Onshape vs. SOLIDWORKS: The Complete Story

Onshape vs. SOLIDWORKS is perhaps the most top-of-mind 3D CAD rivalry at the moment. Onshape is the nimble, cloud-based newcomer, and SOLIDWORKS is the world-leading champion of the last couple of decades. Onshape makes an undeniable splash – it’s easy to sign up and get started – but your needs on day 1 aren’t the same as on day 90 or day 365. They aren’t the same as every other designer, or the analysis department, or manufacturing, or any of the other contributors that work with your software ecosystem.

Onshape and SOLIDWORKS – not that different at first glance?

The correct choice for a long-lasting business requires careful consideration and research, not just a CAD trial. In this article, we will compare Onshape and SOLIDWORKS as design tools, but much more beyond that. What happens after design? How do the strengths and limitations of the tool(s) affect what the company can accomplish? How do these tools and processes fare as needs change when the business and business environment evolve?

Section 1

Getting Started & Design

| Onshape | SOLIDWORKS & 3DEXPERIENCE (as purchased from GoEngineer) |

|

| Getting a License |

|

|

| Core Design Experience |

|

|

| Specialized Design Experience |

|

|

| On-Cloud Design Collaboration |

|

|

| Custom Development |

|

|

| Tech Support |

|

|

| Community |

|

|

| Training |

|

|

Getting a License

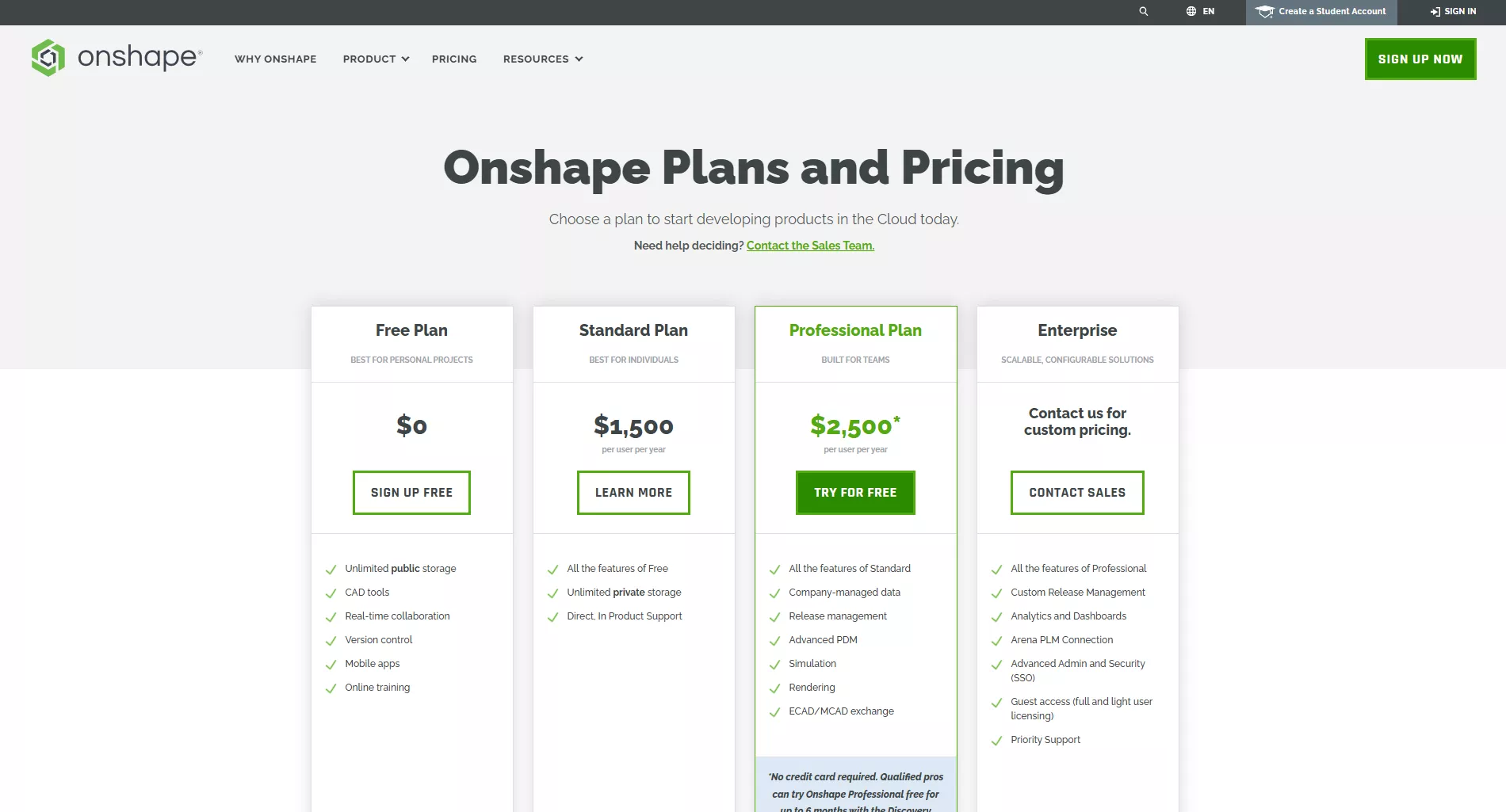

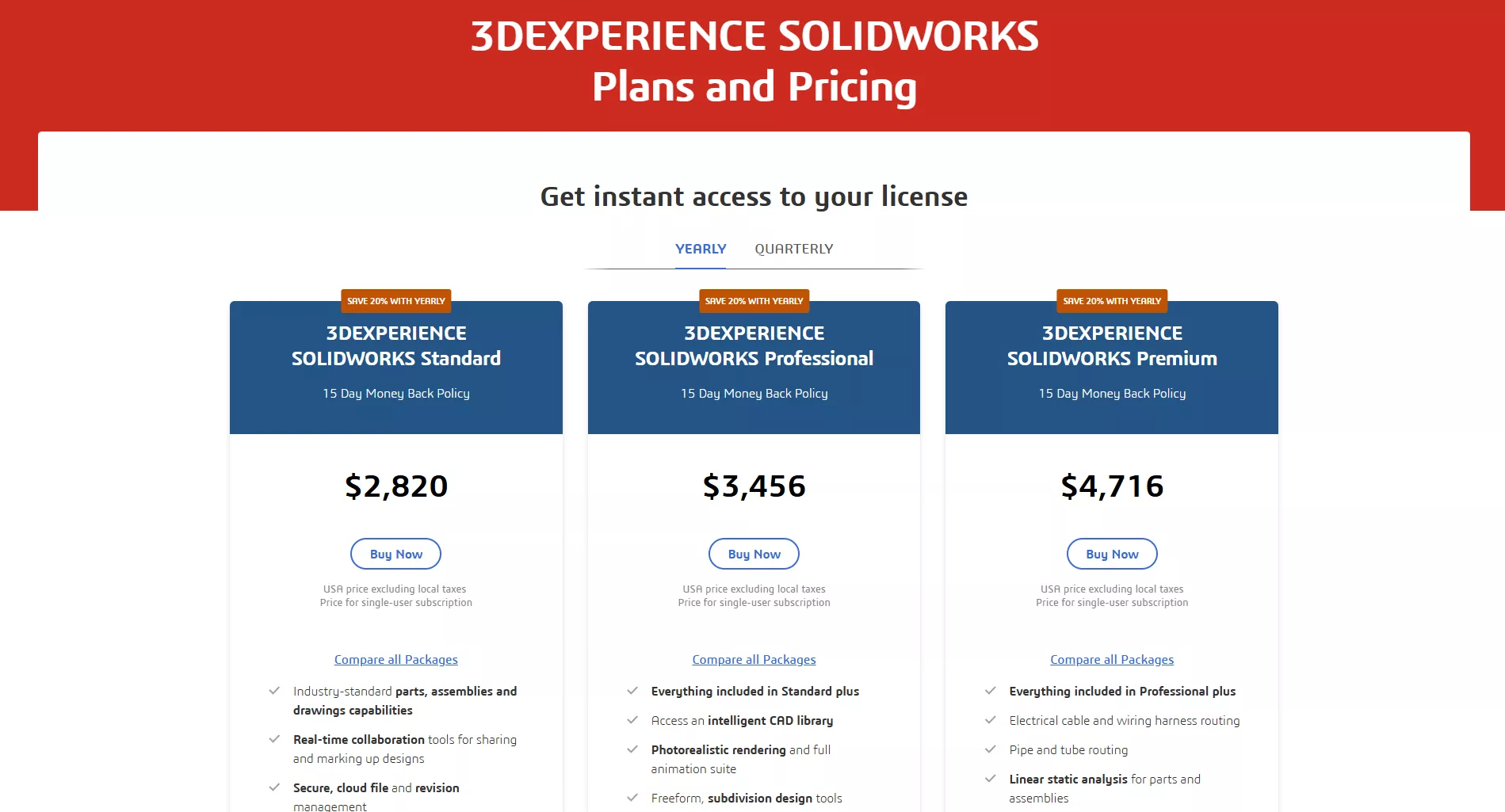

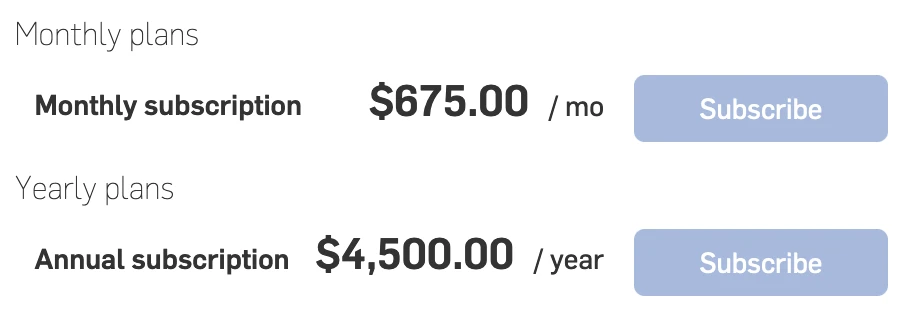

Onshape follows the latest B2B SaaS user experience trends – it’s easy to start a trial or purchase, especially since it’s all in the web browser. You can sign up for an account and be clicking around in the CAD tool in your web browser in just a few minutes, and you won’t need a Windows CAD workstation.

Onshape and SOLIDWORKS both offer quick and easy online purchasing.

SOLIDWORKS is a traditional desktop solution, and there are two ways to get started, assuming you already have said workstation:

- Instant self-service: SOLIDWORKS can now be purchased online, downloaded, and installed within minutes.

- Through customer service: If you contact an official SOLIDWORKS VAR, you can get a license, download, and install in about a day. If you’re not in a big hurry or don’t know exactly what you want, this human-interactive approach has some major benefits – a good VAR, like GoEngineer, provides you with sales and technical experts who can answer questions, propose personalized solutions, find promotional pricing, etc.

If you want to trial the software as soon as possible, Onshape will get you there faster, with the in-browser nature of the app being very helpful in this. If you just want to buy CAD and go, they can get you a paid license in a similar time frame. If you want to take your time and do your research as thoroughly as possible, the consultative sales approach with a SOLIDWORKS VAR will likely produce more personalized and informed results when all is said and done.

In our opinion, it’s wise to take your time talking to experts and considering all angles when deciding on something as important as your CAD tool. Note that this isn’t the same as spending a lot of personal time in that CAD tool, though that should be a part of the process.

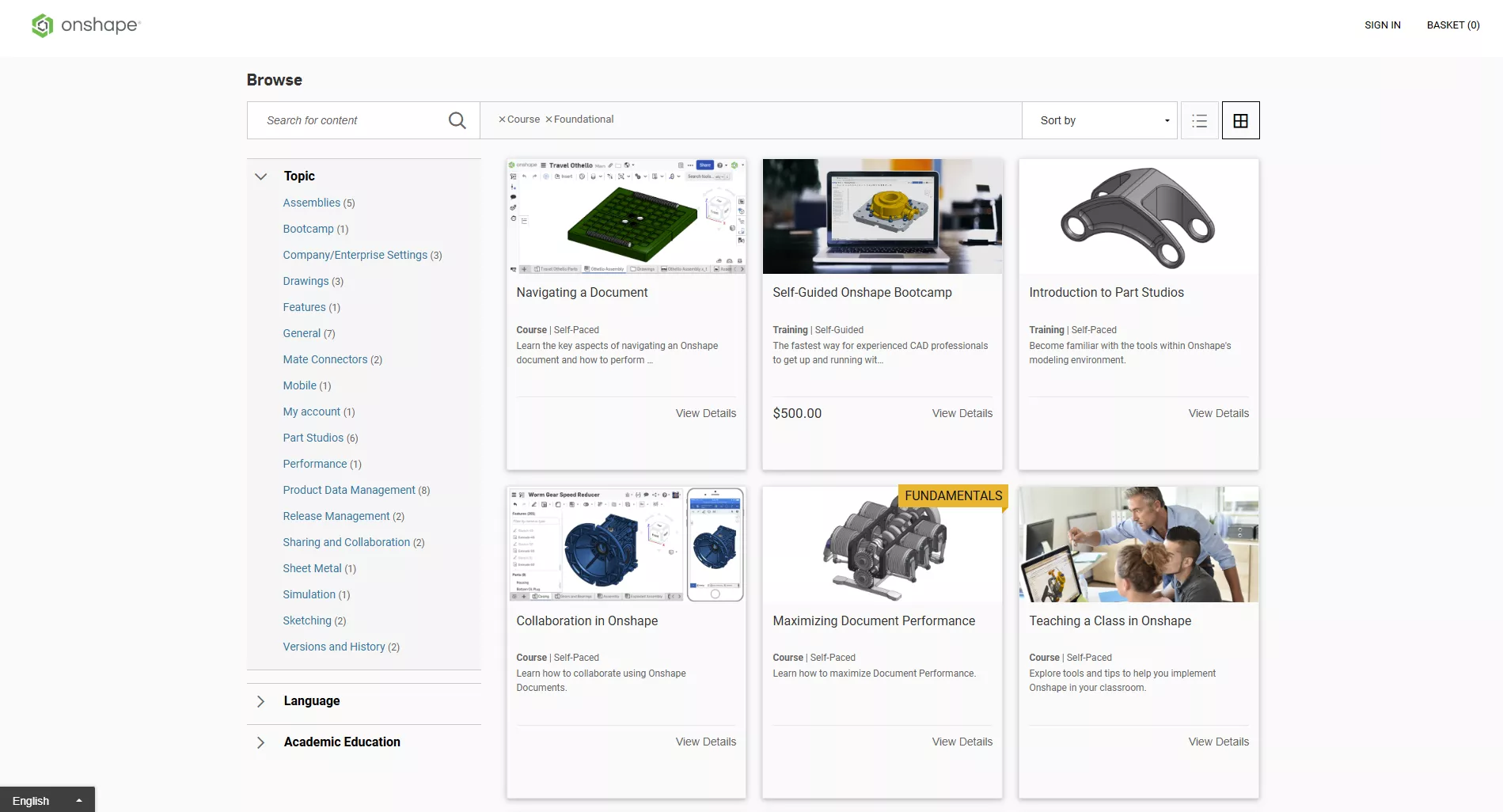

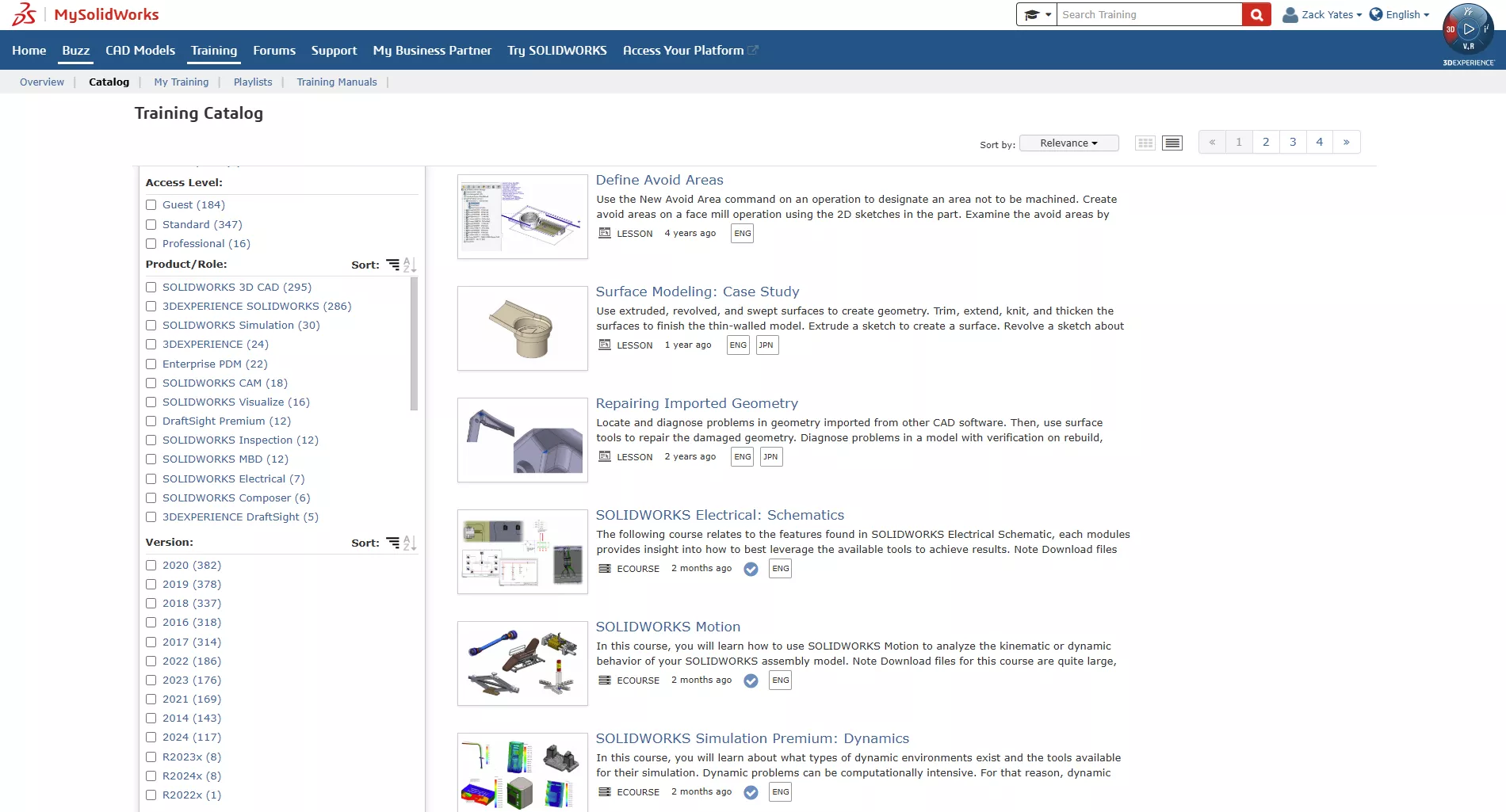

Your First (and Continued) Training

Once you have your license, both Onshape and SOLIDWORKS offer complimentary self-paced online training – Onshape in the form of Courses and SOLIDWORKS through Learning Paths, Courses, and Playlists. Both offer a substantial range of courses, but Onshape comes across as more accessible and organized.

