BLT - 3D Metal Printers

High-Speed, Precision, and Scalable Metal 3D Printing

Now Serving US & Canada

Now Serving US & Canada

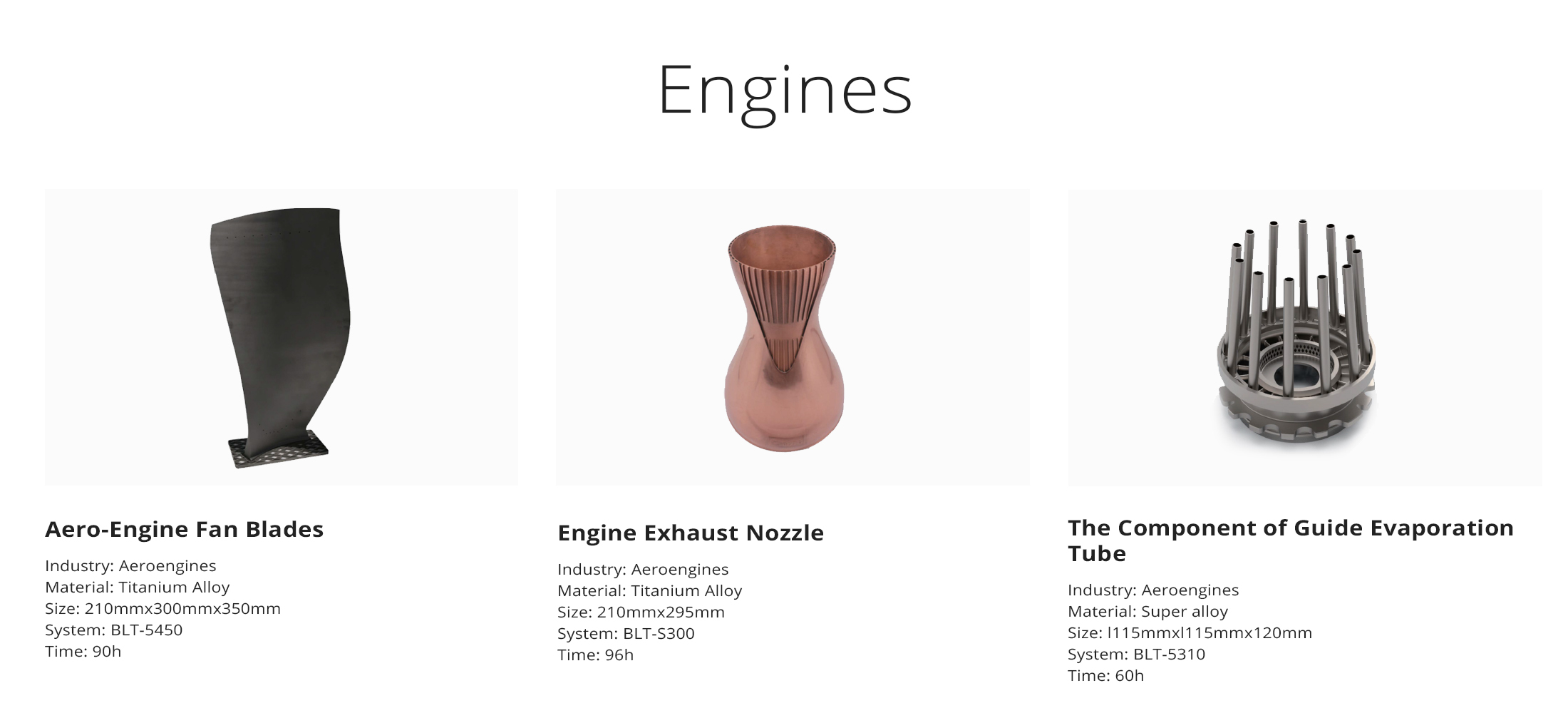

Revolutionizing Metal 3D Printing Across Industries

Bright Laser Technologies (BLT) delivers cutting-edge metal 3D printers suitable for everything from rapid prototyping to high-volume manufacturing. With multi-laser technology and integrated powder production, BLT significantly shortens production cycles, expands design freedom, and consistently delivers exceptional part quality. Trusted by industry leaders in aerospace, automotive, medical, and consumer electronics, BLT pushes the boundaries of additive manufacturing.

