3DEXPERIENCE VIRTUAL FACTORY

Create, simulate, validate, and optimize your entire factory with a 3D virtual twin

Data-Driven Manufacturing Excellence

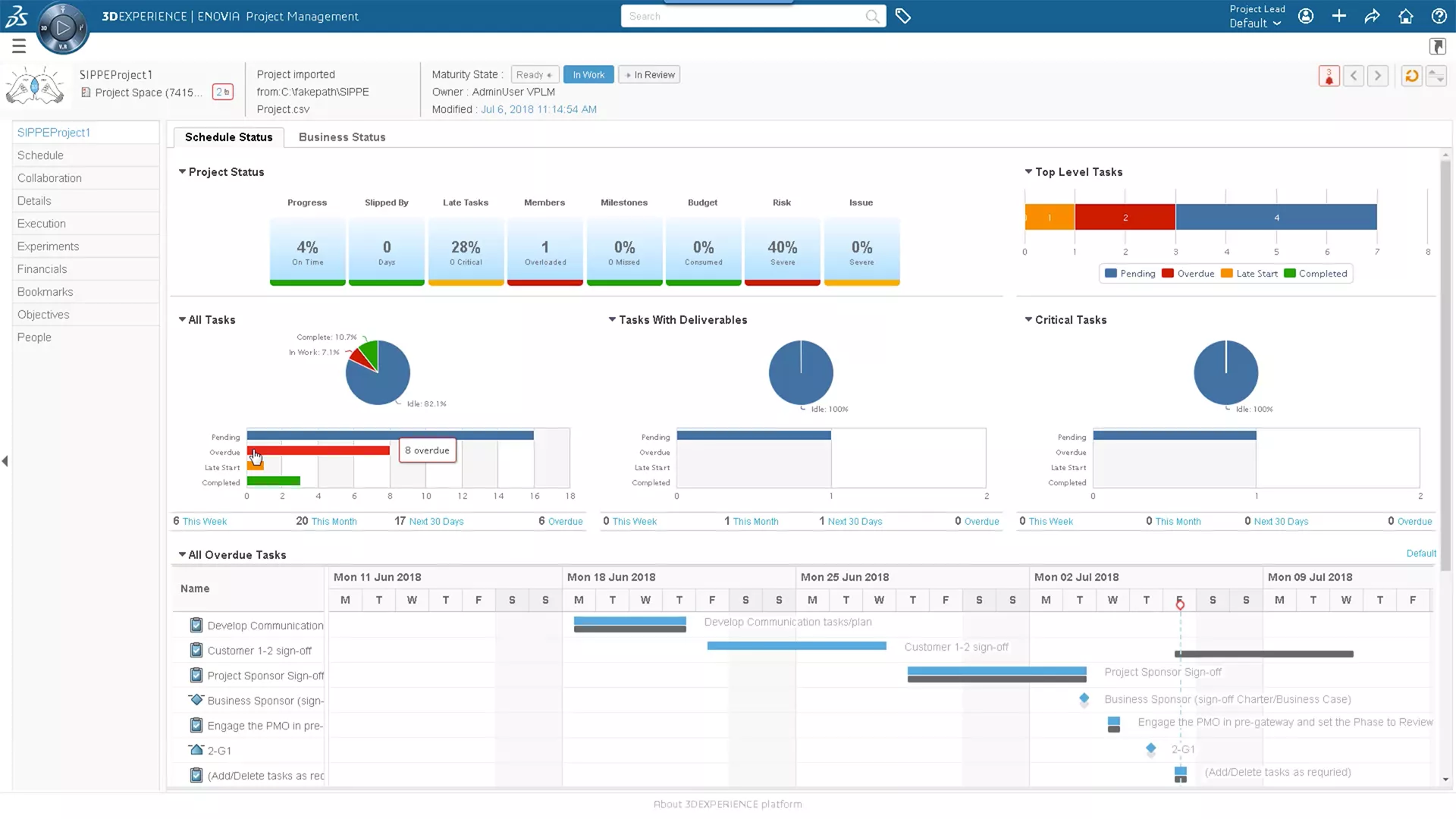

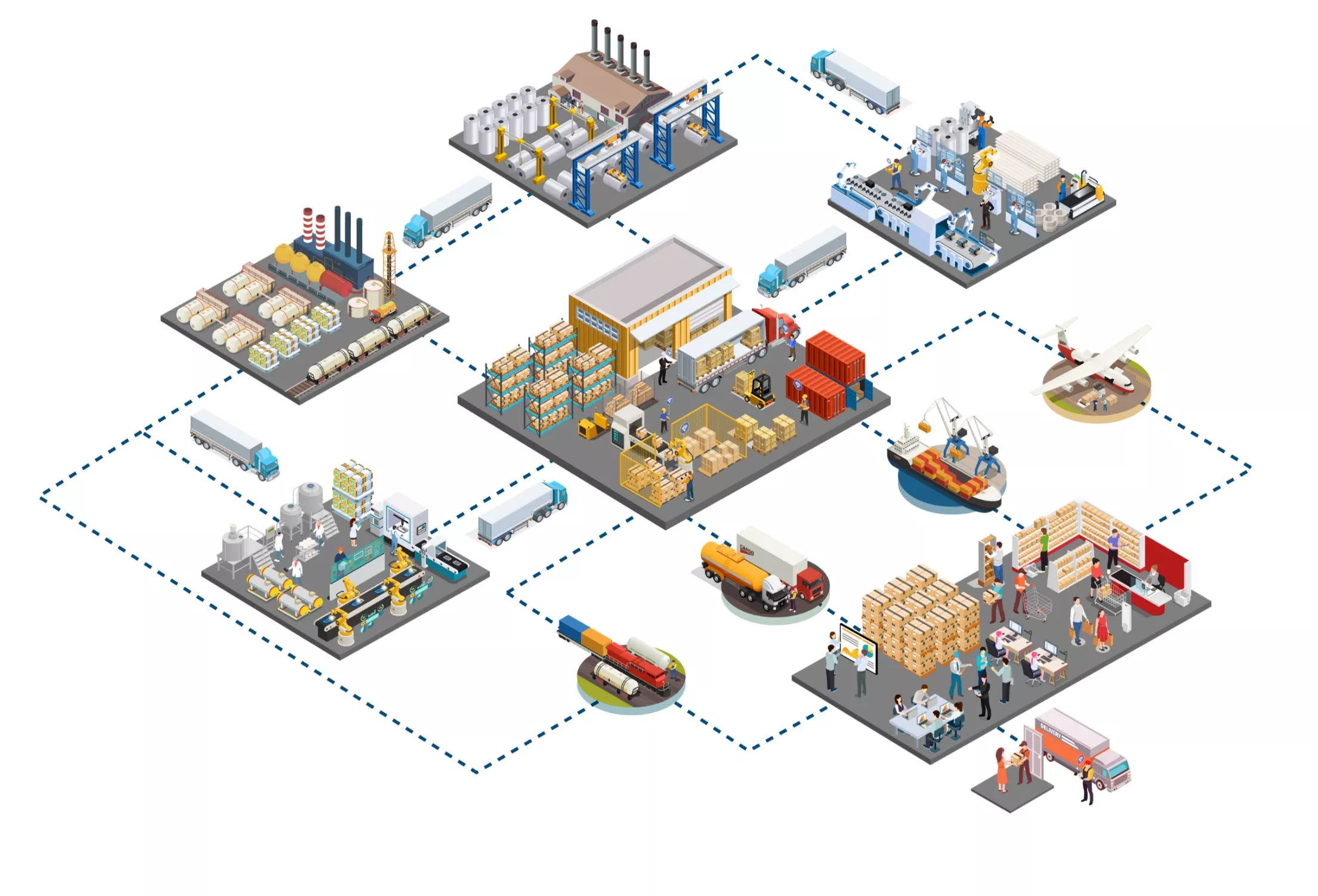

Modern manufacturing facilities need to operate with maximum agility and efficiency. For that, companies need to make fast, low-risk, high-impact decisions about how their factories are setup and run. 3DEXPERIENCE VIRTUAL FACTORY allows companies to plan and optimize plant layouts, workflows, and resources in a risk-free virtual environment before execution.

Create a 3D digital twin of the factory using real-world data, for simulations that cover manufacturing processes, operations, maintenance, and ergonomics. This data-driven approach ensures the well-informed decision making that creates industry leadership.