Onshape and SOLIDWORKS both provide online course libraries.

As a third option, SOLIDWORKS purchased through GoEngineer, with the Elite Success Plan, includes unrestricted access to all of GoEngineer’s self-paced online training with instructor office hours. The course list here is simple, organized, and more extensive than what is available in the Onshape catalog, covering not just advanced CAD, but also simulation, CAM, electrical, PDM, certification prep, and more.

For live online training, Onshape offers a regularly scheduled boot camp covering the fundamentals. For SOLIDWORKS, GoEngineer offers a full catalog of live online courses including both fundamentals and specialized/advanced topics.

SOLIDWORKS and SOLIDWORKS VARs also offer in-person training, with GoEngineer offering this at local office locations across the United States. Customers can also request training on-site at their own campuses.

Many people are self-starters and comfortable learning on their own, which Onshape excels at. If you plan to step into truly unfamiliar workflows or simply prefer in-person experiences, SOLIDWORKS from a VAR will offer you more options with a human touch.

Between purchasing and introductory training, the options for your first-hour experience with Onshape or SOLIDWORKS could be vastly different – neither is inherently better. If you don’t have a lot of time or budget, Onshape has the lowest barrier to entry and excellent beginner’s resources. If you’re a deliberate and exhaustive planner or appreciate a human touch, talking to a SOLIDWORKS VAR would be a good idea. Either way, it’s important to consider how your choice at this juncture will impact the next sixty days, the next year, and so on.

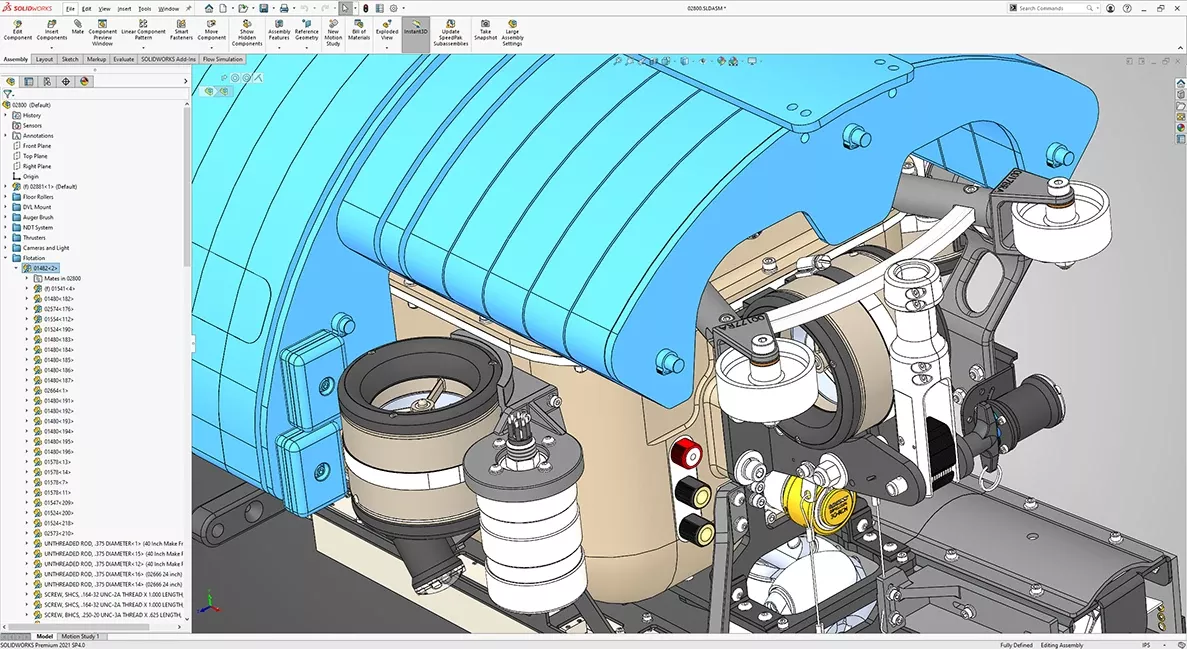

Core Design Experience

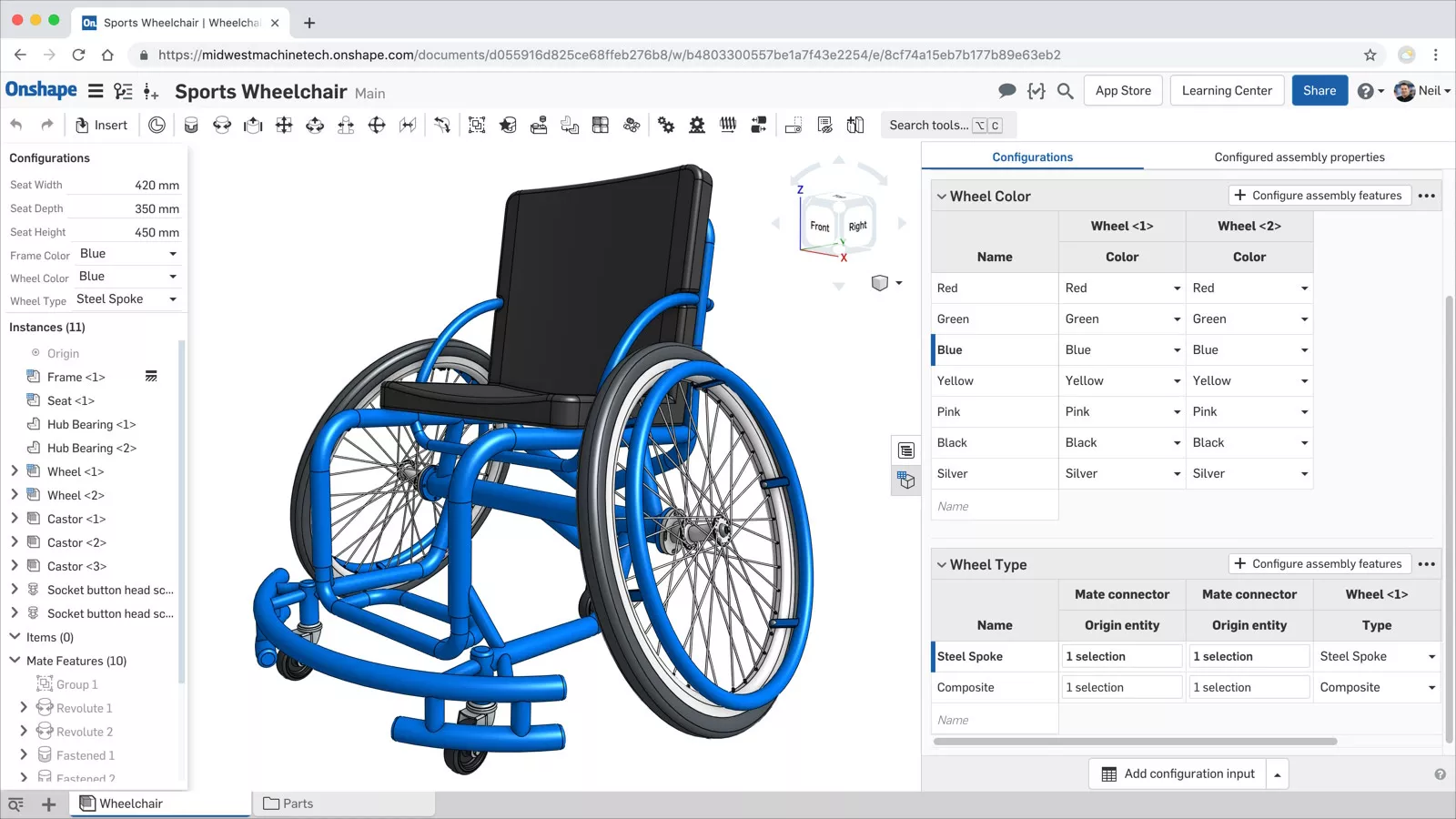

Both SOLIDWORKS and Onshape are highly regarded for their usability and intuitiveness. Ease of use is one of the many reasons SOLIDWORKS has risen to the top of the market over the decades, as it has accrued user-driven enhancements all that time.

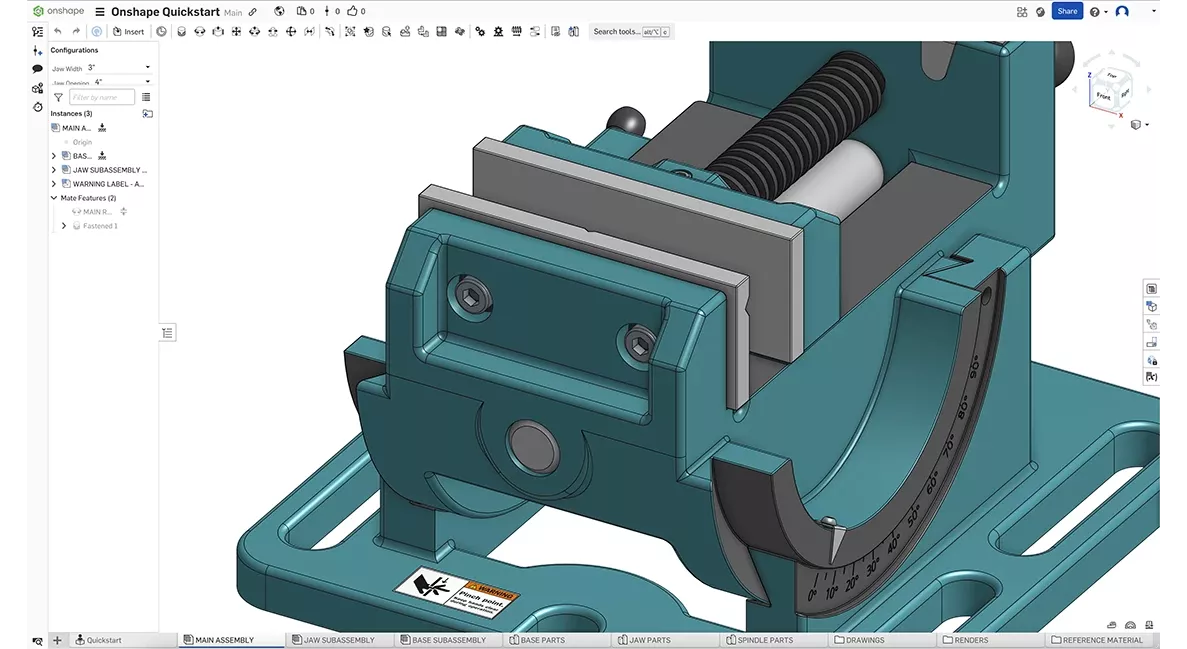

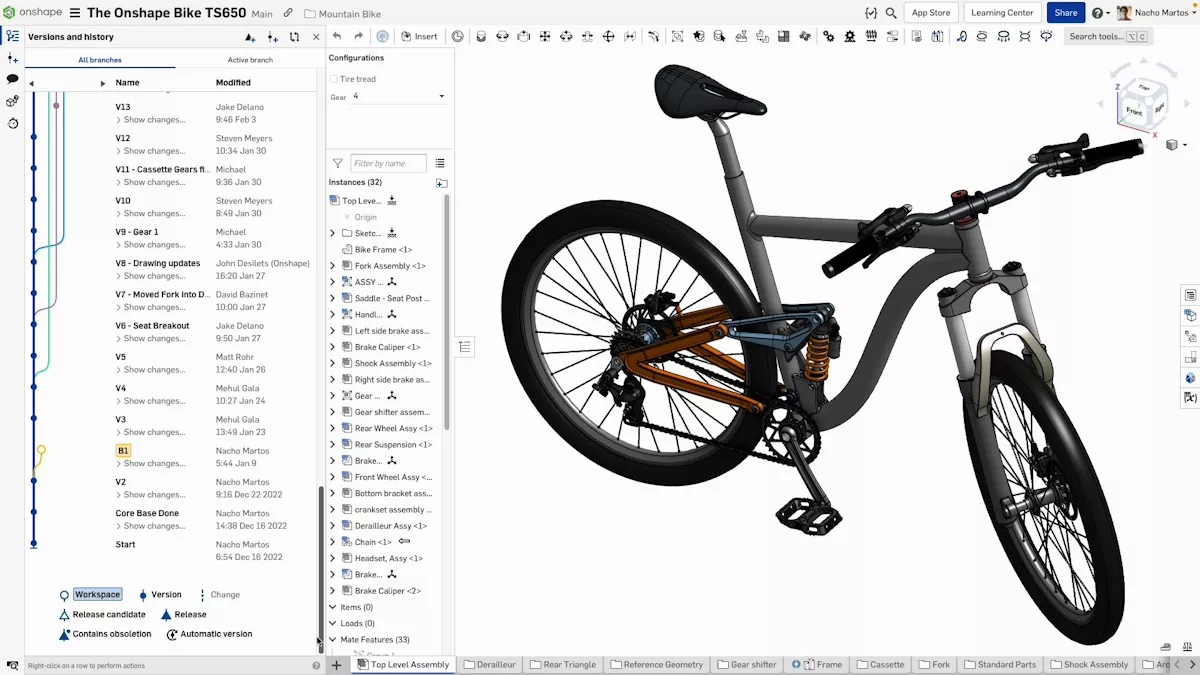

Configuration management in Onshape.

Onshape is on a similar track, with frequent updates in response to customer feedback. As far as the everyday design experience goes, Onshape has a couple of unique features that users enjoy: an unlimited undo buffer and great stability. Regular saving and appropriately configured workstations can minimize issues of this kind with SOLIDWORKS, but these are advantages of Onshape that many users appreciate. Note that Onshape does have performance limitations. It may not run on your local machine, but it does tax its server hardware. Onshape offers tips for how to deal with it. Everyone has a different idea of what a “large” assembly is, so if you’re concerned about the size of your assemblies, it’s worth looking into how both Onshape and SOLIDWORKS do.

In general, they are both very capable tools at core mechanical CAD, though they may go about certain things (like assemblies, for example) in very different ways. Simple personal preference will likely be a large factor. Keep in mind, that gaps in one’s training could give the wrong impression about how good either software is at a particular thing – many comparative CAD discussions end in “you were doing it wrong” after a strongly worded first impression. It’s always best to ask a technical expert about any specific shortcomings that are important to you.

Specialized Design Experience

Beyond the foundational things, SOLIDWORKS has had many years to develop specialized design features and workflows that Onshape does not have yet. The more complex your designs and the farther you stray from core mechanical design, the more likely this will become an issue. Onshape is improving at a quick pace, but for now, SOLIDWORKS has many considerable strengths that may be very important to your organization. Some are so large as to be add-ons or separate programs unto themselves. The list includes but is not limited to:

- Sheet metal: SOLIDWORKS is very strong in sheet metal. There’s a two-day course covering SOLIDWORKS’s extensive capabilities here. Furthermore, Onshape does not support the type of midsurface FEA these types of assemblies require. If something like weld fatigue analysis is required, a sophisticated structural FEA tool (easily available first-party from SOLIDWORKS) will do the trick.

- Electrical: SOLIDWORKS Electrical Schematic and 3D are extremely mature products, separate from mechanical 3D CAD. Onshape doesn’t currently address electrical design.

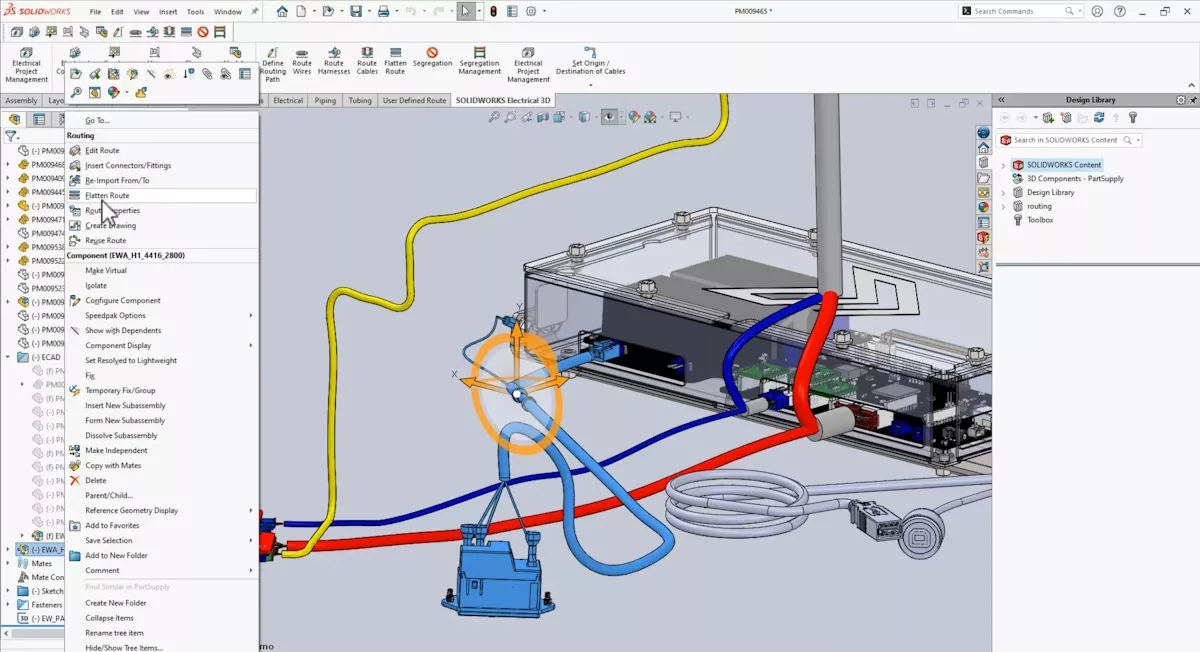

- Routing: Electrical and fluid routing are not natively supported in Onshape, but it may be coming soon. This is natively handled in SOLIDWORKS and has been for a long time.

