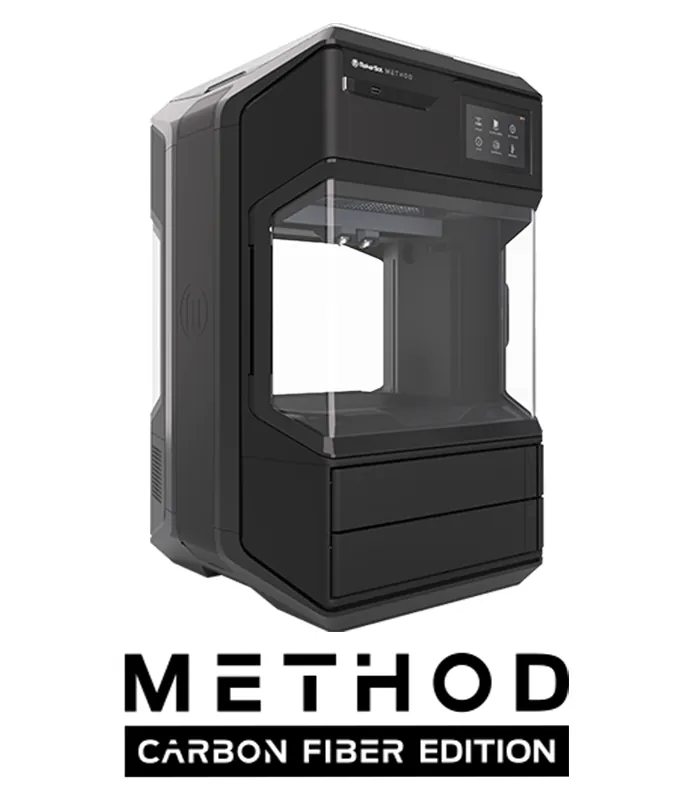

MAKERBOT METHOD

The Next-Generation Desktop 3D printer

Now Serving US & Canada

Now Serving US & Canada

Industrial Quality 3D PRINTING for all

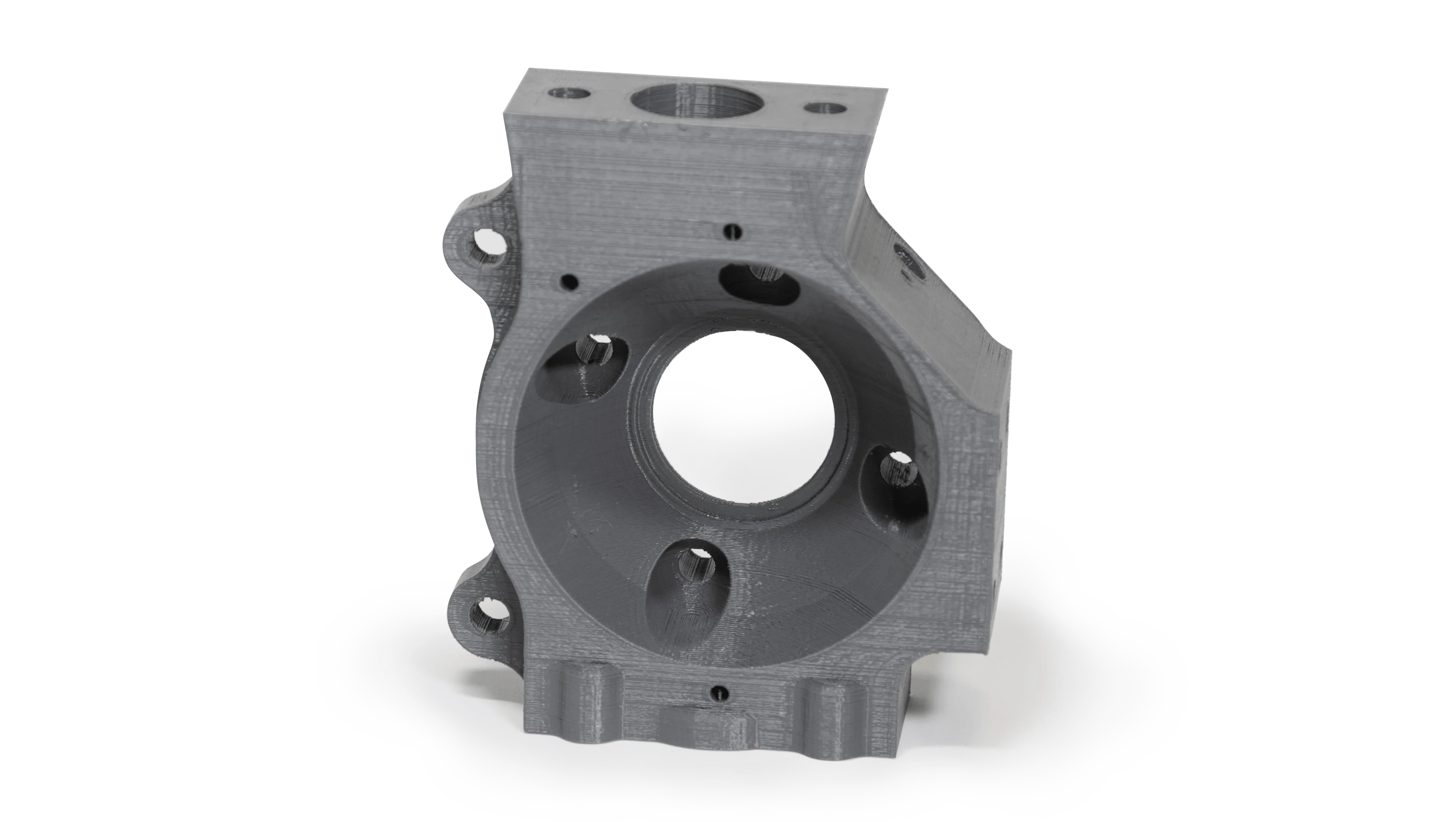

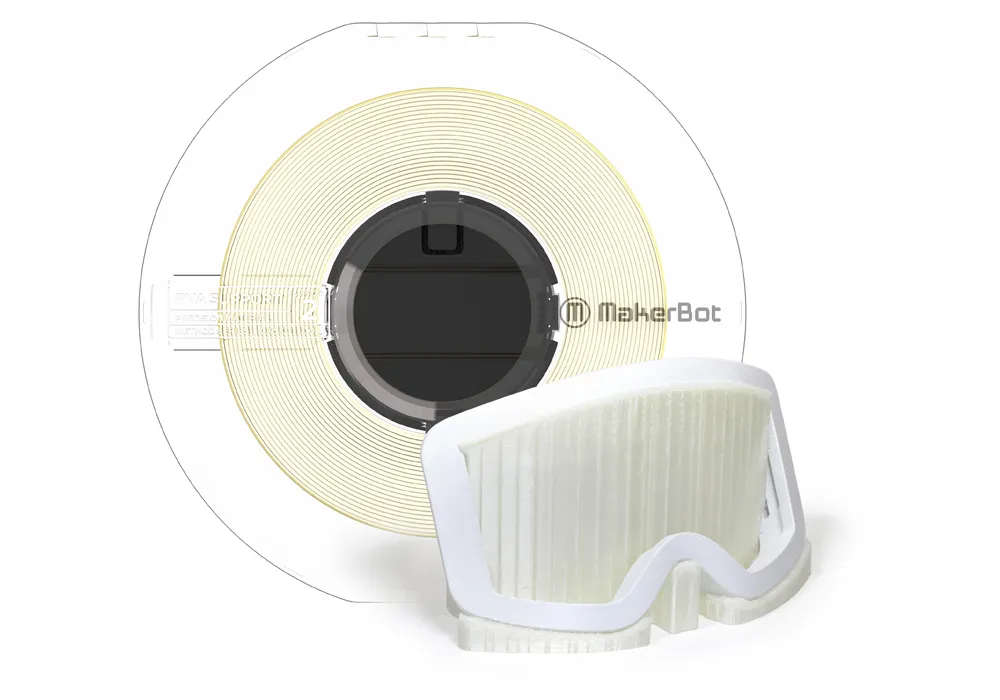

The MakerBot METHOD series is an affordable personal 3D printer that delivers manufacturing grade parts and an open platform for advanced engineering materials. Designed for accuracy and speed, the METHOD features a robust metal frame, heated build chamber, and moisture controlled material storage.

