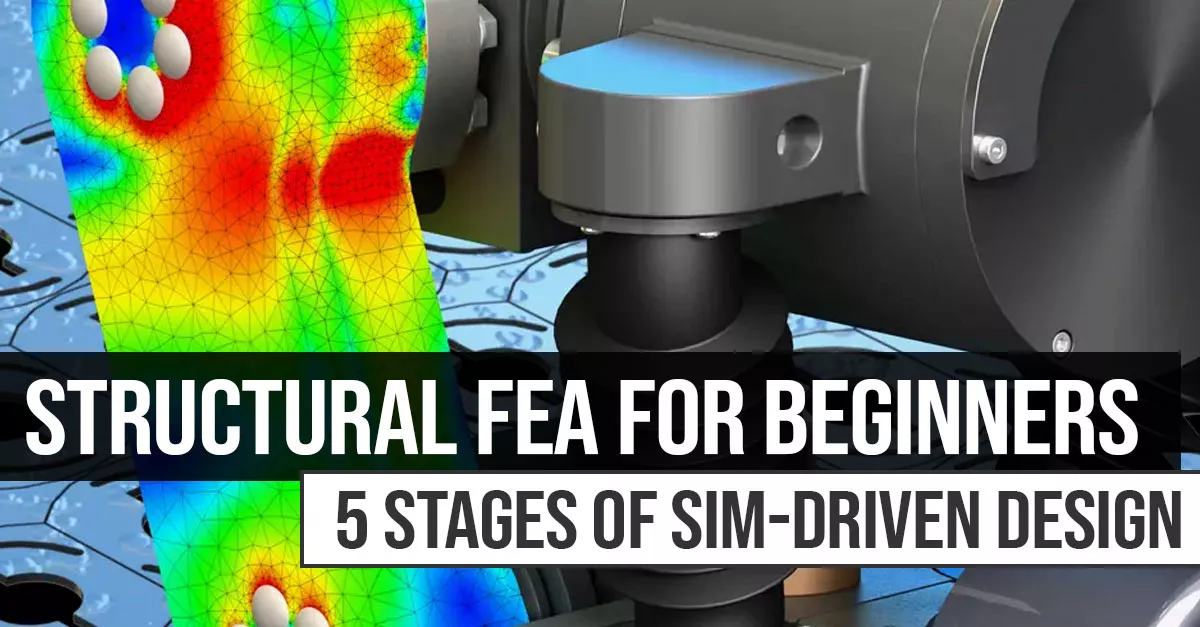

1. Try FEA For Free

Did you know your SOLIDWORKS includes free component-level stress analysis? It's in the SimulationXpress tool, an accessible, scaled-back introduction to simulation for designers.

It's an easy & low-stakes way to:

- Learn SOLIDWORKS FEA fundamentals

- Get rough stress validation on your principal component loads

2. Start Low-Cost, High-Impact

Assembly-level stress and kinematic simulations are the “low-hanging fruit”, providing great engineering value with minimal investment of time and money.

With only basic FEA know-how, you can:

- Ensure fundamental design objectives

- Reduce iteration cycles

- Make design decisions with confidence

Start getting stress & motion insights with:

3. Add Real-World Context

With just a bit more training and budget, designers can virtualize their drop test, buckling, frequency, pressure-vessel, and thermal analyses.

This “virtual testing” regime assesses more real-world concerns to:

- Uncover innovative new approaches

- Eliminate costly “overdesign”

- Predict field failures

Expand your virtual testing regime using:

![]() SOLIDWORKS Simulation

SOLIDWORKS Simulation

Professional

![]() 3DEXPERIENCE

3DEXPERIENCE

Structural Designer

4. Get Sophisticated

As physical tests get more difficult and costly, virtualizing them can have outsized ROI. Simulation capabilities such as material nonlinearity, assembly interactions, linear dynamics, fluids, and thermal analysis make it possible.

This higher level of fidelity and complexity allows you to:

- Push innovation & quality further

- Validate manufacturability

- Reduce physical prototyping

Begin substituting simulation for prototyping with:

![]() SOLIDWORKS Simulation

SOLIDWORKS Simulation

Premium

![]() 3DEXPERIENCE

3DEXPERIENCE

Structural Engineer

5. Simulate Anything

At the final stage of simulation, anything is possible -- all-inclusive assemblies & interactions, minimal assumptions, multiphysics, etc. With keen engineering judgment and creativity, a complete virtual prototype can be enormously beneficial to development costs and outcomes.

Virtual prototyping is critical in order to:

- Compete at the cutting edge

- Maximize quality & efficiency

- Replace physical testing & certification

Graduate to unlimited, open-ended FEA using:

![]() 3DEXPERIENCE Structural

3DEXPERIENCE Structural

Performance Engineer

![]() 3DEXPERIENCE Structural

3DEXPERIENCE Structural

Mechanics Engineer

Simulation Is Important. This Is How You Do It.

It’s common knowledge that simulation helps us design faster, better, and at lower cost… but knowing and doing are two different things.

With our 20+ years experience implementing simulation at companies of all sizes, this is how we help companies ensure success and ROI at every stage, from simulation novice to analytical expert.

Why Do We Simulate?

They don’t make them like they used to – product innovation is more challenging than ever.

This eBook shows you how top performers are using simulation today, along with several success stories for you to learn from.

Why Do We Simulate?

They don’t make them like they used to – product innovation is more challenging than ever.

This eBook shows you how top performers are using simulation today, along with several success stories for you to learn from.

Getting Started Is Easy.

How do you smoothly go from sim novice to sim expert? The GoEngineer Sim Team has made it happen time and again at all kinds of companies. Here’s the process we recommend, in detail.

![]()

carousel area (will consist of text and image subcolumns)

![]()

“Using SOLIDWORKS Simulation tools helped us save a ton of time and money during product development.”

-David Gardner, COO, RoboHelix

These Sim Tools Make Immediate Impact.

-

-

SOLIDWORKS Simulation

-

The flagship structural FEA tool for SOLIDWORKS users is built directly into the CAD interface.

Its three tiers provide a huge array of simulation capabilities for beginning to expert users.

-

-

3DEXPERIENCE STRUCTURAL

-

From the makers of SOLIDWORKS & Abaqus, the introductory tiers of 3DEXPERIENCE STRUCTURAL are the very best in fast, robust, CAD-connected linear FEA.

-

-

SOLIDWORKS Flow SIMULATION

-

Powerful CFD built directly into the SOLIDWORKS CAD interface, Flow Sim provides invaluable performance prediction and optimization.

-

-

SOLIDWORKS Plastics

-

GoEngineer's Jeff Lendermon has 30 years' experience in the plastic injection molding industry. In this interview, he shares his insights on the benefits of this manufacturing process simulation.

Ready to Learn More?

Reach out to GoEngineer today to ask questions or see for yourself what you can do with SOLIDWORKS simulation solutions.