- Design-for-manufacturing: Onshape’s in-CAD DFM is similar to what SOLIDWORKS has historically offered in this area, but as of this year, SOLIDWORKS now comes with access to the 3DEXPERIENCE Manufacturability Checker app. It provides checks like maximum part size, minimum wall thickness, minimum gap between faces, detection of closed cavity, overhang surfaces, blind hole relief, deep holes, flat bottom holes, through-holes maximum depth, and non-through-holes maximum depth. It has checks for both subtractive and additive manufacturing. Besides CAD and CAM, costly and complex manufacturing processes can be simulated using first-party, nonlinear CAD-associated FEA, typically with Abaqus.

- Technical communications: Onshape is known to have trouble with drawings. SOLIDWORKS has long-standing and well-loved drawing functionality, SOLIDWORKS Composer for easy technical documentation, SOLIDWORKS MBD for model-based definition (3D interactive drawings), and more.

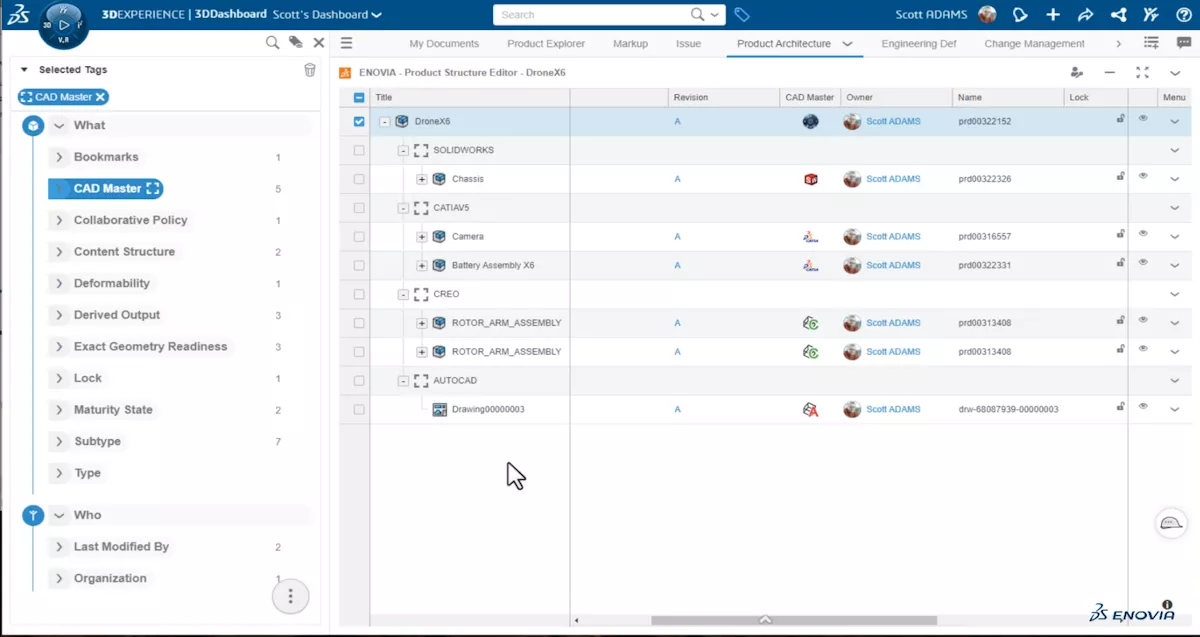

- External design tools: Onshape companies have less freedom to use other design tools when it is advantageous to do so. Leaving Onshape requires old-school CAD exports. In contrast, the 3DEXPERIENCE cloud PDM/PLM platform that comes with SOLIDWORKS is unique in that it has connectors to most competitive CAD and EDA tools, including PTC Creo, Autodesk Inventor and AutoCAD, Siemens NX, Altium Designer, Cadence OrCAD, and more. Designers can pick whatever tool is appropriate for the task and have their native design data managed and controlled in one place, even sharing a product structure. This vastly improves CAD management, product definition, simulation, manufacturing, and other parts of the development process – no broken links in the chain.

SOLIDWORKS’s electrical schematic and routing capabilities are a winning combo.

Because SOLIDWORKS’s cloud PDM/PLM (i.e., the 3DEXPERIENCE Platform) allows for multi-CAD product structures, SOLIDWORKS companies can also easily integrate first-party non-SOLIDWORKS tools for users who need them, chiefly benefitting:

- Large assembly & systems engineering: CATIA is well-known for its handling of extremely large assemblies and integration of systems engineering.

- Surfacing: Dassault Systèmes offers specialized surfacing solutions at two price points with 3D Sculptor and 3DEXPERIENCE CATIA.

- Composite materials: CATIA offers industry-leading composites design and simulation capabilities.

- Complex 3D patterning: 3DEXPERIENCE 3D Pattern Shape Creator is a web-native, node-based 3D CAD tool that enables the easy generation of complex 3D patterns that would be practically impossible by more conventional modeling methods.

- Complex latticing: 3DEXPERIENCE Lattice Designer is a CAD tool that enables the design strong and lightweight parts meant for 3D printing.

You may find specialized design solutions on the Onshape app store, but they will need to be vetted, trialed, (if necessary) purchased, and supported separately. If you can anticipate your future design needs, ask how each software handles them. With Onshape, there is a greater likelihood that your unique needs are in active development or farther down the roadmap. In an ideal situation, all the design functionality you’ll need is already there for you when you need it, minimizing the need for prerelease testing or third-party add-ons.

On-Cloud Design Collaboration

Many users tout the ease of collaboration in Onshape, and they are not wrong to do so. All your CAD data is stored in the cloud and all applications are web-based, so it’s as easy as possible for everyone to review and/or work on a design together. It’s just a matter of account permissions, not computer hardware, software installation, or CAD file transfer.

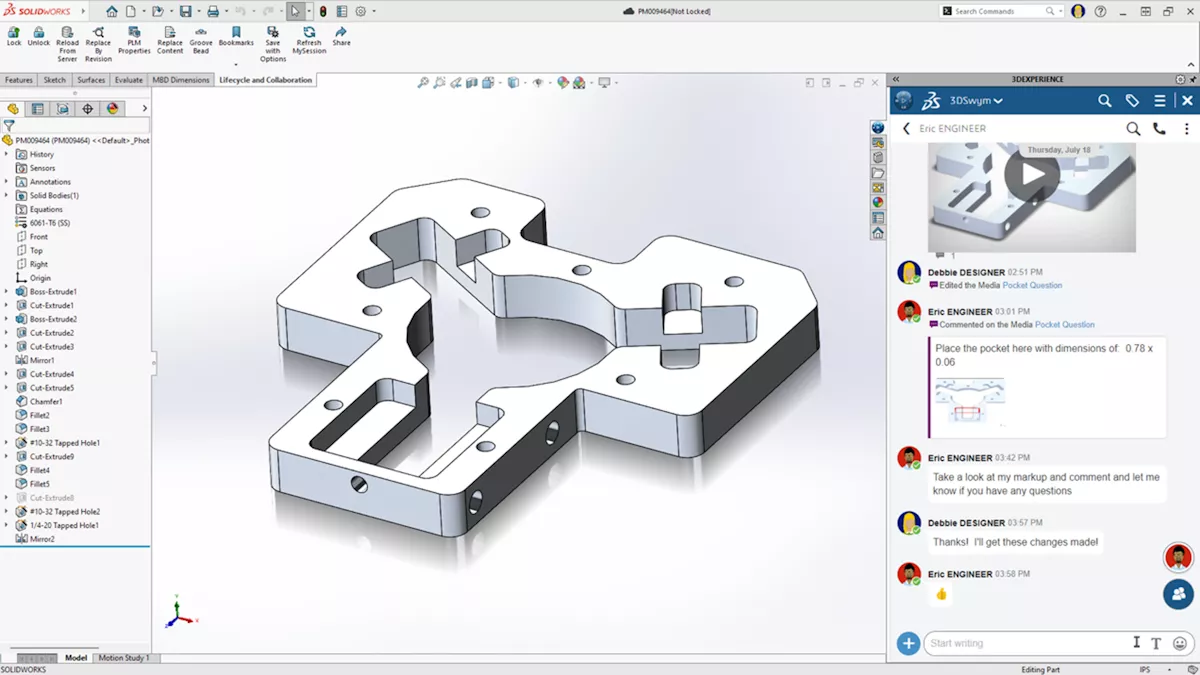

However, this is also true for SOLIDWORKS. All SOLIDWORKS (and CATIA, for that matter) seats, even the traditional desktop versions, come with cloud collaboration tools, often called ”Cloud Services". The user can choose to save their SOLIDWORKS data locally or to the 3DEXPERIENCE PDM cloud. No matter where they choose to keep their data, they can email any stakeholder a link to a web-based CAD viewer, where that stakeholder can review and markup in 3D. That design data is also accessible to other SOLIDWORKS CAD collaborators, from anywhere, as permissions dictate.

Onshape’s version history view and SOLIDWORKS PDM’s release status visualization

Long story short, both Onshape and SOLIDWORKS come with a full-featured cloud PDM system. With Onshape, it is mandatory. SOLIDWORKS users can opt to use traditional SOLIDWORKS PDM, SOLIDWORKS Manage, or no PDM, and save their data wherever they want.

There are a couple other key differences. Onshape allows two people to simultaneously work on the same part in real-time (i.e., you don’t have to lock a part and keep it to yourself while you’re designing). This could be a benefit or a source of confusion. It has built-in versioning and history, some convenient branching and merging functionality, and CAD-associated task management.

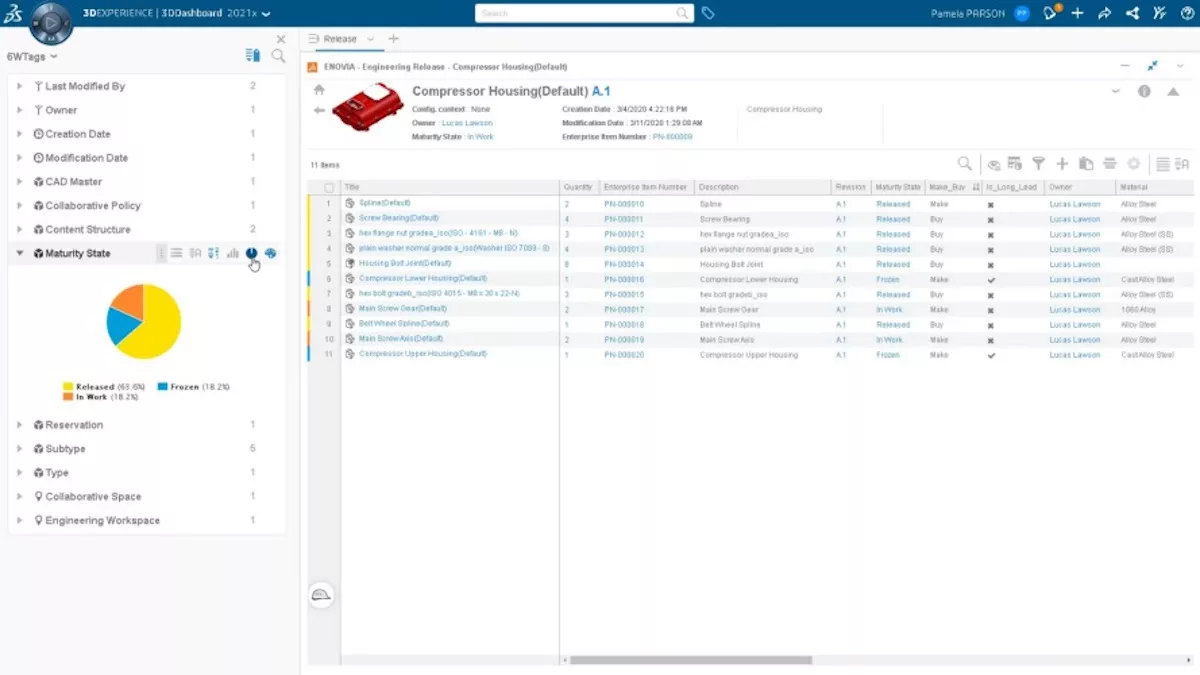

SOLIDWORKS’s included cloud PDM includes change action & issue management capabilities.

SOLIDWORKS retains the typical part lock system to avoid conflicting design activity. Its Cloud Services also provide robust revision management and CAD-associated task management, but also add a complete issue and change management system that anyone can participate in.

Ultimately, Onshape and SOLIDWORKS are comparable in terms of on-cloud CAD collaboration capabilities. Onshape may have an edge in ease-of-use for the designer, but SOLIDWORKS offers more capabilities, such as change management; and, once you move downstream into simulation and manufacturing, only SOLIDWORKS has full-featured first-party tools that will offer native integration and familiar user, vendor, and training experiences. For more sophisticated or challenging product development aspirations, you will find a competitive advantage in more capable tools and more efficient collaboration beyond the CAD team.

Custom & Third-Party Development

SOLIDWORKS and Onshape both offer custom development, Onshape through the higher-level FeatureScript and the Onshape API, and SOLIDWORKS through the SOLIDWORKS API, SOLIDWORKS PDM API, and 3DEXPERIENCE API.

FeatureScript and the SOLIDWORKS API both allow users to develop custom features, add-ons, or macros that can do new things or save time on repetitive tasks. Both Onshape and SOLIDWORKS (and your SOLIDWORKS VAR) offer resources for learning, feedback, and support with custom development.

If your outside-the-box need isn’t too unusual and elaborate, you may find what you need (for either SOLIDWORKS or Onshape) already made by other users on the web, free to download and use yourself.

If you don’t have programming resources or your needs are extensive, in the case of SOLIDWORKS, there is a market for custom development. Such services are offered by GoEngineer, for example. With the maturity of SOLIDWORKS, the market for and professional skills underlying such services have had plenty of time to develop. The Onshape custom development services experience may differ.

While both products’ custom programming languages offer great possibilities, keep in mind that one of the trade-offs with cloud solutions (whether that be Onshape’s CAD and PDM or SOLIDWORKS’ own 3DEXPERIENCE PDM) is that you lose that complete and total freedom to customize. If you expect to customize to the extreme, traditional on-premise SOLIDWORKS is probably the solution for you.

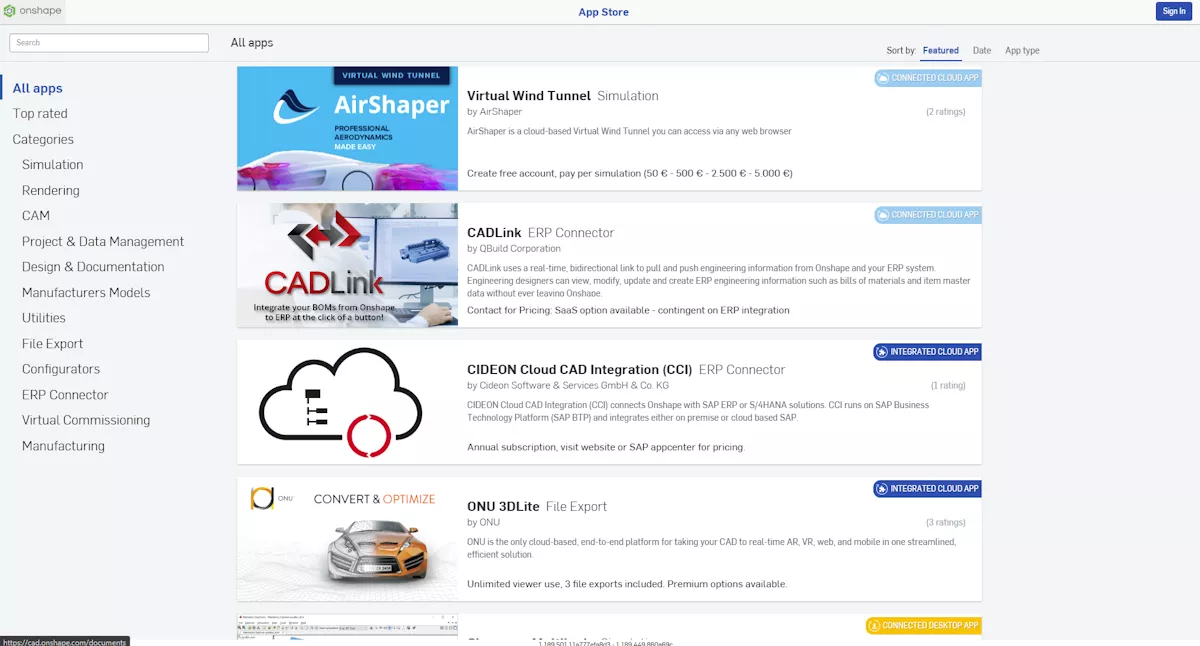

The Onshape store is a mix of cloud and desktop tools, purchased independently of Onshape.

