Promotion ends on Dec 31st, 2024

*Additional terms and restrictions may apply. Reach out for the full details.

The SOLIDWORKS ecosystem is a one-stop-shop for all things engineering simulation. Whether you’re a new designer or a career analyst; whether you’re working with manufactured structures, PCBs, or even biomechanics; there’s a CAD-connected simulation solution for you.

Structural Solutions for

Every

User

Structural Solutions for

Every

User

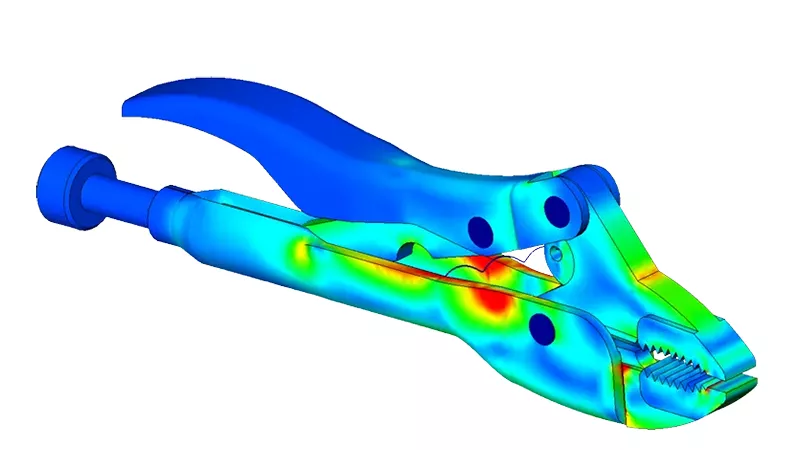

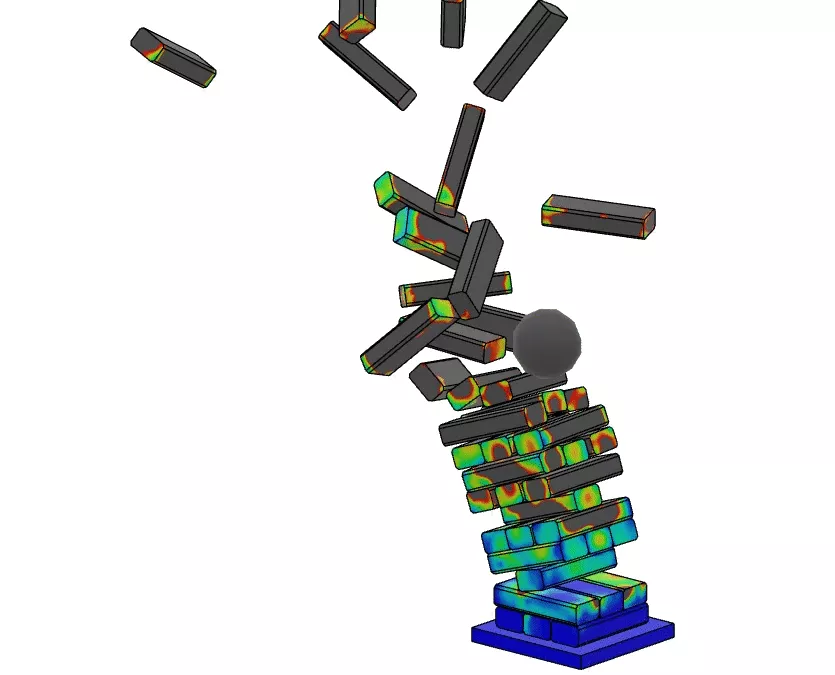

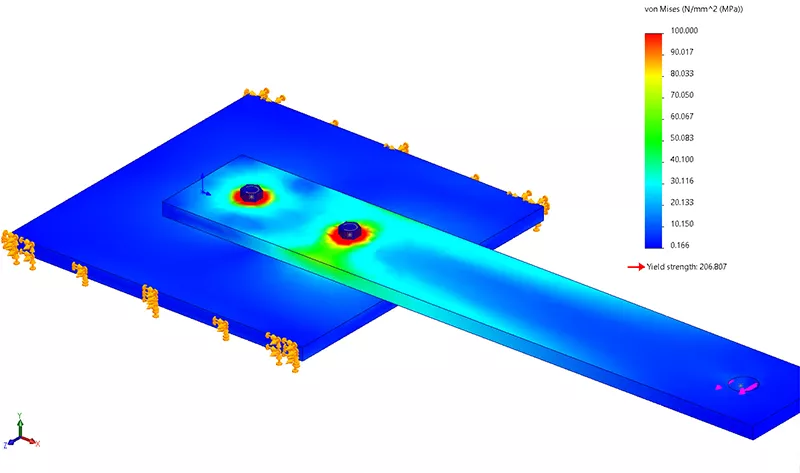

Structural analysis is the most popular type of simulation amongst SOLIDWORKS designers. Between the very familiar SOLIDWORKS Simulation solutions and 3DEXPERIENCE STRUCTURAL solutions that scale to the very top, there is something for every stage of FEA-driven design.