Key Advantages

-

Multi-laser Technology:

High-throughput, scalable production capabilities

- Integrated Powder Production: Ensures material consistency and repeatability

- Flexible Scalability: Ideal for small-batch prototypes to large-scale manufacturing needs

Proven in Flight: BLT Parts Take Off with Airbus

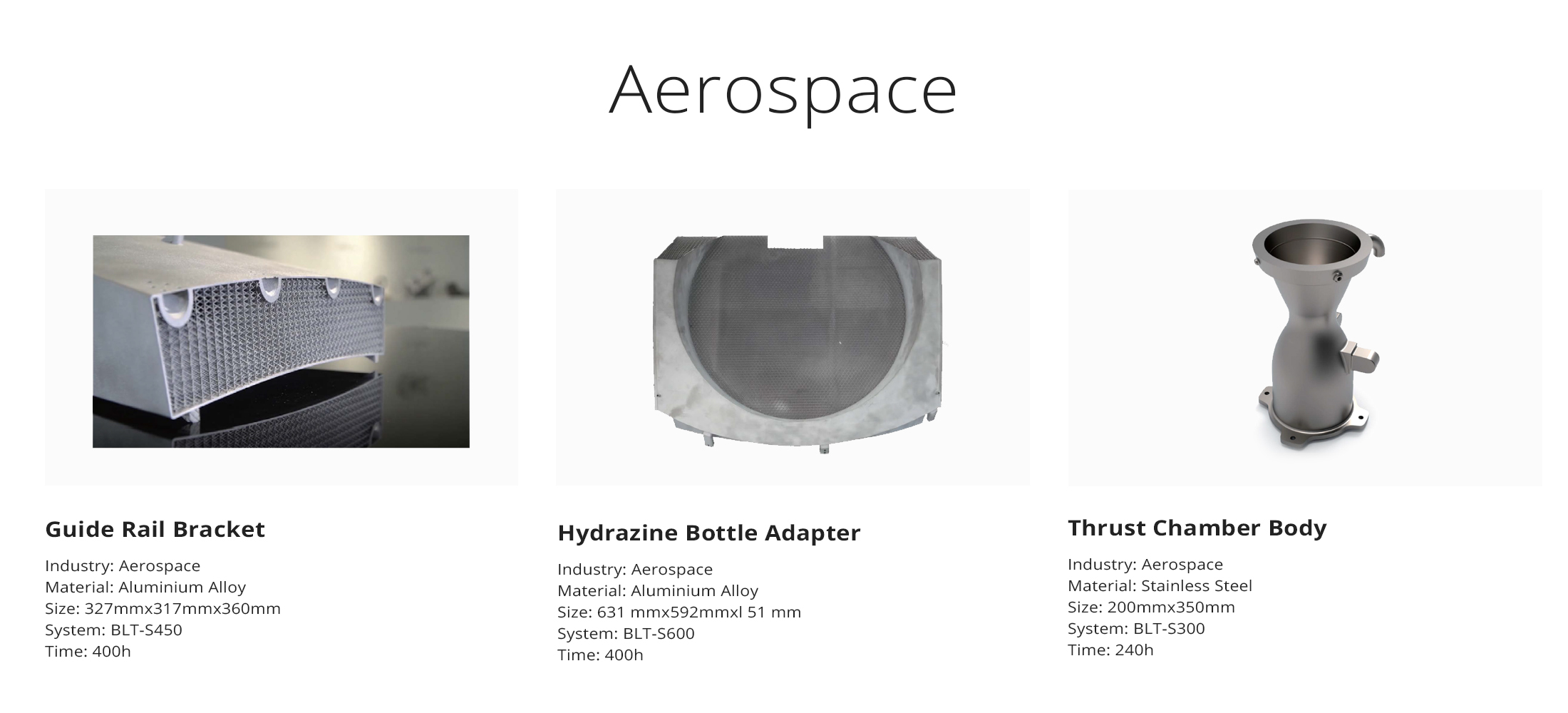

BLT’s reputation for quality and precision is more than just marketing — it’s airborne. Aerospace leaders like Airbus rely on BLT metal 3D printing systems to produce flight-critical components used in next-generation jet aircraft. From engine brackets to structural supports, BLT’s multi-laser technology ensures unmatched consistency and reliability, even in the most demanding environments.

