SOLIDWORKS Simulation 2025 - What's New

SOLIDWORKS Simulation 2025 brings some exciting new updates for your simulation needs. This article will explore new enhancements to the component selection tools for your analysis, bonding interactions, weld pin and spring connector options, and mesh improvements for assemblies.

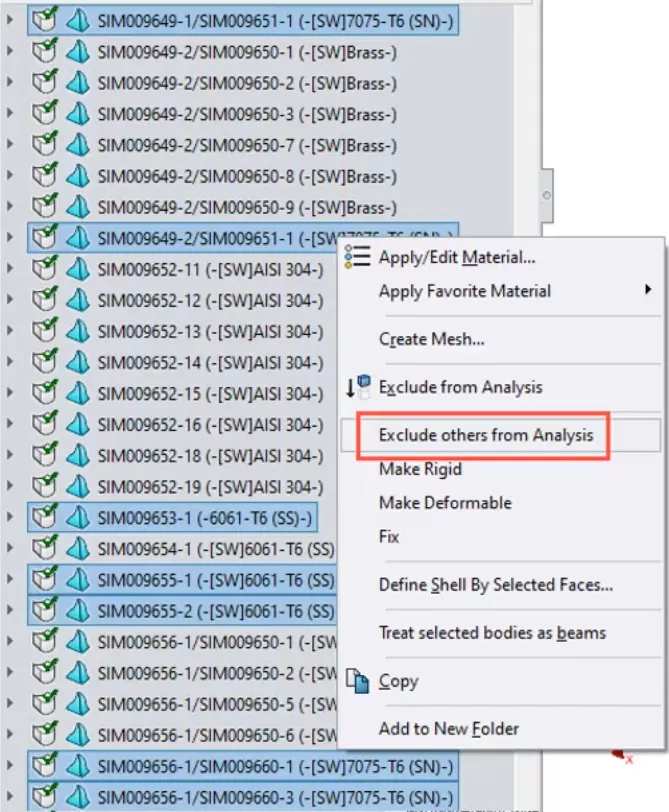

Component Selection Improvements

There are several components that are required for the handle to function properly in the Proteus Motion Machine, yet many are integral to the handle structure.

New in SOLIDWORKS Simulation 2025, you can now select the structural components you want to keep in the analysis and exclude all others.

This is a huge time saver when working with large assemblies.