Both Onshape and SOLIDWORKS allow the development and sale of custom software for their products. With Onshape, you will find these products in their App Store, which currently houses 50-60 items. These apps range from fully integrated into the Onshape web app to “connected” desktop software. Take note of what the pricing on these apps may mean for your budget as you scale up seats and capabilities.

SOLIDWORKS seal of a rigorously certified partner product.

SOLIDWORKS has a directory of partner companies where you can see partner hardware and software solutions. A SOLIDWORKS partner product labeled “gold” is software that has been rigorously certified by SOLIDWORKS. Many such products, like DriveWorks and CAMWorks, are well-established enough to have independent VAR relationships alongside SOLIDWORKS.

Onshape’s App Store looks great and offers a convenient shopping experience, but much like the contents of the SOLIDWORKS partner product directory, all products have their own independent pricing, license models, and implementations. With Onshape, you will have an easier time shopping amongst fewer and younger products.

SOLIDWORKS partner products are quite numerous, highly specialized, and generally mature in development, but more traditionally priced. You can be especially confident in any gold-certified ones, though the cost may reflect that.

Support

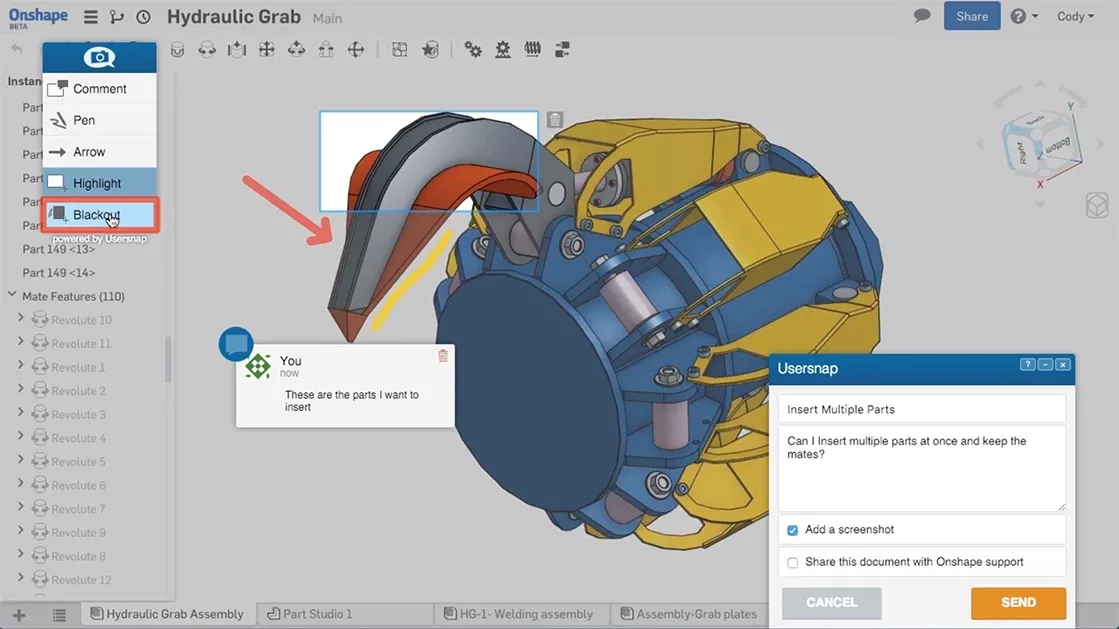

Onshape offers direct support from within the in-app. It is a very streamlined experience that saves time in sharing the necessary data. They respond promptly and receive very satisfactory reviews from customers.

Onshape sports a very convenient in-app support system.

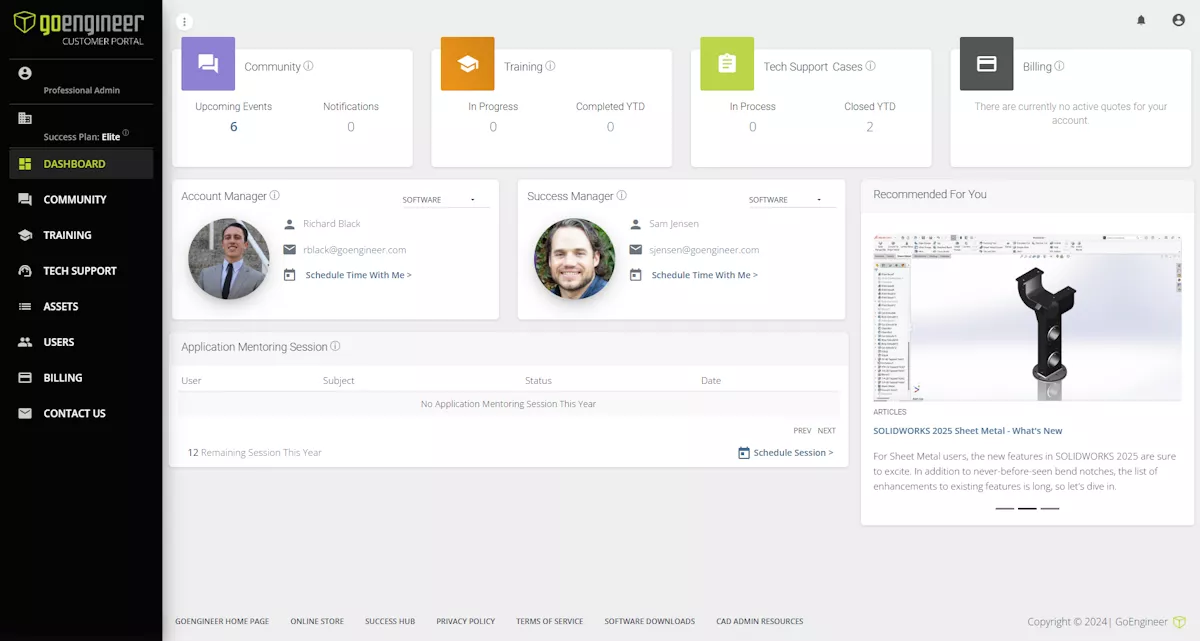

SOLIDWORKS support is given primarily at the partner level, and partners compete for business on quality of service like technical support. GoEngineer SOLIDWORKS customers email their issues, open a ticket and share files on the customer portal, or call in for instant support. Like with Onshape, you will find no shortage of positive endorsements of support.

Every GoEngineer customer has an assigned Success Manager to ensure they’re getting the most out of their SOLIDWORKS investment. From this portal interface, they can also submit SOLIDWORKS support tickets with the associated data.

As with training, GoEngineer offers additional human-centered support offerings to its customers. First, each customer is assigned a Customer Success Manager, whose job is to get to know you and ensure you remain successful. The second is application mentoring sessions, which are one-on-one sessions with a subject expert on a topic of your choice. Customers receive two free sessions yearly.

Both Onshape and SOLIDWORKS (through GoEngineer) provide high-quality support. Onshape will have a more streamlined ticketing experience, while SOLIDWORKS from GoEngineer will offer more human interaction.

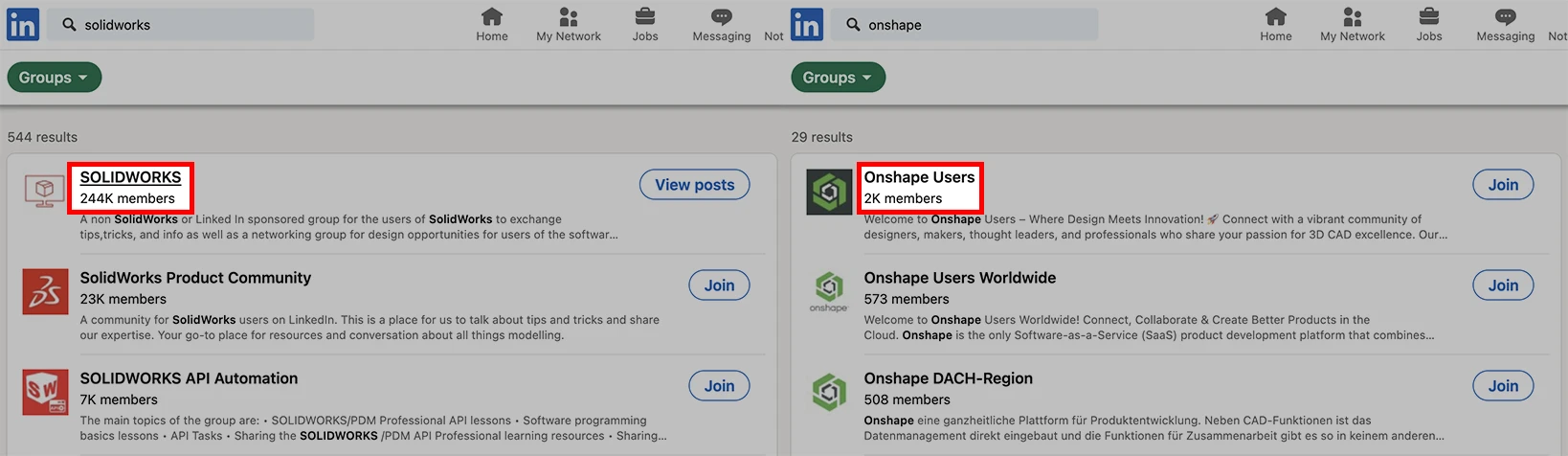

Community & Employment

After decades of leadership in professional and academic markets, the SOLIDWORKS community is as big as it gets in 3D CAD, and it is naturally weighted toward competence. Community size and makeup is a major factor in many companies’ CAD purchasing decision because it affects their hiring pool and training costs. From a user perspective, aspiring professionals who dedicate themselves to a popular tool will improve their opportunities for career growth and mentorship.

The SOLIDWORKS professional community is a great source for professional growth, career opportunities, and talent pool. Onshape doesn't really have this.

Onshape has a growing community, but with its low barrier to entry (i.e., free tier), this community will be weighted toward hobbyists and novices. The importance of this distinction will depend on the difficulty and specialization of the necessary design tasks. It may be relevant to consider other departments’ professional familiarity with a chosen CAD tool as well – collaboration across teams and integration with other systems and tools may be affected.

SOLIDWORKS User Forum is one of many user forums on the 3DEXPERIENCE Platform.

Onshape and SOLIDWORKS each have enthusiastic online communities to connect with both users and developer staff. Onshape has its user forum, while SOLIDWORKS has the GoEngineer user forum and the 3DEXPERIENCE 3DSwym communities (of which SOLIDWORKS is one such community). The Onshape and GoEngineer forums are the traditional forum structure you may be used to. On the other hand, 3DEXPERIENCE 3DSwym Communities take some getting used to, looking more like a social media scroll. 3DSwym Communities segregate subject matter much like subforums traditionally do. You can filter a Community’s scrolling feed by the tags that are applied to individual posts.

For unofficial community on the highly active Reddit platform, there are subreddits for both Onshape (7K users) and SOLIDWORKS (90K users). In terms of in-person networking, Onshape has started to have in-person events and user groups, which have been a tradition for the SOLIDWORKS community for years. You may find SOLIDWORKS support teams, like that of GoEngineer, present at SOLIDWORKS community gatherings giving in-person technical talks.

Section 2

Simulation

| Onshape | SOLIDWORKS & 3DEXPERIENCE (as purchased from GoEngineer) |

|

| Structural FEA |

3rd party solution in the app store |

1st party solutions for all user levels |

| Motion & Kinematic Analysis |

3rd party solution in the app store | 1st party solutions for all user levels |

| Computational Fluid Dynamics |

3rd party solution in the app store | 1st party solutions for all user levels |

| Injection Molding |

Not Available | 1st party solutions for all user levels |

| Electromagnetics |

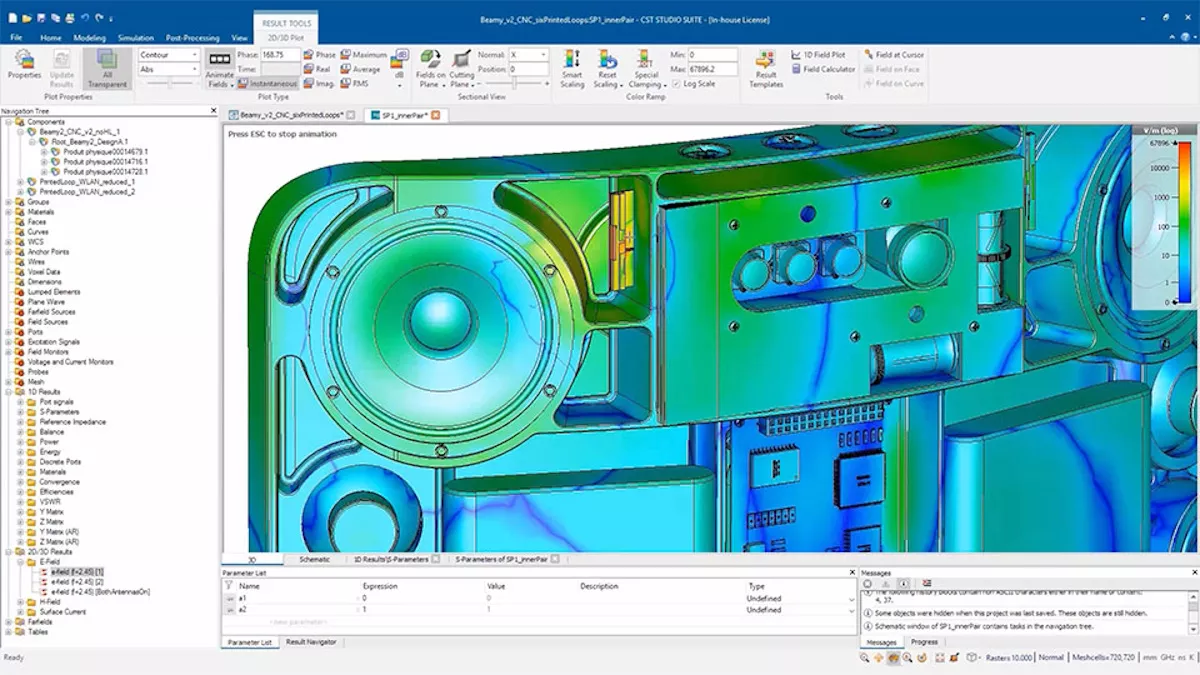

3rd party low-frequency solution in the app store | Advanced 1st party full-spectrum solutions |

| Generative Design | Not available | 1st party solutions for all user levels |

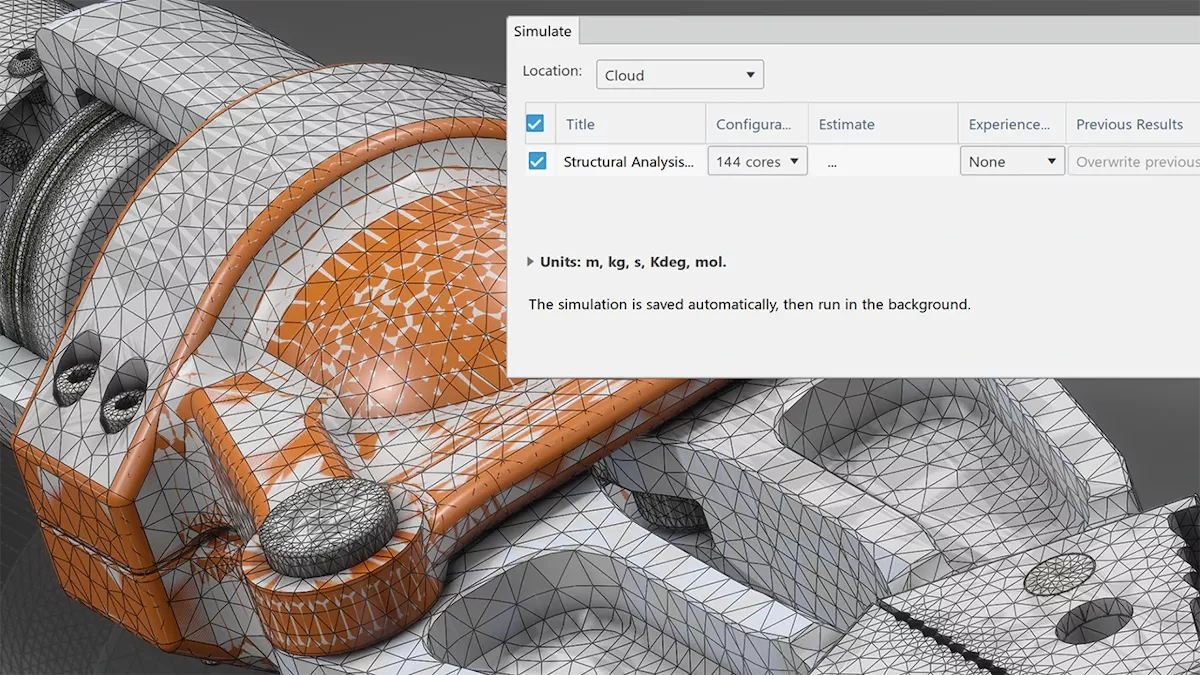

| Cloud Compute | 3rd party solutions usually include cloud compute | Included with 3DEXPERIENCE SIMULATION solutions |

| Support & Consulting | Unknown – varies by vendor | Tech support, training, custom methodology development, project consulting |

First-Party or Third-Party?

Onshape and SOLIDWORKS are known primarily for CAD, but they do offer in-app simulation (to differing degrees), and CAD data can be exported for use in third-party simulation software. Generally speaking, a designer would prefer to enjoy the benefits of first-party simulation as much as possible, only purchasing and developing workflows for third-party tools when necessary.