Why Aerospace Leaders Trust BLT

- Flight-Ready Certification: BLT-produced parts meet Airbus’ rigorous aerospace standards for safety and performance.

- Extreme Precision & Repeatability: Essential for mission-critical jet engine components.

- Production at Scale: Airbus leverages large-format BLT printers to manufacture both prototype and end-use parts.

Metal 3D Printers

Features

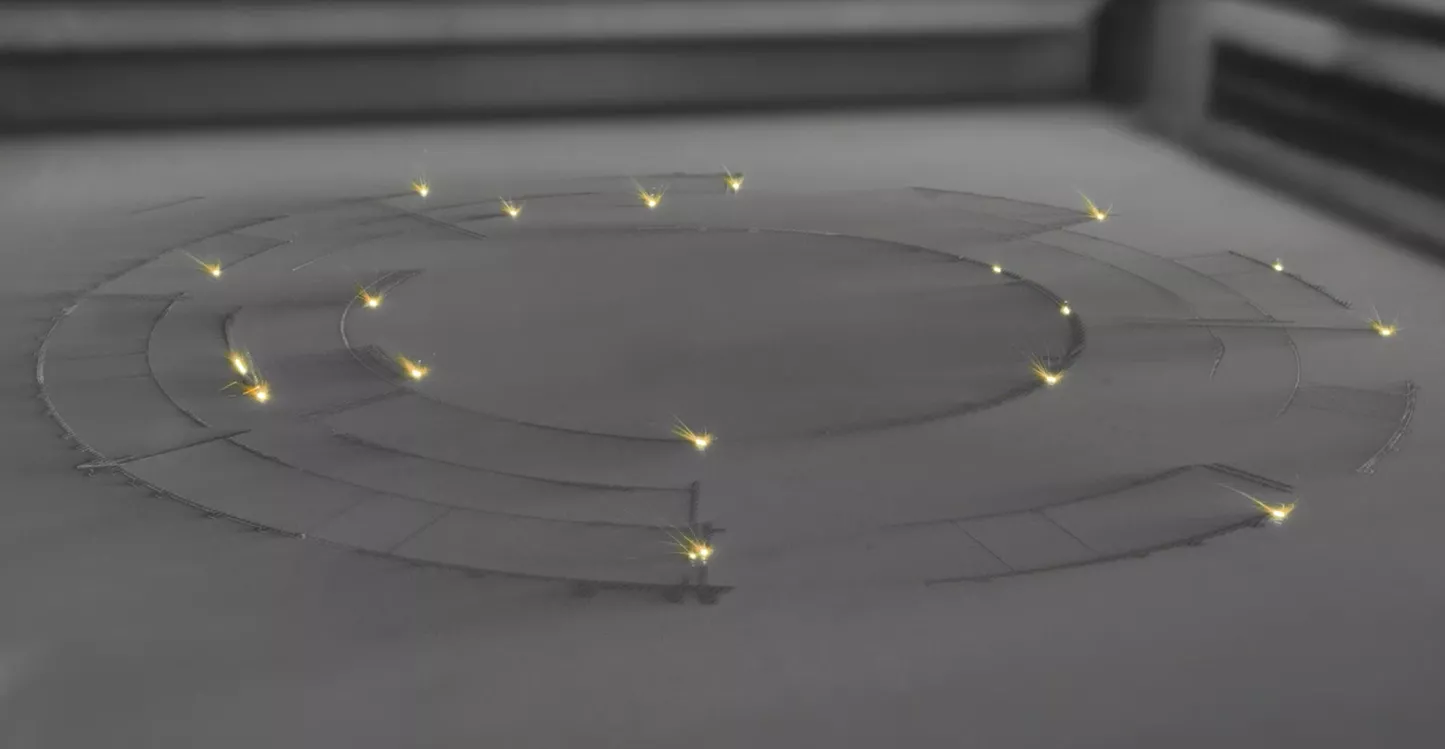

Multi-Laser Printing for Maximum Throughput

BLT’s multi-laser technology enables high-speed printing, reducing production times by up to 70% compared to traditional systems. With up to 26 fiber lasers, manufacturers can scale production without sacrificing quality.

