3DEXPERIENCE ROBOTICS

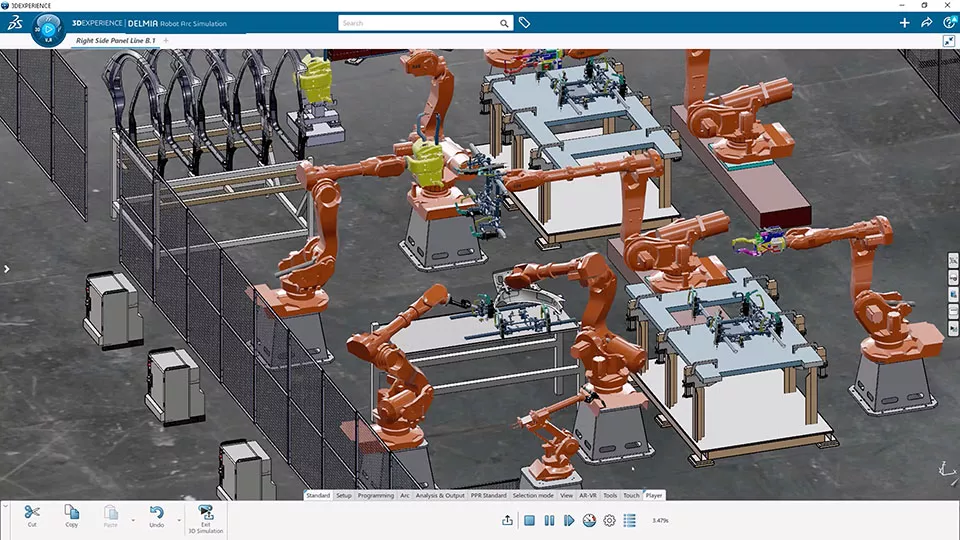

A virtual workplace to program, simulate, and validate industrial robots

Empowering Robot Programmers

3DEXPERIENCE ROBOTICS is a scalable, comprehensive, and robust array of software tools designed to empower robot programmers. This innovative platform simplifies the entire manufacturing engineering process, offering features for layout, simulation, validation, calibration, and offline robot programming, all seamlessly integrated with the 3DEXPERIENCE Platform.

With 3DEXPERIENCE ROBOTICS, achieve offline robot programming without disrupting production, ensuring precise virtual validation through digital twin technology. This not only saves valuable time and reduces costs but instills confidence in your systems' performance. Say goodbye to extended production downtimes and the error-prone process of manual robot programming as you embrace a safer and more efficient approach to robotics for manufacturing.

3DEXPERIENCE ROBOTICS is part of the DELMIA manufacturing software portfolio.

“We chose a 3D EXPERIENCE Works Simulation solution because it’s cloud-based, which supports our remotely located engineering organization, works seamlessly with SOLIDWORKS design data, and incorporates the Abaqus Explicit solver, which is best suited for the types of simulation studies that we need to conduct on our parts, which can involve hyperelasticity, creep, fatigue, and contact.”

– Thomas Morgan

Design Engineer

HIGHLIGHTS

One Solution Streamlines Process Engineering

3D EXPERIENCE ROBOTICS cover all aspects of layout, simulation, and programming. As a comprehensive robot programming tool encompassing dozens of manufacturing processes and robot brands, it reduces license costs, training requirements, process fragmentation, and other associated overhead.

The regularly-updated robot library contains over two thousand 3D robot models from 25 robot vendors, with fully-defined kinematics.

