Eureka Robot

REAL-TIME SIMULATION WITH MILLIONS OF MOVEMENTS

REAL-TIME SIMULATION WITH MILLIONS OF MOVEMENTS

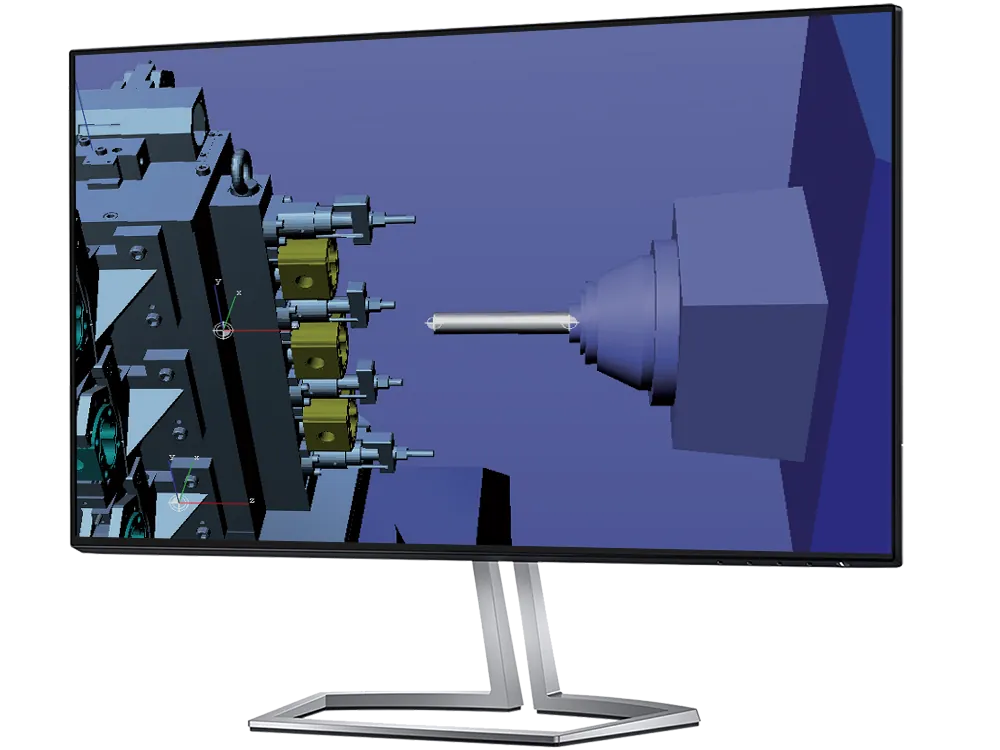

Eureka has been leading the robot milling applications arena for many years.