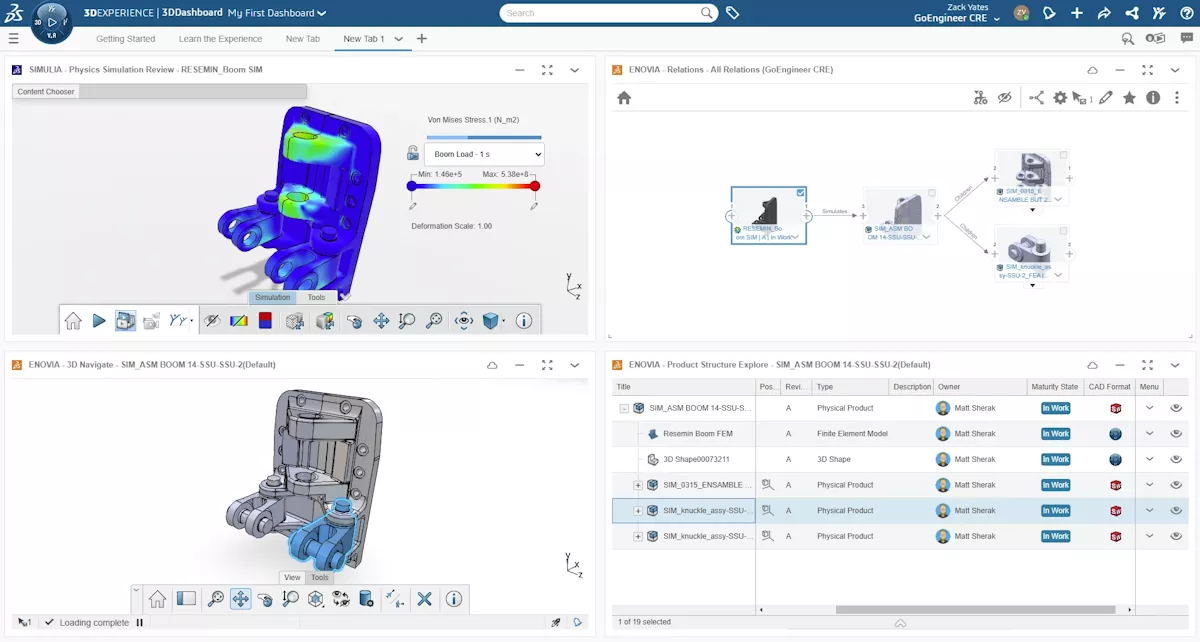

First-party simulation can be deeply integrated with CAD and PDM.

The nature of this preference is that a first-party solution is going to have better access to native CAD data (possibly integrated with the PDM system too), which reduces the opportunity for error (such as analyzing the wrong design and losing track of data and its associations) and labor (such as converting geometry, fixing translation errors, assigning materials and connections, and repeating tedious simulation setups). All of that can take up a lot of time, and those work hours rapidly multiply as you go through different configurations and/or iterations. A shared first-party source for CAD & CAE also opens the door to generative design – direct, automated generation of native CAD in response to simulation results.

SOLIDWORKS Simulation includes both parametric and topology optimization tools that use automated simulation converge on the best design parameters and shapes.

Third-party solutions may enjoy some of the aforementioned features and benefits, but in-house development of CAE tools can maximize integrated functionality, workflow efficiency, consistency in user experience (and training), and product and customer support.

Third-party simulation tools are not to be discounted – they may be very high quality or uniquely specialized – but CAD software companies spend many millions to acquire downstream CAE/CAM developers for a reason: connected solutions make users’ lives a lot easier. Also, for every external analysis tool, you’ll have to do independent research, purchasing, training, and support, so it pays not to rely on too many.

| Onshape (PTC) |

Onshape App Store (Open market) |

SOLIDWORKS (Dassault Systèmes) |

3DEXPERIENCE (Dassault Systèmes) |

|

| Basic Structural FEA | Limited | ✓ (3rd party) | ✓ | ✓ |

| Intermediate Structural FEA | ✗ | ✓ (3rd party) | ✓ | ✓ |

| Advanced Structural FEA | ✗ | ✓ (3rd party) | ✗ | ✓ |

| Multibody Motion | ✗ | ✓ (3rd party) | ✓ | ✓ |

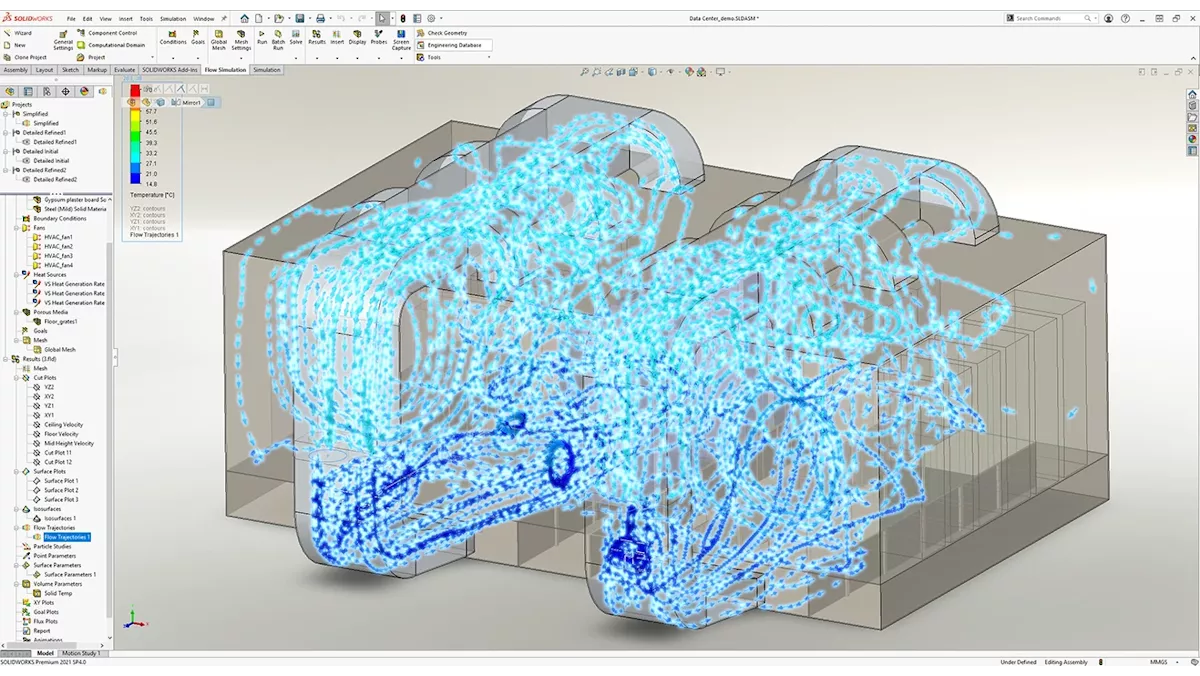

| General CFD | ✗ | ✓ (3rd party) | ✓ | ✓ |

| Injection Molding CFD | ✗ | ✗ | ✓ | ✓ |

| LF Emag | ✗ | ✓ (3rd party) | ✗ | ✓ |

| HF Emag | ✗ | ✗ | ✗ | ✓ |

| Generative Design | ✗ | ✗ | ✓ | ✓ |

| Cloud Compute | ✓ | ✓ (3rd party) | ✗ | ✓ |

A more detailed table of simulation capabilities by physics domain for Onshape and SOLIDWORKS.

Both SOLIDWORKS and Onshape can export neutral geometry for use in completely external simulation tools, so as we compare simulation capabilities, we compare what is available with either partial or total CAD integration, knowing this brings many benefits to purchasing, training, collaboration, accessibility, and efficiency.

Basic & Intermediate Simulation

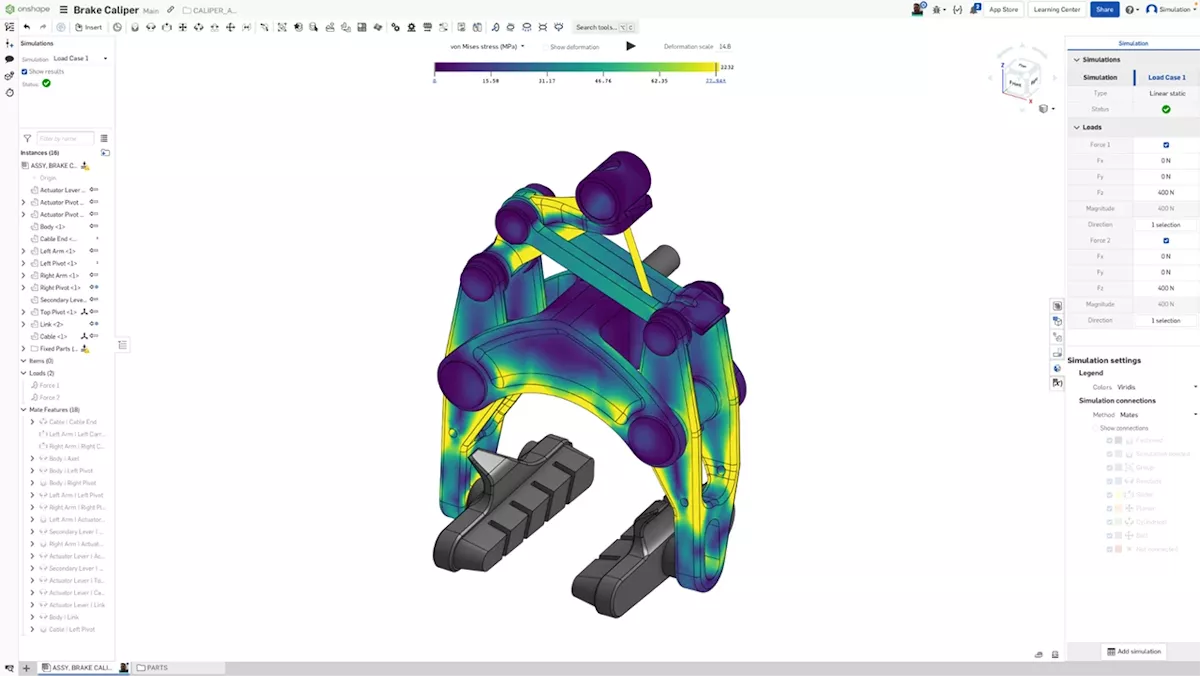

Onshape does limited structural simulation. CFD is a routine SOLIDWORKS simulation capability.

Onshape cannot compete with SOLIDWORKS in simulation. Its on-board simulation tool has a very specific and limited application: if your assembly falls within its geometric criteria (parts mustn’t be too thin and contact interactions must be simple), Onshape can locate stress hotspots and do some modal analysis. Anything more would be out of bounds. In other words, Onshape does not have a numerically accurate, general-purpose tool for linear static or any other type of FEA, making it an unlikely choice for simulation in production.

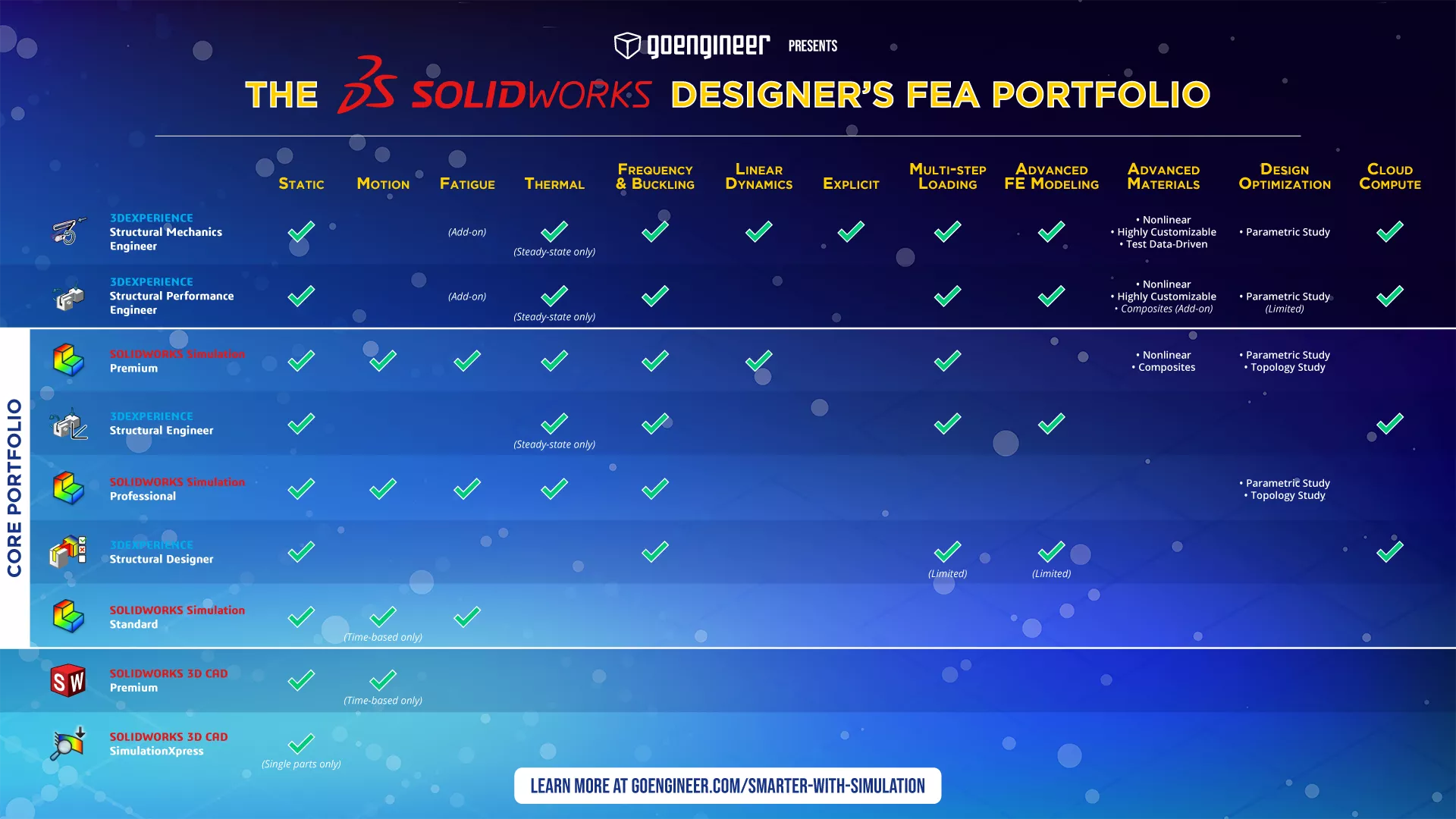

These are the first-party structural FEA solutions for SOLIDWORKS users. They start at zero cost and scale up to enterprise.

SOLIDWORKS provides general-purpose structural FEA as a baseline, with none of the above limitations – it is part of the 3D CAD Premium package and uses the COSMOS FEA solver (developed by Structural Research and Analysis Corporation from the 1980s till acquisition in 2000). For intermediate capabilities, the SOLIDWORKS Simulation portfolio (purchased separately from 3D CAD) provides nonlinear static FEA, frequency, fatigue, linear dynamics, specialized virtual tests, general-purpose CFD, injection molding CFD, simulation-based design optimization, etc. Everything is contained within the 3D CAD interface and runs on the local machine.

Many times, the loads for structural analysis need to be derived from motion analysis. There are tools from PRINCIPIA (cloud-based) and MathWorks (desktop) in the Onshape app store to accomplish this. They have their own separate pricing. SOLIDWORKS offers easy-to-setup motion analysis within their Simulation packages.

Between SOLIDWORKS and Onshape, SOLIDWORKS is the easier choice for basic or intermediate simulation. The SOLIDWORKS Simulation tools are very popular and users can grow into their wide range of capabilities over time. The fact that they’re inside the 3D CAD UI maximizes their usability. Competitive functionality in Onshape will come from one of two sources:

- Integrated third parties in the app store – Altair SIMSOLID Cloud and SimScale are popular solutions. See how their strengths and weaknesses align with your needs and budget. For example, SIMSOLID Cloud can be much faster than traditional FEA to set up and solve, but has model size/solve time limitations and is missing some fairly standard capabilities. SIMSOLID runs in the Onshape interface while SimScale pulls Onshape data into its own separate interface.

- Completely external solutions – Abaqus, Nastran, Optistruct, etc. Naturally, these tools are available to SOLIDWORKS as well. They tend to cost more than CAD-integrated solutions but offer more advanced capabilities.

Advanced Simulation

For nonlinear static FEA, explicit dynamic analysis, high-frequency electromagnetic simulation, multiphysics workflows, HPC-level cloud compute, process automation, and other top-end simulation technologies, the SOLIDWORKS ecosystem can integrate 3DEXPERIENCE SIMULATION. 3DEXPERIENCE SIMULATION is a parallel first-party portfolio that, while traditionally targeted toward enterprise, it is now available (both in price and native CAD/PLM integration) for SOLIDWORKS users. The upper range of SOLIDWORKS Simulation overlaps with 3DEXPERIENCE SIMULATION’s middle range, and then 3DEXPERIENCE goes further for bigger and more sophisticated analysis. All of the 3DEXPERIENCE SIMULATION portfolio is powered by solvers with decades of industry acceptance, such as Abaqus and CST Studio Suite.

3DEXPERIENCE SIMULATION solutions can access substantial cloud compute resources and cover electromagnetics in addition to structural and fluid physics.

Onshape does not offer advanced FEA, any kind of CFD, or electromagnetics simulation. To do intermediate to advanced structural FEA and CFD, Onshape users will need to look to the app store for the aforementioned SimScale, a cloud-based simulation platform that has an Onshape CAD importer. SimScale has been well received by the industry for its capabilities and usability; pricing is not publicly disclosed. However, it lacks high-frequency electromagnetics (antennas, PCBs, etc.). Here, Onshape users will need to work with a third-party desktop tool like CST Studio Suite.