Benefits:

- Faster print cycles – increased productivity

- Greater part consistency – high-quality results at scale

- Reduced operational costs – optimized energy use

Support-Free Printing for Complex Designs

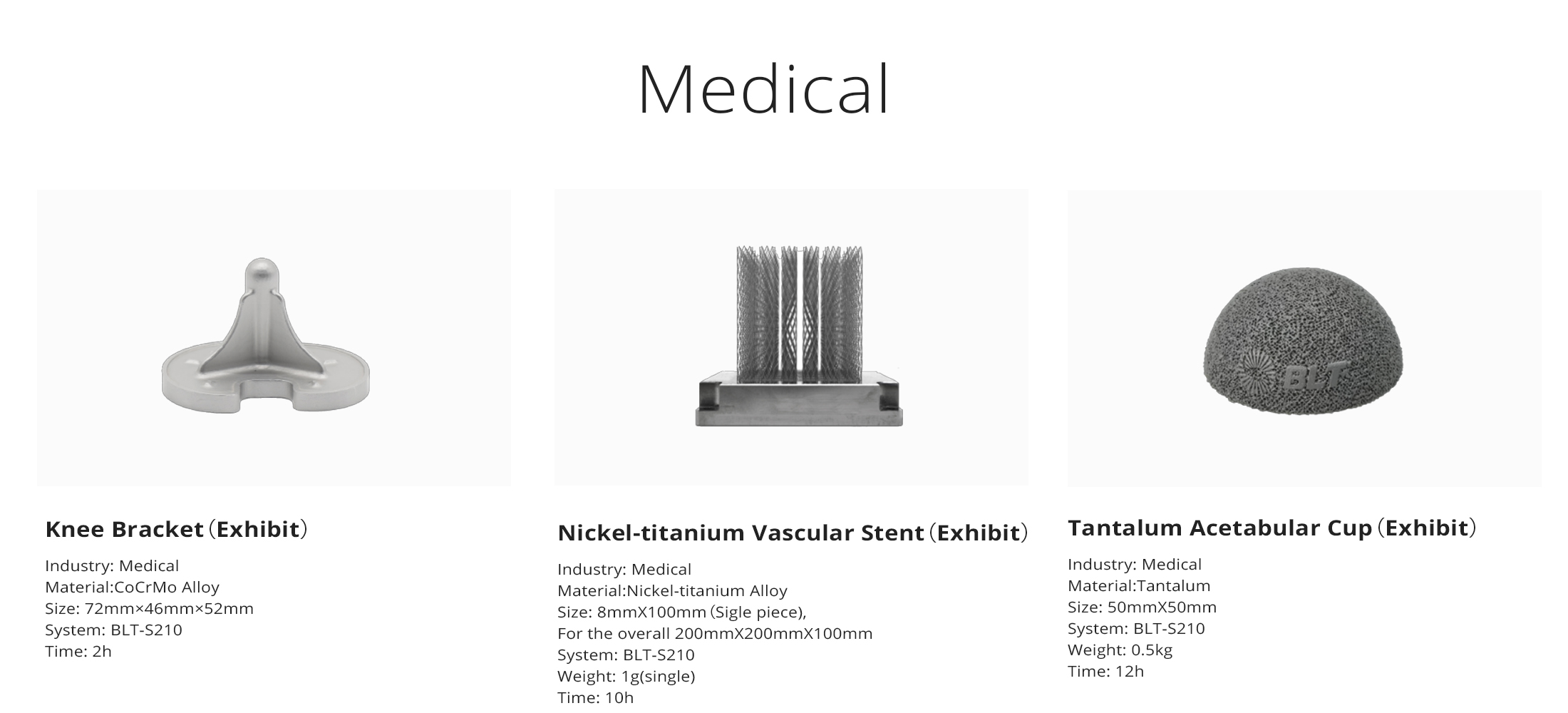

BLT eliminates the need for support structures on angles below 30°, enabling more intricate geometries and reducing post-processing time. This is crucial for aerospace, medical implants, and conformal cooling channels.

Why It Matters:

-

Less material waste – improved efficiency

-

Greater design freedom – push manufacturing limits

-

Lower post-processing costs – faster turnaround

High-Resolution Printing

BLT controls the entire production ecosystem, from powder manufacturing to build parameter optimization, ensuring consistent material properties. Compatible with titanium, nickel, stainless steel, aluminum, and more.