3DEXPERIENCE VIRTUAL FACTORY is part of the DELMIA manufacturing software portfolio.

How Do You Eliminate Factory Update Guesswork?

Keeping today’s production facilities up-to-date, modernized, and running at optimum capacity is no easy feat. Any change or update often triggers a cascade of associated changes, so updates must be thoughtfully planned out. When that change requires a shutdown, time is of the essence and every misstep comes with a big price.

Fortunately, virtual factory simulation software enables companies of all sizes to leverage their own data to create full digital replicas, or digital twins, of their factories. Using virtual tools, they can simulate the impact of changes before they are made in the real world.

Download this whitepaper to learn how virtual factory simulation software can help you expand and grow your production facility safely and efficiently—without the guesswork and anxiety.

“We chose a

3D

EXPERIENCE Works Simulation solution because it’s cloud-based, which supports our remotely located engineering organization, works seamlessly with SOLIDWORKS design data, and incorporates the Abaqus Explicit solver, which is best suited for the types of simulation studies that we need to conduct on our parts, which can involve hyperelasticity, creep, fatigue, and contact.”

– Thomas Morgan

Design Engineer

HIGHLIGHTS

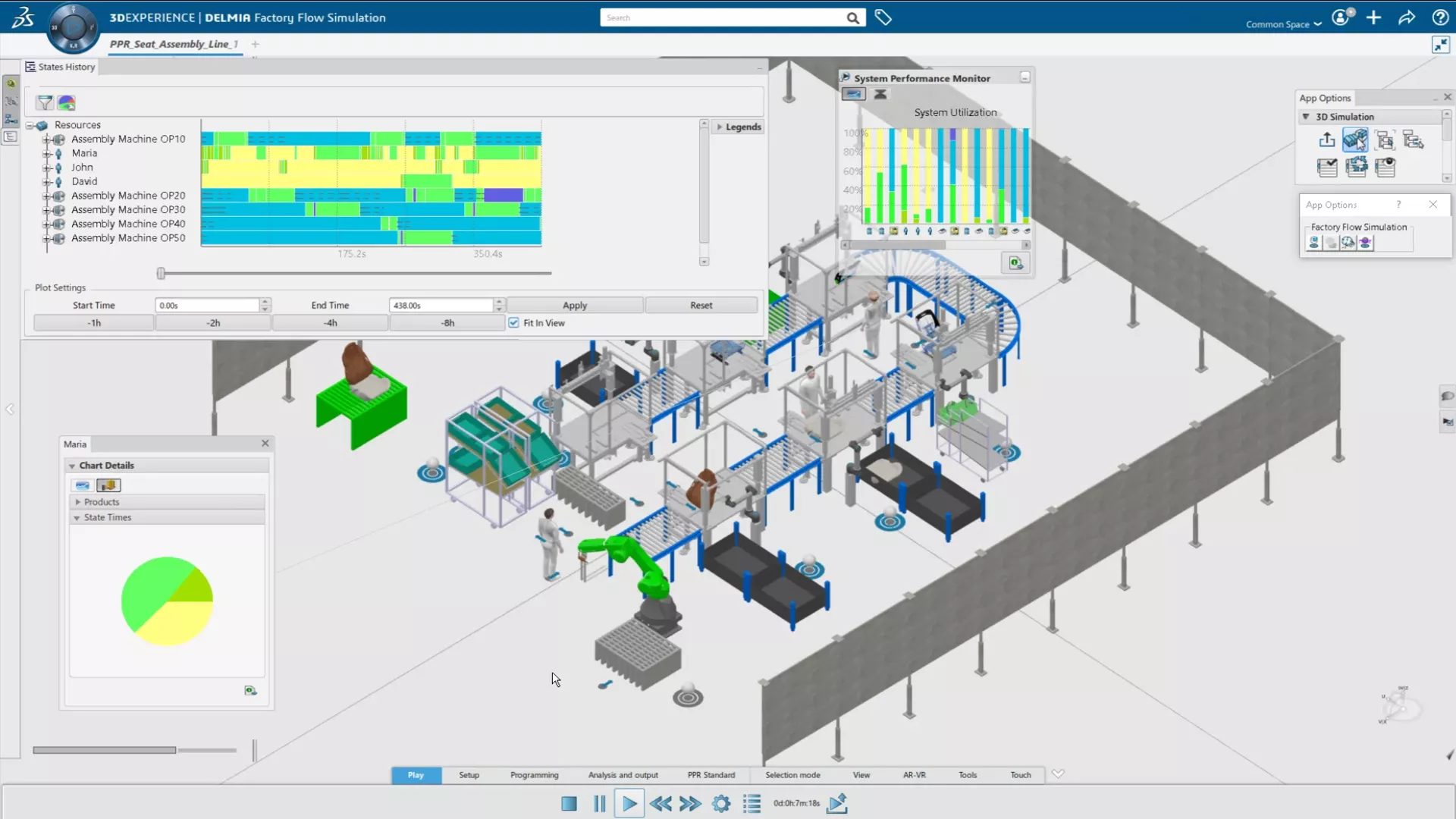

It Starts with the Factory Digital Twin

The digital twin of your factory is a 3D representation of the layout and behavior of all the manufacturing personnel, equipment, and materials in your facilities.

It's the low-risk, low-cost way to compare and validate any manufacturing plans before they go live, a powerful competitive advantage.

Manufacturing Process Optimization

Virtual plant layout and equipment configuration is a powerful predictive tool for increasing production efficiency:

- Recognize design flaws early

- Uncover reachability issues

- Identify bottlenecks, deadlocks, and collisions

- Optimize maintenance scheduling

- Verify manufacturability

Wiser Capital Investment

An "as-is" analysis on the digitized shop floor creates a data-driven starting point from which to conduct "what-if" comparative analyses.

Improve floor space utilization before physically moving or purchasing any equipment with validation in silico.