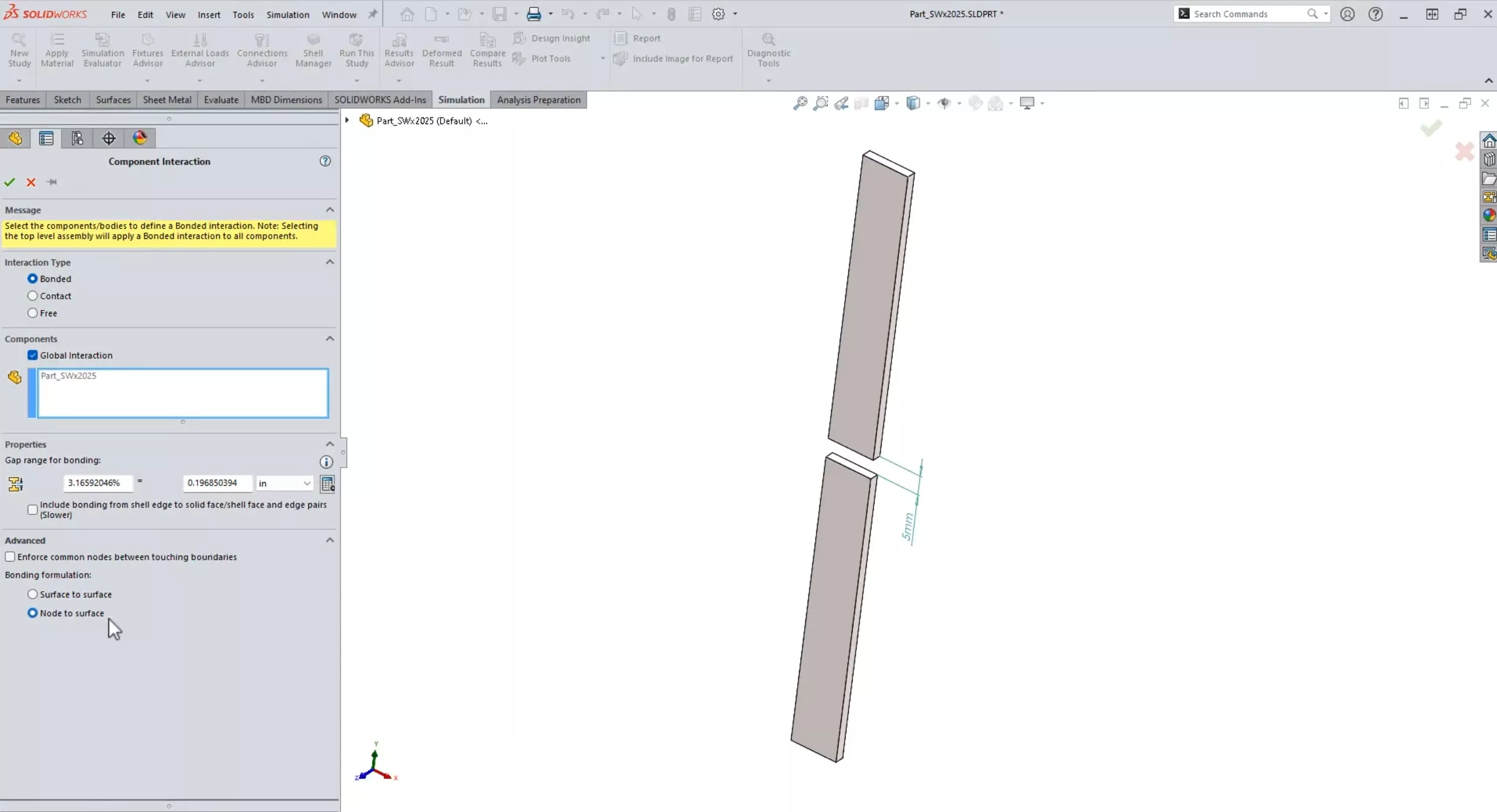

Enhanced Node to Surface Bonding Accuracy

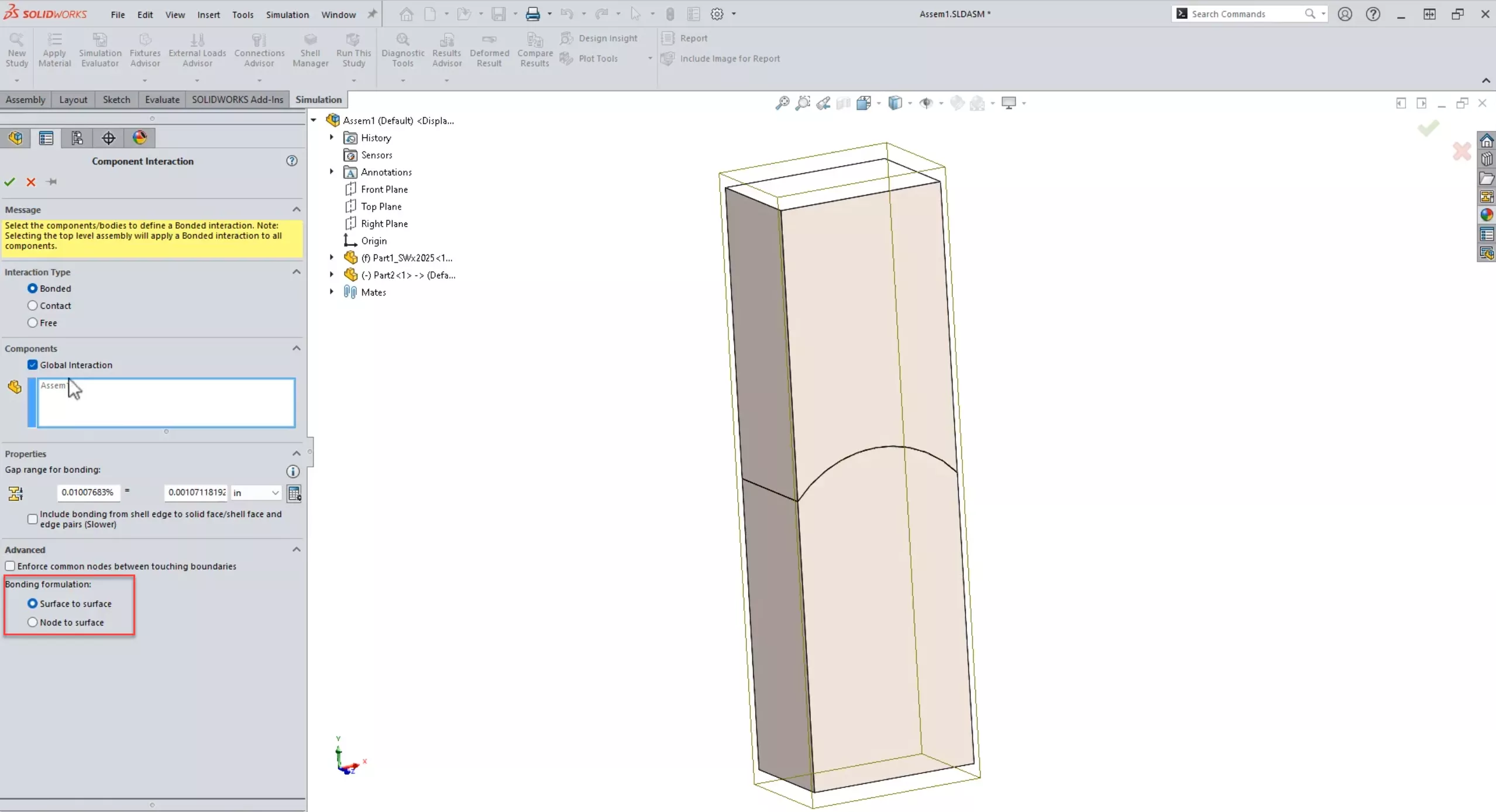

The enforcement of Node to Surface bonding interactions between geometries within the user-defined gap has been improved in SOLIDWORKS Simulation 2025.

This new enhancement improves the accuracy for bonding offset defined by the user-defined gap range for bonding.

This will lead to improved solution accuracy for all bonding interactions that are based on either a draft or high-quality mesh.