Key Advantages:

-

Guaranteed material quality – in-house powder production

-

Optimized build parameters – precise control for every print

-

Reliable, repeatable results – even flight-critical parts

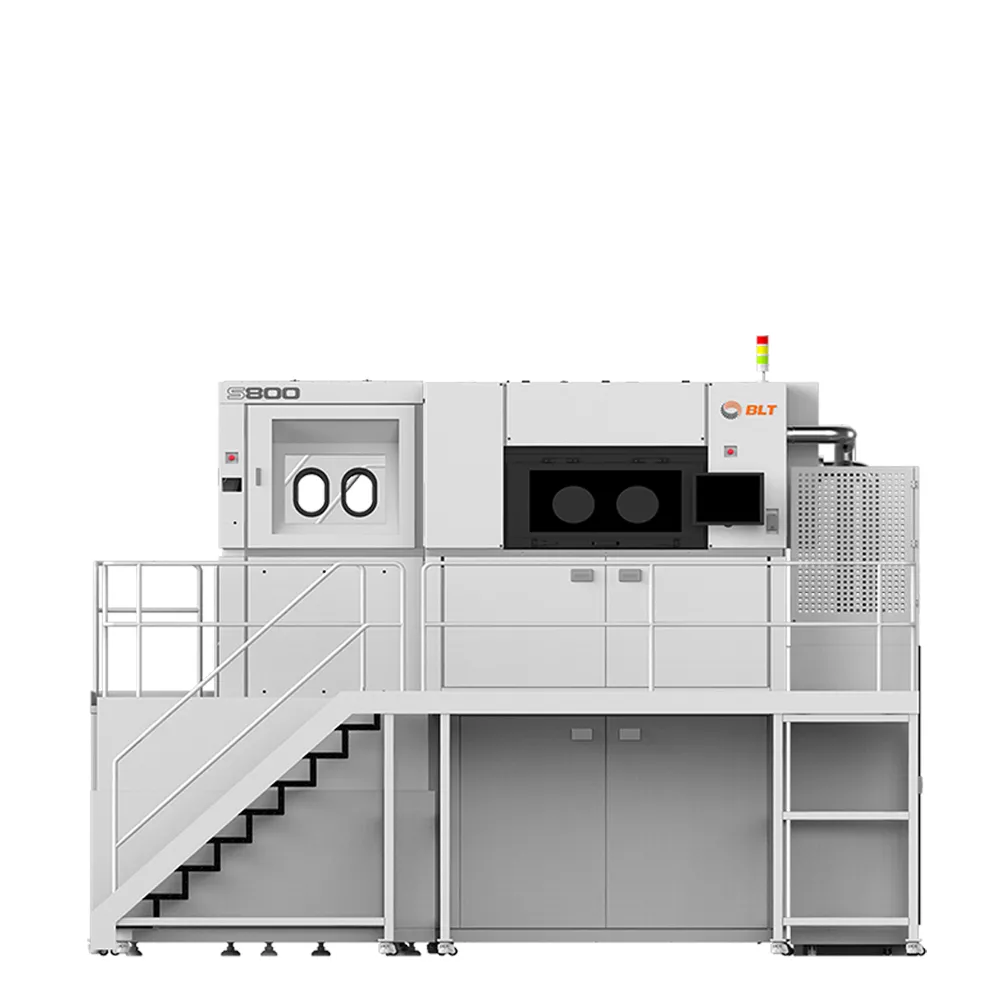

Scalable Solutions for Any Industry

BLT’s modular printer lineup scales with your needs, whether you're prototyping in a research lab or mass-manufacturing titanium housings for consumer electronics.