Here is our visual guide to the CAD-connected FEA solutions available to you, from bottom to top:

The SOLIDWORKS and 3D EXPERIENCE brands both offer linear static FEA solutions at competitive prices, but there are several differences between them.

We’ll give you the information you need to decide which is better for your situation.

blog thumbnail

![]()

carousel area (will consist of text and image subcolumns)

![]()

Execute various levels of static analysis, all the way from hand calc up to nonlinear FEA.

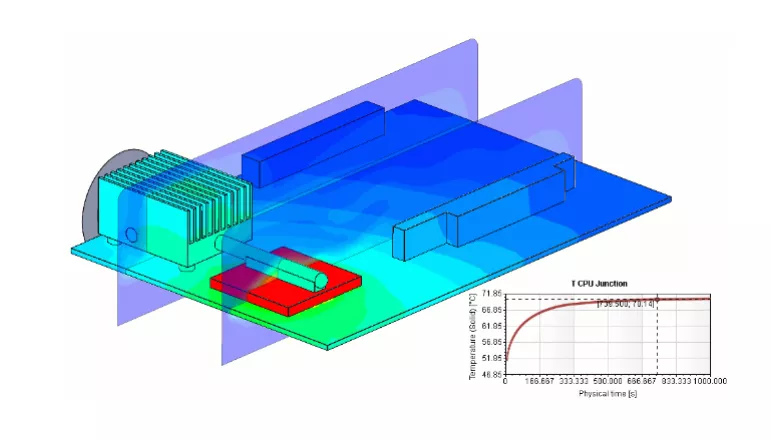

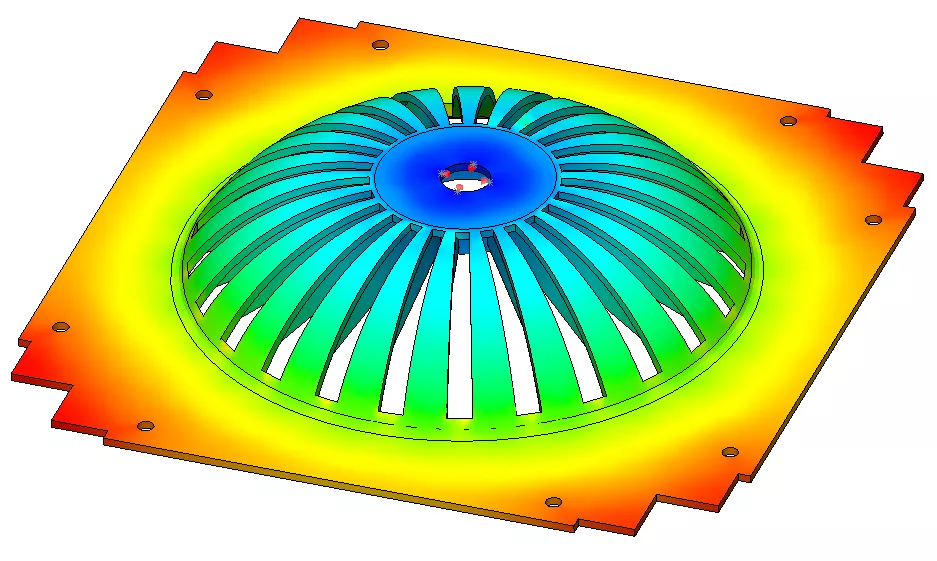

Explore thermal analysis methods from hand calc to coupled FEA+CFD, using SOLIDWORKS Simulation & Flow Simulation.

Compare buckling analyses from basic hand calcs to SOLIDWORKS Simulation to advanced Abaqus-powered FEA.

Compare vibration analyses from hand calc to frequency to linear and nonlinear dynamics.

Explore shock and impact analysis from hand calc to various techniques in SOLIDWORKS Simulation.