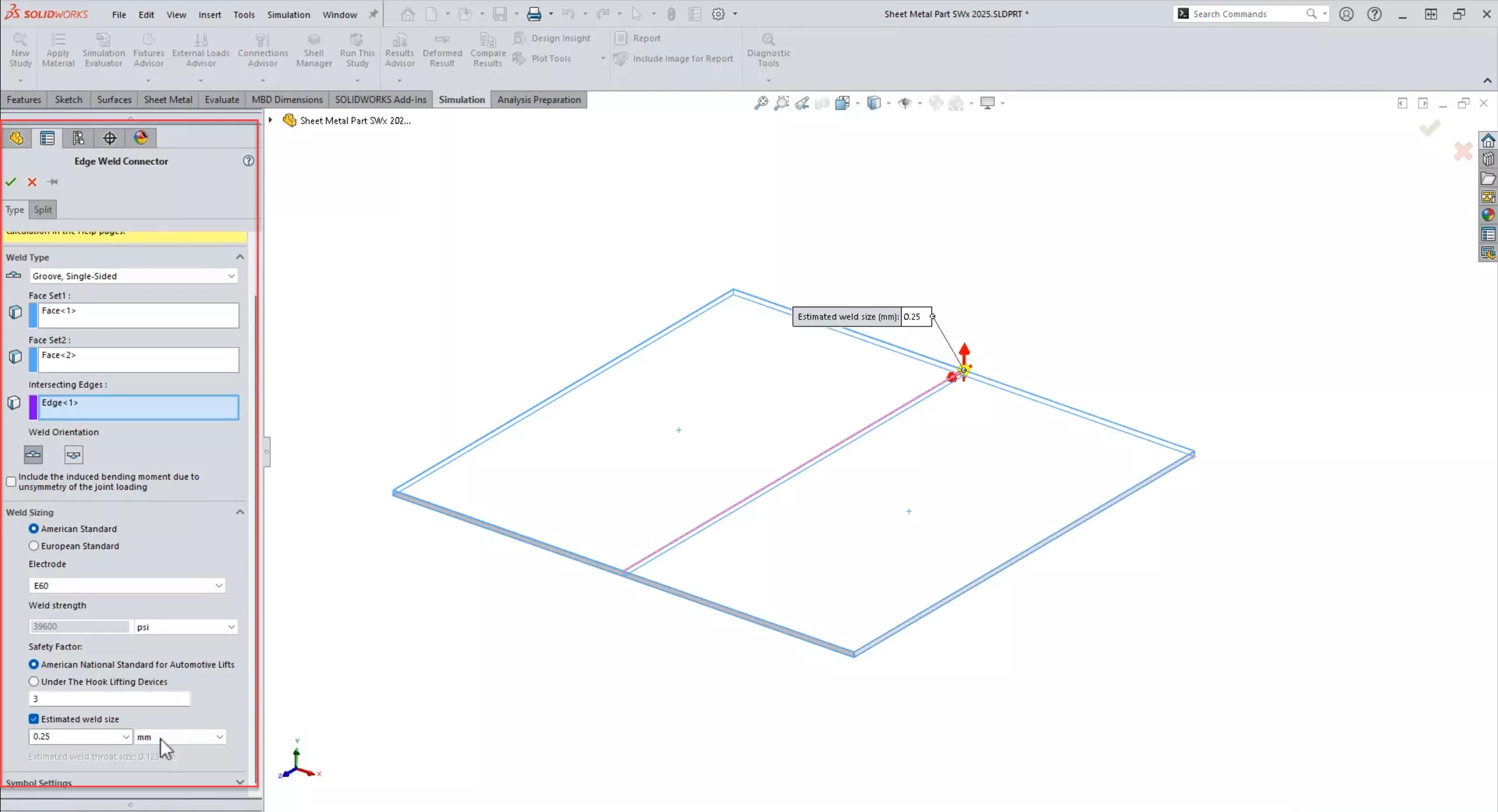

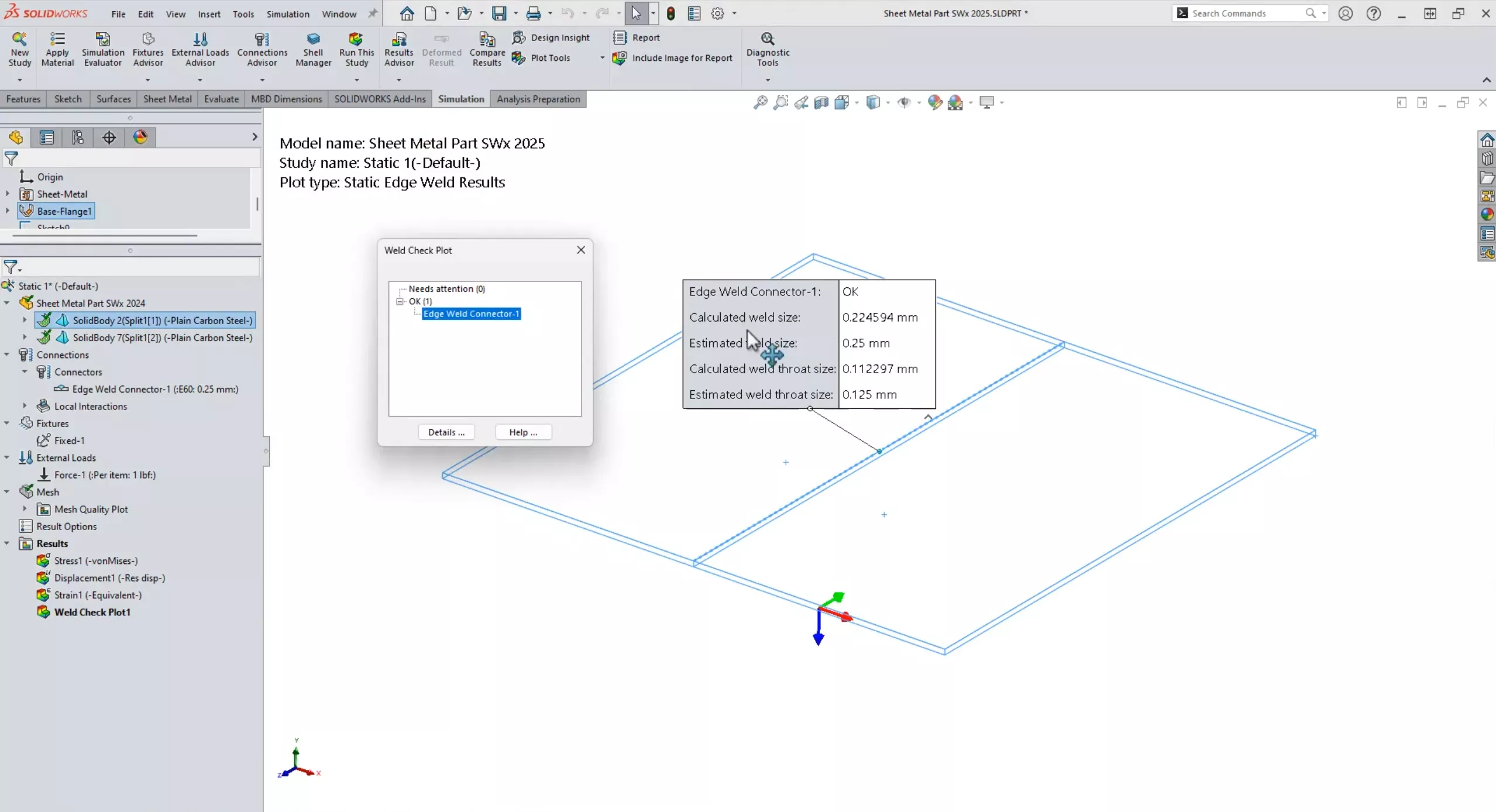

Weld Connector Enhancements

The Edge Weld Connector calculations and annotations have also been improved. New in SOLIDWORKS Simulation 2025, the program calculates the estimated weld throat size when you define an edge weld connector. Also, the icons for weld orientation in the Edge Weld Connector PropertyManager for the groove single-sided type are updated to show the accurate representation of the edge weld type.

Lastly, the Weld Check Plot annotation node now lists the calculated weld throat size and the estimated weld throat size for each edge weld connector.

