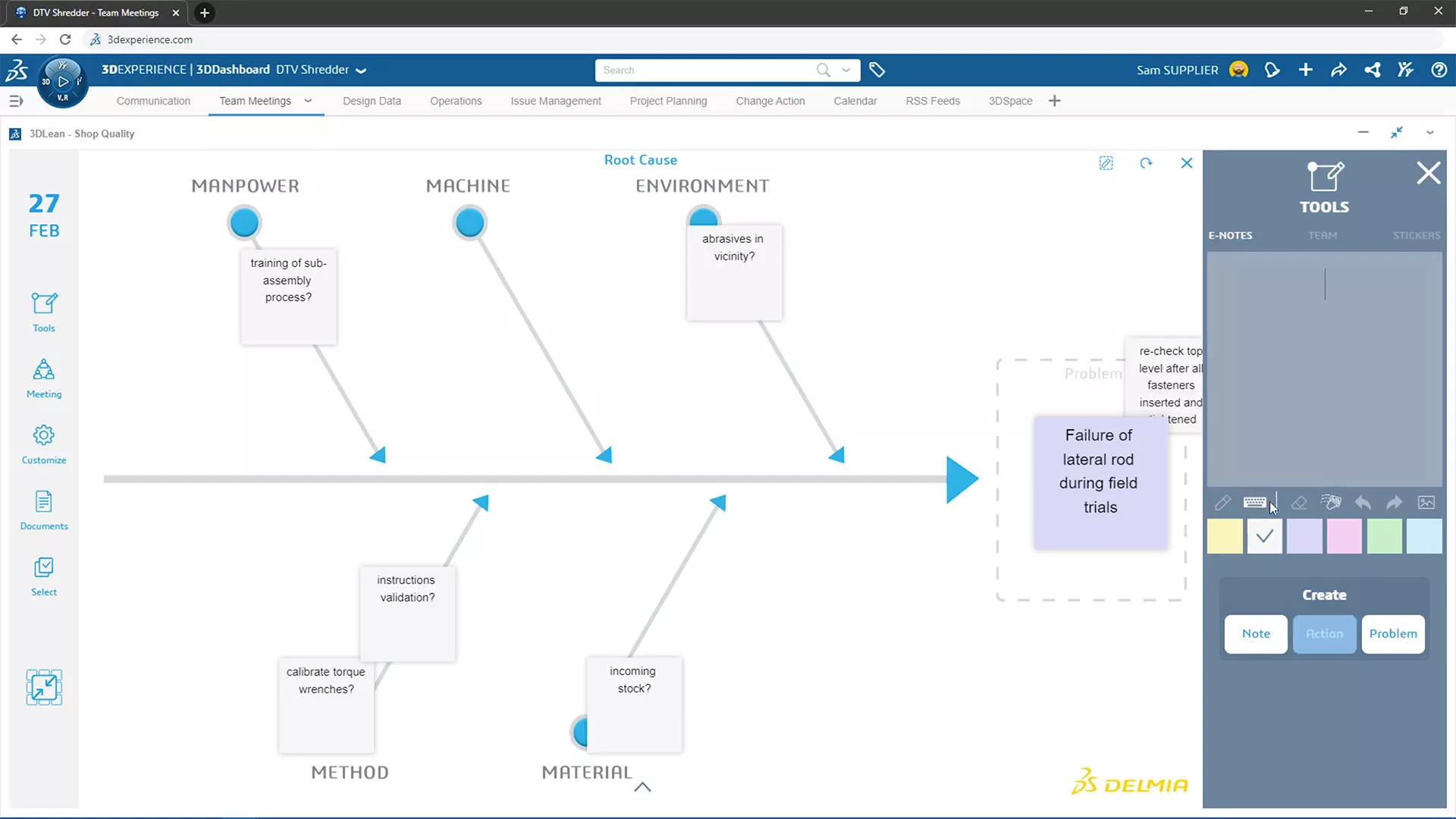

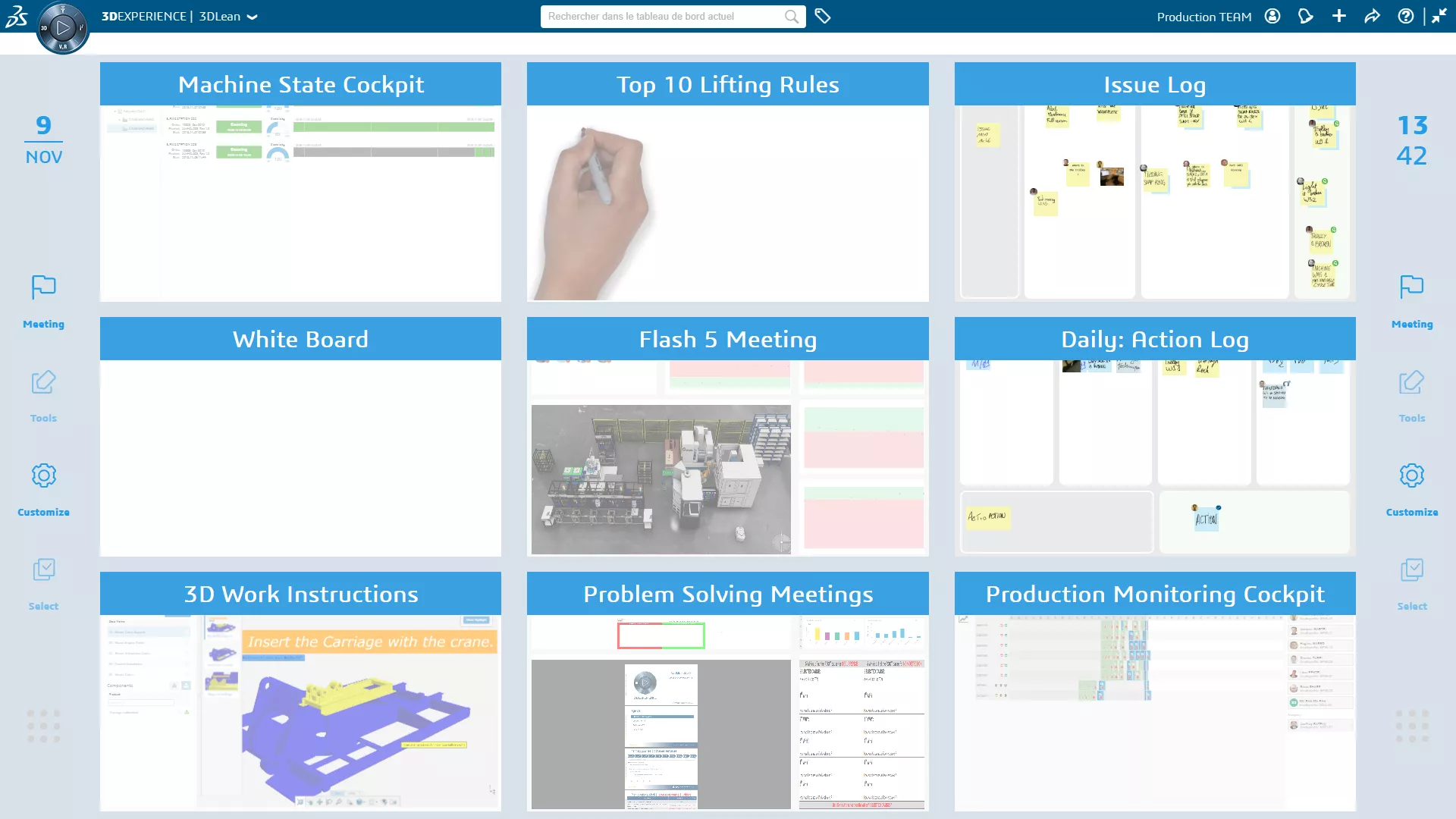

Local and remote teams can access data and rich 3D content to reveal issues and facilitate problem-solving with structure and accountability. By guiding the adoption of lean behaviors, 3DEXPERIENCE FACTORY OPERATIONS empowers teams to work autonomously and improve performance in every meeting, every day.

“We chose a

3D

EXPERIENCE Works Simulation solution because it’s cloud-based, which supports our remotely located engineering organization, works seamlessly with SOLIDWORKS design data, and incorporates the Abaqus Explicit solver, which is best suited for the types of simulation studies that we need to conduct on our parts, which can involve hyperelasticity, creep, fatigue, and contact.”