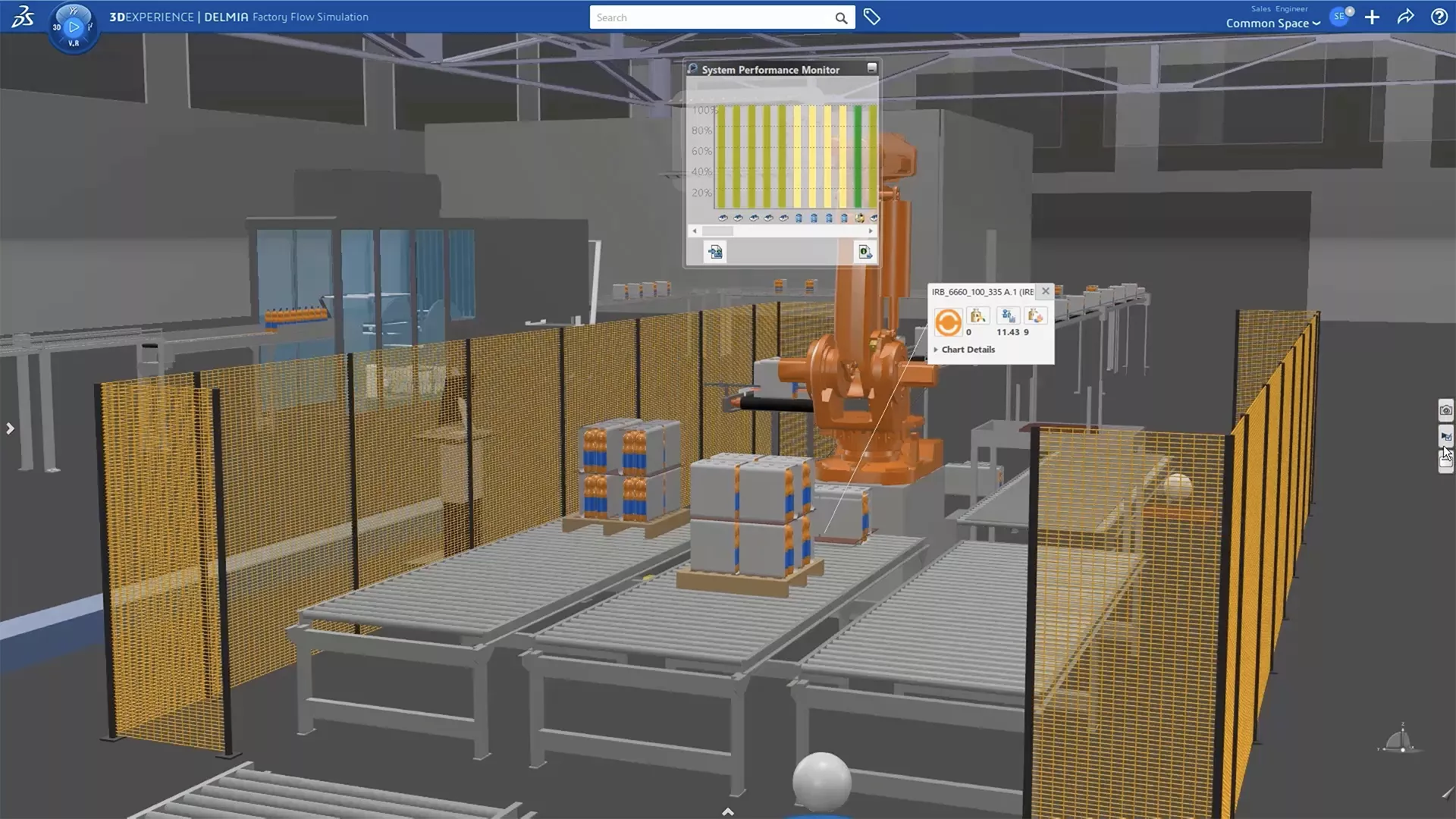

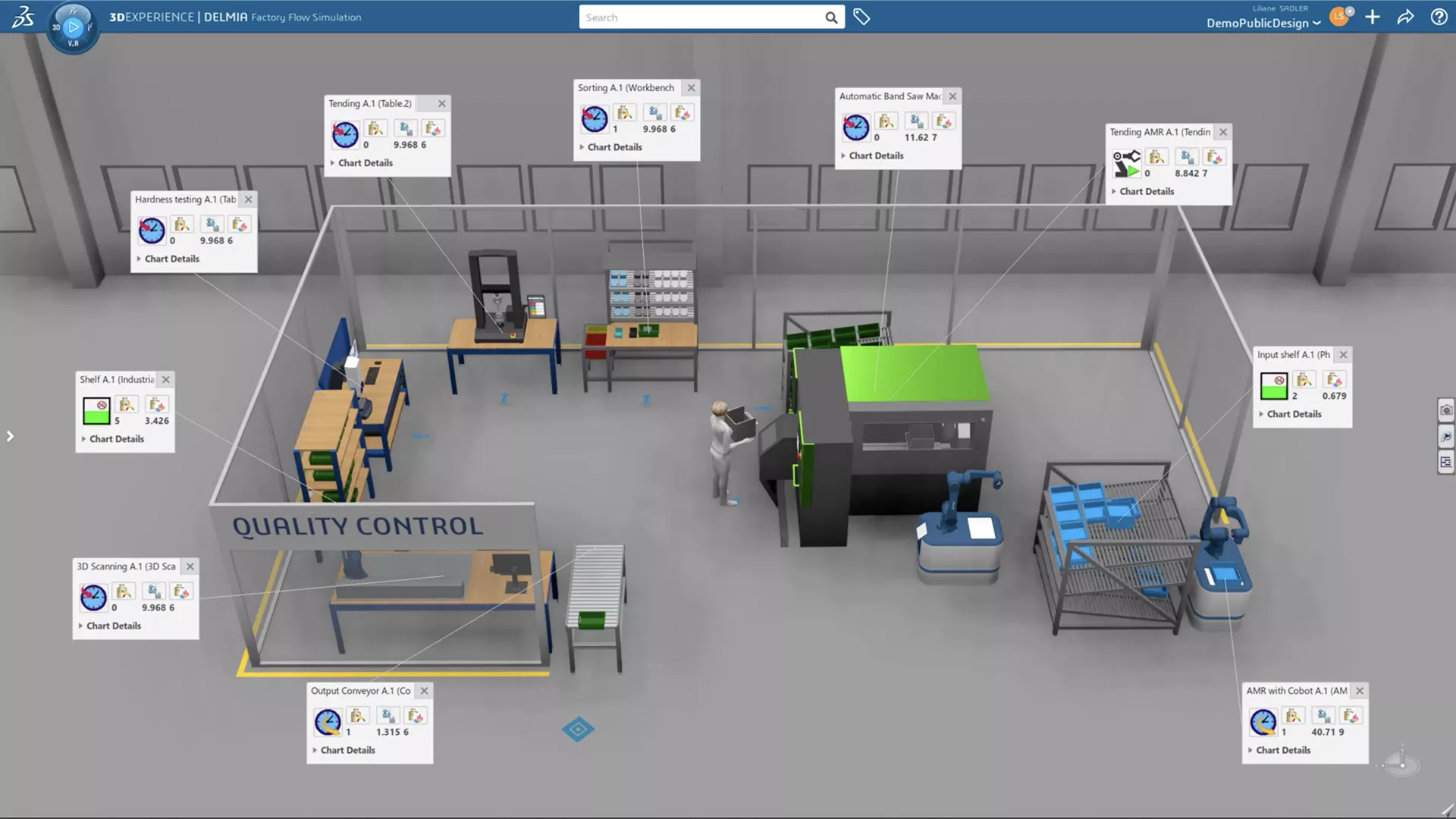

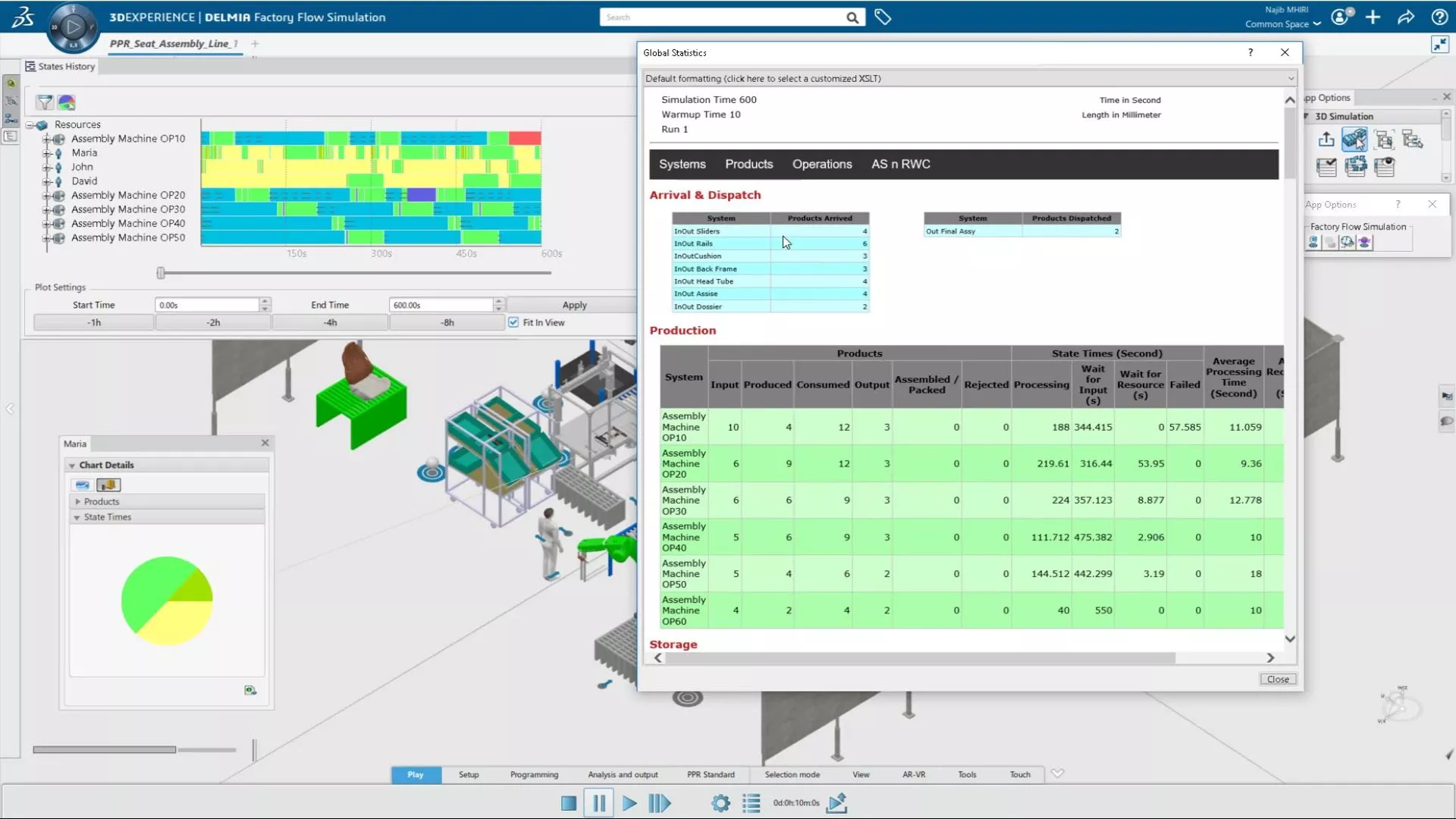

Actionable Resource Flow Analytics

By defining production equipment, line behavior, material flow logic, and robot and human tasks, it's possible to design and test material flow scenarios against KPIs, from the station to factory level.