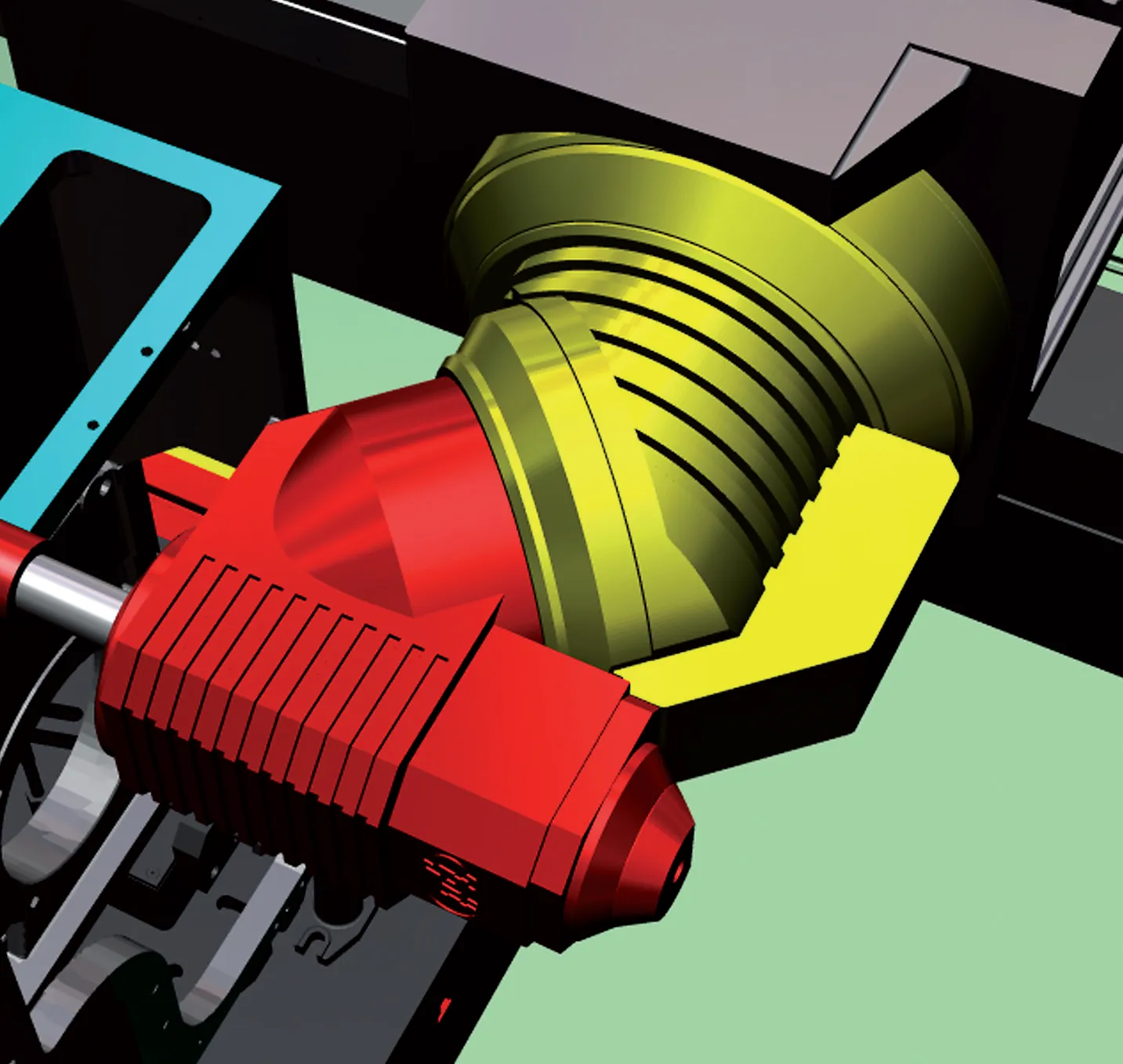

Eureka makes it possible to create models and artistic objects combining the flexibility of a 6 axes industrial robot with the reliable technology of a CNC machining center .

Eureka converts APT code generated by a CAM system into a program for a 6 or more axes robot cell using a dedicated postprocessing module. During the conversion process Eureka calculates the optimal movements of the robots and of the external axes simulating all

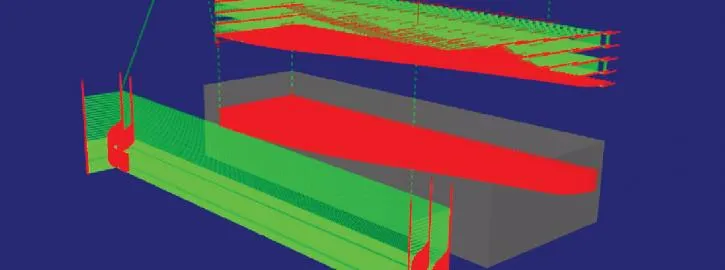

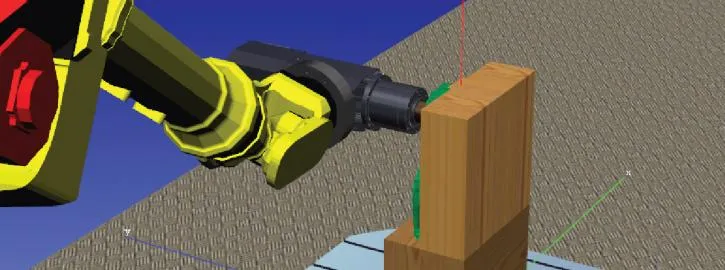

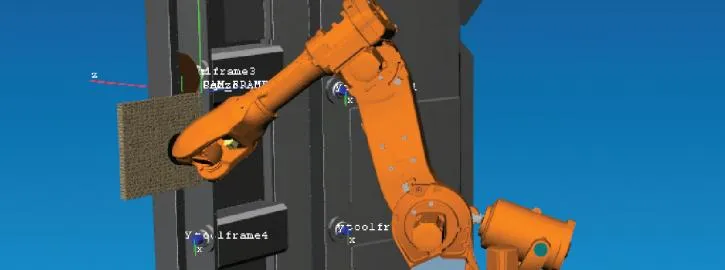

Reduce Collisions By Detecting Problems Fast

The software detects problems like singularities, collisions, out of limits and it offers powerful, easy to use tools to overcome them. Collisions are computed taking into account all the parts including the machined stock. The 64 bit version allows very fast processing of files of unlimited size.

