Stratasys J4100

Build industrial-scale parts and mixed trays

Now Serving US & Canada

Now Serving US & Canada

High Throughput, Low Cost of Ownership

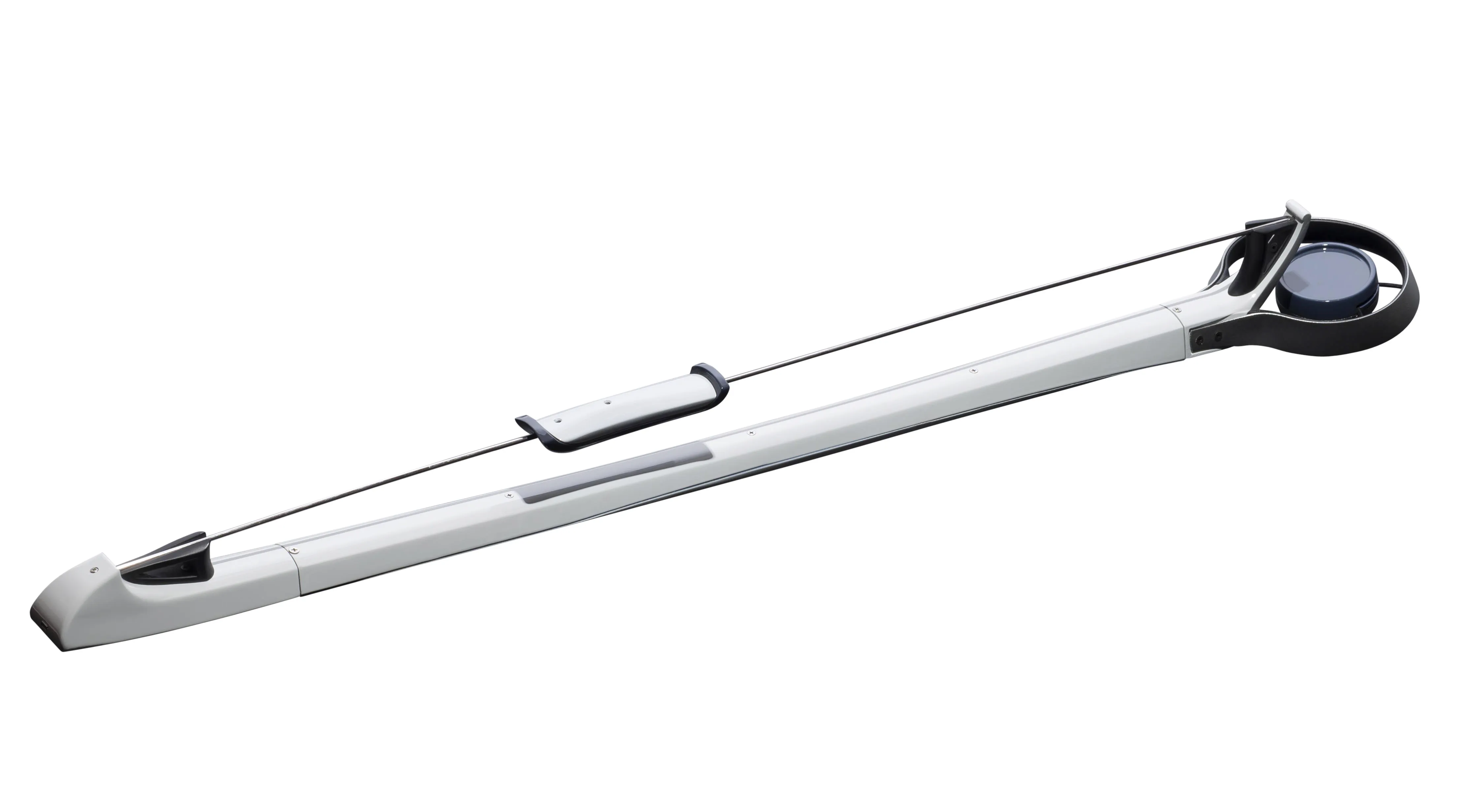

The Stratasys J4100 is the world’s largest multi-material 3D printer. From full-scale prototypes to fully packed trays of precise, small parts, PolyJet’s signature precision and material range deliver accuracy and aesthetics on a grand scale.

With an ultra-large build tray measuring 39.3 x 31.4 x 19.6 in., the versatile J4100 amplifies productivity without sacrificing accuracy. It works largely unattended to produce multi-material parts directly from CAD data, preserving fine details and geometric complexity at any scale.