Attack the challenges of bolt fasteners, starting with hand calc and moving into step-by-step FEA tasks.

video thumb

The 3D EXPERIENCE STRUCTURAL portfolio -- powered by Abaqus and cloud compute -- gives SOLIDWORKS users unprecedented access to high-end FEA software AND hardware. At its higher product tiers, companies enjoy the benefits of end-product physical testing during early design phases. This can save huge sums of money while making innovation easier and faster.

GoEngineer’s simulation team is here to help you on your simulation journey. Contact us today to compare solutions, schedule a demo, start a trial, or get pricing.

“Simulation can take the place of physical prototyping on jobs for which the customer wants proof of product performance.”

-David Daou, Simulation Engineer, Wilson Case

Best-in-Class

CFD In Your CAD UI

Best-in-Class

CFD In Your CAD UI

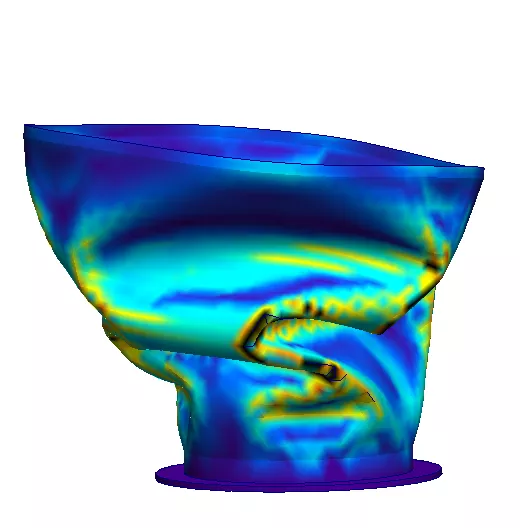

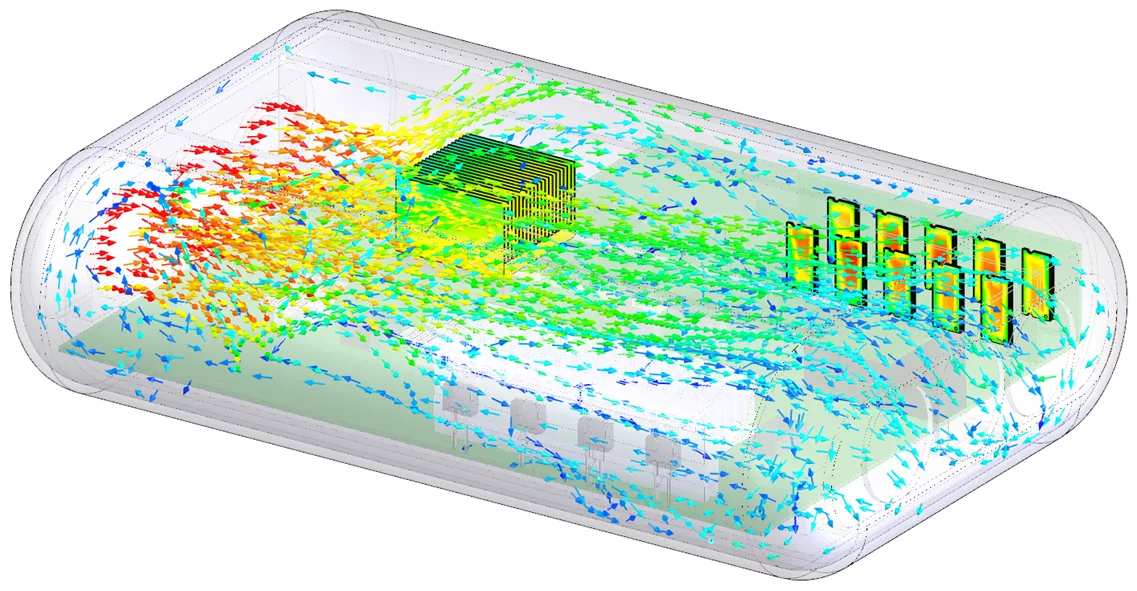

SOLIDWORKS users have access to high-end general-purpose and plastic injection molding CFD right in the SOLIDWORKS interface. This unprecedented quality of simulation from a "CAD company" will quickly prove ROI.

For cloud-inclined individuals, 3DEXPERIENCE versions of both general CFD and injection molding sim provide the same or enhanced CFD capabilities with the 3DEXPERIENCE user interface and unlimited 8-core cloud compute.

SOLIDWORKS Flow Simulation is the easiest way for SOLIDWORKS designers to do CFD that will improve the bottom line. In this article, one of our experts discusses the top 5 use cases.