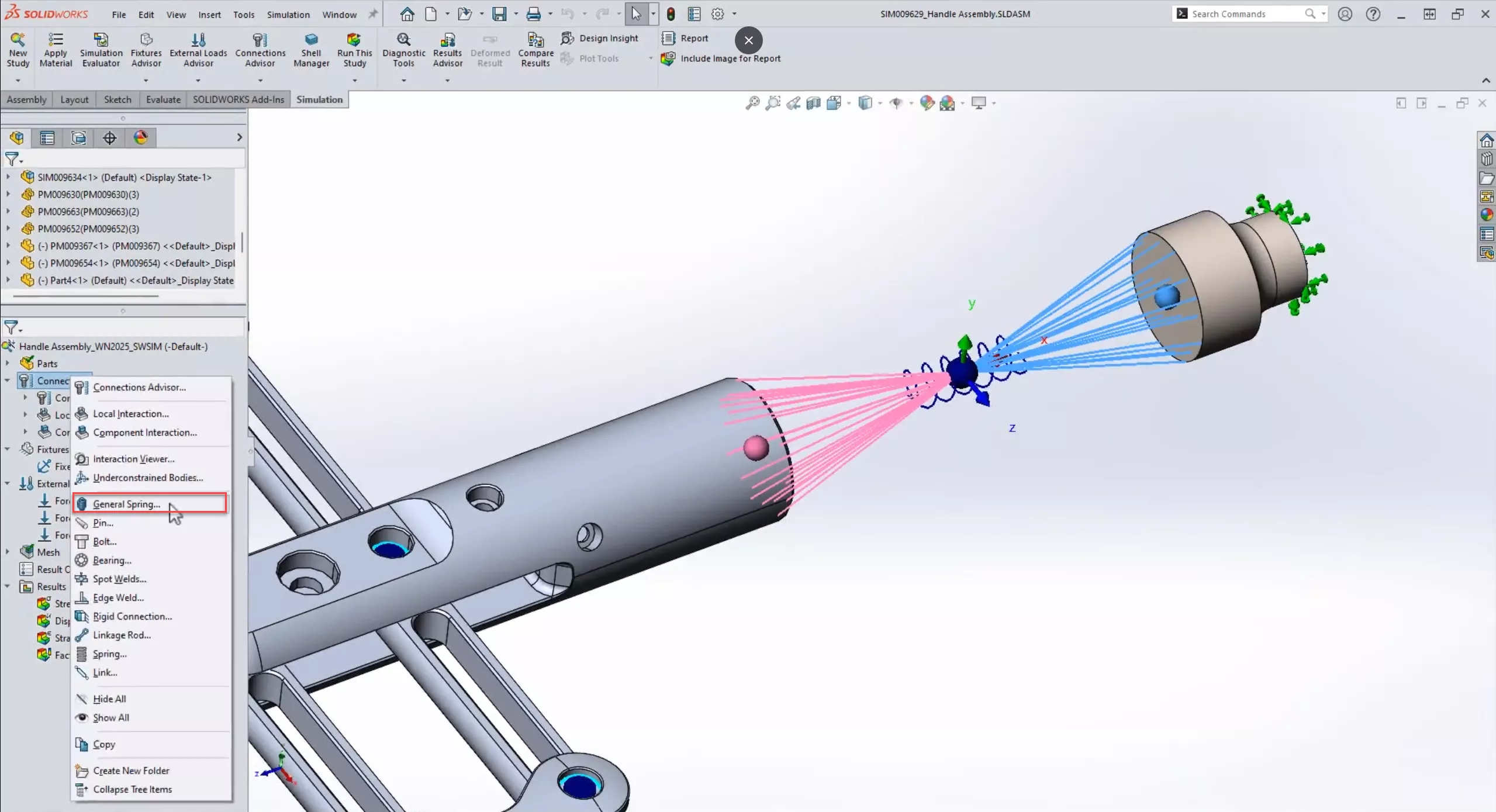

Spring Connection Options

Next up is the new General Spring connection option for a connector type.