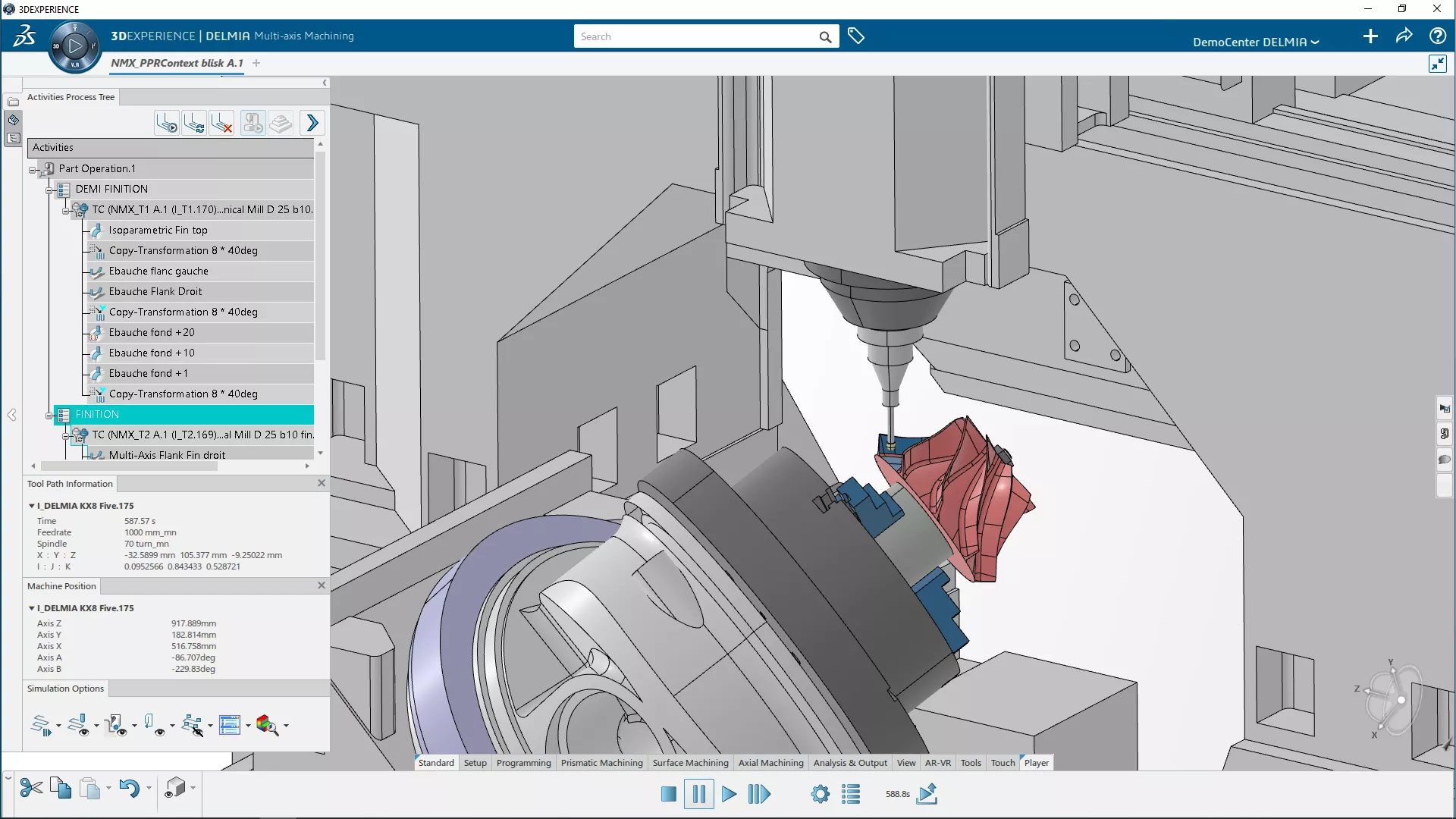

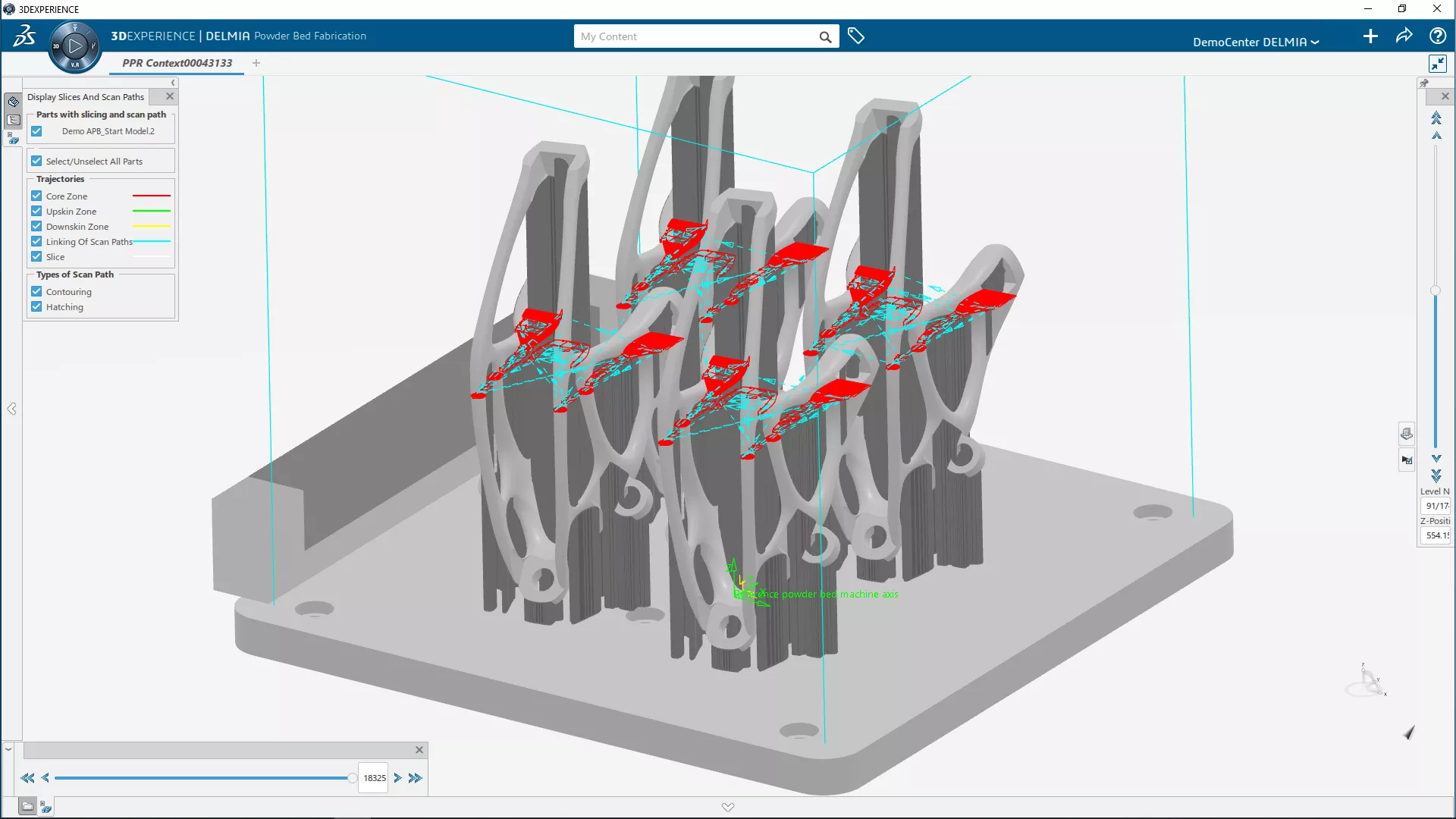

Perfectly complements 3DEXPERIENCE NC PROGRAMMING and ADDITIVE MANUFACTURING solutions.

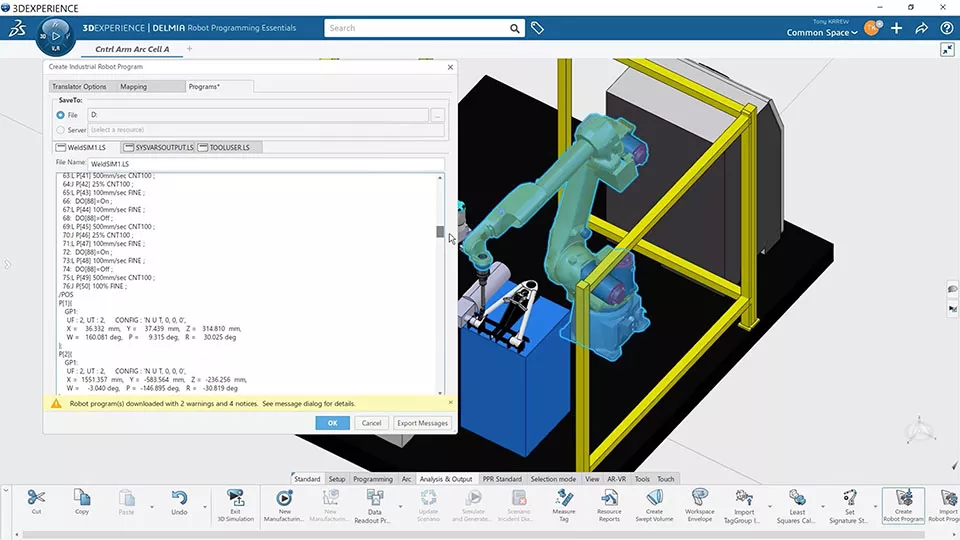

A Better Way to Program Robots

3DEXPERIENCE ROBOTICS delivers accurate, validated programs to the shop floor without interrupting production.

- Offline programming in a 3D virtual factory environment with calibration tools to align virtual and physical workcells

- Offline robot translators and controllers for production logic & I/O

- Open architecture to write or customize translators using VB.NET

- Control over robot position, motion, attributes, and multi-robot coordination

- Welding, adhesives, cutting, machine tending, pick & place, drilling & riveting, and more

- Kinematics for end effectors, clamps, and fixtures

- Workcell and plant layout

- Program import/export and customization

Optimize Efficiency & Risk with Simulation

Getting it right the first time saves potentially enormous amounts of time and money. For this reason, 3DEXPERIENCE ROBOTICS provides process simulation prior to any real-world commitment.

- Detect collisions virtually and fix them before they happen

- Analyze cycle time by simulating the entire production process

- Evaluate robot tasks, with motion, in the full manufacturing context

- Account for the actual production environment, accounting for machines, tools, and robot guns