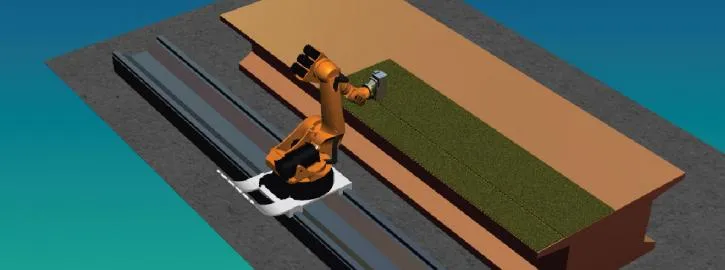

- Realistic 3D simulation of the whole workcell;

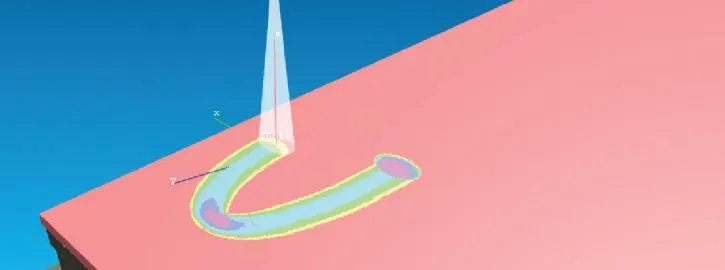

- Real time material removal simulation;

- Collisions, singularities and out of limits detection;

- Automatic tool change management;

- Handling of huge tool paths with millions of points;

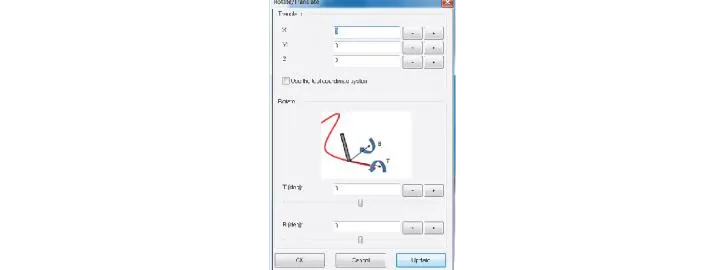

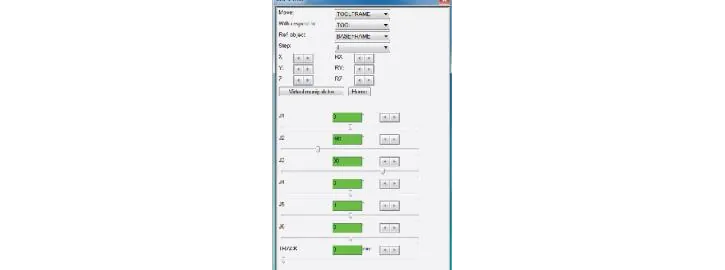

- Interactive editing of trajectories;

- Automatic robot and external axes movements optimization;

- Powerful visual tools for fixing collisions, singularities and out of limits;

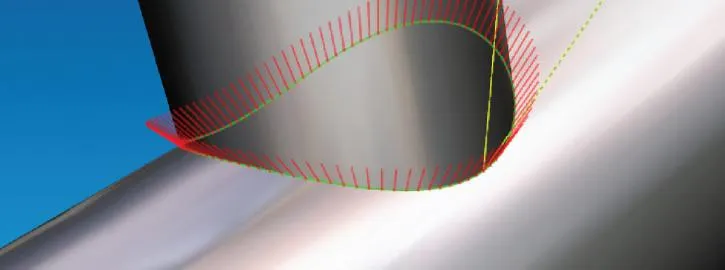

- Machining with disks and blades;

- Machining with the workpiece mounted on the robot and fixed tools;

- Designed for all the industrial robots in the market: ABB, Kuka, Fanuc, Motoman, Kawasaki, Staubli, Comau;

- Can be interfaced with the most popular CAD/CAM and tools management systems: ALPHACAM, VISI, RTM, EDGECAM, GO2CAM, CAMWORKS, CREO, MASTERCAM, CIMATRON, GIBBSCAM, DELCAM, WORKNC, TEBIS, ZW3D, WINTOOL, ZOLLER TMS.

Eureka ROBOTS Features

Deposited Material Preview

The spraying paths can be simulated and calibrated getting back an accurate estimate of the deposited material thickness.

Blade Cutting

Eureka can manage all the degrees of freedom to keep the blade correctly oriented.