Key Industries:

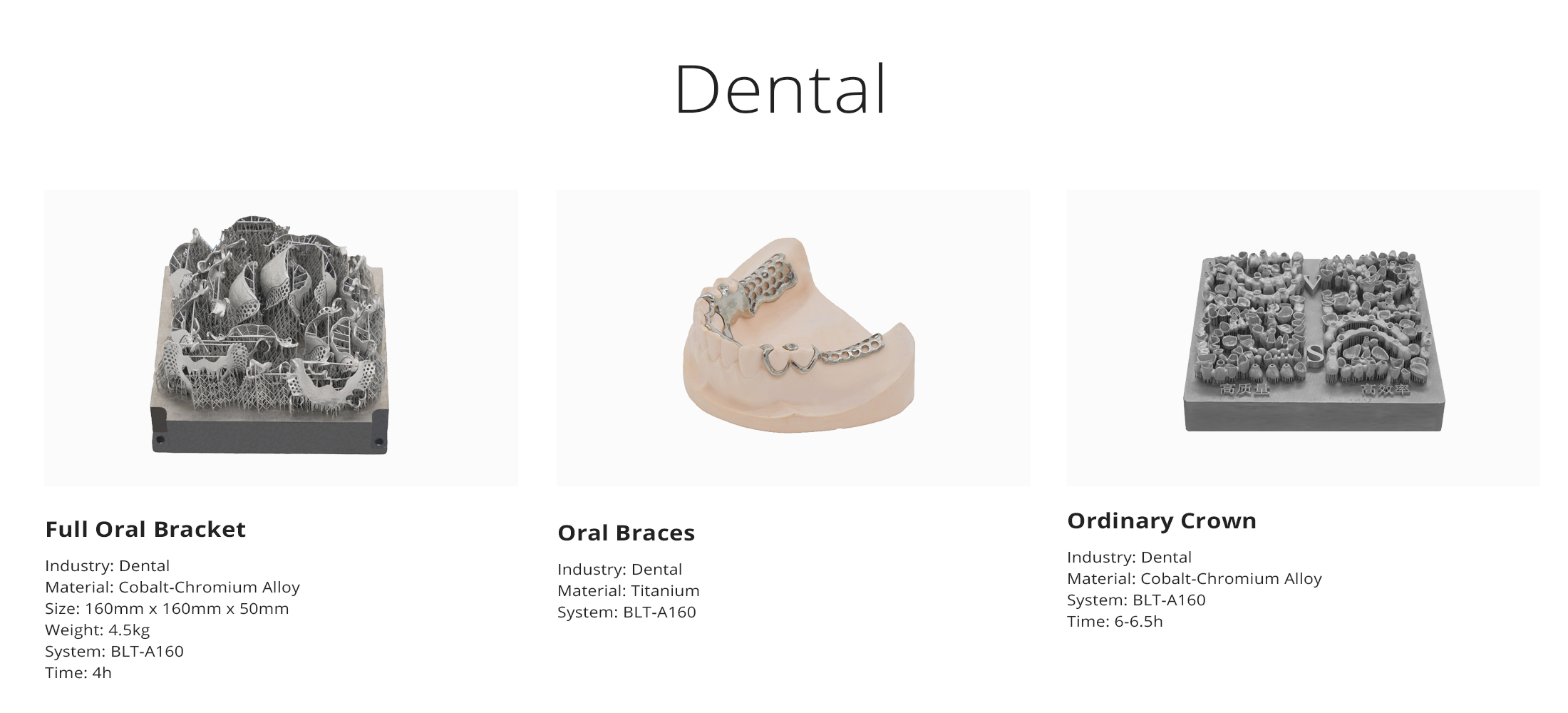

- R&D & Medical – Compact precision printers for medical implants, dental applications, and fine-detail prototypes