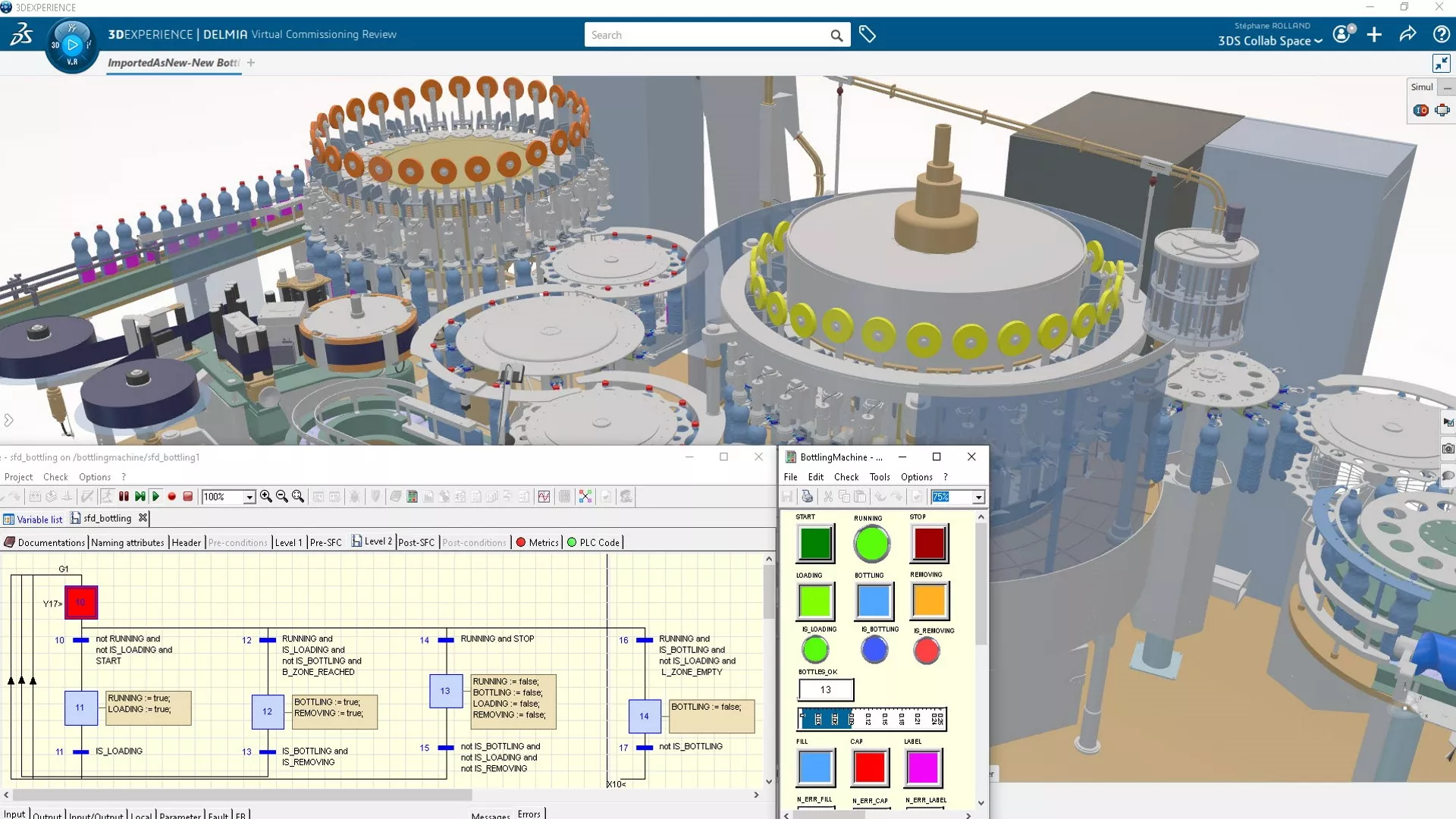

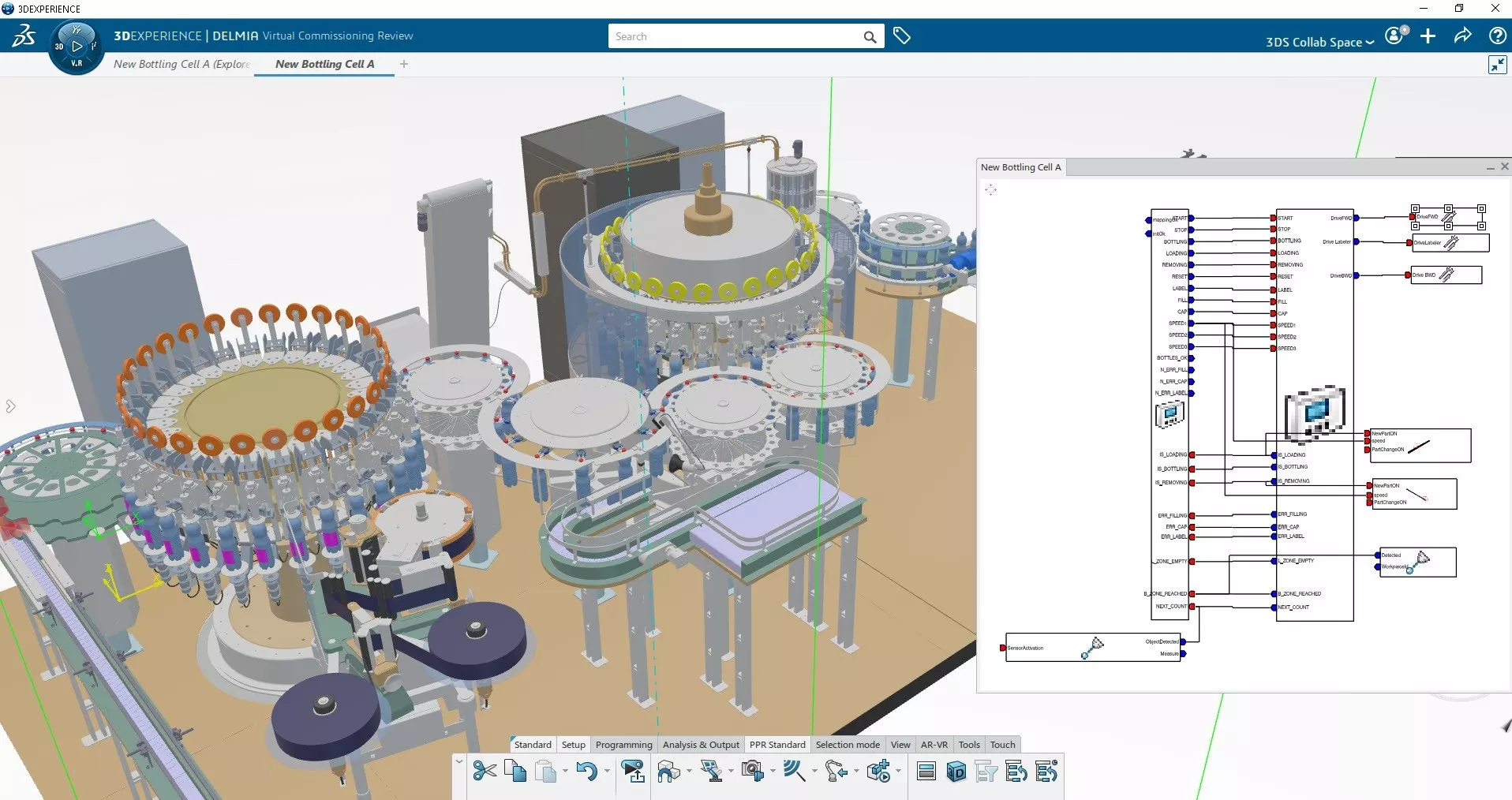

Risk-free Factory Systems Deployment

Virtual commissioning is the simulated commissioning of the new layout, equipment, tooling, and sensors in the virtual factory environment before real-world deployment.

