Beating COVID-19 with a Snorkel

Samuel Adams (shown below) from Star EMS came to Cyb Llings Inc and GoEngineer with a design problem. He wanted to make an adaptor that would convert a snorkel mask into a respirator to help beat COVID-19. With the partnership of CAD, computer simulation, and 3D printing experience, we were able to get a working prototype in less than 24 hours and over the course of a week of tweaking and fine-tuning, it passed a qualitative fit test.

Design constraints

Having the snorkel mask in hand and a pair of digital calipers made it easy to replicate the portion of the mask that the adaptor needed to fit.

Figure 1 – Snorkel Mask Measurements.

Once the dimensions were determined for the proper fit of the adaptor, the remaining design still needed to satisfy two constraints:

- Inhaled air must pass through the filters so the mask wearer will not get infected.

- Exhaled air must not circulate in the eye cavity of the mask so that mask will not fog up.

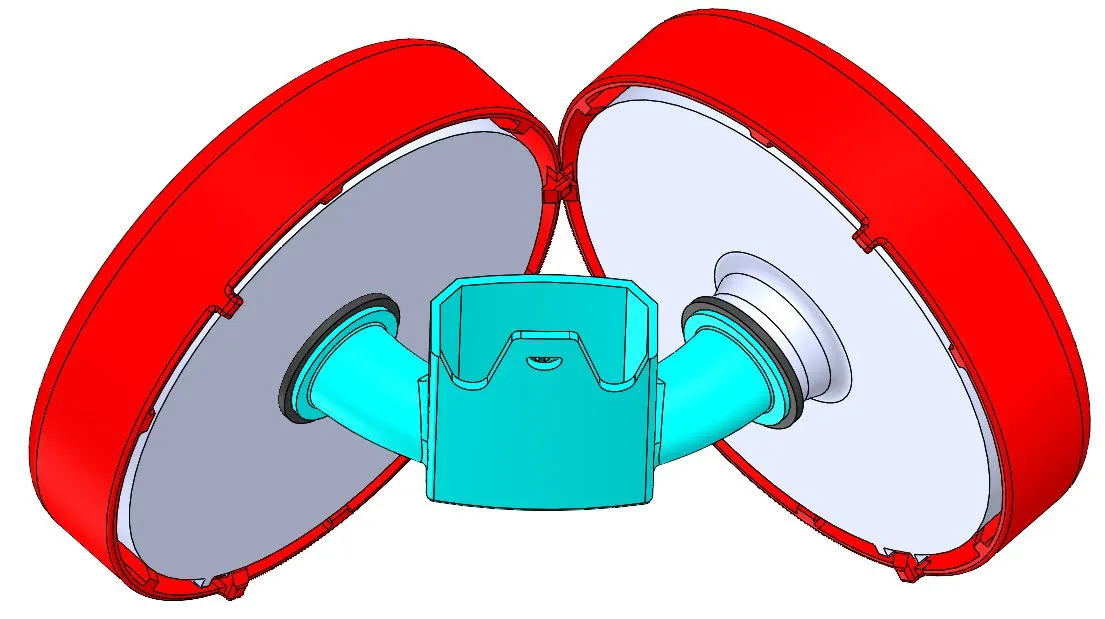

We used SOLIDWORKS to create the design below.

Figure 2 – Snorkel Adaptor Design.

With the use of Cyb Llings’ Connex 3D printer, we printed and tested many versions of this design to make sure it fit correctly with seals.

Figure 3 – Cyb Lings Inc. Multi-jet 3D Printer.

Constraint 1: Inhaled air must pass through the filters

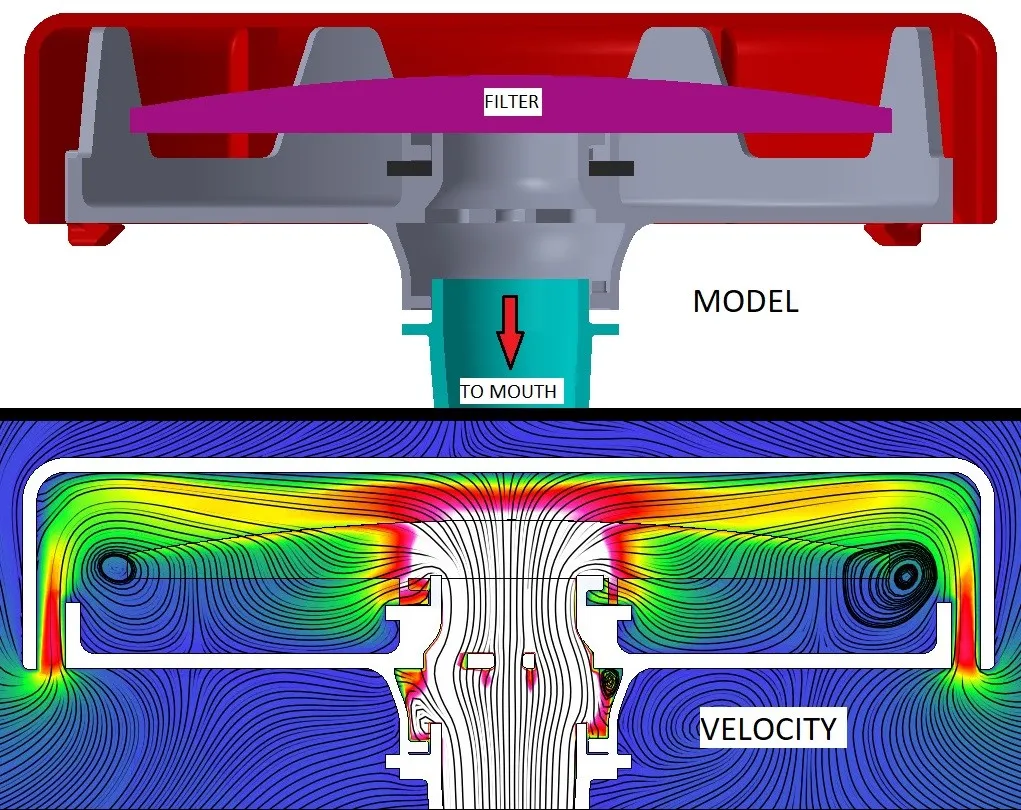

To see how this mask and adaptor function together, we have compiled a batch of animations using SOLIDWORKS Flow Simulation. The animation below shows the airflow when Sam inhales.