In industries like automotive and aerospace, the J4100 streamlines production of 1:1 models, patterns, molds, fixtures, and other manufacturing tools. It’s up to 40% faster than its predecessor and offers the lowest cost of ownership per part of any PolyJet system. Its size, speed, and precision amount to higher throughput, lower cost per part – and ultimately a quick return on investment.

Multiple Materials for Minimal Post Processing

Tough material options withstand drilling and assembly, while multi-material capabilities often render those steps optional. Smooth surfaces in contrasting shades and textures eliminate the need for painting, polishing, or rubberizing. Combine as many as 14 material properties in a single, automated job to quickly produce durable tools with rubberized grips, clear gauges, or heat-resistant surfaces. Or, 3D print 1:1 scale prototypes that are virtually indistinguishable from the final product and require no assembly. Support removal is easy, so you can maximize productivity.

J4100 MATERIALS

Vero

Realistic & vibrant colors

– Multi-purpose, multi-color family of materials | CMYKBWV

– Good stiffness and strength

– Blend together or with other materials to change properties

• Hardness | flexibility | translucency | heat resistance

– Wash-away or soluble support available

Potential applications:

– Visually realistic prototypes

– Fit, form, and function prototypes

– Surgical models

– Jigs, fixtures, & tooling

VeroClear / VeroUltraClear

Simulated acrylic

– Transparent material similar to Polymethyl methacrylate (PMMA)

– Used to Simulate Transparent Products

– Blend together or with other materials to change properties

• Hardness | Opacities | Hues

Potential applications:

– Simulated clear and transparent parts

– Fit and form prototypes

– See-through parts & visual aids

TANGO

Simulated Rubber

– Flexible, rubber-like material

– Test and verify visual, tactile, and functional applications

– Offers shock absorption & vibration dampening

– Blend with other materials to change properties

• Hardness | Elongation | Tear resistance

Potential applications:

– Soft touch coatings

– Non-slip surfaces

– Grips | Pulls | handles | buttons

– Footwear prototypes

Digital ABS Plus

Simulated ABS

– Most mechanically robust Polyjet material

– Combines temperature resistance with toughness

– Good impact strength

– 2 material blend

Potential applications:

– Design verification

– Functional testing

– Jigs & fixtures

– Manufacturing tooling

Durus

Simulated Polypropylene

– Developed to simulate common consumer thermoplastic

– Improved resilience and elongation while remaining rigid

– Good for parts with delicate features and small cavities

• Hardness | Flexibility | Translucency | Heat resistance

– Wash-away or soluble support available

Potential applications:

– Fit, form, function prototypes

– Snap-fit features

– Living hinges

Rigur

Simulated Polypropylene

– Advanced simulated polypropylene material

– Improved durability, toughness, and fatigue resistance

– Excellent option for blending with other materials

– Bright white color ideal for some aesthetic applications

Potential applications:

– Fit, form, and function prototypes

– Snap-fit features

– Living hinges

– Reusable containers & packaging

J4100 Specifications

Model Materials

- Rigid Opaque: Vero family

- Rubber-like: TangoPlus and TangoBlackPlus

- Transparent: VeroClear

- Simulated Polypropylene (Endur)

digital materials

- Digital ABS and Digital ABS2

- Wide range of translucencies

- Rubber-like blends in a range of Shore A values

- Simulated Polypropylene materials with improved heat resistance

printing modes

- Digital Material (DM): 34-micron (0.001 in.)

- High Quality (HQ): 16-micron (0.0006 in.)

- High Speed (HS): 34-micron (0.001 in.)

input format

STL, OBJDF and SLC File

workstation compatibility

Windows 10

network connectivity

LAN TCP/IP

size and weight

Height: 77.5 in.

Width: 113 in.

Depth: 83 in.

Weight: 4850 lbs.

layer thickness

Horizontal build layers down to 16-microns (0.0006 in.)

build resolution

X-axis: 300 dpi; Y-axis: 300 dpi; Z-axis: 1600 dpi

accuracy

Up to 85 microns for features smaller than 50mm;

Up to 600 microns for full model size (for rigid materials only, depending on geometry, build parameters

and model orientation)

support material

FullCure 705 non-toxic gel-like photopolymer support

material cartridges

- Six sealed 39.6 lb cartridges

- Two different model materials loaded

- Hot-swappable replacement during print

net build size

39.3 x 31.4 x 19.6 in.