- Test scenarios for cost, floor space, and other factors

- Visualize the entire space and process before any physical build

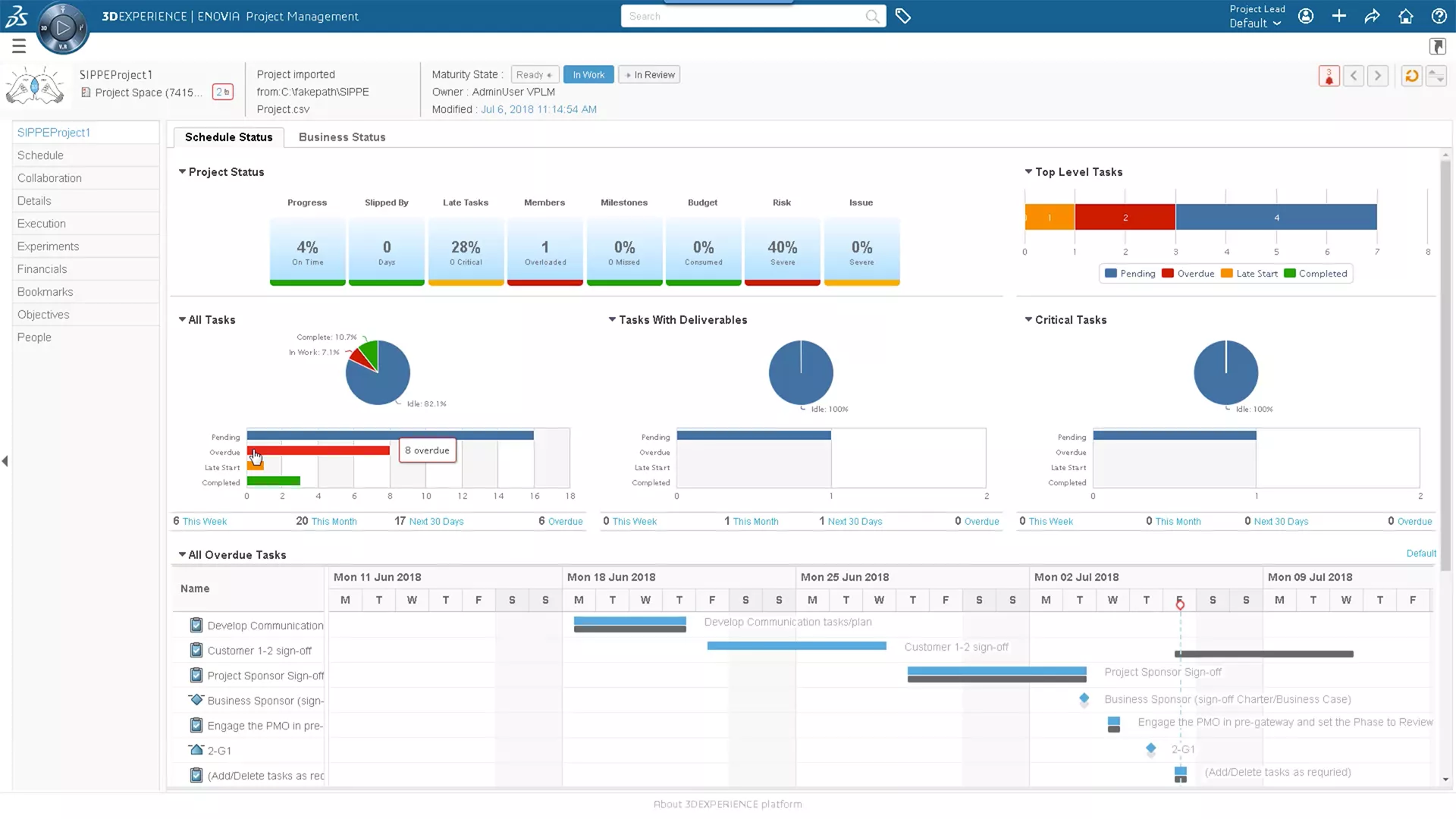

Design & Manufacturing in Tandem

Shared product data on the 3DEXPERIENCE Platform enables design and manufacturing to optimize their output concurrently and collaboratively, in real-time.

- Single-click program updates after design changes

- Quickly reveal manufacturing issues and understand downstream impact of such changes

- Conduct feasibility and optimization studies on robot tasks

- Accelerate timelines by working concurrently and identifying potential problems before they're locked in

The Future of Robotics in Your Shop – Get the Guide

DELMIA Robotics helps manufacturers program, simulate, and optimize robotic systems in a virtual environment before production begins. With built-in robot libraries, automatic trajectory optimization, and seamless integration with SOLIDWORKS and CATIA, it simplifies complex automation tasks and reduces downtime.

This guide explains how DELMIA Robotics improves efficiency, minimizes errors, and speeds up production. Learn how virtual commissioning and real-time simulation can help you get the most out of your robotic systems. Download now to get started.

3DEXPERIENCE NC PROGRAMMING Feature Matrix

Floor

Programmer

Programmer

& Die

Programmer

& Mill-Turn

Programmer

Machine

Programmer

NC Programming Wizard

CAD-Associative Instant Update

Quick Toolpath Verification

Machining Process Simulation

Prismatic Machining

WireEDM Programming (2-Axis & 4-Axis)

4- & 5-Axis Indexing/Pre-Positioning Milling

Single- & Multi-Stylus Probe Operations

3-Axis Milling

High-Speed Rough Milling

Advanced 3-Axis Milling

4- & 5-Axis Milling (5-Axis Nurbs APT Output)

2-Axis Turning

Mill-Turn Machining

Swiss Machine

Robot Programming

CASE STUDY

Learn how Morgan Polymer Seals accelerated their seal development to meet electric vehicle market demand with 3D EXPERIENCE Works Simulation.

3DEXPERIENCE ROBOTICS Products

-

Robot Programmer

- A single, cost-effective solution for layout, simulation, and offline programming of robot workcells as part of an end-to-end design-to-manufacturing process.