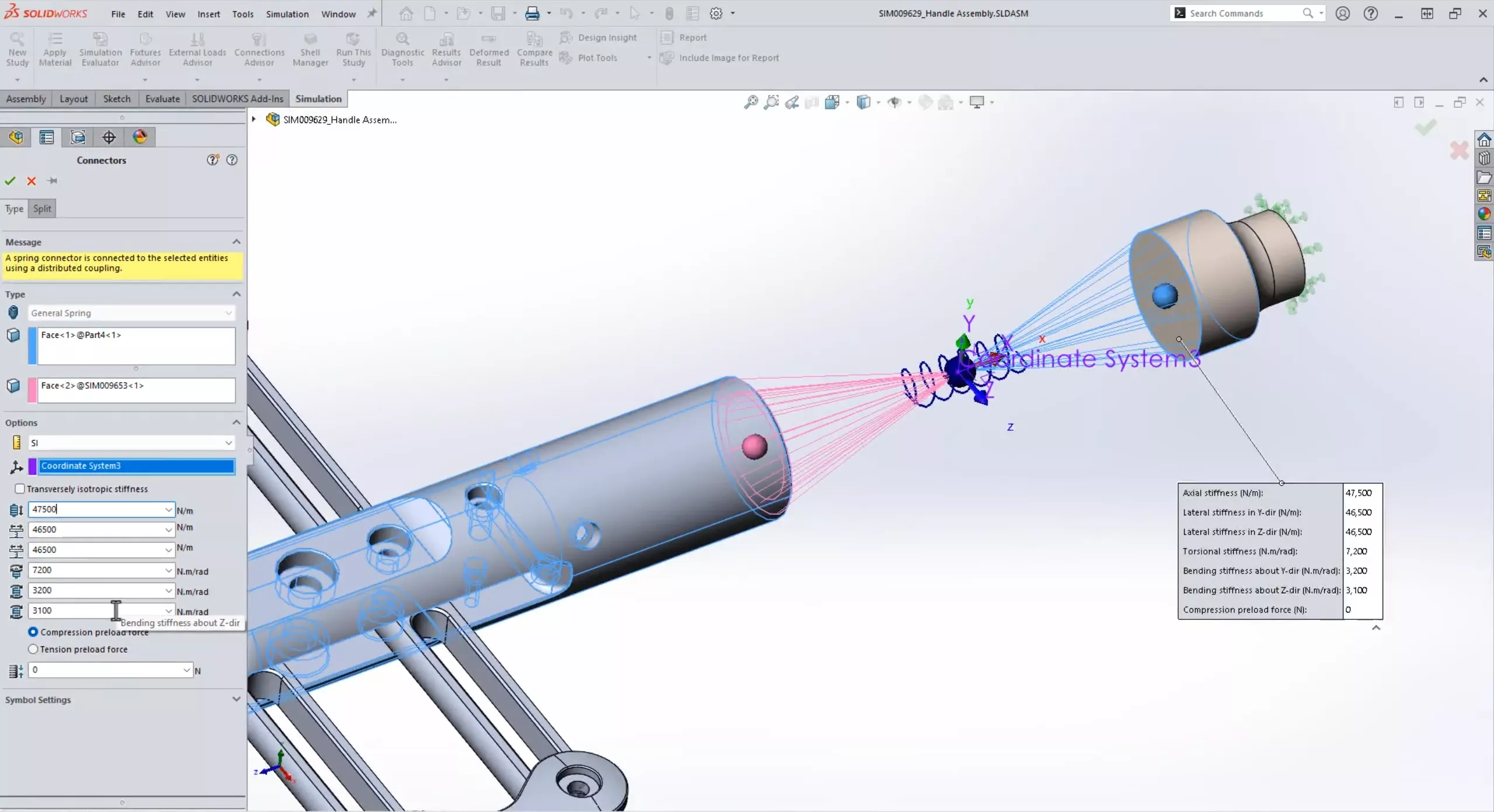

This handle is connected to the rest of the Proteus Motion Machine, but adding a rigid connection condition would over-constrain the model. New in SOLIDWORKS Simulation 2025 is the new Orthotropic Spring connector type that can be defined with unique stiffness values in all orthogonal directions, plus torsional and bending stiffness.

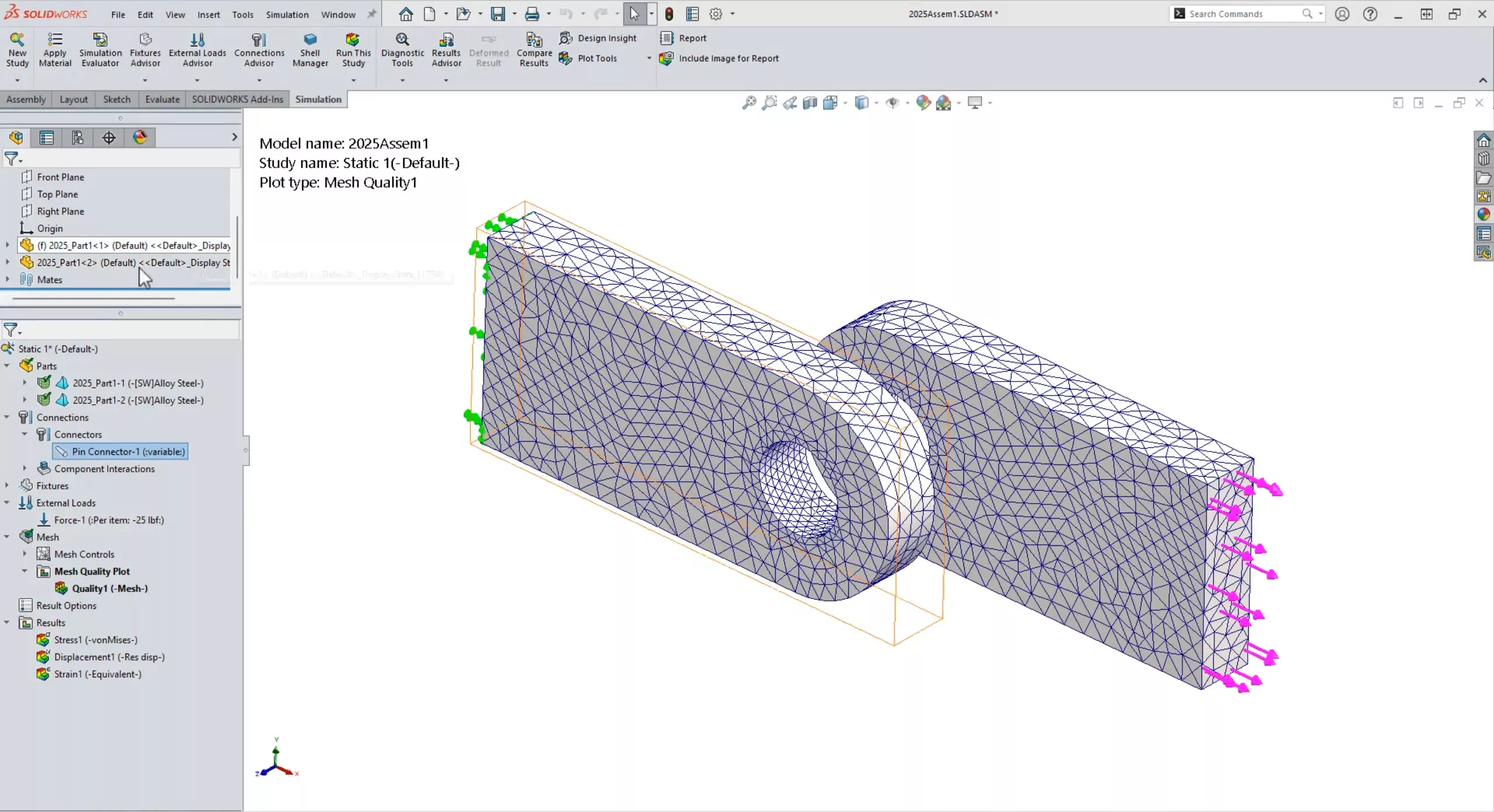

The Pin connector has also been enhanced with improved performance when using the distributed coupling pin connector application.

Virtual hardware like the pin connector is a great way to reduce the overall size of your analysis without sacrificing accuracy.

Now, virtual pins in SOLIDWORKS Simulation 2025 can be defined using distributed coupling technology, which more accurately transfers loads to the surfaces where the pins are located increasing overall accuracy in the analysis.