– Thomas Morgan

Design Engineer

HIGHLIGHTS

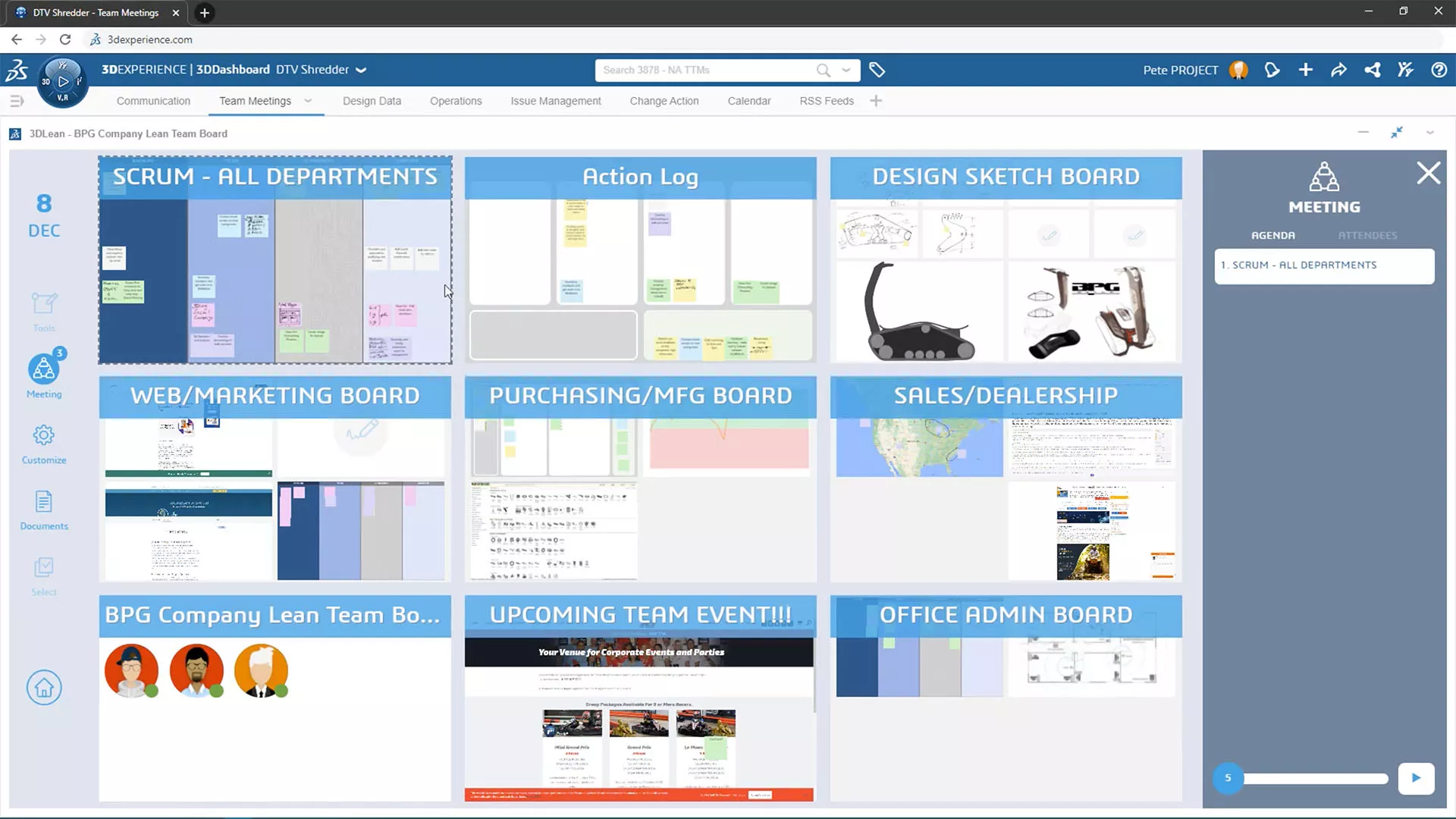

Simplify Live Team Interactions

Team leaders and members can collaborate in-person via touchscreens or virtually in the cloud. In doing so, they can interact and communicate in engaging and natural ways to resolve issues and create effective strategies..