- Key Features:

- Best for arc welding, adhesives, cutting, machine tending, and pick & place applications

- Kinematics for end effectors, clamps, and fixtures

- Robot library covering thousands of robots from leading manufacturers

- Offline programming and calibration in native robot language

- Translation including production logic and I/O

- Customize or write your own translator using VB.NET - Typically used by:

- Robot machine programmer

- Manufacturing engineer/manager

- Production manager

- Engineering manager -

-

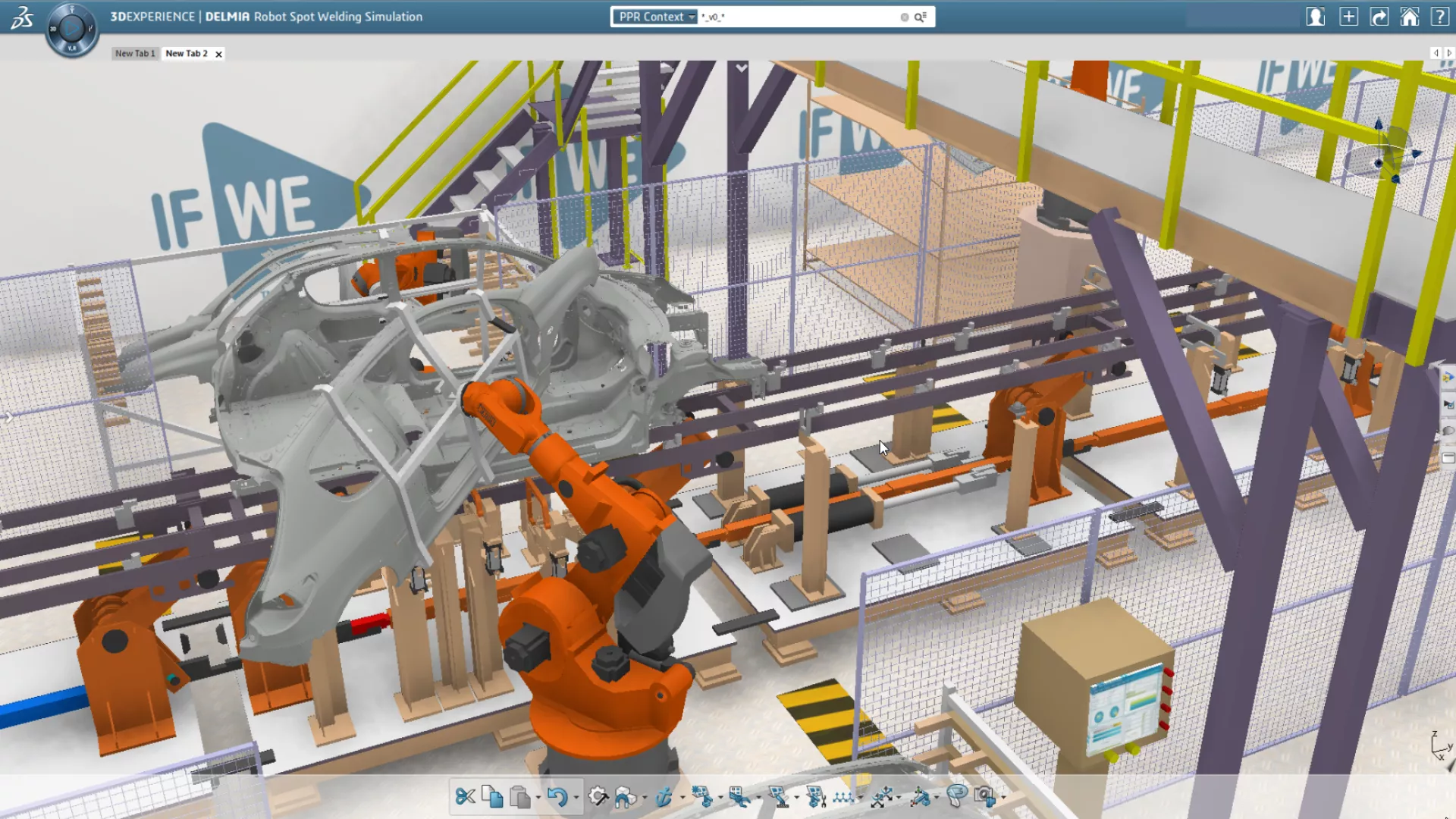

Assembly Robot Programmer

- Build, simulate, validate, and program robot assembly systems (particularly spot welding and drilling & riveting) in an interactive 3D environment.