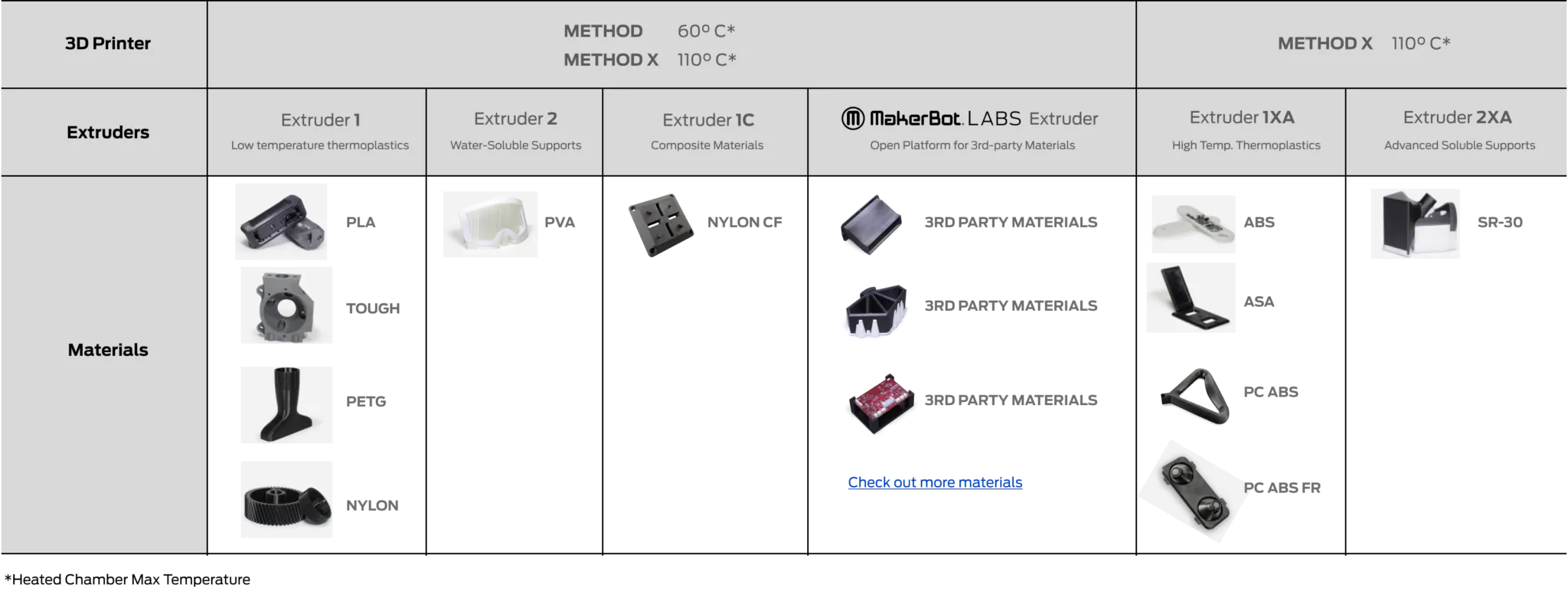

What's Your METHOD?

The MakerBot METHOD comes in two variations: The METHOD, which has an active build chamber that can heat up to 60C, and the METHOD X which heats up to 110C. The result is that you can use a wider variety of materials in the METHOD X. Carbon Fiber Edition printers include the 1C extruder necessary for Carbon Fiber printing.

METHOD 3D PRINTERS

Features

BUILD SPEED

The MakerBot METHOD achieves a buildtime around two times faster than other desktop 3D printers by providing a steady feed of material into extruders to produce 1± 0.2 mm or ± 0.002 mm per mm of travel.

Desktop

Progress: 57%

METHOD

Progress: Done

Reliable Accuracy

Print consistent parts with ± 0.2 mm dimensional accuracy, a level of precision once only possible on industrial 3D printers. The rigid metal frame of the MakerBot METHOD eliminates flexing and instability to ensure accurate prints at high speeds.