For advanced simulation, the SOLIDWORKS ecosystem still has an edge through the first-party 3DEXPERIENCE SIMULATION tools. This is because of the Abaqus solver (which is well known for its user control and accuracy in extreme scenarios) and a more substantial first-party CAD/PLM integration. It is also the only source for electromagnetic simulation, generative design, and process automation. Onshape users will likely have an easier time getting started with SimScale, but the functional advantages of 3DEXPERIENCE SIMULATION (which do include cloud HPC compute) will serve heavy users very well.

The Support & Consulting Advantage

With simulation for Onshape consisting of third-party offerings, the quality and extent of simulation support is going to vary by vendor.

With SOLIDWORKS and 3DEXPERIENCE simulation from GoEngineer, one of the major benefits is that GoEngineer has a simulation consulting team in addition to the standard SOLIDWORKS software support team. These consultants not only provide advanced tech support, but they also offer full project consulting services and custom methodology development and training for the FEA software you’ve purchased.

It is hard to make a case for Onshape if simulation is important to your product development. The SOLIDWORKS and 3DEXPERIENCE product ecosystem offers complete physics coverage and serves all levels of simulation usage, with the added security of a supporting consulting team (if GoEngineer is your SOLIDWORKS reseller).

Section 3

Manufacturing

| Onshape | SOLIDWORKS & 3DEXPERIENCE (as purchased from GoEngineer) |

|

| CAM (NC Programming) |

|

|

| Additive Programming | Third-party (printer OEM & others) solution market is strong |

|

| Manufacturing Process Simulation | May be possible through third-party tools | Often accomplished with Abaqus and SOLIDWORKS Plastics. |

| Virtual Factory | Limited third-party solution in the app store | First-party solutions for robot programming, factory layout, factory flow simulation, etc. |

Computer-Aided Manufacturing (CAM)

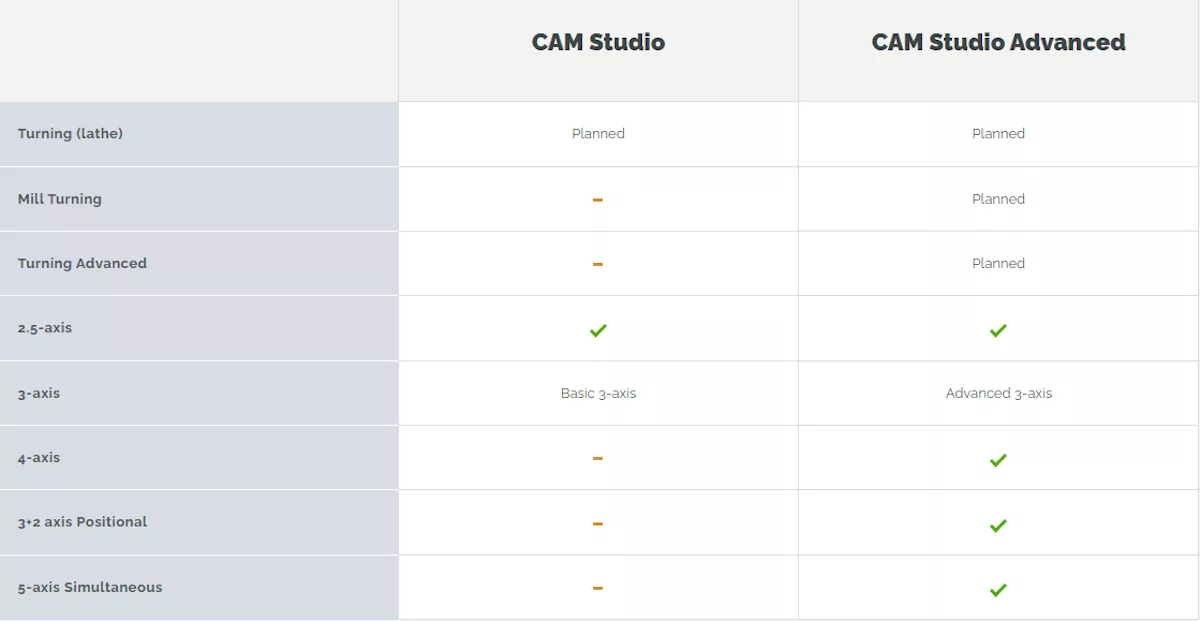

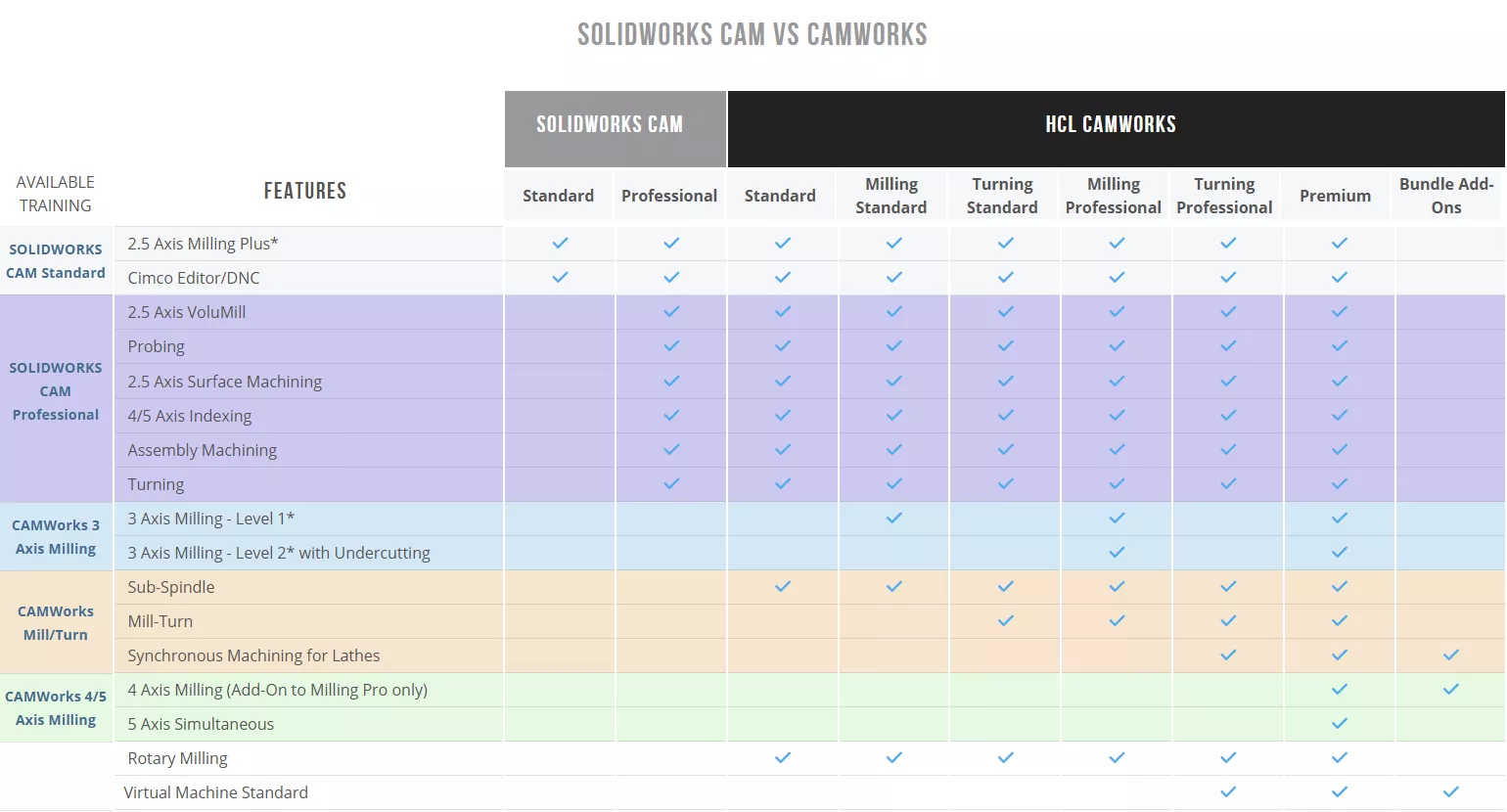

CAD-associated NC programming and simulation can be a game-changer for efficiency between design and manufacturing teams. It's no surprise that both Onshape and SOLIDWORKS offer (or intend to offer) user-friendly CAM with any paid license. Onshape's CAM solution recently entered open beta and provides basic 3-axis milling. You can get an idea of how they plan to grow the tool in their product matrix below.

Feature matrix for Onshape’s upcoming in-house CAM solution

For Onshape users who need full CAM capabilities right now, SprutCAM, ESPRIT, and MasterCAM have developed CAD-linked add-ons for their programs. The CAM user will need a Windows PC to run these popular CAM tools, preferably using a workstation GPU.

Feature matrix for CAM tools inside the SOLIDWORKS UI

The first-party SOLIDWORKS CAM Standard comes with any active SOLIDWORKS subscription, and it is upgradable to CAM Professional, followed by HCL CAMWorks proper. (HCL, the SOLIDWORKS gold partner, is actually responsible for SOLIDWORKS CAM, so there is total continuity from there into CAMWorks.) It all happens within the SOLIDWORKS UI and saves to the CAD files.

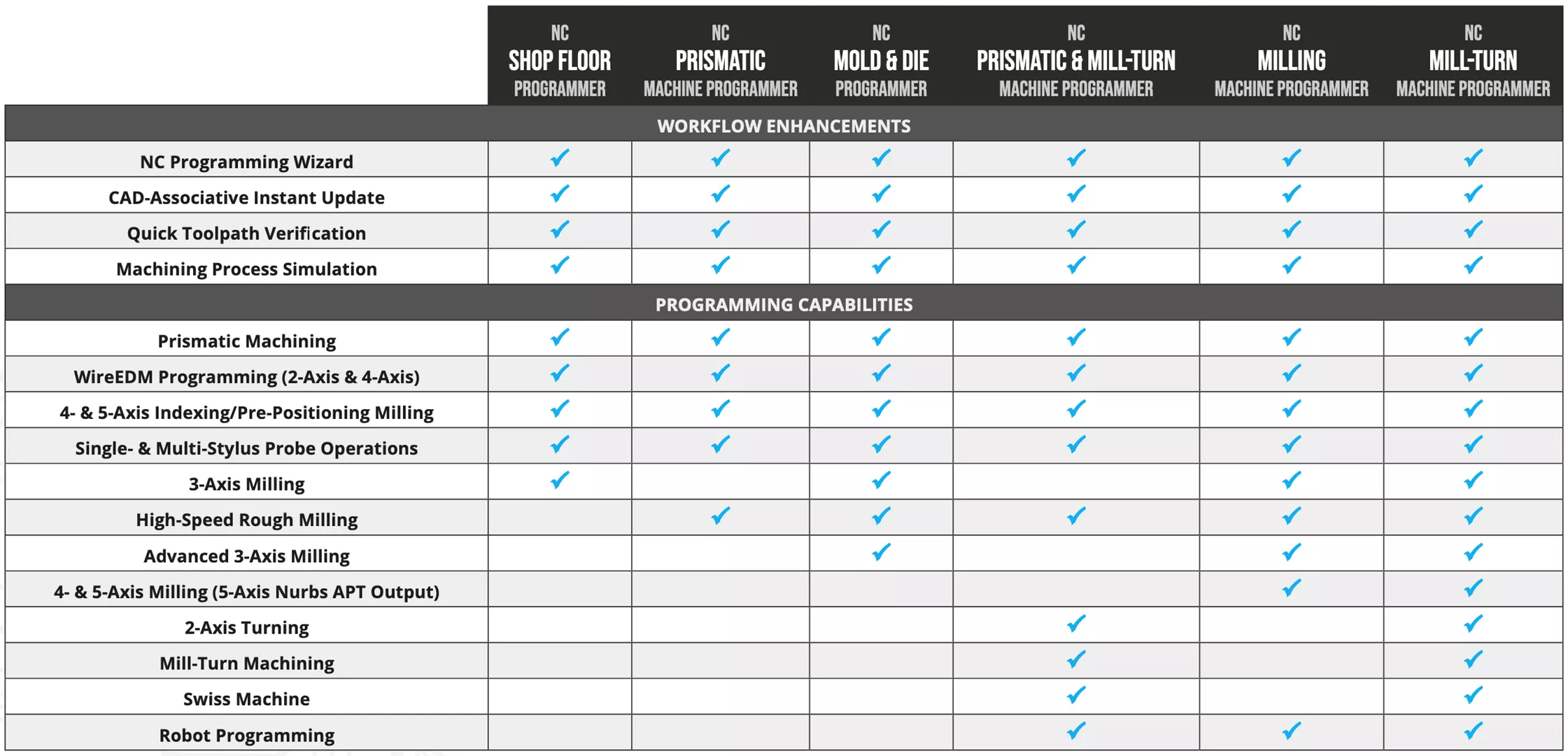

Feature matrix for 3DEXPERIENCE CAM tools, which are first-party to SOLIDWORKS but in the 3DEXPERIENCE interface

As with simulation, 3DEXPERIENCE -- the other first-party brand -- has solutions for SOLIDWORKS users as well. The 3DEXPERIENCE NC PROGRAMMING portfolio provides advanced NC programming and simulation. 3DEXPERIENCE’s capabilities overlap with SOLIDWORKS CAM and CAMWorks but then grow beyond at the high end. The first tier of this product line, NC Shop Floor Programmer, comes free with all new purchases of SOLIDWORKS 3D CAD.

If you need CAD-integrated CAM capabilities today, both SOLIDWORKS and Onshape offer built-in CAM, but Onshape is currently in limited beta while SOLIDWORKS offers a wide array of capabilities. Both brands can work with third-party desktop CAM solutions, but there are many drawbacks to that:

- Third-party CAM will have to be researched, purchased, and implemented separately; Onshape makes this a little easier by aggregating several popular CAM tools onto their app store.

- The Onshape app store’s CAM tools are desktop apps with separate licensing.

- A “connector” for a CAM tool could mean many things – is it basically a one-time file importer? Does it automatically or manually update the toolpath when the CAD is updated? Will it warn you if toolpaths are out of date after design changes?

- Your CAM data may not be stored and managed alongside your CAD data.

- Higher risk that a developer may drop support for a connector.

Additive Manufacturing

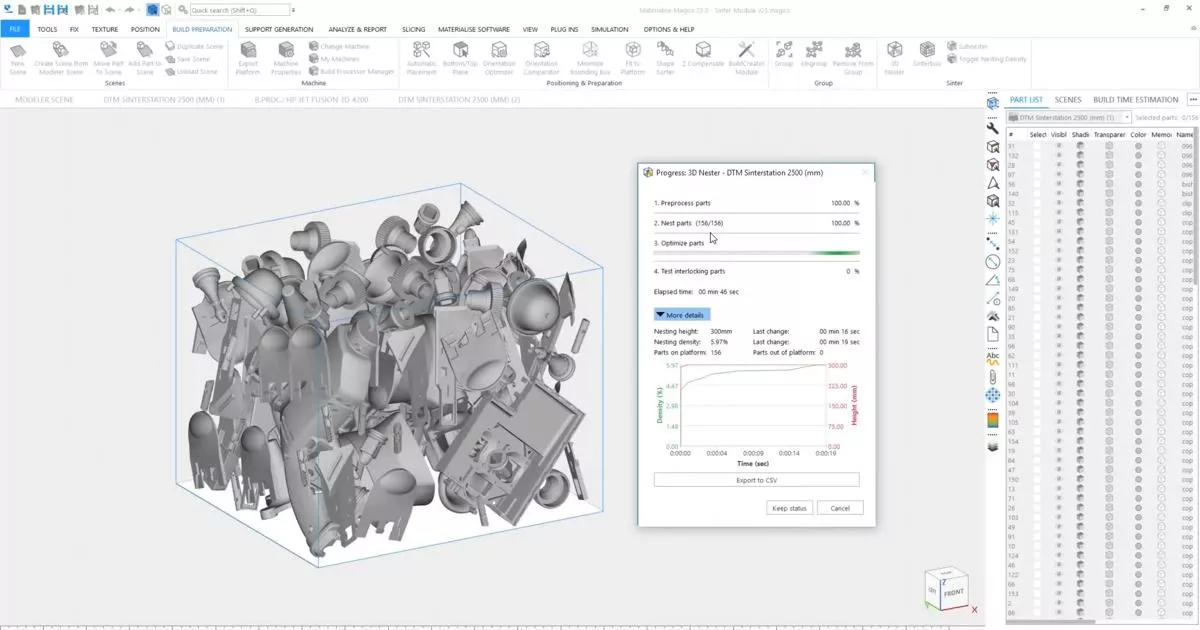

3D printing build preparation with Materialise Magics.

Those wishing to 3D print their designs usually find print software outside of their design software ecosystem. Hobbyists have many options to choose from while professionals have fewer, on account of the sophistication of the machines involved and the capabilities required. For business needs, 3D printing software typically comes from the printer manufacturer or a third party like Materialise, making it less of a CAD choice issue. SOLIDWORKS users do have a first-party option in the form of 3DEXPERIENCE ADDITIVE MANUFACTURING, which does print programming, sophisticated print simulation (based on the Abaqus solver), and is CAD/PLM-integrated.

Manufacturing Process Simulation

Besides NC programming, other manufacturing processes such as plastic injection molding, 3D printing, welding, and machine handling & assembly can be simulated to ensure designs are viable and manufacturing methods are optimal. Many of these simulations are actually advanced FEA tasks because they are very sensitive to accurate contact behavior; materials must behave true-to-life under temperature change, time dependency, and other complicating factors; and loading scenarios may be complex and multistep.

By simulating the injection molding process and then vessel pressurization with 3DEXPERIENCE SIMULATION, the designer reveals a catastrophic failure mode at the weld line at 1250psi. They need to change the gate location.

Such simulations require an analyst using 3DEXPERIENCE SIMULATION or third-party desktop FEA/CFD applications. A fully CAD/PLM-integrated solution like the 3DEXPERIENCE SIMULATION portfolio will help the analyst focus more on their high-value work and less on data handling, translation, preparation, etc.