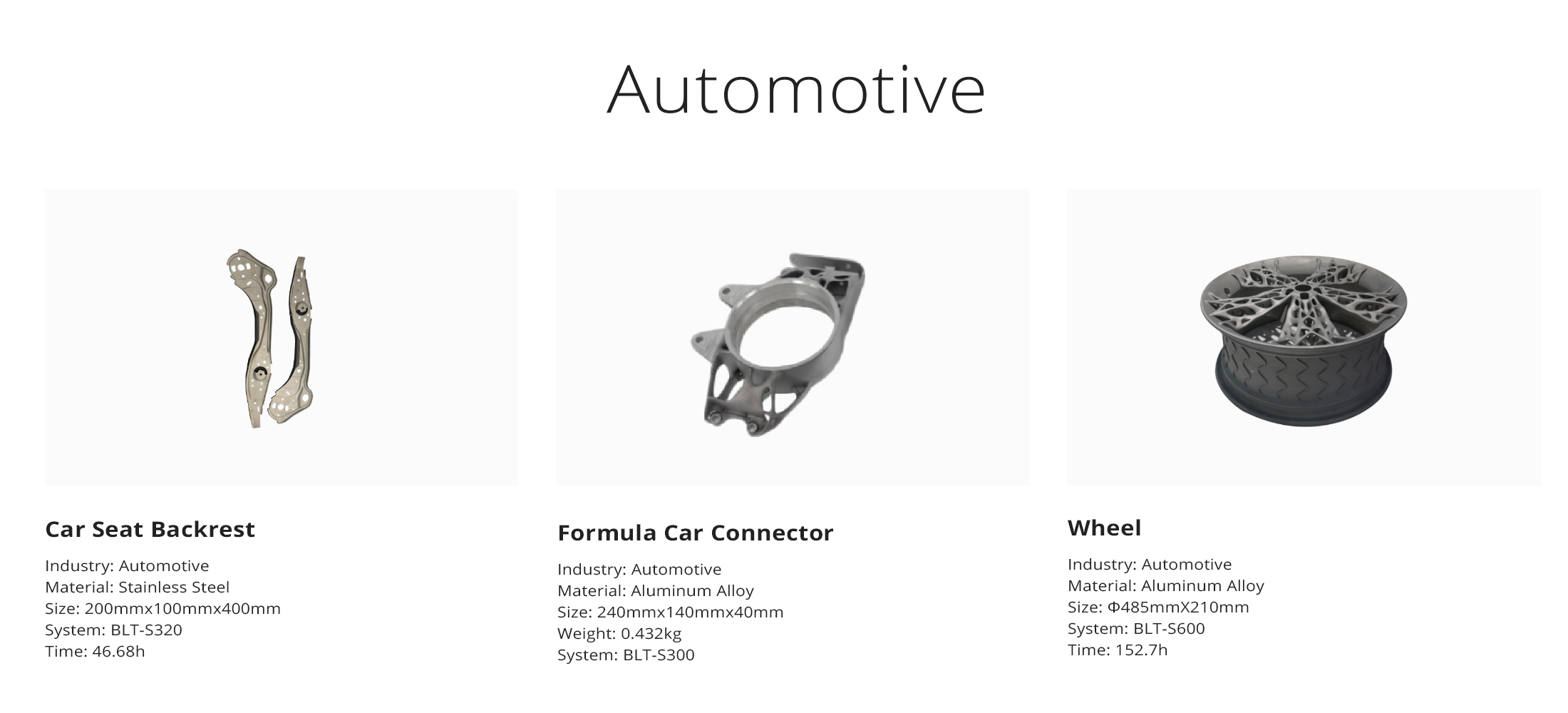

- Automotive & Tooling – Mid-volume workhorses for engine components, molds, and industrial parts