- Key Features:

- Accurate, production-ready robot programming in native controller language

- Programmable I/O between robots and other devices

- Robot program import/export/customization

- Coordinated multi-robot simulation

- RRS-I protocol for increased simulation accuracy

- High-volume drilling & riveting simulation

- Riveting operation & patterning profiles

- Easy-to-use teach-pendant interface

- Easy and intuitive welding scenario analysis

- Automatically generated robot tasks with motions, motion attributes, and spot operations

- Automatic distribution of welds according to robot proximity

- Automatic robot path updates to accommodate design changes - Typically used by:

- Robot machine programmer

- Manufacturing engineer/manager

- Production manager

- Engineering manager -

-

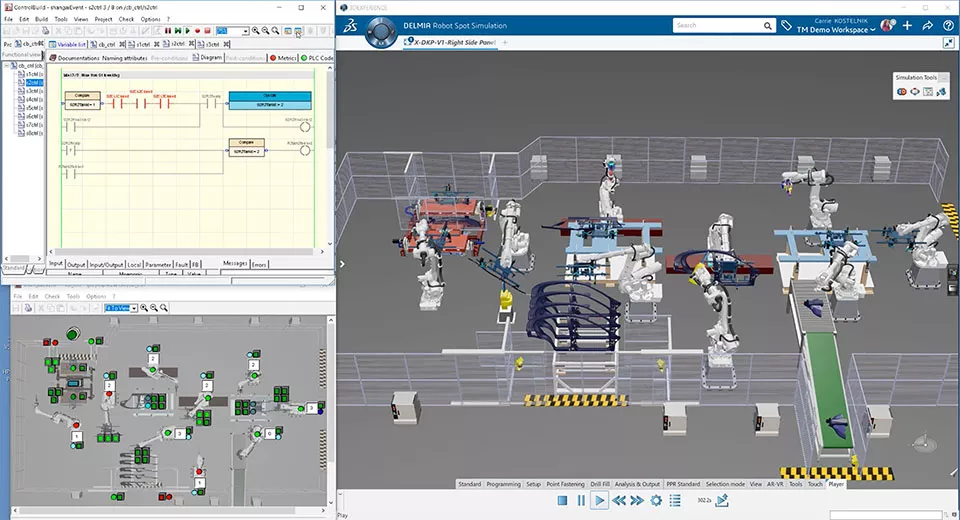

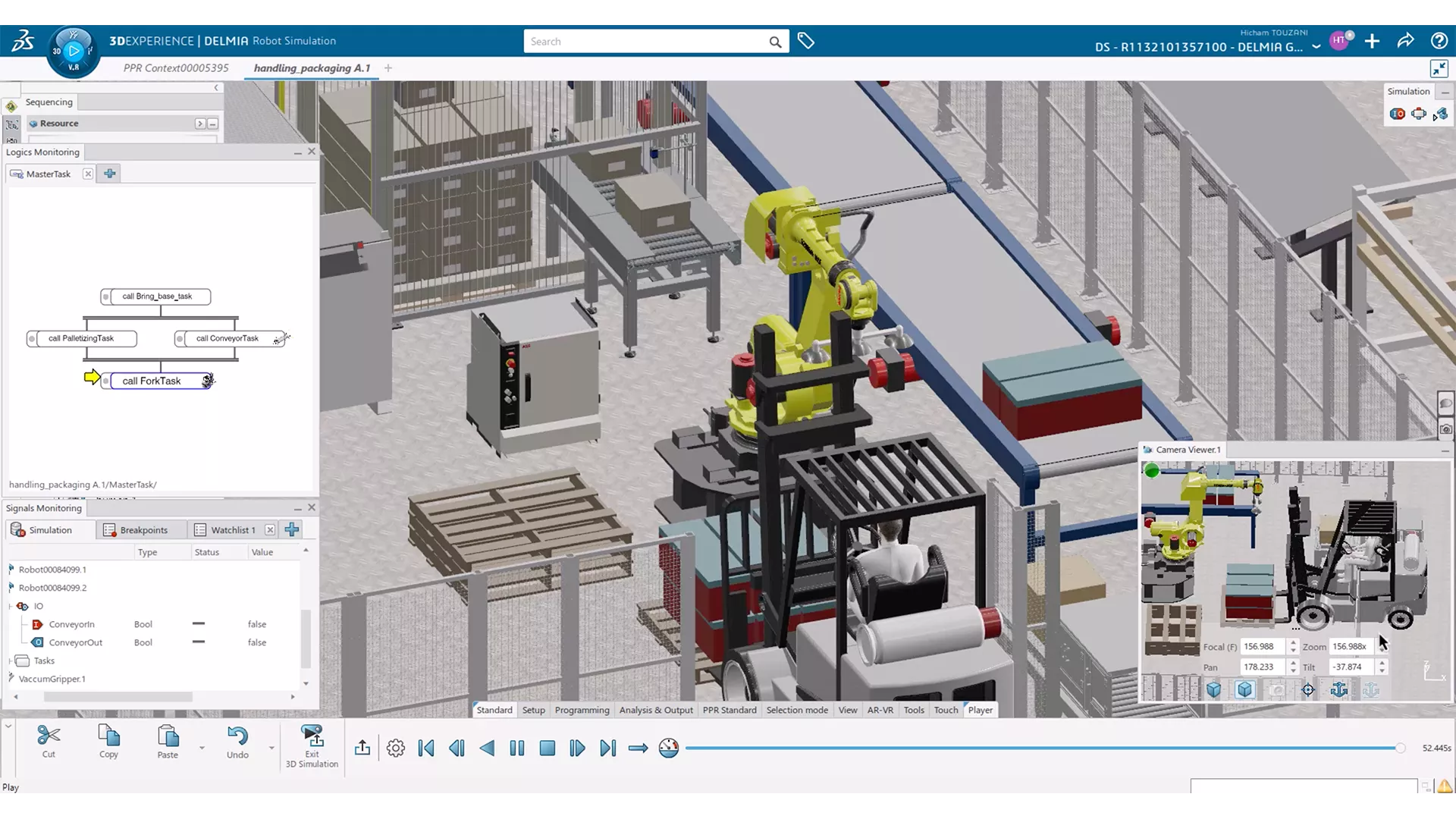

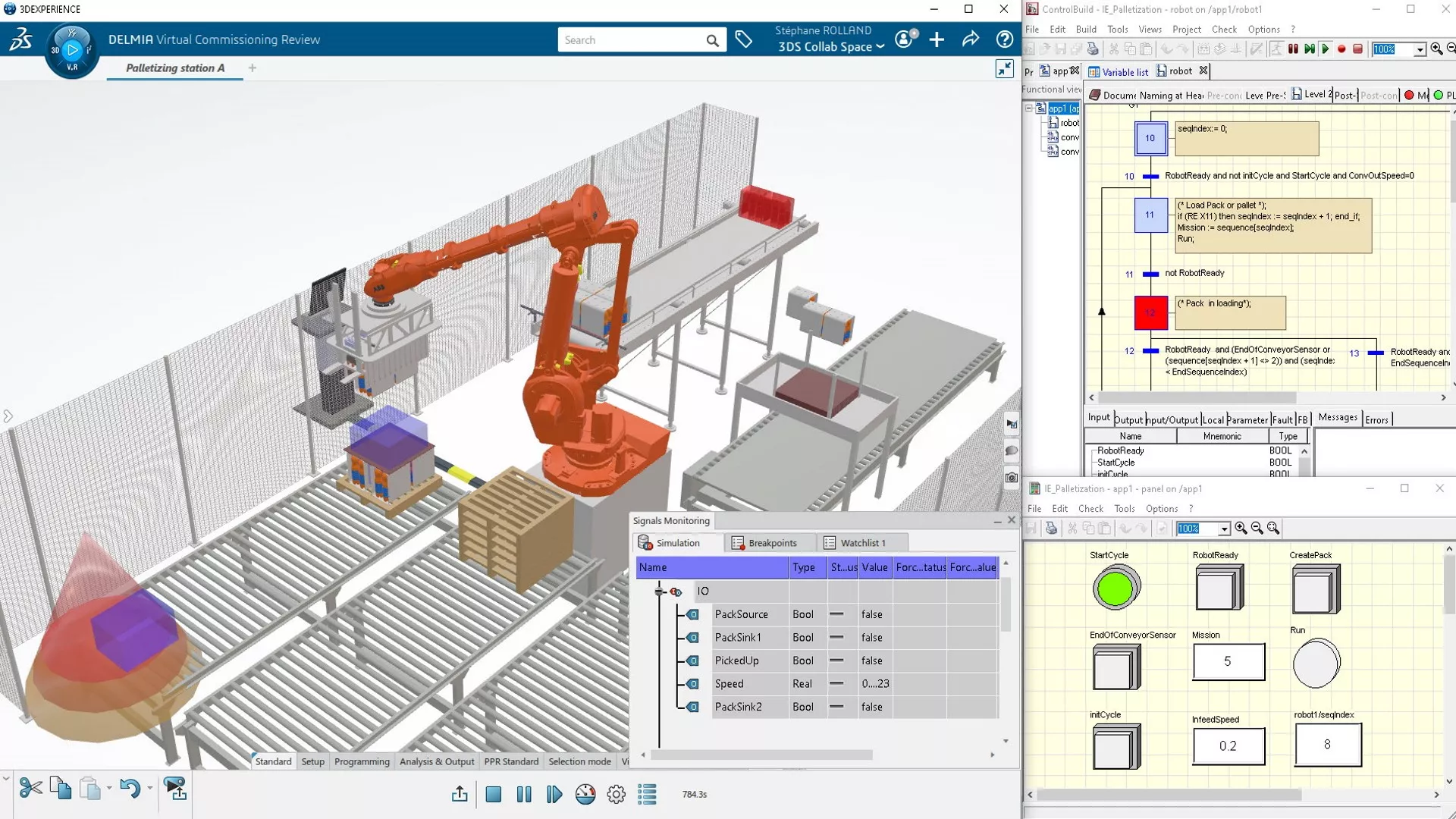

Robotics Virtual Commissioning Analyst

- Validate the PLC program of robots, equipment, and sensors in a simulated virtual factory environment.