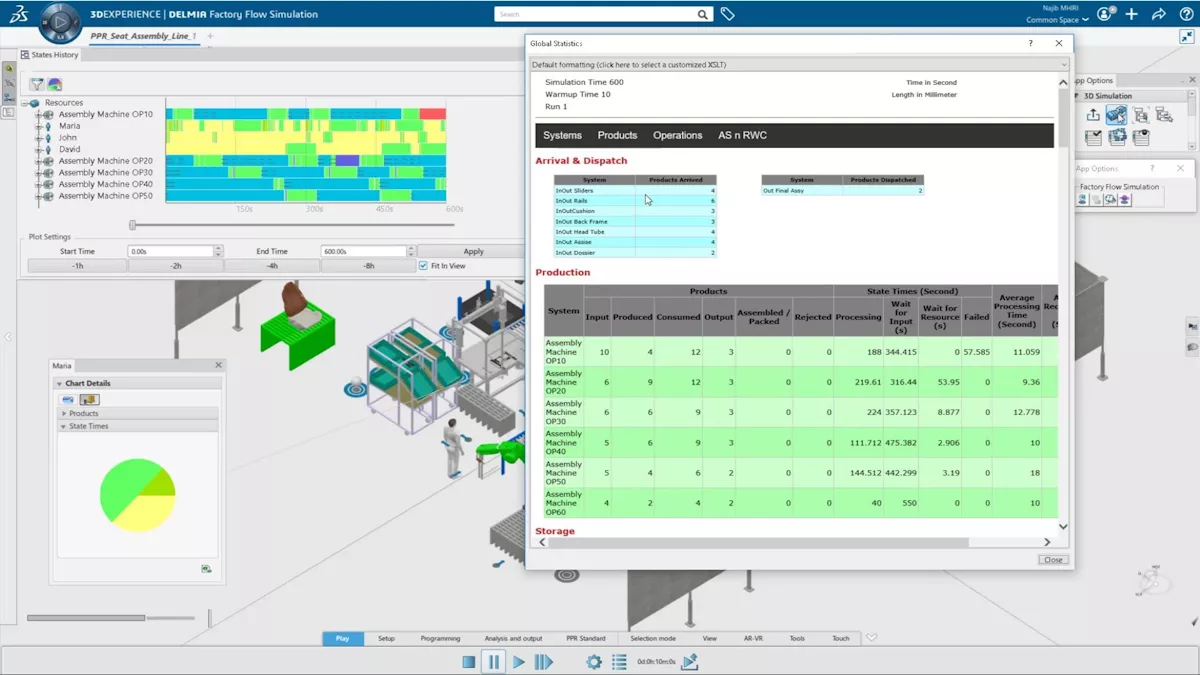

Virtual Factory

One of the most exciting new areas of manufacturing software is “virtual twin” and “virtual factory” technology. This is the complete modeling of factory layouts, equipment and staff behavior, and material flow – a digital twin of a real facility that can be analyzed and optimized at much lower cost than the real thing.

Virtual commissioning is one component of factory operations simulation.

Onshape partially covers this capability with the third-party apps in the virtual commissioning section of its app store, but virtual factory is a larger topic than this. You can get a more complete picture by reviewing the SOLIDWORKS company’s 3DEXPERIENCE VIRTUAL FACTORY offering. This page details the many additional software components required to build a complete and functional virtual factory. That said, a virtual factory can be built up one step at a time, starting with something like robot programming before moving on to simulating factory flow, worker behavior, factory layout, and more. Unique to 3DEXPERIENCE, existing facilities can be 3D scanned as a starting point for your virtual factory.

As always, a first-party solution ensures the best compatibility, deeper and more robust integrations, simpler purchasing, and better chances of product longevity.

Onshape and SOLIDWORKS both have access to some virtual factory capability, but SOLIDWORKS alone has access to a first-party suite of factory programming and simulation software with the holistic end point in mind – the fully-representative “virtual factory”.

Section 4

Data, Platform, and Collaboration

| Onshape | SOLIDWORKS & 3DEXPERIENCE (as purchased from GoEngineer) |

|

| Data Management Options |

|

|

| As an Integrated “Platform” |

|

|

| Multi-CAD Collaboration |

|

|

| Product Lifecycle Management (PLM) |

|

|

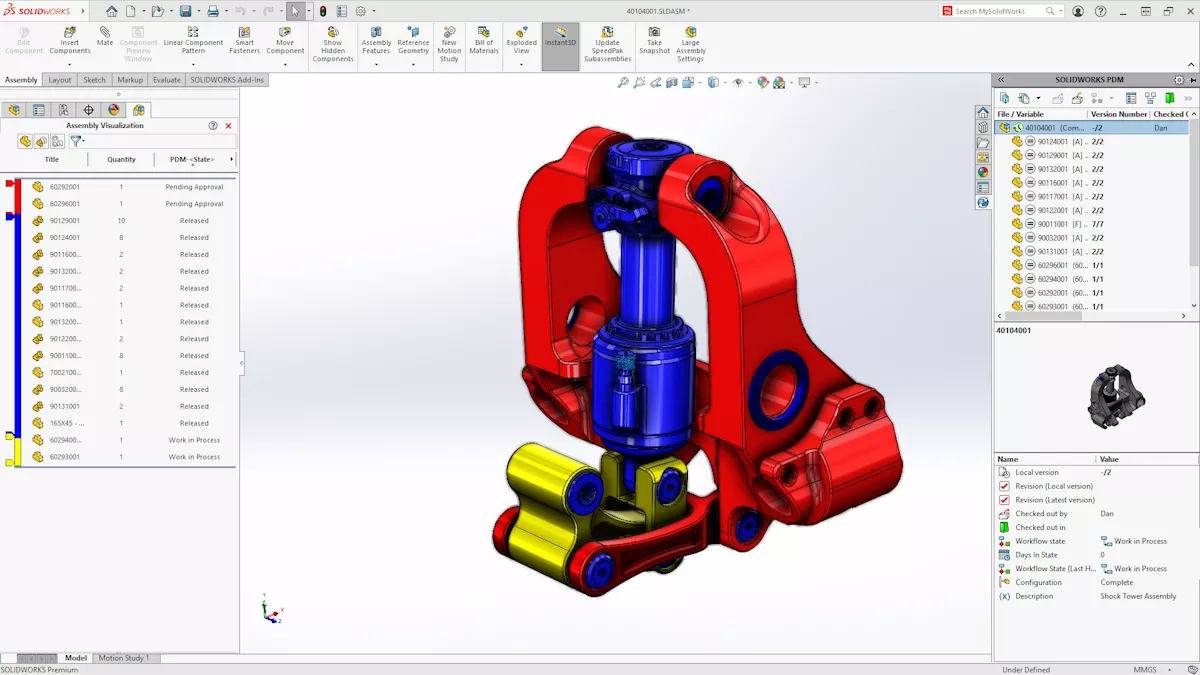

When it comes to data and lifecycle management with Onshape and SOLIDWORKS, there are actually three options: Onshape, SOLIDWORKS, and 3DEXPERIENCE. As previously discussed, 3DEXPERIENCE is essentially the official cloud for SOLIDWORKS. A seat of 3DEXPERIENCE cloud PDM comes free with each new SOLIDWORKS 3D CAD purchase.

Choosing a Data Management Option

Onshape’s cloud-based PDM system is excellent at what it does, but it’s the only way for an Onshape designer to handle their data. It is included at no additional cost, but there is no on-premise or self-hosted cloud option. Native data resides on Onshape’s servers and cannot be retrieved and stored elsewhere in its original form. It can be exported in neutral CAD formats and in SOLIDWORKS format. The completeness and quality of a SOLIDWORKS export from Onshape (or any other CAD software) is something that would need to be verified.

Engineers communicating using SOLIDWORKS’ included cloud PDM tools.

SOLIDWORKS users have three options:

- No PDM system: By just using files on the workstation, an individual user or small team can keep things as simple as possible, retaining full ownership and readability of files. However, it doesn’t take much growth of operations for the simplicity and lack of strict organization to become limiting.

- SOLIDWORKS PDM: A paid option that requires a well-planned and executed implementation, SOLIDWORKS PDM retains an on-premise nature, allowing total ownership and control of company data. It comes with both responsibilities (such as security and redundancy) and autonomy (customization and total oversight/compliance).

- 3DEXPERIENCE PDM: Interestingly, for SOLIDWORKS (and CATIA V5) customers, this option is included with new purchases at no additional charge. It is a cloud option that shares all the benefits and drawbacks of Onshape PDM, except that design data can leave the 3DEXPERIENCE cloud in its native format as loose files for offline CAD software.

About Product Development Platforms

Onshape is not just a CAD software – it’s a product development platform. Are you evaluating it as one?

Both Onshape and SOLIDWORKS (and 3DEXPERIENCE) describe themselves as “product development platforms”, and there’s a good reason for this: in concept, a single platform for your value chain functions much better than a patchwork of components from different sources. A unified platform should improve the quality and accessibility of data, simplify and enable new processes, reduce labor in reconciling and managing disparate sources, and simplify and speed up training. The ultimate result should be improved decision-making, faster development, and increased product quality.

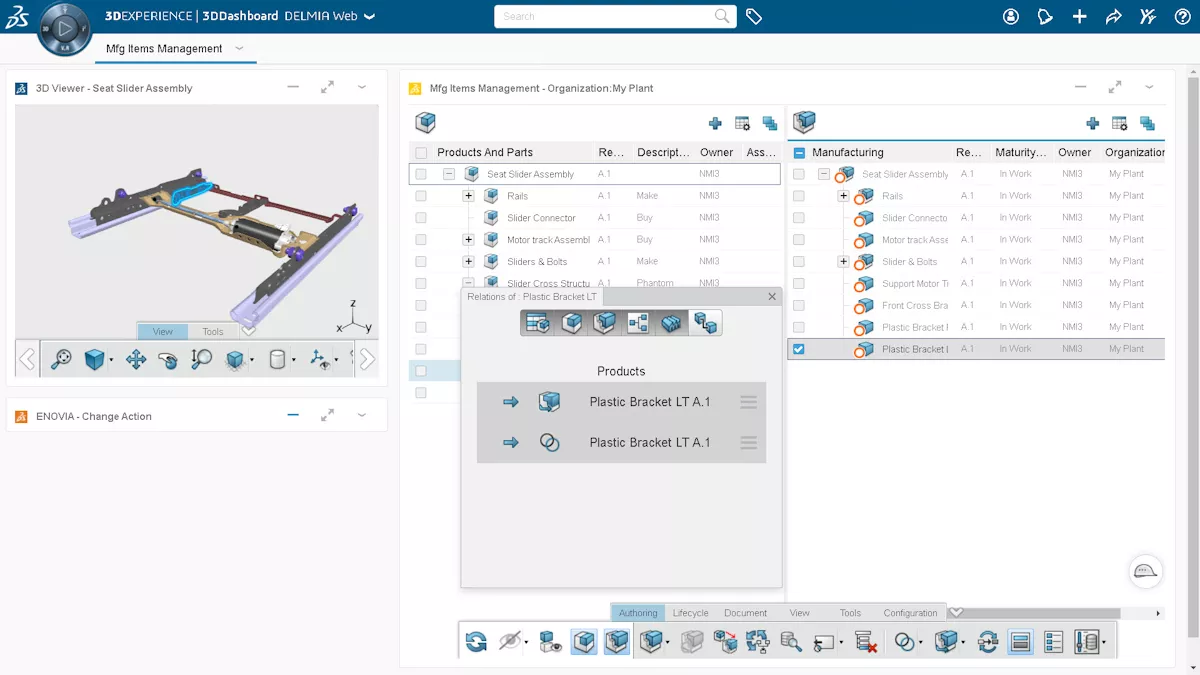

Expansion of platform coverage is a major priority for Dassault Systèmes, particularly in 3DEXPERIENCE (as opposed to SOLIDWORKS, whose file-based nature is limiting in this regard). You can see this in the capabilities of their simulation, manufacturing, and management tools, only the last of which Onshape is competing in.

Onshape splits development resources between the dual priorities of its base CAD tool and the expansion of its platform. While they are making good progress, SOLIDWORKS (and other competitors) have had quite a head start.

Managing the manufacturing BOM after engineering changes with 3DEXPERIENCE.

Many businesses aren’t ready or don’t need to go beyond CAD and may be comfortable without (or with waiting for Onshape to develop further). Businesses that do need platform integration downstream of CAD into CAE, CAM, PLM, etc., will find a great deal of what they need is already available with SOLIDWORKS and 3DEXPERIENCE.

Multi-CAD Collaboration

3DEXPERIENCE does something that neither Onshape nor SOLIDWORKS PDM does, and that is to allow multi-CAD product structures. 3DEXPERIENCE offers “connector” add-ins for SOLIDWORKS, CATIA, Inventor, NX, and many other CAD tools. They bring design data into the 3DEXPERIENCE format where they can share an assembly. That complete product structure is available to 3D CAD viewers, BOM management, change management, simulation, manufacturing, and more. All geometry must be edited in its native application. When one CAD tool simply doesn’t suffice, this functionality can help.

The product structure indicates which CAD authoring tools were used for various parts and assemblies, here SOLIDWORKS, CATIA, Creo, and AutoCAD. The full product can be viewed in 3D in the web browser.

Onshape and SOLIDWORKS can both import a variety of CAD formats, but product structure and version history are restricted to the native format. Fully PLM-integrated multi-CAD functionality could solve a serious efficiency issue for some companies.

Product Lifecycle Management (PLM)

| Product Data Management (PDM) | Product Lifecycle Management (PLM) | |

| Scope | Design & engineering phases | All phases of product lifecycle from conception to retirement |

| Primary Function | Centralize, organize, and manage product design & engineering data | Integrate people, data, processes, and business systems across the entire organization |

| Typical Features | Data storage & organization, access control, version control, design collaboration tools | Lifecycle stage management, change & configuration management, BOM management, compliance & reporting, interdepartmental collaboration tools, supplier & customer integration, automation, digital thread/twin support |

| Integrations | Focused on CAD tools | Possibly includes ERP, MES, SCM, QMS, CRM, and more |

| Implementation & Training | The focused scope and smaller user base make it faster and easier to adopt | The broad scope means more systems to integrate, more licenses to purchase, and more training on more diverse functionalities |

| Budget | Lower, possibly free with CAD purchase. Paid training or implementation help may still be wise | Tens to hundreds of thousands for initial setup and first year of operation. Cloud solutions can dramatically reduce this cost |

| Benefits | Reduced error & rework in design, better control of sensitive data, more efficient change process | Better decision making through visibility, better collaboration across all teams, better innovation, quality, and compliance, shorter time-to-market, cost control & risk mitigation |

| Examples | SOLIDWORKS PDM, 3DEXPERIENCE CLOUD PDM, Onshape | SOLIDWORKS Manage, 3DEXPERIENCE CLOUD PLM, Arena PLM |

Most companies using Onshape and SOLIDWORKS are not prime candidates for product lifecycle management software. PDM, which is widely considered a subset of PLM, is usually sufficient. However, many Onshape and SOLIDWORKS companies are large enough to need PLM, and others would be wise to plan in such a way that PLM will be easier to implement in the future.

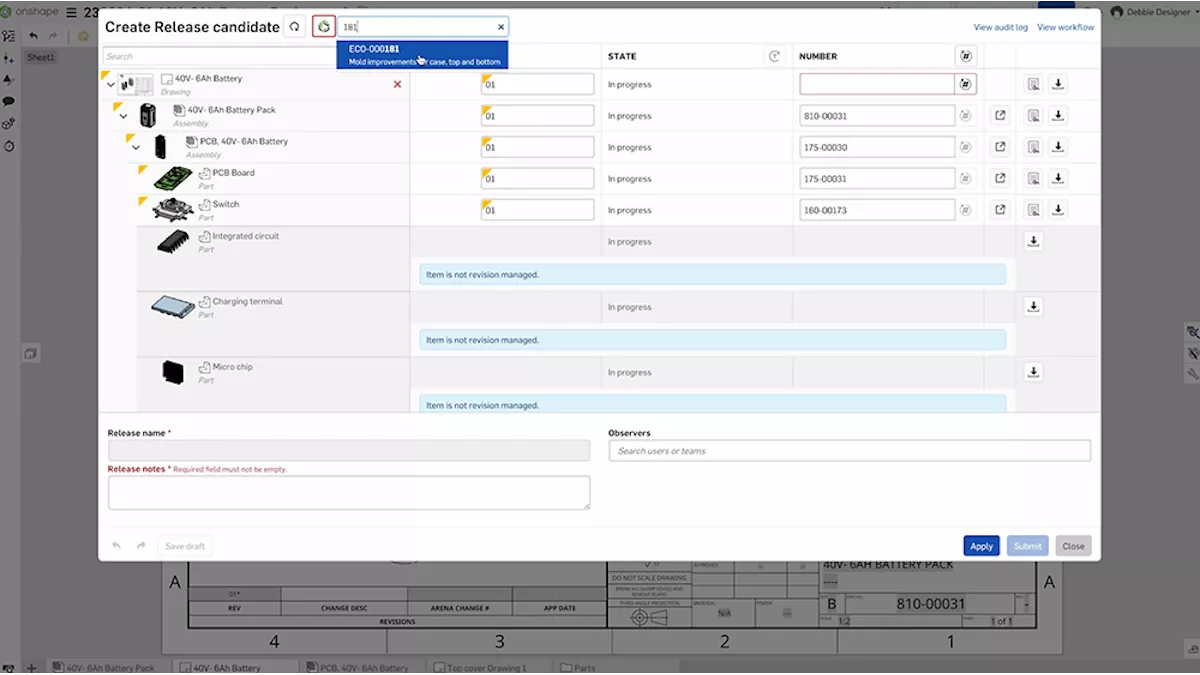

Product release management with Arena PLM and 3DEXPERIENCE PLM

No article can provide a sufficient comparison of PLM solutions – it requires detailed conversations with expert representatives of every solution in consideration. However, these are the in-house options for Onshape and SOLIDWORKS:

- Arena PLM is the first-party cloud PLM solution to pair with Onshape. Both tools are owned by PTC. As an Onshape integration, Arena PLM focuses on real-time design data, BOM, drawing and STEP export, change and release management, and supply chain info, with all the benefits and drawbacks of cloud solutions.