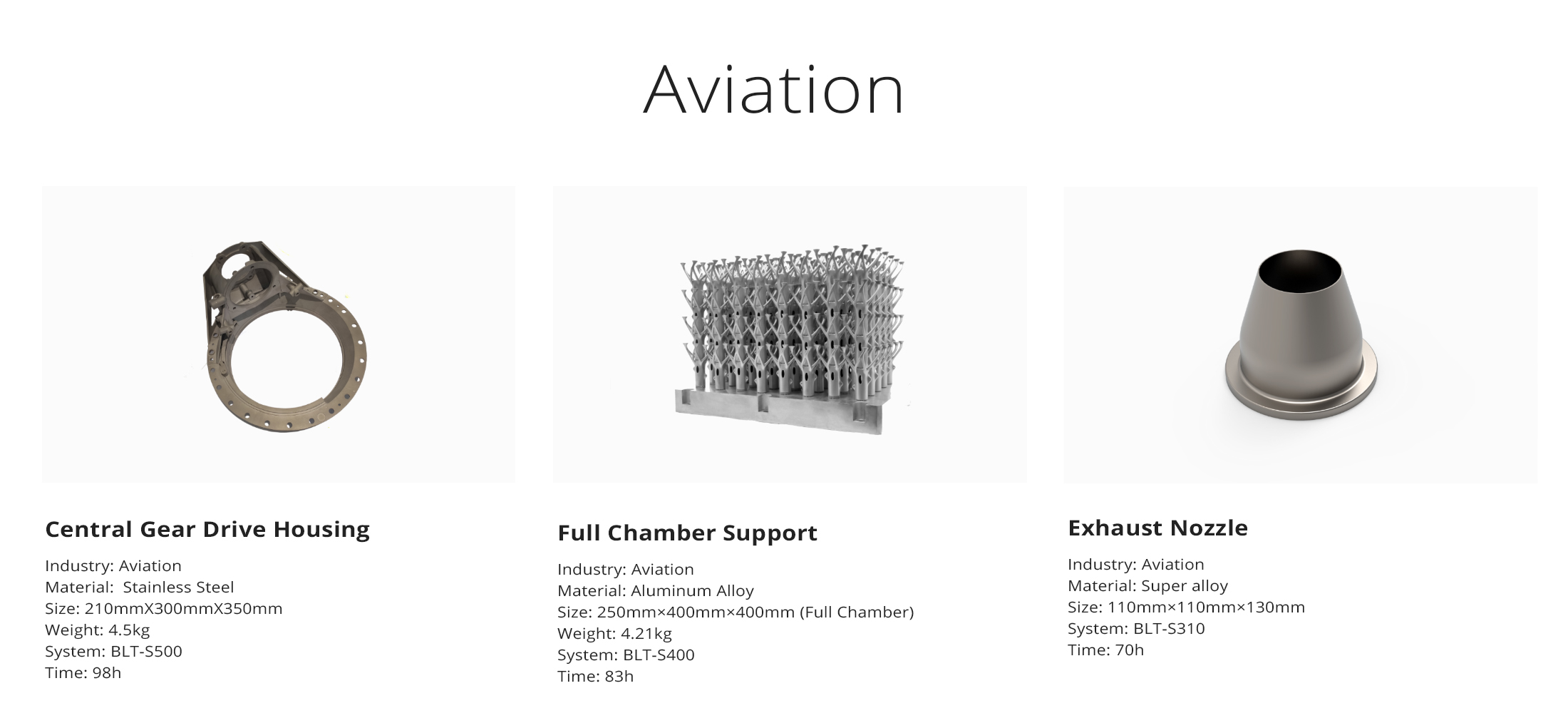

- Aerospace & High-Volume Manufacturing – Large-format printers for aircraft structures, energy applications, and defense components

BLT Materials

In-House Powder Production and Process Control

With BLT, you don’t just get a 3D printer, you gain an integrated ecosystem. BLT manufactures its own metal powders under strict quality standards, pairing them with precisely tuned build parameters for each machine. This vertical integration ensures full control over material quality, mechanical properties, and repeatability.

BLT supports a wide range of alloys, including:

- Titanium

- Nickel

- Stainless steel

- Aluminum

- Copper

- And more!

Why CHoose BLT?

BLT’s multi-laser architecture dramatically reduces metal 3D printing times without compromising quality. Equipped with up to 26 lasers working simultaneously, BLT machines accelerate manufacturing, reduce overall processing time, and enable the creation of intricate designs, including conformal cooling channels, complex impellers, and aerospace-grade components.

Software

GrabCAD Voxel

Unleash the power of the voxel. In combination with PolyJet Studio and GrabCAD Print, now experience GrabCAD Voxel Print for limitless color and material capabilities at the voxel level.

- PolyJet Studio’s intuitive interface makes it easy to choose materials and optimize the build and print queues.

- GrabCAD Print software makes 3D printing on Stratasys 3D Printers easy, accessible, and connected. The software’s efficient workflow streamlines job management in shared office and model shop environments.

- GrabCAD Voxel Print delivers unprecedented user control over color and material placement.

Frequently Asked Questions

ADDITIONAL 3D PRINTERS

FDM

FDM 3D printers streamline processes from design through manufacturing, reducing costs and eliminating traditional barriers along the way. Manufacturing FDM 3D PrintersPOLYJET

3D print realistic prototypes and models with full-color elements, labels, and true-to-life textures in one operation . PolyJet 3D PrintersSAF

Selective Absorption Fusion™ SAF™ technology that delivers functional, production-grade parts with optimum consistency. Production SAF 3D PrintersP3

Programmable PhotoPolymerization P3™ technology delivers industry leading accuracy, consistency, and details. Production P3 3D Printers

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services