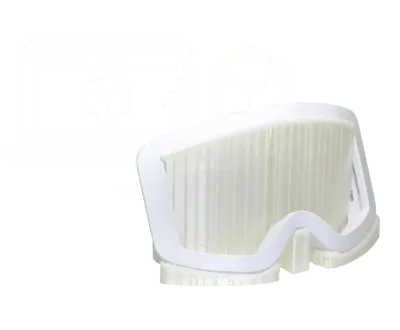

Heated Chamber

The METHOD's fully heated enclosure evenly heats the air inside your build chamber up to 110C. This enables superior layer adhesion, eliminates warping and results in extremely accurate parts. This approach is a vast improvement over machines with heated build plates which fail to provide even heat distribution.

open source materials

Native File compatibility with MakerBot Print

Access to Stratasys grade materials

MakerBot Materials

Available with: METHOD

PLA

Polylactic acid

– Low-cost material option for fast-draft part iterations

– Low melt temperature = fast print speeds

– Available in multiple colors and translucent blends

– Breakaway support material only

Potential applications:

– Low-cost iterations

– Conceptual prototypes

Available with: METHOD

ASA

Acrylonitrile styrene acrylate

– New Standard material for all-purpose prototyping

– UV-stabilized for outdoor production parts

– Superior aesthetics and 10 color options

– All-around average mechanical performance

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

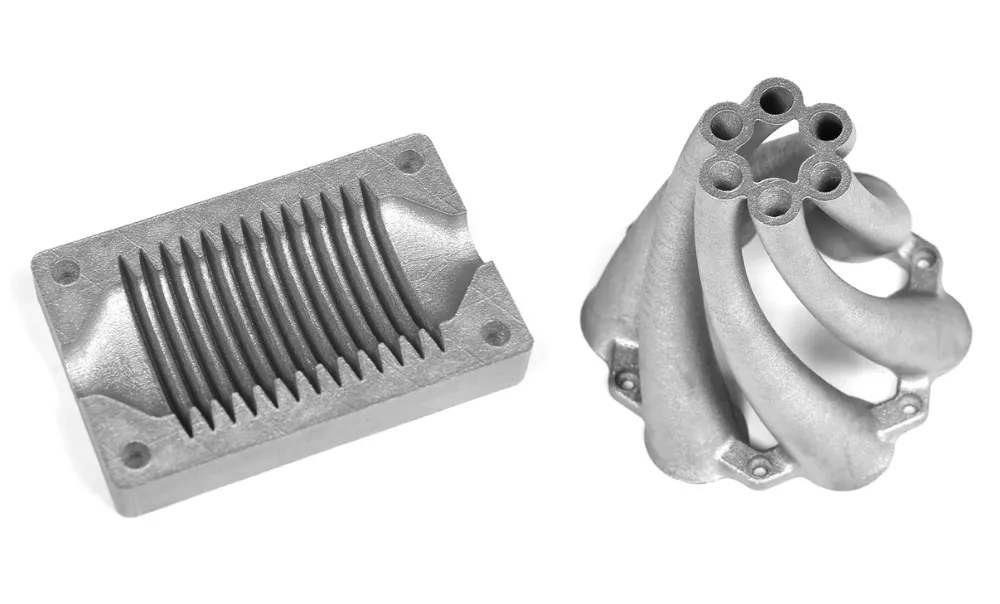

Stainless Steel

Ultrafuse 316L

A metal-polymer composite filament to create metal parts in a stainless steel type 316L using a standard printer and finishing with an industry standard debinding and sintering process.

Potential applications:

– Tooling

– Functional prototypes

– Jigs and fixtures

– Production parts

TOUGH

– 2X the impact strength of ABS for extremely durable prototypes

– Ideal for working prototypes and manufacturing aids

– Less warping and curling than ABS

Potential applications:

– Conceptual models

– Functional prototypes

– End-use parts

– Production parts

PETG

Poly ethylene terephthalate glycol

– Excellent mechanical properties, including high durability and toughness: 8.1 kJ/m² Impact Strength (ISO 179)

– Heat Resistant: 70C Heat Deflection Temperature (ASTM 648)

– Moisture Resistance: 1104 ppm moisture absorption (ISO 62)

Potential applications:

– End-use parts

– Functional prototypes

– Jigs & fixtures

Available with: METHOD

PC-ABS FR

Flame Retardant Polycarbonate + Acrylonitrile Butadiene styrene

– PC-ABS FR is a flame retardant version of PC-ABS.