print heads

8 units

power requirements

230 VAC 50/60Hz; 8A single phase

operational environment

Temperature 18 C-22 C (64.5 F-71.5 F); relative humidity 30-70%

Software

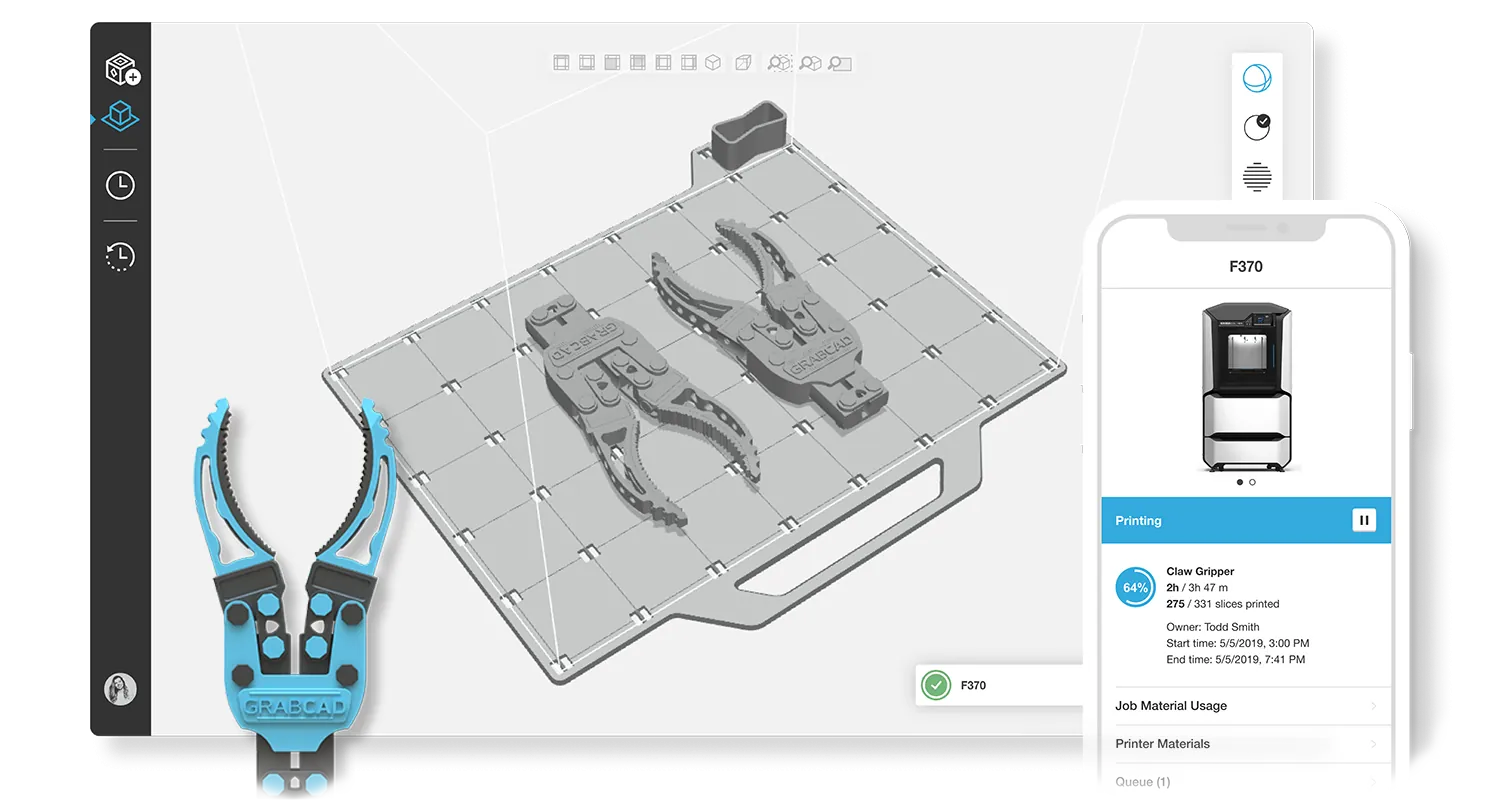

GrabCAD Print

GrabCAD Print makes 3D printing easy, with thoughtful features:

- Automatically corrects files and reduces print time with automatic tray arrangement.

- Calculates the time and material resources needed for production before printing.

- 3MF file supported – significantly simplifies color assignment in your workflow.

- New feature alerts the user if there has been cross-contamination with a biocompatible material.

- Schedule and monitor the print job remotely from your mobile device or browser.

- Get automatic alerts remotely when the job is printing and finished.

ADDITIONAL 3D Printing RESOURCES

AWARD-WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services