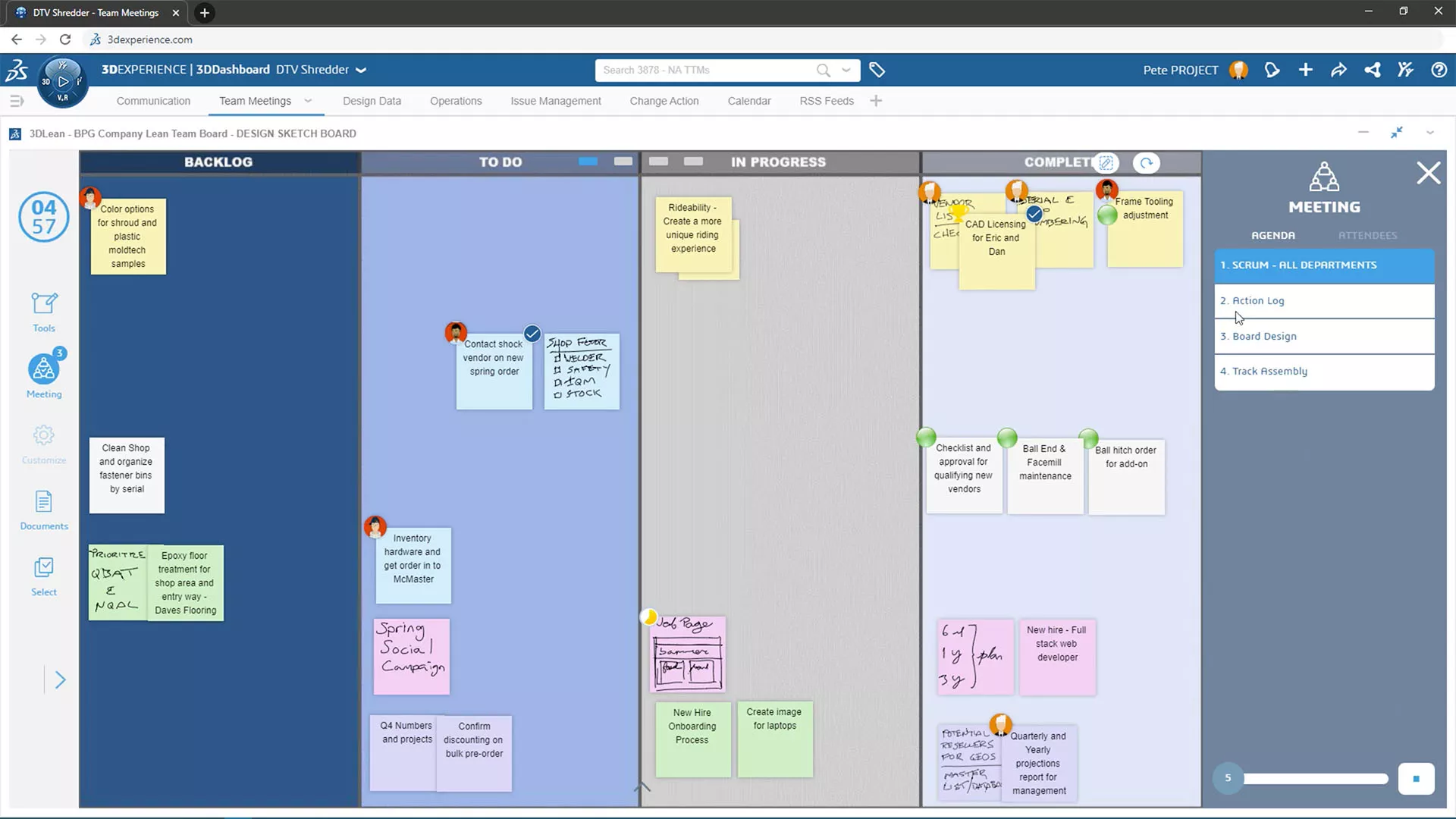

Empower Teams to Work Autonomously

Managers can effectively communicate with their teams on a daily basis. Team members are more aware of the team’s goals and can set the conditions for continuous improvement. When teams can see and track their progress, they take ownership of daily operations and contributions.

Capture Team Knowledge and Know-How

As teams architect and implement their individual strategies, the team’s success can be captured, evaluated, and re-used as a corporate best practice. It then provides a conduit for socializing the information into practice.