- Key Features:

- Create sensors, generate and transform parts for multicycle scenarios

- Enable virtual validation and correction of the PLC program to accelerate the start of production

- Reduce costly downtime by leveraging the virtual twin to train operators and maintenance workers

- Forecast workcell cycle time by connecting the virtual robot to the RRS II standard or any proprietary virtual robot controller server - Typically used by:

- Robot machine programmer

- Manufacturing engineer/manager

- Production manager

- Engineering manager -

-

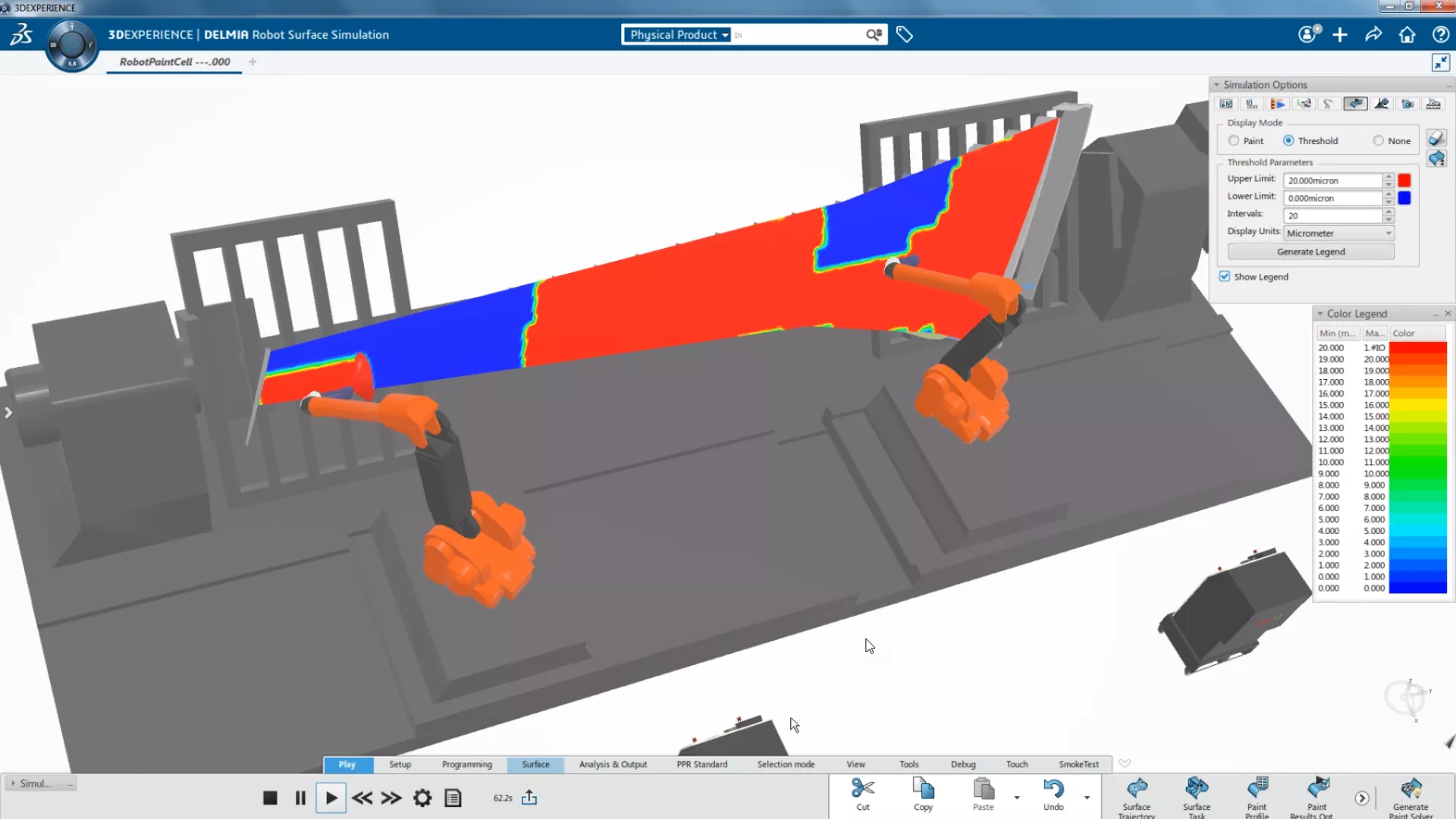

Surface Robot Programmer

- Create, program, and validate robot workcells for finishing systems in an interactive 3D virtual factory, ensuring accuracy and efficiency in surface processes.

- Key Features:

- Optimize motion in the painting and shot peening processes

- Reduce waste in coating and surface treatment processes

- Save and re-use programming styles

- Support for part positioners and spindles

- Support for advanced logic and I/O in the simulation

- Robot simulation "on-the-go" (offline mode)

- Alignment of 3D virtual workcells with physical workcells - Typically used by:

- Manufacturing engineer/manager

- Robot programmer

- Robot simulation engineer -

-

Robotic Workcell Simulation Engineer

- Design and validate complete robotic handle systems to ensure workcell feasibility before procuring expensive equipment.

- Key Features:

- Complete workcell validation

- Advanced logic and I/O support in the simulation

- Realistic Robot Simulation (RRS-I) for increased simulation accuracy

- Create, validate, and reuse mechanisms with automated support

- Calculate interference zones

- Fast and easy robot placement

- Robot simulation "on-the-go" (offline mode)

- Create 3D parts or assemblies - Typically used by:

- Engineering manager

- Production manager

- Manufacturing engineer/manager

- Machine programmer -

Learning 3DEXPERIENCE Cloud PDM: Goengineer is here to help

More Connected Manufacturing Solutions

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services