– Blended material that shares properties with ABS and PC

– High impact strength

– Good toughness, durability, and heat resistance

Potential applications:

– Flame retardance meets production vehicle requirements

– Functional prototypes

– Manufacturing tools

– Production parts

Available with: METHOD

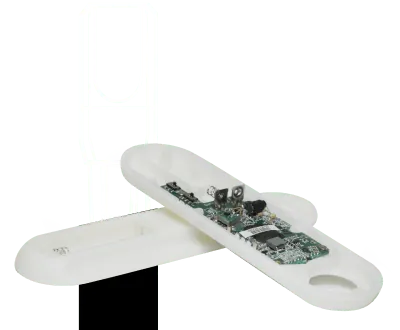

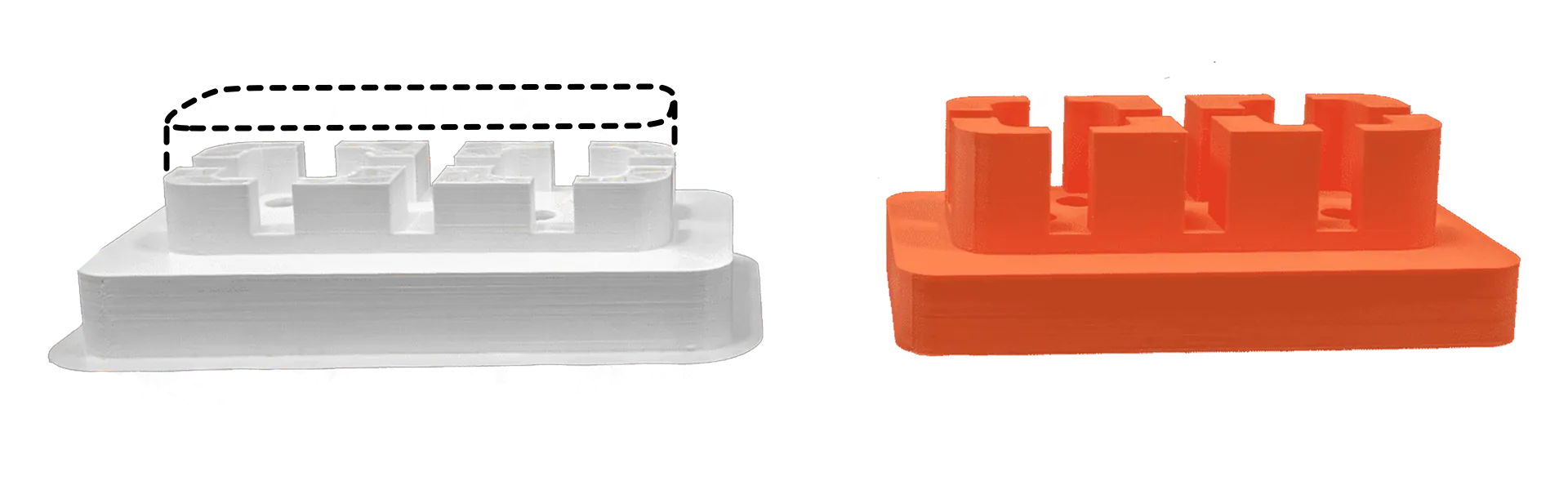

PVA

Polyvinyl Alcohol

– Water soluble support material for complex parts

– C ompatible with many lower temperature model materials such as PLA and PETG.

– Disolves in water for office friendly support removal

– G reat for printing complex geometries in a prototyping environment

Material Compatibility:

– PLA

– Nylon

– Tough

– PETG

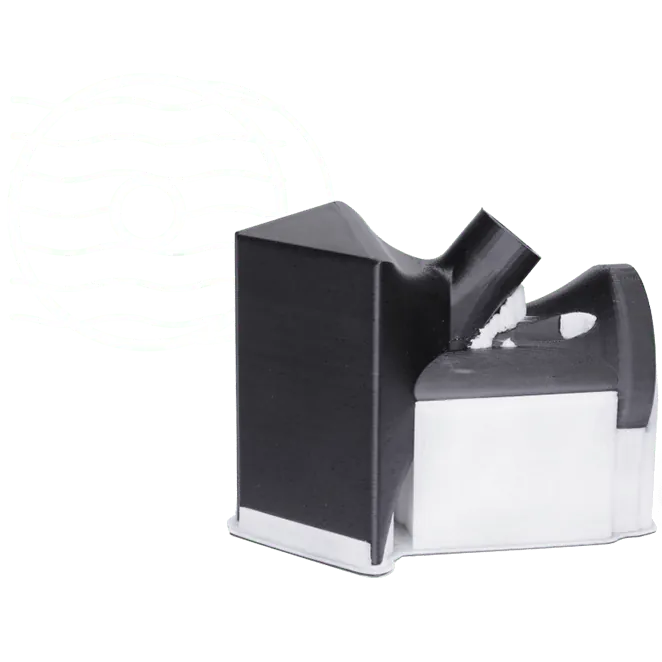

Nylon Carbon Fiber

– Carbon fiber reinforced Nylon

– Optimized for high strength to weight ratio, stiffness, and heat resistance

– Ideal for structural applications and metal replacements

Nylon (6/66) Carbon Fiber has the greater performance in all categories, but is significantly affected by moisture which reduces strength and modulus.

Nylon 12 Carbon Fiber is less affected by moisture and will retain more of its performance in moist environments.

Potential applications:

– Structural supports

– Metal Replacements

– Automotive brackets

– Inspection gauges

– Tooling

NYLON

– High abrasion and temperature resistance

– Superior surface finish and aesthetic appearance

– Great material for functional prototypes and end use parts

Potential applications:

– Manufacturing Tools & fixtures

– Snap fits, hinges, articulated parts

– Gears, Pulleys

– Air intakes, Gaskets, Manifolds

METHOD Specifications

PRINT TECHNOLOGY

- Fused Deposition Modeling (FDM)

- 2 Print Heads

- ± 0.2 mm Dimensional Accuracy

BUILD VOLUME

- Single Extrusion: 7.5 x 7.5 x 7.75 in

- Dual Extrusion: 6.0 x 7.5 x 7.75 in

System Size and Weight

- 17.2 x 16.3 x 25.6 in, 65 lbs

SENSOR SUITE

- 21 sensors throughout the printer monitor temperature, humidity, materials, calibration, and more.

OPERATION

- Ambient Operating Temperature: 15 - 26º C / 59 - 78º F, 10 - 70% RH non-condensing

- Storage Temperature: 0 - 38º C / 32 - 100º F

- Printer Automation: Automatic Z Calibration, Automatic Nozzle Calibration, Automatic Material Loading

SAFETY AND COMPLIANCE

- FCC, EMC, Low Voltage Directive 60950-1, 62368

ELECTRICAL

- 100–230 VAC, 50–60 Hz, Single phase, 1000W

Software

- Software Bundle: MakerBot Print, MakerBot Mobile

- Supported File Types: MakerBot (.makerbot), STL (.stl), SolidWorks (.sldprt, .sldasm), InventorOBJ (.ipt, .iam), IGES (.iges, .igs), STEP AP203/214 (.step, .stp), CATIA (.CATPart, .CATProduct), Wavefront Object (.obj), Unigraphics/NX (.prt), Solid Edge (.par, .asm), ProE/Creo (.prt, .asm), VRML (.wrl), Parasolid (.x_t, .x_b)

- Operating Systems: Windows (7, 10), Mac OS X (10.9+)

Software

GrabCAD Voxel

Unleash the power of the voxel. In combination with PolyJet Studio and GrabCAD Print, now experience GrabCAD Voxel Print for limitless color and material capabilities at the voxel level.

- PolyJet Studio’s intuitive interface makes it easy to choose materials and optimize the build and print queues.

- GrabCAD Print software makes 3D printing on Stratasys 3D Printers easy, accessible, and connected. The software’s efficient workflow streamlines job management in shared office and model shop environments.

- GrabCAD Voxel Print delivers unprecedented user control over color and material placement.

ADDITIONAL 3D PRINTERS

POLYJET

3D print realistic prototypes and models with full-color elements, labels, and true-to-life textures in one operation . PolyJet 3D PrintersMETAL

3D print functional metal parts and prototypes for industrial, commercial, and private applications. Metal 3D PrintersSAF

Selective Absorption Fusion™ SAF™ technology that delivers functional, production grade parts with optimum consistency. Production SAF 3D PrintersP3

Programmable PhotoPolymerization P3™ technology delivers industry leading accuracy, consistency, and details. Production P3 3D Printers

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services