SOLIDWORKS Plastics verifies manufacturability early in the design phase. It is such a powerful tool that it comes in three tiers to match your needs. This is a 38-minute discussion of the capabilities and benefits.

If you are considering a problem involving thermal analysis, SOLIDWORKS has two tools capable of solving heat transfer and thermal analysis, and both cover conduction, convection, and radiation. So which should you use?

GoEngineer’s simulation team is here to help you on your simulation journey. Contact us today to compare solutions, schedule a demo, start a trial, or get pricing.

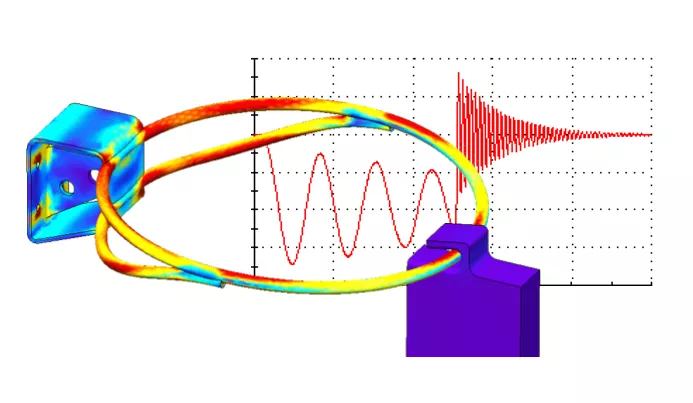

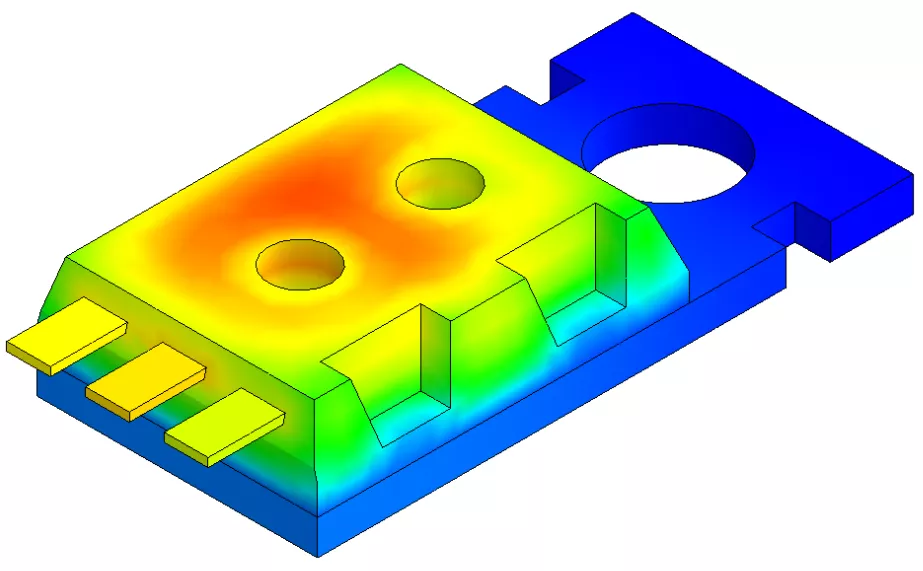

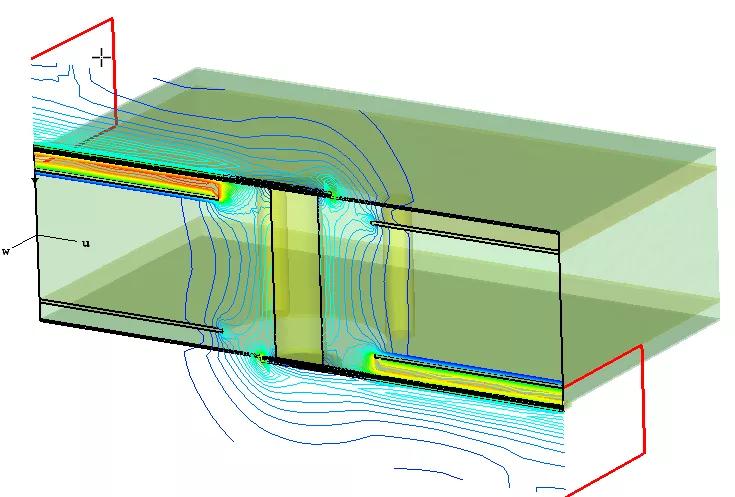

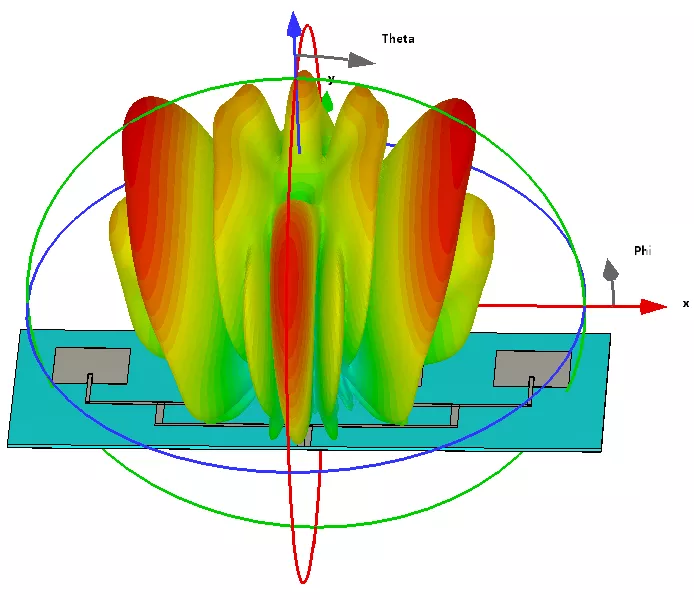

SOLIDWORKS and PCB designers now have access to CST Studio Suite, a first-party, CAD-/EDA-connected, all-in-one electromagnetic simulation solution. It contains multiple application "studios", such as PCB Studio, Microwave Studio, Cable Studio, Boardcheck, Multiphysics Studio, and more.

Like the other physics, it too is available on 3DEXPERIENCE with unlimited 16-core cloud compute, plus a browser-based preprocessor.

CST Studio Suite is high-performance design & simulation software for electromagnetics. What are its key strengths, features, packages, and hardware requirements?

This guide provides answers.