Performance can be validated and any issues can be addressed right away, without ever interrupting production.

3DEXPERIENCE Case Study

Behlen Manufacturing: Streamlining Flow with Factory Simulation Engineer

It’s never too late to reinvent yourself. Just ask Behlen Manufacturing, a company that’s been in business since 1936. The company is retooling its nearly one-million-square-foot facility in Columbus, Nebraska, using a virtual twin of its facility created with Factory Simulation Engineer, a new solution in the 3DEXPERIENCE portfolio.

Using this new virtual factory planning software, the company was able to fully optimize its production and assembly facility virtually—before ever moving a single piece of equipment. They were able to identify ways to optimize, streamline, and improve efficiency, productivity, and factory flow within the facility without incurring the cost of physical move iterations.

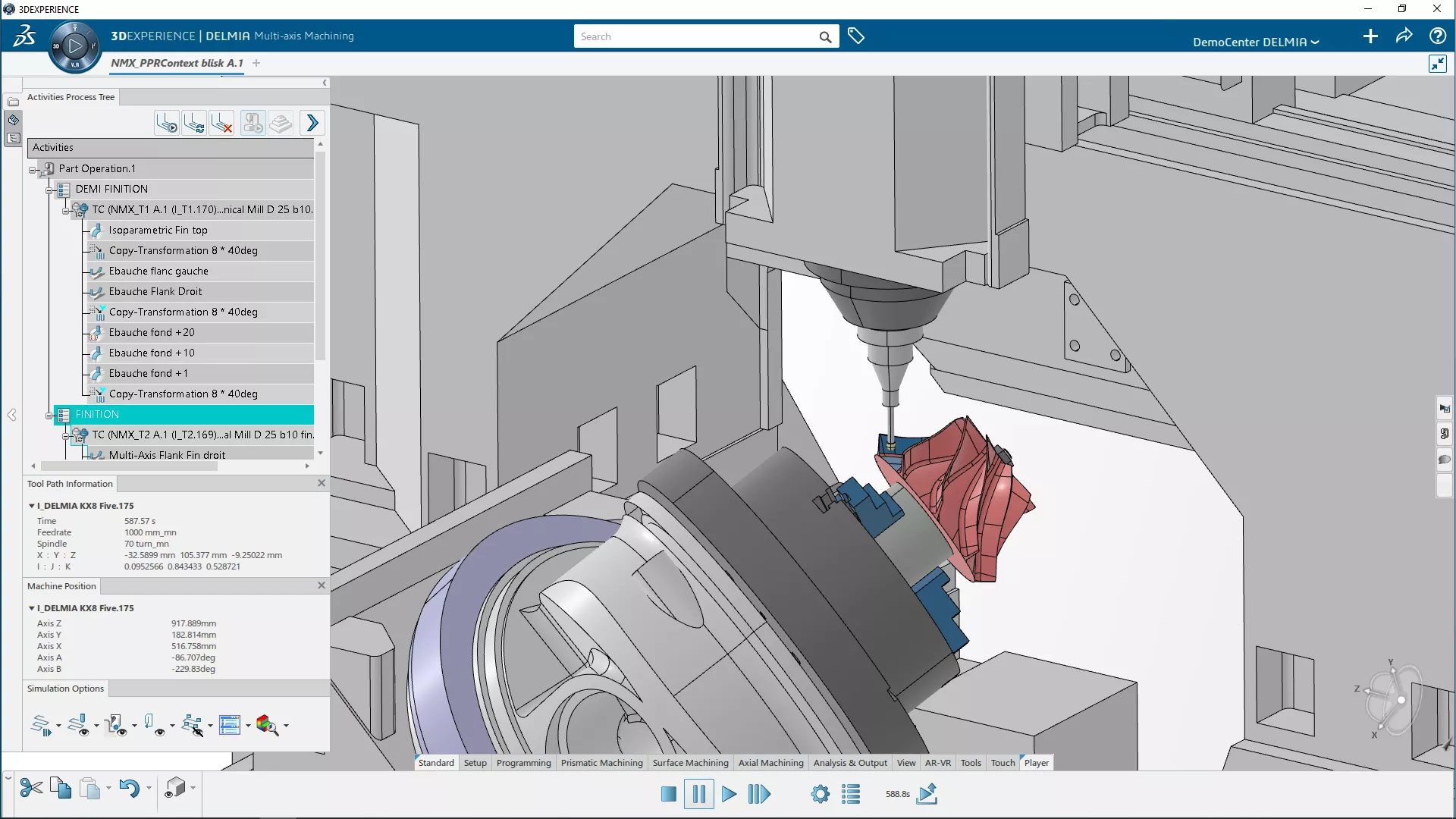

3DEXPERIENCE NC PROGRAMMING Feature Matrix

Floor

Programmer

Programmer

& Die

Programmer

& Mill-Turn

Programmer

Machine

Programmer

NC Programming Wizard

CAD-Associative Instant Update

Quick Toolpath Verification

Machining Process Simulation

Prismatic Machining

WireEDM Programming (2-Axis & 4-Axis)

4- & 5-Axis Indexing/Pre-Positioning Milling

Single- & Multi-Stylus Probe Operations

3-Axis Milling

High-Speed Rough Milling

Advanced 3-Axis Milling

4- & 5-Axis Milling (5-Axis Nurbs APT Output)