Figure 4 – Inhaled air flow. Colors show relative air restrictions.

The colors of the arrows show regions where there are restrictions on the flow. We wanted to make sure the wearer did not feel like they were trying to “breath through a straw,” so this type of visualization is important to help make design decisions.

The image below shows a detailed view of the filter region and how the air enters through the filter before being guided to Sam’s lungs.

Figure 5 – Detailed view of the filter body design and flow.

To verify that the respirator does not leak, Star EMS tested it with a qualitative fit test (shown below) and it passed.

Figure 6 – Qualitative Fit Test.

Constraint 2: Exhaled air should not fog up the mask

When Sam exhales, the respirator has several check valves to prevent fogging up the eye cavity. The animation of exhaling below shows the airflow pattern that accomplishes this.

Figure 7 – Exhaled airflow. Colors show relative air restrictions.

Air is only allowed to leave through the check valve port in the mouth of the mask or back out the left filter. Additionally, another check valve is 3D printed and installed on the right filter to disallow air from leaving out of this port since this side of the mask connects directly to the eye cavity. This check valve is important to create a dead-end in the flow since the nosepiece does not completely seal the mouth-cavity from the eye-cavity.

Additional considerations

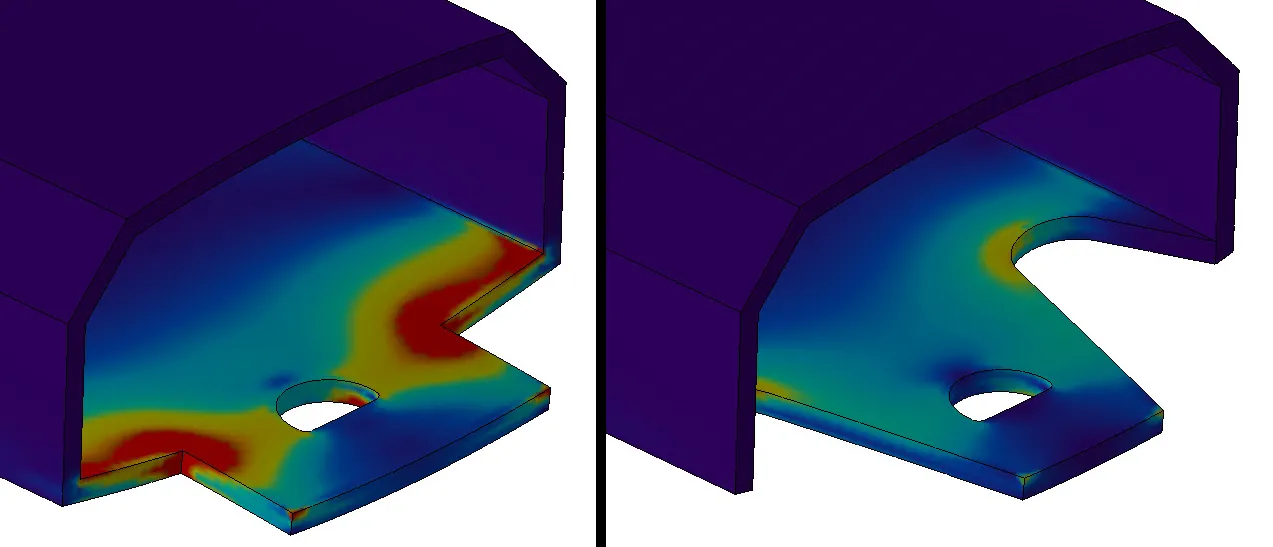

There were many other considerations that we needed to factor into the design. We used SOLIDWORKS Simulation to help design and optimize some features such as the attach/release tab shown below.

Figure 8 – Stresses on attachment tab.

With the added relief cuts, it makes it both easier to release and less likely to snap the printed plastic.

Summary

With the help and collaboration of the teams at Star EMS, Cyb Llings Inc, and GoEngineer, we were able to quickly design, and 3D print a functional adaptor that converted a snorkel mask into a temporary respirator-like device. This can potentially can be used to help protect Sam and his team from COVID-19 while supplies of other protective gear are short.

Want to do great things with SOLIDWORKS Simulation? Contact us.

About Shaun Bentley

Shaun Bentley is passionate about applied mathematics and engineering, which led him to pursue and understand real world applications of FEA, CFD, kinematics, dynamics, and 3D & 2D modeling. He teaches many simulation classes to both new and advanced users attending training at GoEngineer. Since 2006, Shaun has been working with simulation tools to solve real world engineering problems. With every new project, he seeks to find ways to push simulation to its uppermost limits, even going so far as to write bespoke code and macros. He has passed the Michigan FE exam and mentors or consults for virtually any industry that uses SOLIDWORKS, especially automotive and automated tools. He is a speed 3D modeling champion and one of the first Certified SOLIDWORKS Experts in Simulation in the world.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.