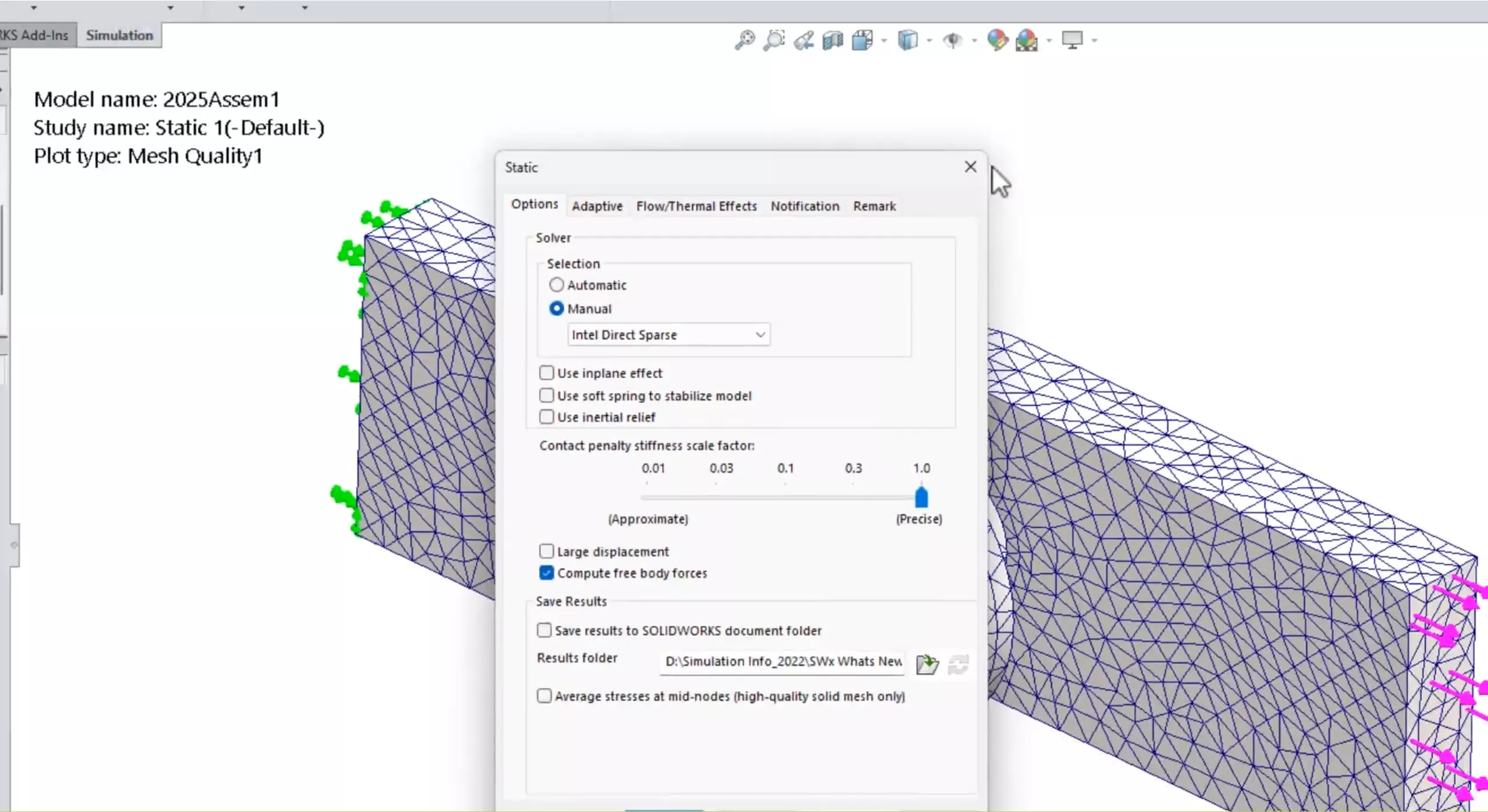

Also, the solution time for these studies is improved using the Intel Direct Sparse solver.