2-Axis Turning

Mill-Turn Machining

Swiss Machine

Robot Programming

CASE STUDY

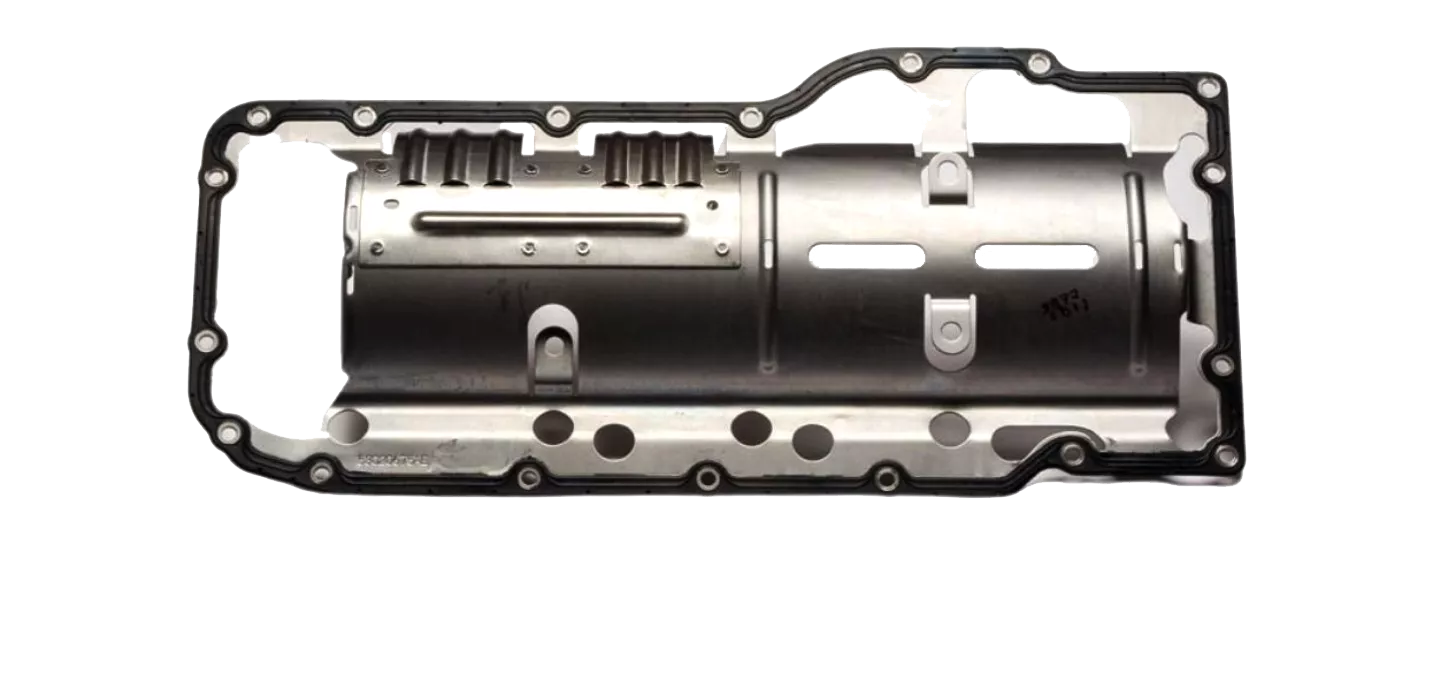

Learn how Morgan Polymer Seals accelerated their seal development to meet electric vehicle market demand with 3D EXPERIENCE Works Simulation.

3DEXPERIENCE VIRTUAL FACTORY Products

-

Factory Simulation Engineer

- Build, define, and simulate the operation of your 3D virtual factory layouts. Validate and compare performance of multiple production lines.

- Key Features:

- Define/import layout and manufacturing processes

- Visualize material flow

- Predict production rate, utilization rate, bottlenecks, collisions, and deadlocks

- Optimize layouts, pathing, maintenance, calendar shifts, and more

- Include random events (failure, missing parts, etc.)

- Robot and human behavior and pathing

- Advanced AGV traffic management

- Devise alternative factory configurations for batch "what-if" analyses

- KPI monitoring, analysis, and reporting - Typically used by:

- Plant layout & equipment designer

- Manufacturing engineer

- Process planner

- Industrial engineer -

-

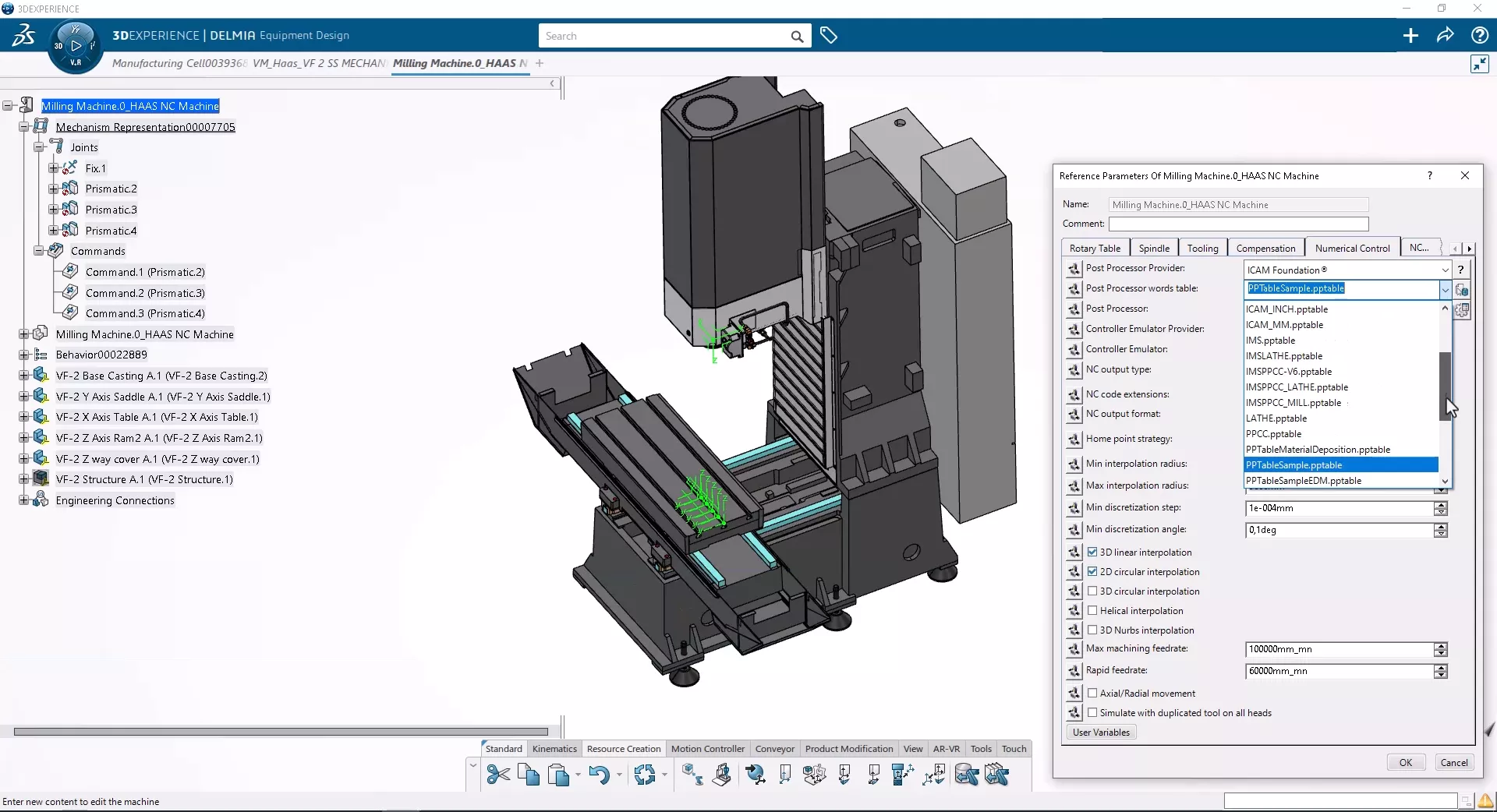

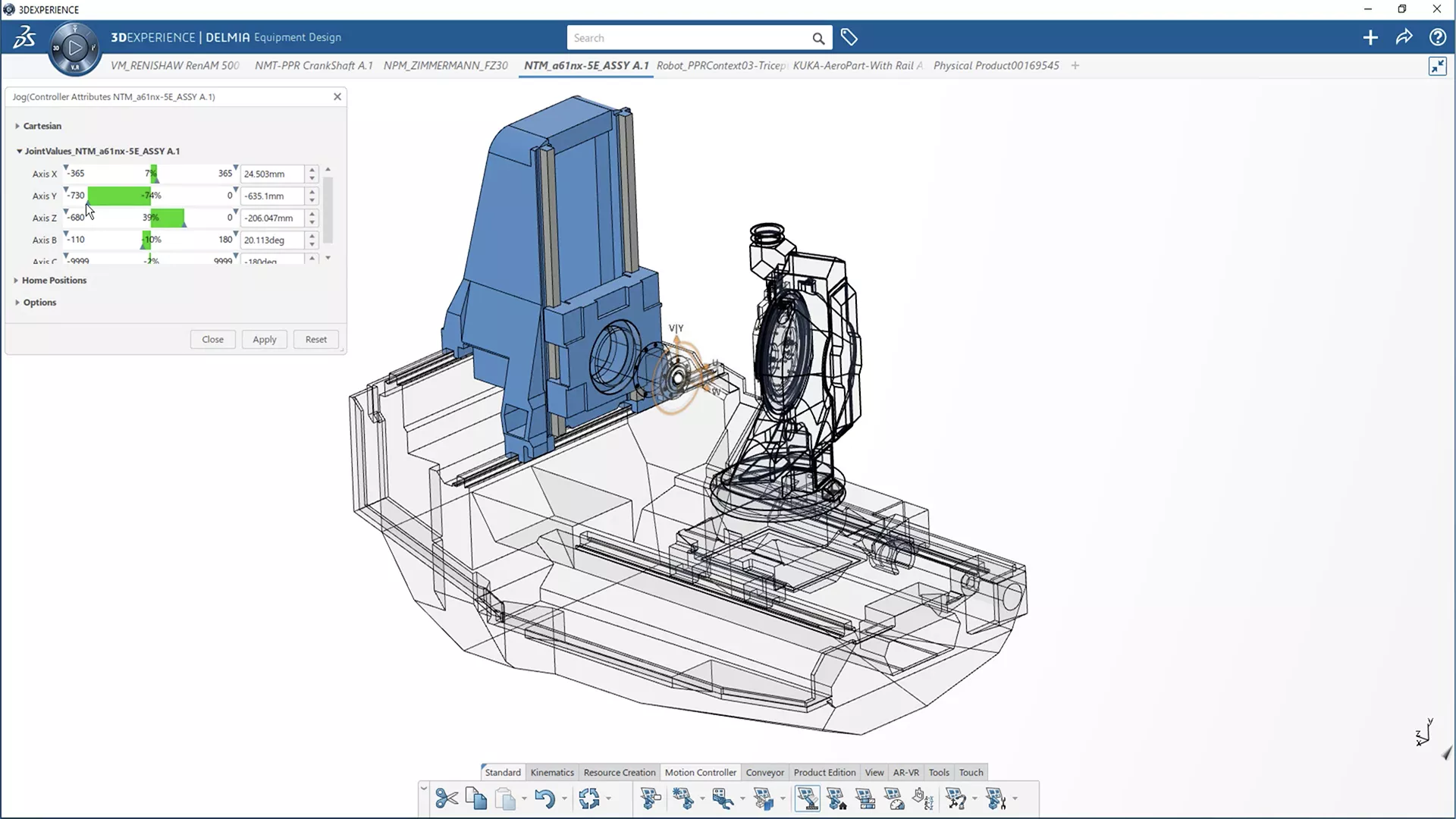

Shop Floor Equipment Engineer

- Using existing CAD geometry, quickly and intuitively build simulation models of the shop floor equipment in your virtual factory. Configure kinematics and key characteristics for use in factory layout, programming, and simulation.

- Key Features:

- Design and manage product structure

- Create and validate kinematic models of manufacturing devices including NC machines, clamps, tools, conveyors, and complex robots

- Define motion constraints and leverage inverse kinematics

- Define motion controllers and manage motion groups

- Customize controller attributes through profiles

- Define the work envelope for robot devices - Typically used by:

- Machine programmer

- Manufacturing engineer/manager

- Production manager

- Engineering manager

- Plant layout & equipment designer

- Process planner

- Industrial engineer -

-

Virtual Commissioning Analyst

- Validate your equipment and sensors' PLC programs offline in your virtual factory environment, so that the real commission goes right the first time.

- Key Features:

- Create sensors, generate and transform parts for multicycle scenarios

- Simulate mechanical, electrical, and control systems to validate workcell behavior for function and safety

- 3D sensor modeling capabilities in the realistic virtual factory allow input and output for PLC-simulation interaction

- Supports Open Platform Communication (OPC) to control simulations with PLC ladder logic

- Supports Functional Mock-up Interface (FMI) - Typically used by:

- Machine programmer

- Manufacturing engineer/manager

- Production manager

- Engineering manager -

-

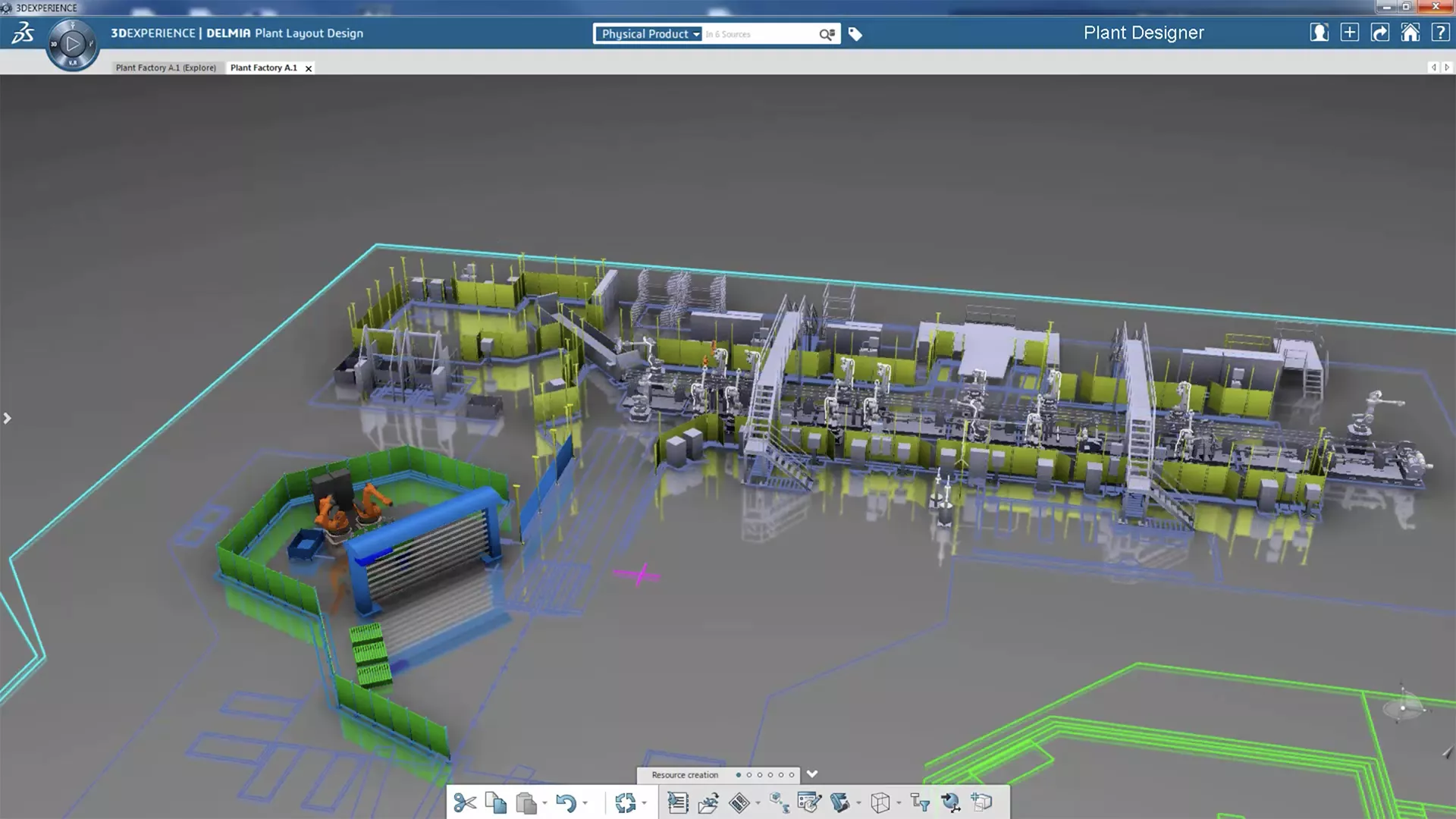

Plant Layout Designer

- Build new and existing 3D shop floor layouts for your virtual factory, enabling layout validation and optimization on the digital twin.

- Key Features:

- Import 2D factory layout drawings

- Import 3D point cloud data of an existing facility (on-premise only)

- Pick and place ready-to-use parametric and non-parametric resources from the catalog

- Manipulate resources in the 3D space with ease

- Categorize resources and define hierarchy - Typically used by:

- Plant layout & equipment designer

- Manufacturing engineer

- Process planner

- Industrial engineer -

-

Machine & Tooling Designer

- Design your shop floor equipment and build simulation models for their virtual factory counterparts. Configure kinematics and key characteristics for use in factory layout, programming, and simulation.