If you're going to beat the competition to market, you need a method to reduce respins and reliably optimize your designs. Watch our webinar series on how CST Studio Suite does it.

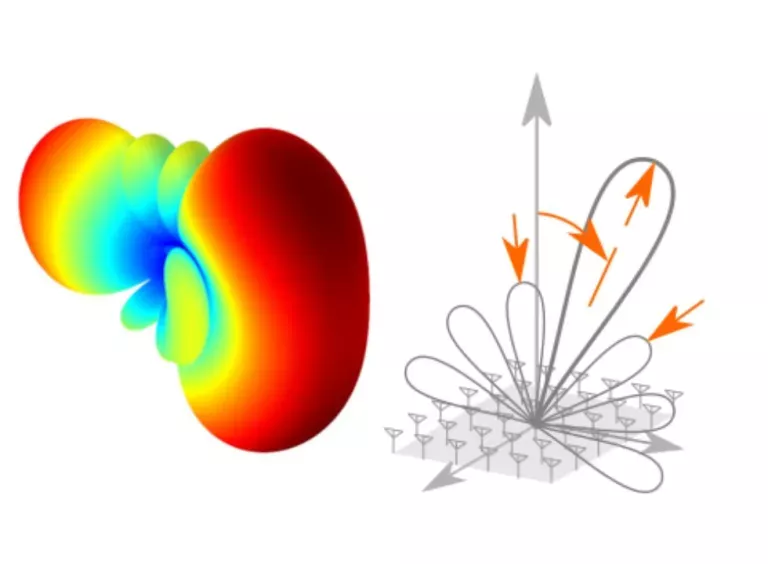

CST Studio Suite, already a SOLIDWORKS-integrated CAE tool, also has the Antenna Magus add-on for easy, application-driven antenna design, modeling, and placement.

We will walk through the steps in building a model in CST Design Studio where the 3D full-wave simulations are mixed with measured data and other simulation models. New 3D results will be generated without running another full-wave simulation. This approach provides CST users a powerful tool capable of incorporating their component simulations into a multiple component and SPICE simulation.

GoEngineer’s simulation team is here to help you on your simulation journey. Contact us today to compare solutions, schedule a demo, start a trial, or get pricing.

When you Bundle SOLIDWORKS Premium and Simulation Professional.

Promotion ends on Dec 31st, 2024

*Additional terms and restrictions may apply. Reach out for the full details.

Reach out to GoEngineer today to ask questions or see for yourself what you can do with SOLIDWORKS simulation solutions.

© GoEngineer. All rights reserved | Privacy Policy

GoEngineer delivers software, technology and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 30 years’ experience and thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS, Stratasys, CAMWorks, Product Lifecycle Management (PLM) and more.