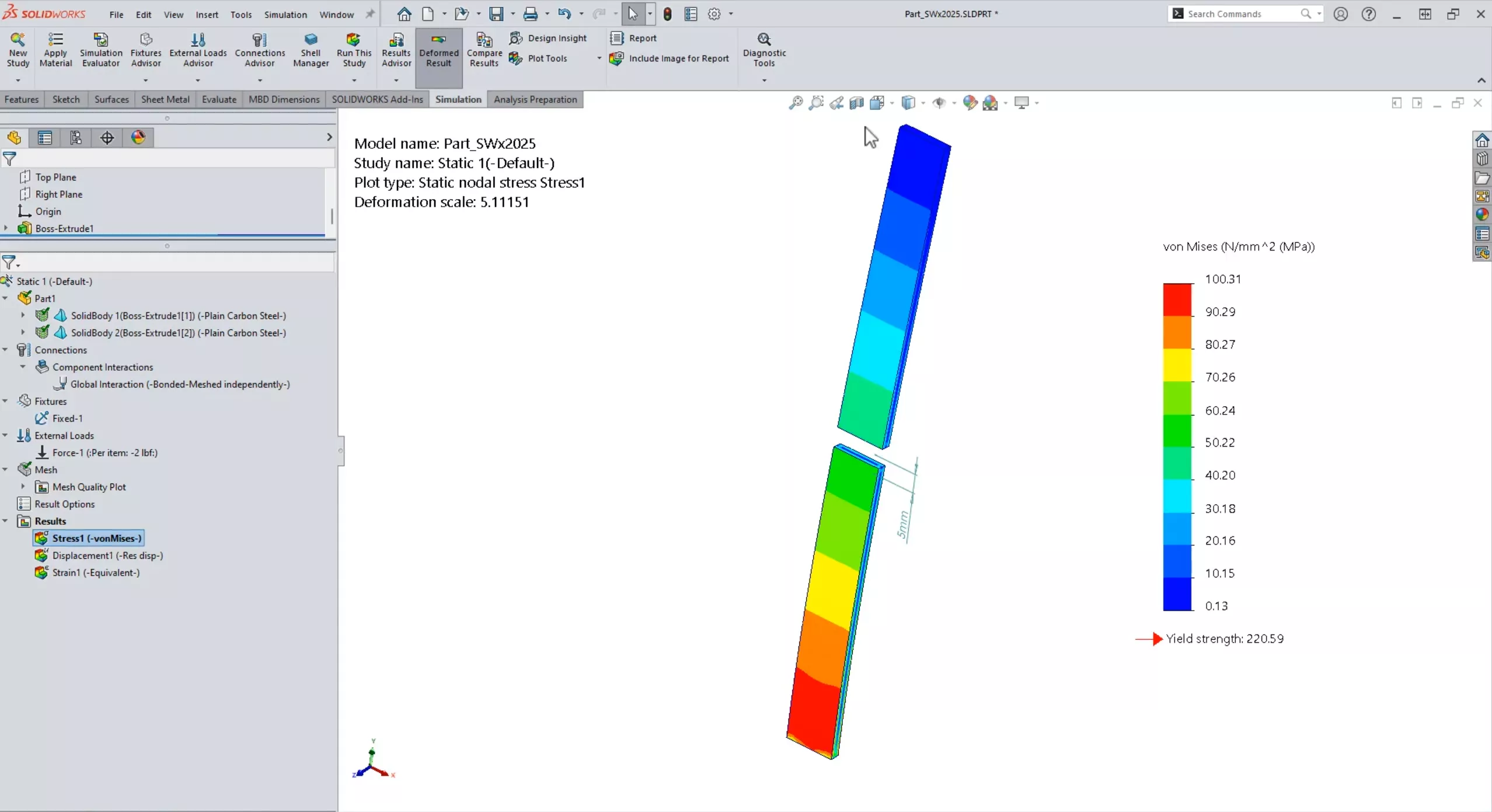

Mesh Accuracy Enhancements

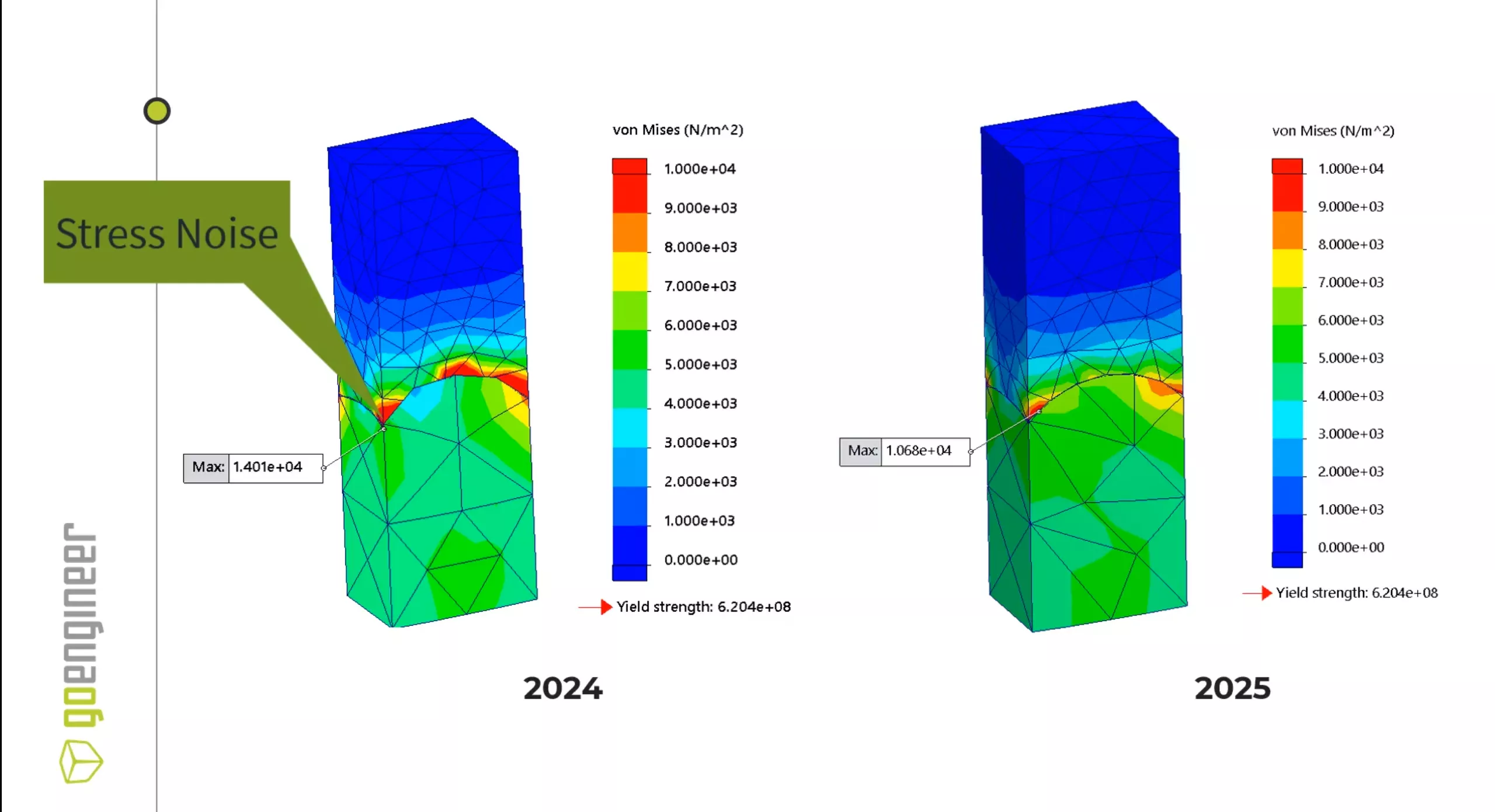

Simulation accuracy has also been improved for studies with bonded curve surfaces when the mesh size and the source of the target surfaces are different.

The algorithm that enforces surface to surface bonding in SOLIDWORKS Simulation 2025 now integrates geometry correction factors that improve the representation of curved surfaces of cylindrical, spherical, and conical geometries.

The integration of surface geometry correction reduces the stress noise at the vicinity of bonded curved surfaces which improves the solution accuracy.

This side-by-side comparison shows the stress noise reduction at the boundary where the solid-to-surface bounding with the geometry correction is applied between the two curved surfaces, and it is solved more accurately in SOLIDWORKS Simulation 2025 compared to 2024.