- Key Features:

- Design shop floor equipment from scratch (or modify existing design data) using CATIA 3D CAD tools

- Design and manage product structure

- Create and validate kinematic models of manufacturing devices including NC machines, clamps, tools, conveyors, and complex robots

- Define motion constraints and leverage inverse kinematics

- Define motion controllers and manage motion groups

- Customize controller attributes through profiles

- Define the work envelope for robot devices - Typically used by:

- Machine programmer

- Manufacturing engineer/manager

- Production manager

- Engineering manager

- Plant layout & equipment designer

- Process planner

- Industrial engineer -

-

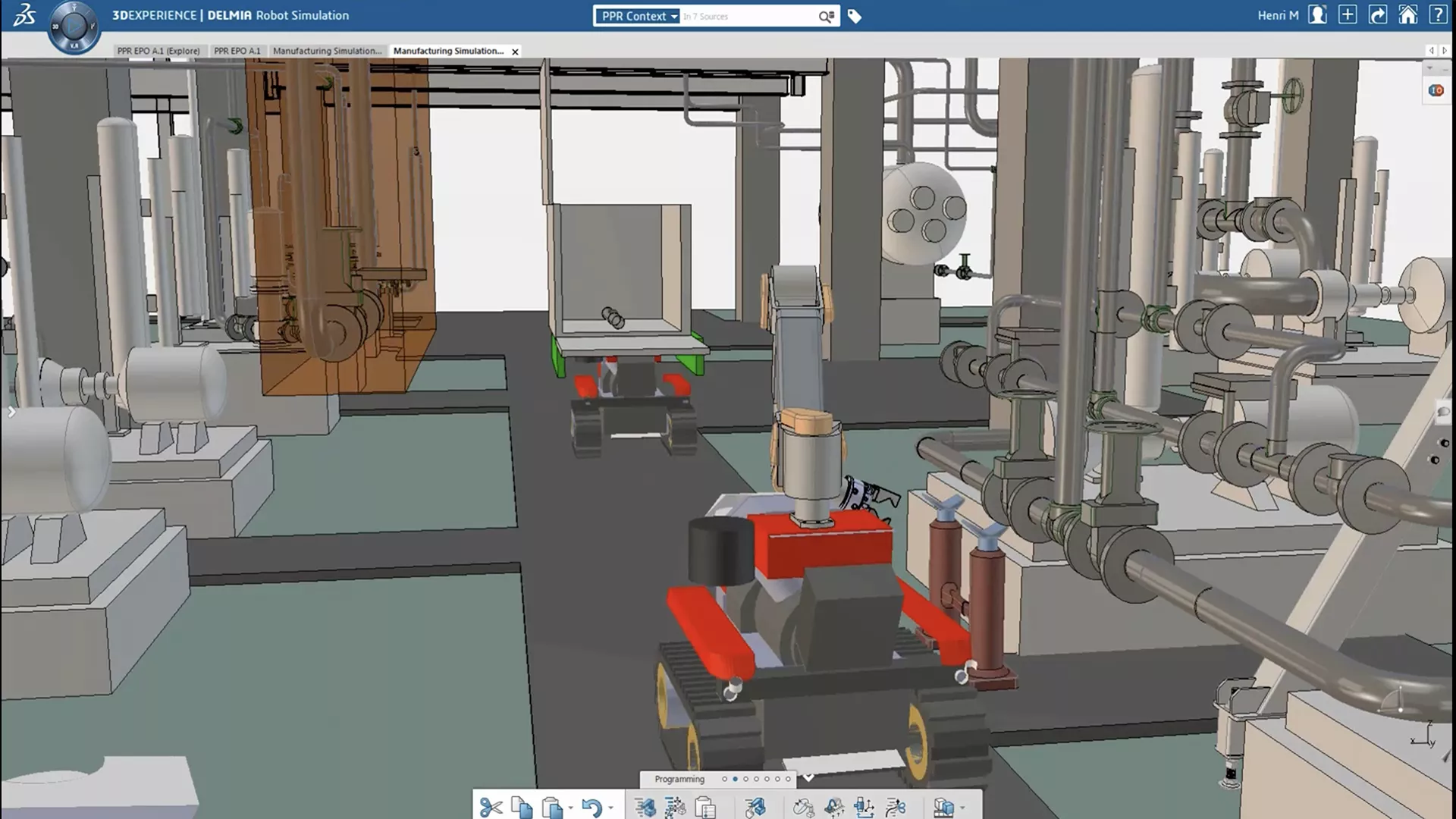

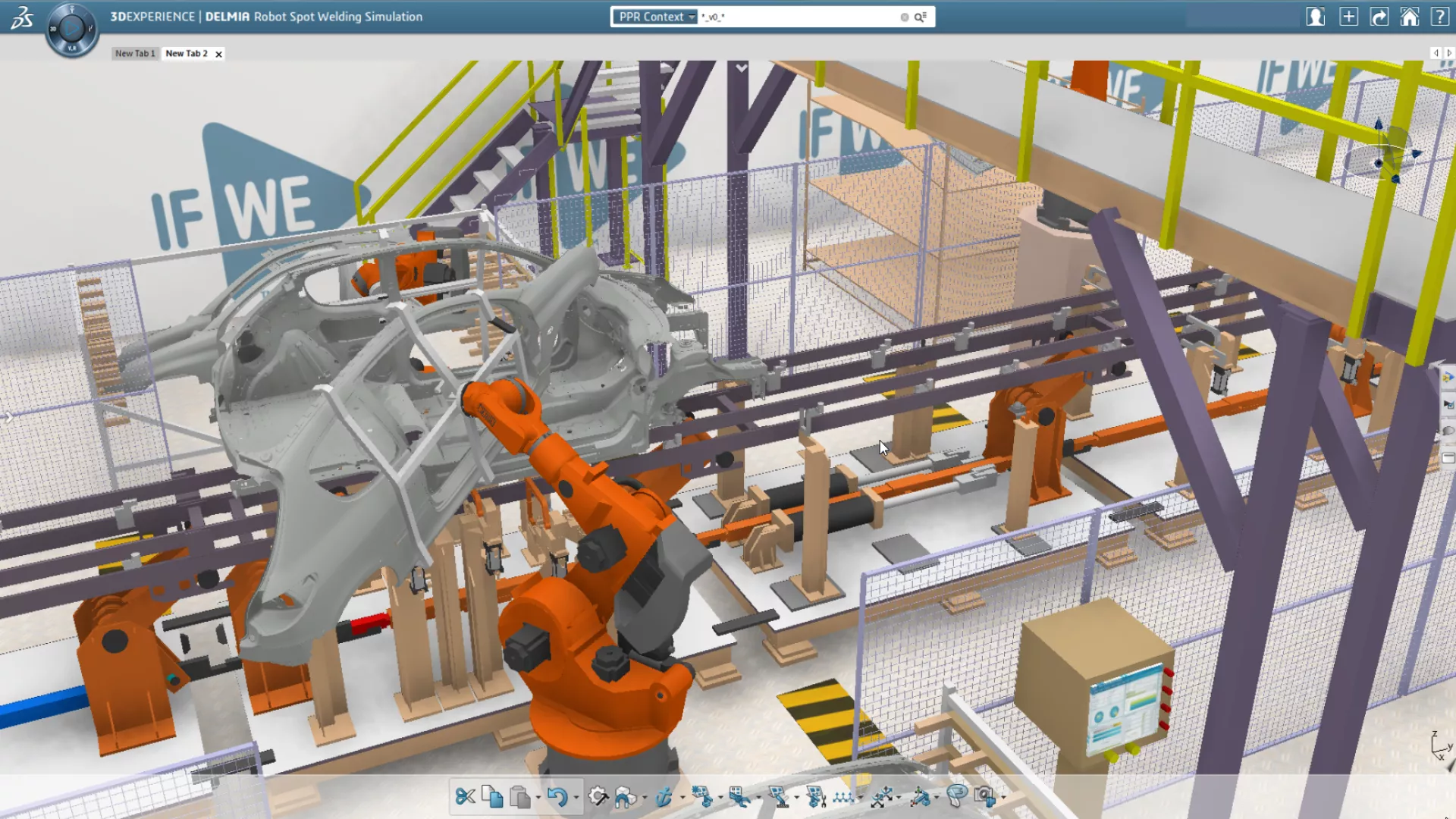

Robotic Workcell Simulation Engineer

- Design and validate complete robotic handle systems to ensure workcell feasibility before procuring expensive equipment.

- Key Features:

- Complete workcell validation

- Advanced logic and I/O support in the simulation

- Realistic Robot Simulation (RRS-I) for increased simulation accuracy

- Create, validate, and reuse mechanisms with automated support

- Calculate interference zones

- Fast and easy robot placement

- Robot simulation "on-the-go" (offline mode)

- Create 3D parts or assemblies - Typically used by:

- Engineering manager

- Production manager

- Manufacturing engineer/manager

- Machine programmer -

Learning 3DEXPERIENCE Cloud PDM: Goengineer is here to help

More Connected Manufacturing Solutions

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services