- SOLIDWORKS Manage offers small- to mid-market on-premise PLM with the closest possible integration with SOLIDWORKS. It focuses on BOM, document and item master management, change and project management, and business intelligence. It is a very powerful tool, but it will take more to implement and maintain than a cloud solution.

- 3DEXPERIENCE CLOUD PLM is the first-party cloud PLM option for SOLIDWORKS (and CATIA). It is a highly scalable mid-market-to-enterprise solution, offering a very wide array of capabilities à la carte, though items are often bundled for convenience. It is a deep and open platform, even capable of native multi-CAD product structures, as described above.

With Onshape, you have one option, and it’s a good one (especially with the benefits of cloud), but won’t easily go as far as other PLM systems. How well it integrates with third-party PLM would need some serious research, especially given Onshape’s withholding of native CAD data from exportation. A SOLIDWORKS company can have their choice between a more modest SOLIDWORKS Manage and the far more scalable (in size and scope) 3DEXPERIENCE CLOUD PLM. While rarely discussed, 3DEXPERIENCE is also available on-premise for complete control. Third-party PLM solutions will also have decades of experience working with SOLIDWORKS data.

Cloud vs. On-Premise

Cloud- and online-only business software has some major benefits, but it also imposes limitations. It’s important to consider it all when making a decision that’s going to be hard to turn around later.

- Purchasing and implementation: Cloud software is generally easier to purchase and implement because it usually amounts to software licenses associated with an email address, with fewer things to install or workstations to buy. But this isn’t always the case, and sometimes it makes sense to slow down and buy more consultatively (as opposed to quickly and transactionally) – without careful assessment, you may not have the full picture, like whether the product you intend to buy is the best choice, whether it has important long-term or second-order ramifications, or whether it conflicts with or complicates other important workflows or data.

In terms of purchasing, if you prefer to move fast above all else, Onshape is great here. If you prefer to consult with experts and plan far ahead, SOLIDWORKS will serve you better. In terms of implementation, there is much to be said for the ease of a full cloud approach, whereas SOLIDWORKS is more on-premise or hybrid. - Costs and ownership: Cloud software (like Onshape) is typically only available as a periodic expense, not an outright purchase. Offline or on-premise software traditionally gives you both options, but that may be changing. (SOLIDWORKS is committed to keeping both options open.) Whether your software should be capex or opex will depend on many factors unique to your business such as how scalable you need to be, your tax situation, and maybe even your personal feelings about permanent ownership. (And always remember that businesses are trending toward recurring revenue models because it is in their benefit, with many customers in open revolt.)

If you’re offered both payment options, it makes sense to compare costs over time and decide accordingly. SOLIDWORKS, for example, becomes cheaper to purchase outright than rent after a handful of years; and in terms of ownership, offline or permanent software may be easier to use outside of the primary business or to retain should the business no longer need it. - Performance: Performance can reasonably be claimed as a benefit for cloud or on-premise, depending on the specific tasks being done and the resources available to the business. For smaller businesses, cloud is often a great way to get more for less, like 3D CAD in a web browser or remote compute for CFD. (Note that this creates a strong dependency on a stable and substantial internet connection.) For less-resourced businesses, this can make cloud options like Onshape or 3DEXPERIENCE SIMULATION advantageous.

With cloud data infrastructure, it may outperform or underperform an on-premise analog – this will be specific to the software, hardware, and network in question. As for cloud compute, a more mature business that has invested heavily in its computing hardware will likely be getting more value for their money than if they used cloud solutions. Tools like 3DEXPERIENCE STRUCTURAL offer hybrid licensing that allows a “best of both worlds”, working both on-cloud and on-premise.

Cloud can put better tech in the hands of smaller businesses.

- Internet requirement & downtime: Generally, workers have internet wherever they go (within reason), making internet requirements of cloud software (for licensing, operation, or data) much less of an issue. Still, it is worth considering, in case certain employees have special situations, the business has air gapped operations, or downtime is absolutely intolerable. Cloud-based software tends to have very good uptime, but it’s not perfect, even amongst the biggest players. On-premise tools can and do also experience downtime, however. SMBs, in particular, may experience more downtime than a cloud provider due to their limited resources. With a good IT department, however, a business should have better control over such emergencies, and on-premise solutions will expose fewer opportunities for downtime to happen (for example, SOLIDWORKS simply isn’t vulnerable to a lapse in internet in the way Onshape is).

- Scalability: The ease of implementation of cloud software seats generally makes it very easy to add or remove users and functionality as needs shift. Cloud hardware infrastructure shows similar benefits, allowing a business to avoid major asset purchases before they are necessary (and not leaving wasted resources if they outlast their utility). For core Onshape, the scalability is great. If the user is working with third-party app store apps or if certain customizations become important to company processes, that may complicate things. SOLIDWORKS has traditional scalability, requiring a workstation and a program installation, but if the user opts for 3DEXPERIENCE PDM (which comes with the CAD seat) rather than SOLIDWORKS PDM, then they enjoy the benefits of easy cloud implementation for that.

- Redundancy and backups: Cloud data is generally very well backed up and distributed. By relying on a cloud provider for this, you save tremendously on staff resources and investment in computing assets. For Onshape and 3DEXPERIENCE PDM, this is a huge benefit for small companies.

- Vendor lock-in: Cloud carries the risk of vendor lock-in. Once you’re invested in something as foundational as cloud data management, all systems downstream must play nicely with the system and its data. As a product development platform, this may pose an issue if the developer of the cloud data management system doesn’t serve enough of the rest of the business. With Onshape, once you move beyond CAD to CAE and CAM, for example, you will be adding new vendors, off-platform software, different data formats, etc., if the Onshape offering for your desired functionality isn’t sufficient. Vendor lock-in also impacts your ability to leave the Onshape platform, which you cannot do with native Onshape CAD data.

The SOLIDWORKS/3DEXPERIENCE ecosystem tackles this potential issue by offering absolutely everything possible, and doing so up to an enterprise level. Through years of acquisition, Dassault Systèmes has become a single source for multiple CAD systems, PLM, simulation, manufacturing software, and more. Also, by offering traditional offline CAD tools, users can leave any cloud contracts while retaining accessible data. - Data restrictions: Many businesses work with organizations with strict access control on their data. These institutions, often part of or adjacent to government, may represent extraordinarily lucrative opportunities. When using any cloud tools, be sure to fully understand how the required internet access and handling of your data will affect that business. This can be a snag for using Onshape or 3DEXPERIENCE “out of the box” for sensitive projects – you will need their special government solutions, whose suitability will need to be scrutinized. Pure traditional SOLIDWORKS PDM, on the other hand, is completely in your control.

- Customization: With cloud tools and services being managed by the provider, a business is limited in how deeply they can customize. While it’s normally not a concern, for highly specialized innovators (for example, a power-user simulation analyst who develops their own algorithms for Abaqus, or a customer-facing design configurator and quoting system), this could be an issue. Onshape, SOLIDWORKS, and 3DEXPERIENCE are all very customizable, but the degree of that capability could matter to you.

- Security and compliance: It may surprise some, but security and compliance are a case-by-case victory for cloud or on-premise. It is far more economical for a cloud provider to invest in expertise in security and compliance, as they can serve more customers than just themselves with that investment. Consequently, cloud customers can generally expect high competency in these areas, something that could be costly for them to acquire on an individual basis. Conversely, there is something to be said for knowing and controlling exactly where your data is at all times. However, should you choose this option, you will be fully responsible for guarding against worldwide digital threats, which are likely the bigger concern.

- Data and process unity: Related to vendor lock-in, solutions sourced from the same provider are going to work better together. Fewer technical issues and less process and data reconciliation are going to result in higher productivity. Onshape is lacking in many areas outside of core CAD and PDM, making it highly likely that the product development value chain will require many vendors and a multifaceted integration. With SOLIDWORKS and 3DEXPERIENCE, as a first-party provider of so much of the value chain, this is dramatically streamlined.

Section 5

The Business of CAD Software

The decision between Onshape and SOLIDWORKS is not one to be made on a whim – it’s a foundational choice for the business. We hope the topics covered in this article provoke deep consideration and consultation with experts on both sides. Here are some final considerations.

Products Are Always Changing

Both Onshape and SOLIDWORKS are very active in development and change, usually to the benefit of users. For example, only a year ago, SOLIDWORKS began including cloud PDM with every seat. Onshape is also inching closer to the release of their CAM tool, and SOLIDWORKS is responding with a free 3DEXPERIENCE CAM tool included with all new CAD licenses.

Companies like PTC and Dassault Systèmes are always changing, growing, and adapting to industry trends.

Thinking bigger, PTC and Dassault Systèmes are both massive enterprises that make strategic acquisitions on a regular basis, and this can quickly impact their customers by introducing new offerings oriented toward industry trends.

Is the Business Model Stable?

Many of us know the disruption caused by a critical business tool suddenly “changing the deal”, like major alterations to licensing, pricing, or product availability. This often motivates a painful process of switching software (or hardware). It’s important to be aware of risks of this nature when making a vendor choice that will affect many departments.

SOLIDWORKS has a very stable business model that succeeds, in part, by not surprising the customer with major changes. For example, Dassault Systèmes has stated their commitment to retaining perpetual licensing alongside term licensing. Most importantly, SOLIDWORKS is a financially viable operation and has been for decades, which from the customer’s perspective ensures it is a predictable expense and guarantees the software’s longevity. This is important because many modern products follow a far riskier growth strategy, both for the developer and their customers.

PTC is likely running Onshape at a large deficit. The product is a sophisticated CAD tool with a lot happening behind the scenes. It also has an enormous amount of data to store, distribute, manage, and safeguard. CAD software also experiences heavy and consistent usage of computing resources (more than, for example, cloud project management software). This may be why Onshape has yet to display serious intentions in CAE, which is even more computationally intensive. The operating costs of Onshape, even with economies of scale, must be high. The offering of a relatively unrestricted free product tier further multiplies those costs.

This is not sustainable, and we have seen similar “high value, low/no cost” propositions devolve time and again in tech. From Netflix to Uber to Doordash, we know what eventually happens: large and repeated price increases, poorer value than the displaced incumbents, and sometimes even advertising.

The bottom line is that once enough users have committed to a product that provides subsidized value, the business must turn profitable, or the resources will be reallocated. The question is whether that point of profitability is tolerable to the customers. No one can say what the future holds for Onshape, but this is one assessment to consider.

About the Customer Relationship, Growth, and Pricing

The self-service subscription model of software purchasing is extremely accessible and popular. Both Onshape and SOLIDWORKS offer it now. However, the automated nature of it has some drawbacks when compared to a more traditional purchasing experience, which can provide immediate savings opportunities and safeguard against some costly future situations.

A snapshot of quarterly SOLIDWORKS promotions available through SOLIDWORKS partner GoEngineer.

Firstly, traditional engineering software is frequently discounted and bundled. These deals may be public and standardized, negotiated between the customer and the rep, or specially crafted by the company for individual customers or initiatives. Usually, especially in the latter cases, these kinds of deals are only available through communication with a sales rep.

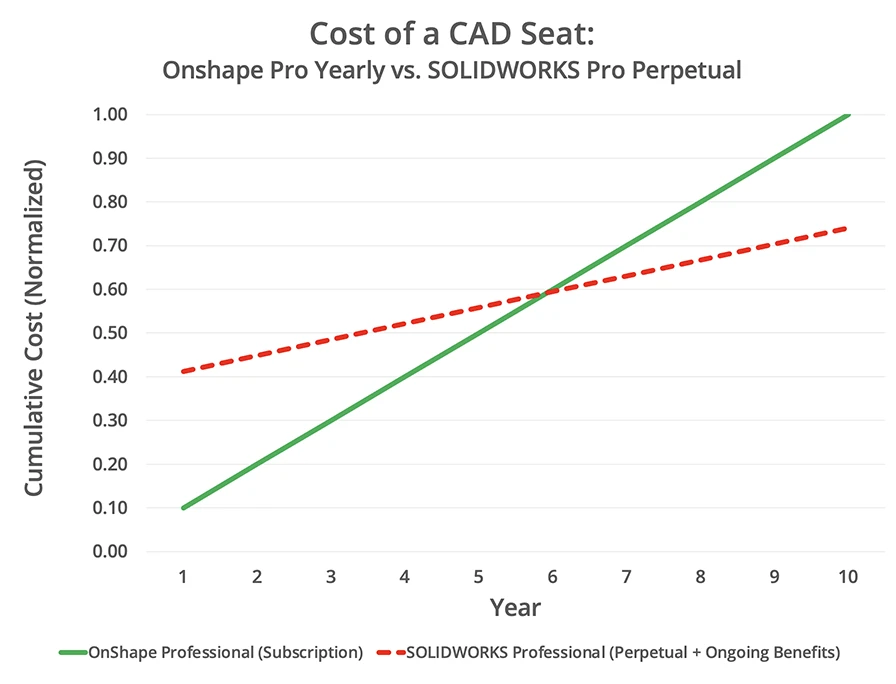

It only takes seven years for SOLIDWORKS Professional with a perpetual license to be cheaper than OnShape Professional.

Secondly, traditional engineering software usually offers perpetual licensing. (It is falling out of fashion with companies like Autodesk and Altium, but Dassault Systèmes remains committed to it.) Term licensing has its benefits for accounting and for the seller, but if the up-front cost can be managed, perpetual licenses eventually become the cheaper option.

Furthermore, should payment cease, consider what assets you retain. Do you still have a CAD tool you can use? Only with a SOLIDWORKS perpetual license would the answer be “yes”. And what about your data? Do you have all your hard work, still editable and in its native format and context/structure? For any type of SOLIDWORKS license, the answer would be yes. For Onshape, the answer would be no – you’d have to export to files in a non-native format, thwarting one of the central pillars of their value proposition.

An Onshape customer must factor in the cost of any tools from the app store, which are often more traditionally priced.

On the other hand, there are also the downstream software costs of growth of the business. What happens to the total cost of ownership when you need capabilities that Onshape does not offer, like high-quality simulation or manufacturing tools? One option is to do without it, simply taking extra time to reach a performant and manufacturable design. Alternatively, you could buy an external solution, which may exceed the cost of Onshape itself. And, if a solution requires a local workstation that may be a necessary purchase as well.

There is the human side as well, when you work with a SOLIDWORKS reseller like GoEngineer, who pairs you with a consistent sales rep and/or customer success manager. This long-term relationship is designed to benefit both parties. These individuals learn your business and proactively offer additional software and training to help you succeed, thus ensuring continued and growing patronage. This can manifest in, for example, helping a company introduce advanced FEA to reduce reliance on physical prototyping and costly late-stage design changes. While some may view proactive sales and enablement cynically, it is a tried-and-true practice that only works because everyone is the better for it.

Section 6

Summary & Conclusion

| Onshape | SOLIDWORKS & 3DEXPERIENCE | |

| Purchasing, Support, and Training | More streamlined: Automation & self-service | More individualized: Customization & person-to-person |

| Design | More accessible: In browser, maximized ease-of-use, core CAD functionality | More capable: Needs workstation, maximized flexibility, advanced CAD functionality |

| Simulation | Very limited: Reliant on third parties for partial physics coverage | Very capable: Covers all physics & user levels |

| Manufacturing | Very limited: CAM is in testing, reliant on third parties for partial coverage | Very capable: Covers machine programming, process simulation, and digital twin |

| Data, Platform, and Collaboration | More streamlined: Mostly CAD-PDM focused, more closed system, easy cloud implementation | More flexible: Full CAD-CAE-CAM-PLM focus, more open system, more complicated cloud or on-premise implementation |

| The Business of CAD Software | Short-term cost-effective: Limited capability for low-cost subscription makes for an affordable start; base and supplementary subscriptions add up over time and scale In flux: Untested business model, profitability pressures likely to come |

Long-term cost-effective: Long-term cost and ownership advantage for higher up-front cost; promotions for growth are common More stable: Proven traditional business model |

In summary, the choice between Onshape and SOLIDWORKS is a complicated one. The more complex your products and the more ambitious your business plans, the more angles you have to consider. For the casual hobbyist or designer of simple products, a straightforward assessment of CAD capabilities and subscription pricing may suffice, Onshape is a strong contender.

On the other hand, a mid-to-large business or enterprise must consider everything happening downstream of CAD and in the context of the whole relationship between customer and software vendor. It's much more than CAD – it’s simulation; manufacturing; lifecycle management; collaboration between departments, organizations, and their systems; support and training; cloud vs. on-premise; and long-term expectations of the vendor. For the customers who push engineering and innovation forward, SOLIDWORKS offers more capabilities, more freedom, and more predictability. Reach out to the GoEngineer team to learn more about SOLIDWORKS and 3DEXPERIENCE.

Related Articles

SOLIDWORKS 2025 Parts & Features - What's New

Getting Started with 3DEXPERIENCE: Setup, Dashboards, Connectors & More

SOLIDWORKS 2025 Weldments - What's New

Creating a 3DEXPERIENCE Dashboard: Step-by-Step Guide

About Zachary Yates

Zack Yates is GoEngineer's Software Product Marketing Manager based out of Ann Arbor, MI. He comes to the position after many years as a consulting CAE Analyst with a focus on Abaqus. He has a degree in music from the University of Michigan and loves to be creative, learn new things, and travel the world.

Get our wide array of technical resources delivered right to your inbox. Unsubscribe at any time.