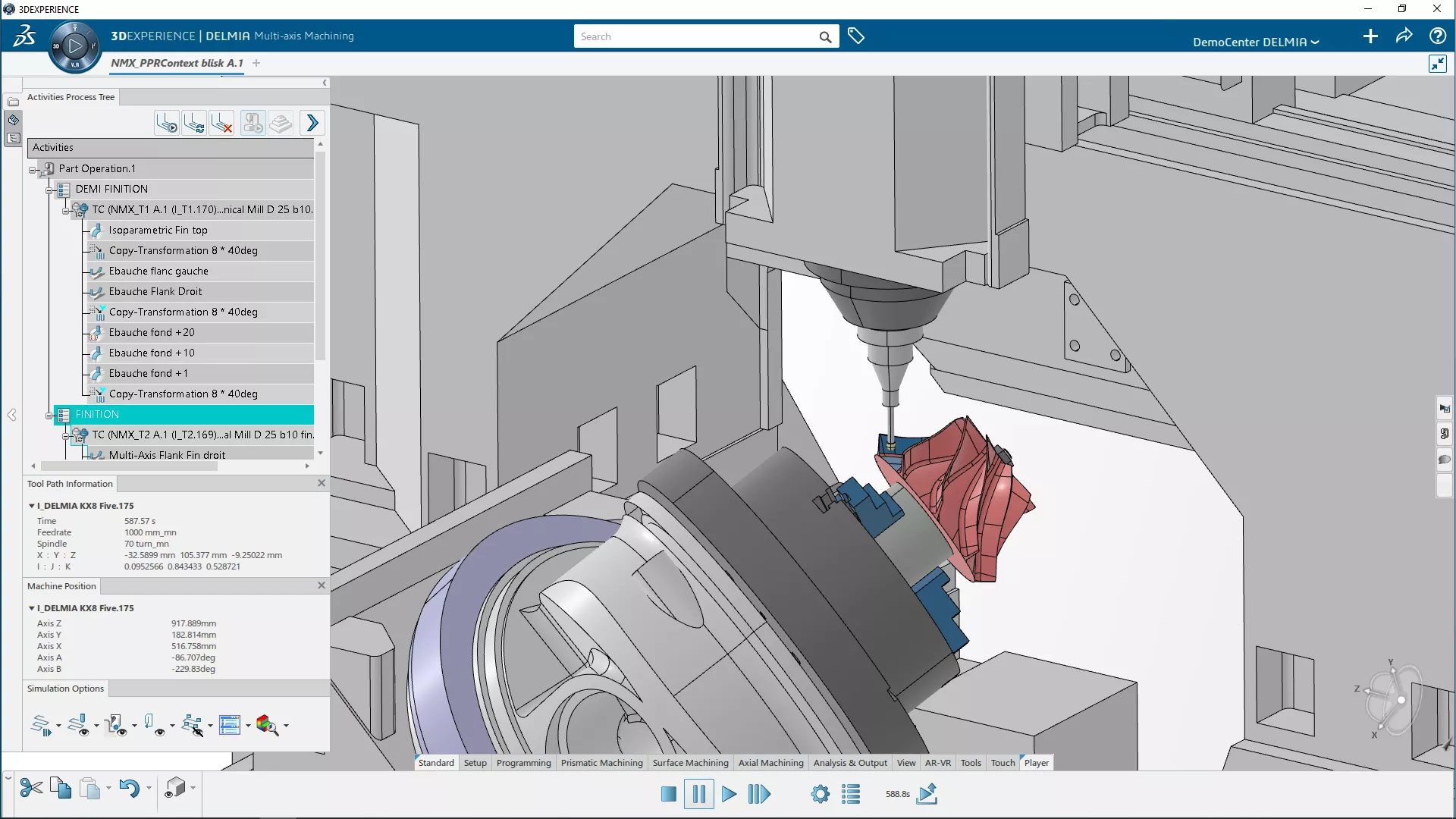

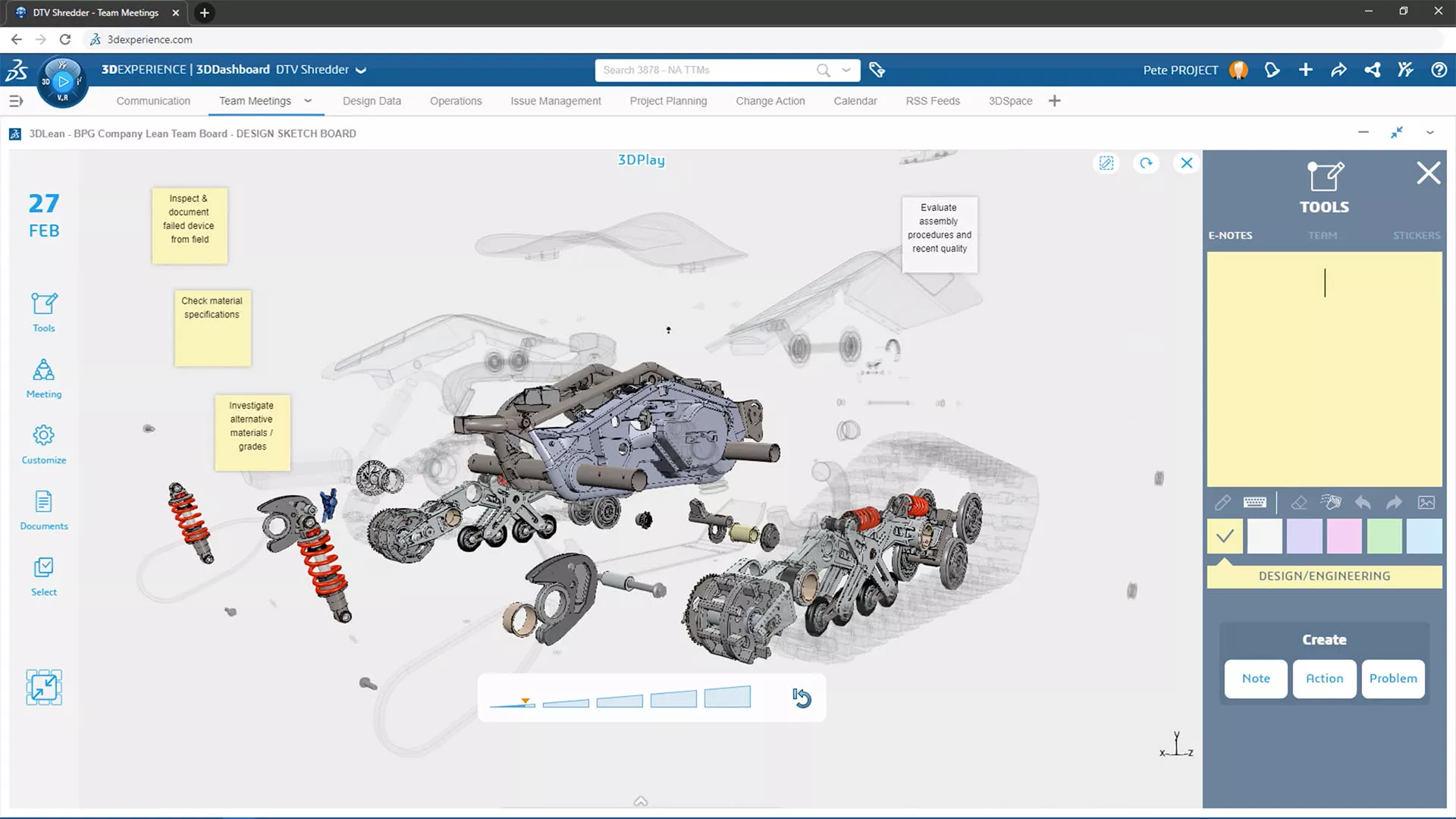

Visualize 3D Content and Data

Teams can leverage lean methodologies with virtual models of product, process, and resources in order to discuss, analyze, and solve problems. External content and information can be included to adapt to different team objectives.