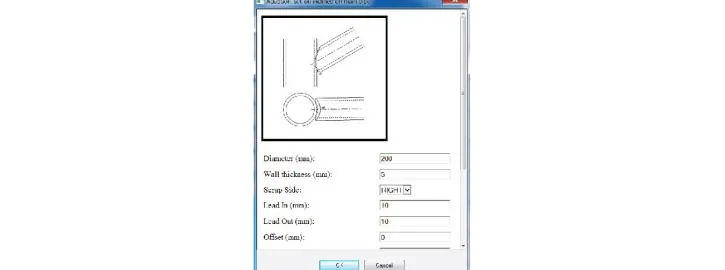

Toolpath Editing DD

The toolpath can be edited directly in Eureka. Filters and interpolate directions can be easily applied.

Custom Macros

Eureka allows you to use custom command macros for fast and easy programming.

3D Digitizers

If you don’t have a digital model, a 3D digitizer allows you to obtain the tool path directly from the real part.

Toolpath Capture

Eureka allows to manually select the tool path.

CAD/CAM Programming

Use your own 3D CAM system model to create and customize the tool paths as you wish.

Any Configuration is Supported

Automatic tool change, multiple spindles, shared motors or fixed tools and part on the robot are supported.

Process any CAM Toolpath

Use your favorite CAM system. No limits on program size. Millions of points are well supported using 64 bit technology.

Fix and Optimize

Detect singularities, out of limits and any kind of collisions, then fix them in Eureka using powerful yet easy to use tools.

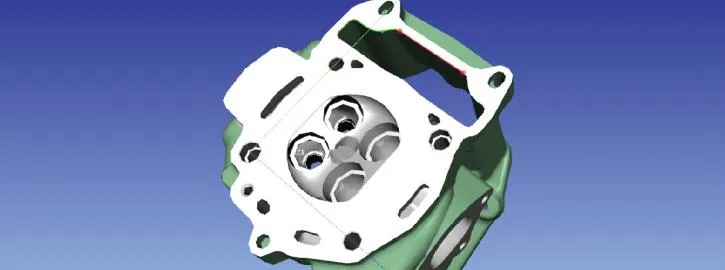

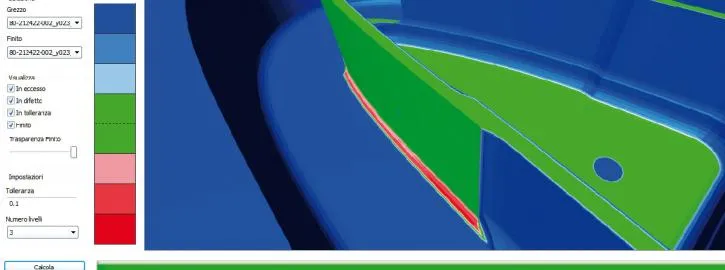

Analyze and Compare Results

Monitor axes and speed, estimate the machining time, compare the machined stock with the theoretical model, save your machined stock.

External Axes Optimization

Extended workspace using external axes. Eureka automatically optimizes the axes position.

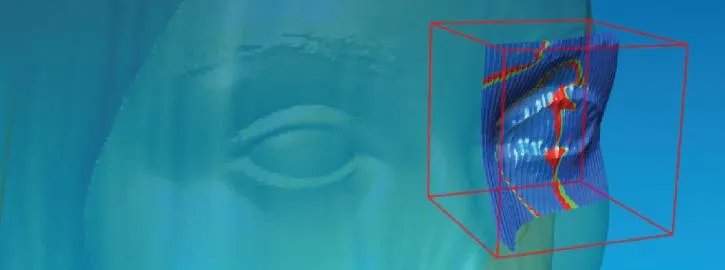

Collision Detection Material Removal

The realtime material removal simulation enables a full collision detection with the machined stock.

Result Analysis

Analyzes and compares the digital model with the machined stock, highlighting areas below or over tolerance.

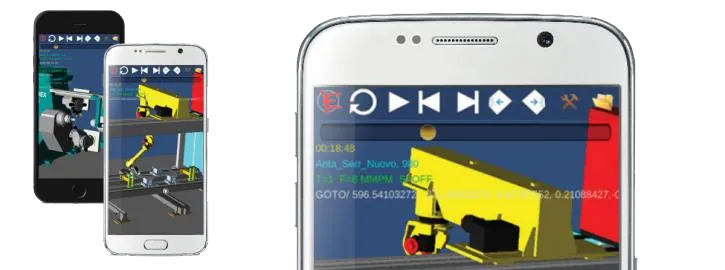

Eureka Mobile

Thanks to EurekaMobile any simulation made by Eureka Virtual Machining can be reviewed and analyzed anywhere on any mobile device.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services