Enable Real-Time Decisions and Actions

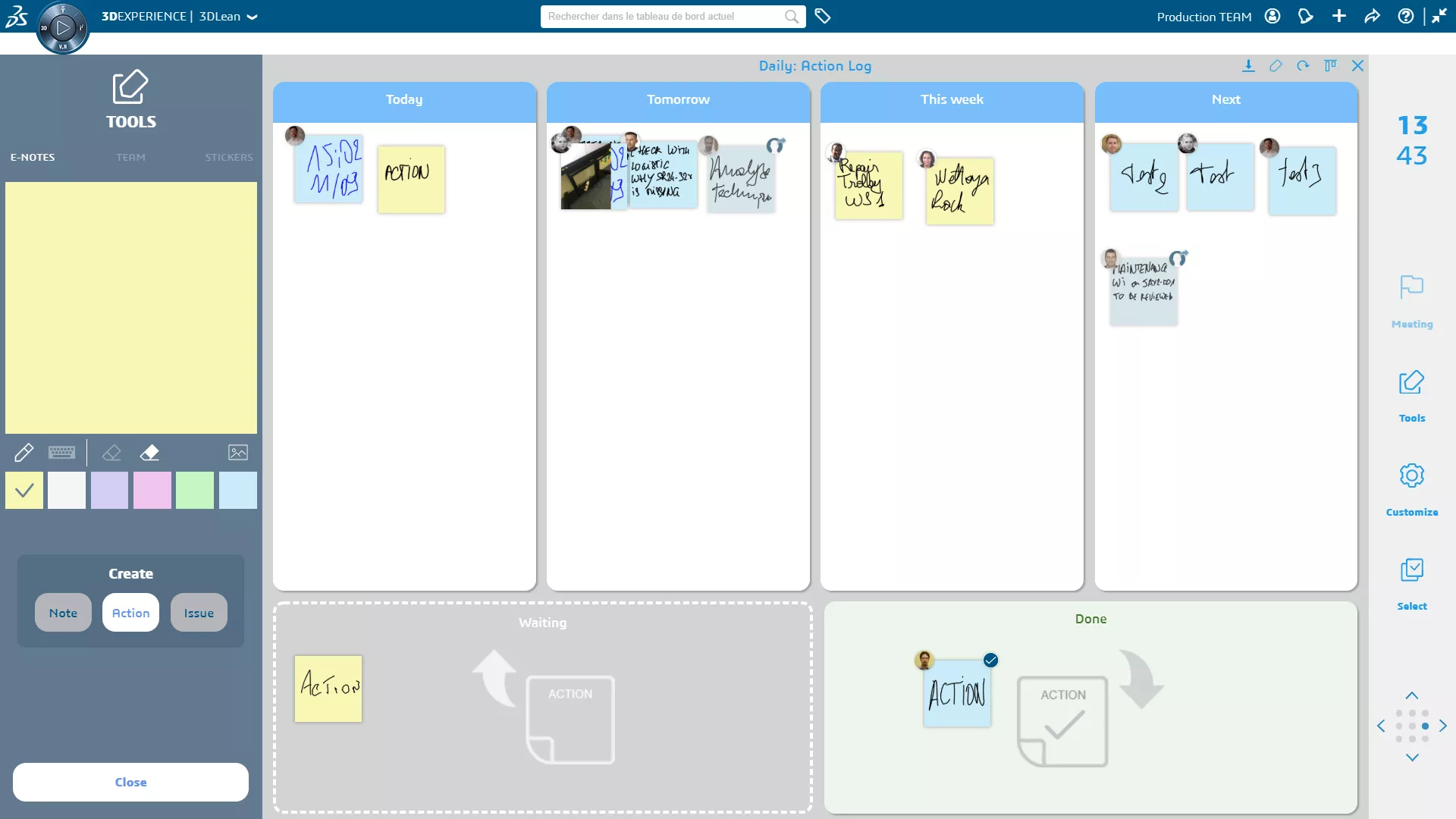

Managers and teams can identify steps required to analyze and resolve issues interactively. Actions can be created and assigned to team members (or other teams) to ensure accountability and follow up. It allows teams to formalize the management of issues and eases the vertical cascading of information.

Make "Lean Thinking" a Standard Part of Business

Drives continuous improvement by systematically guiding teams to use lean principles and methods as part of every meeting. It brings discipline and rigor to the team so they can apply best-practice methodologies.

Feature Matrix

OPTION

OPTION

OPTION

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

Product Feature

CASE STUDY

Learn how Morgan Polymer Seals accelerated their seal development to meet electric vehicle market demand with 3D EXPERIENCE Works Simulation.

3DEXPERIENCE FACTORY OPERATIONS Products

-

Lean Team Player

- Put lean principles into action to address operational waste, variability, and efficiency in a content-rich virtual meeting environment.

- Key Features:

- Simple and easy to use environment accessible to everyone (on the cloud or in person)

- Integrates Lean methodologies into team processes; Incorporates operational data and graphical information to guide collaboration and analysis

- Captures actions and assignments to ensure follow up and issue resolution

- Customizable to different team challenges and goals -

Learning 3DEXPERIENCE Cloud PDM: Goengineer is here to help

More Connected Manufacturing Solutions For You

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services