Mesh Time Reduction Techniques

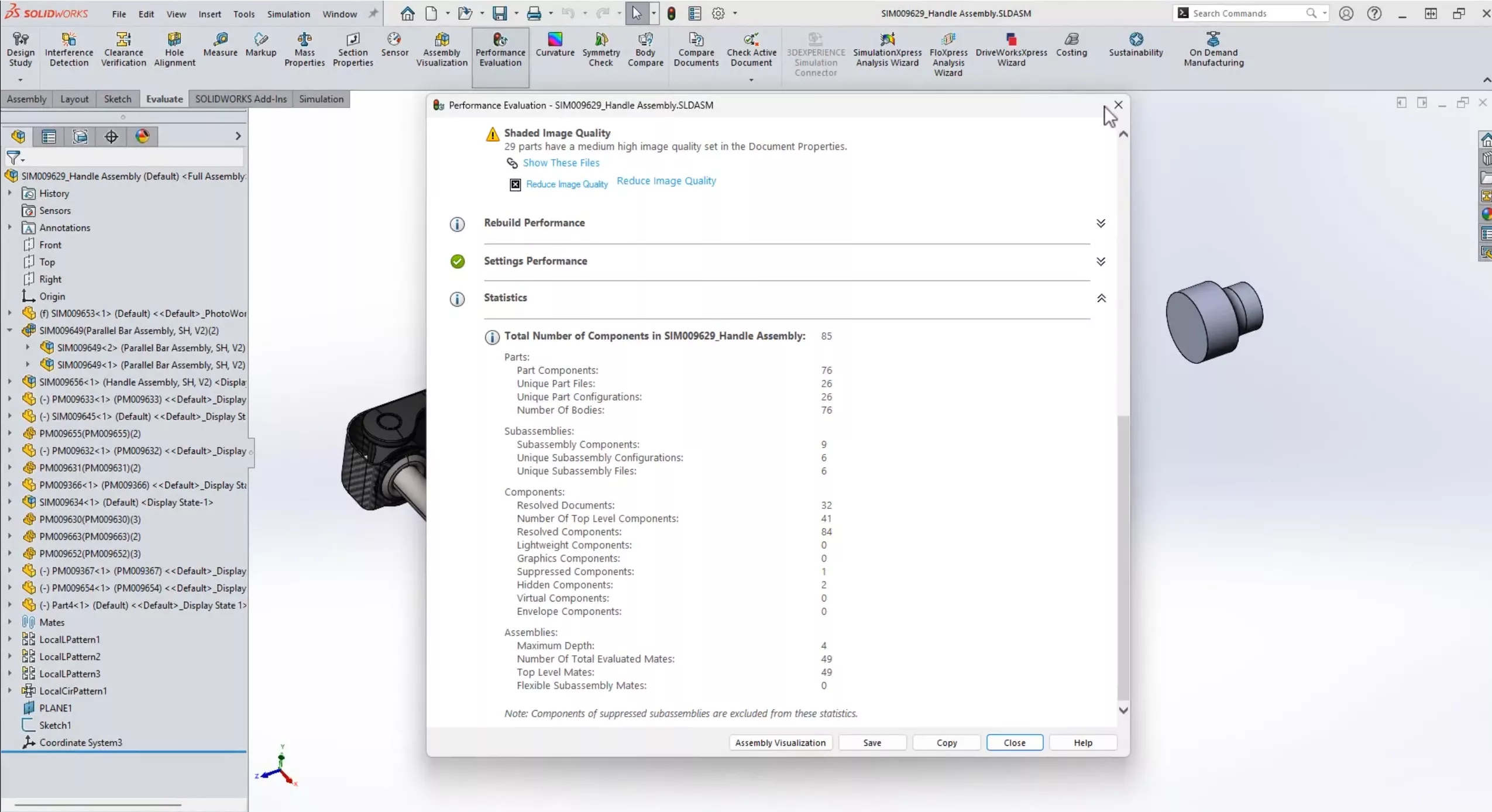

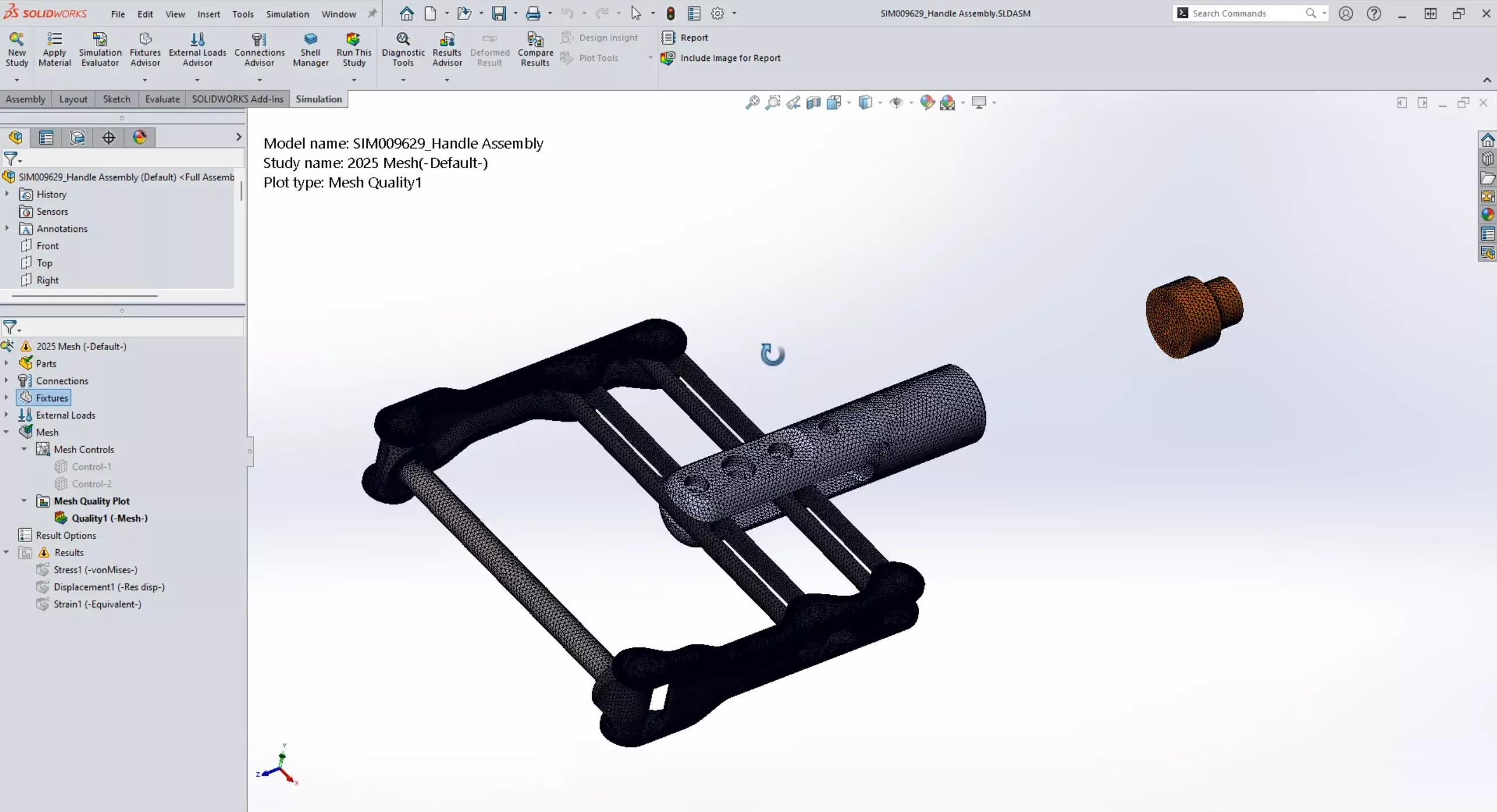

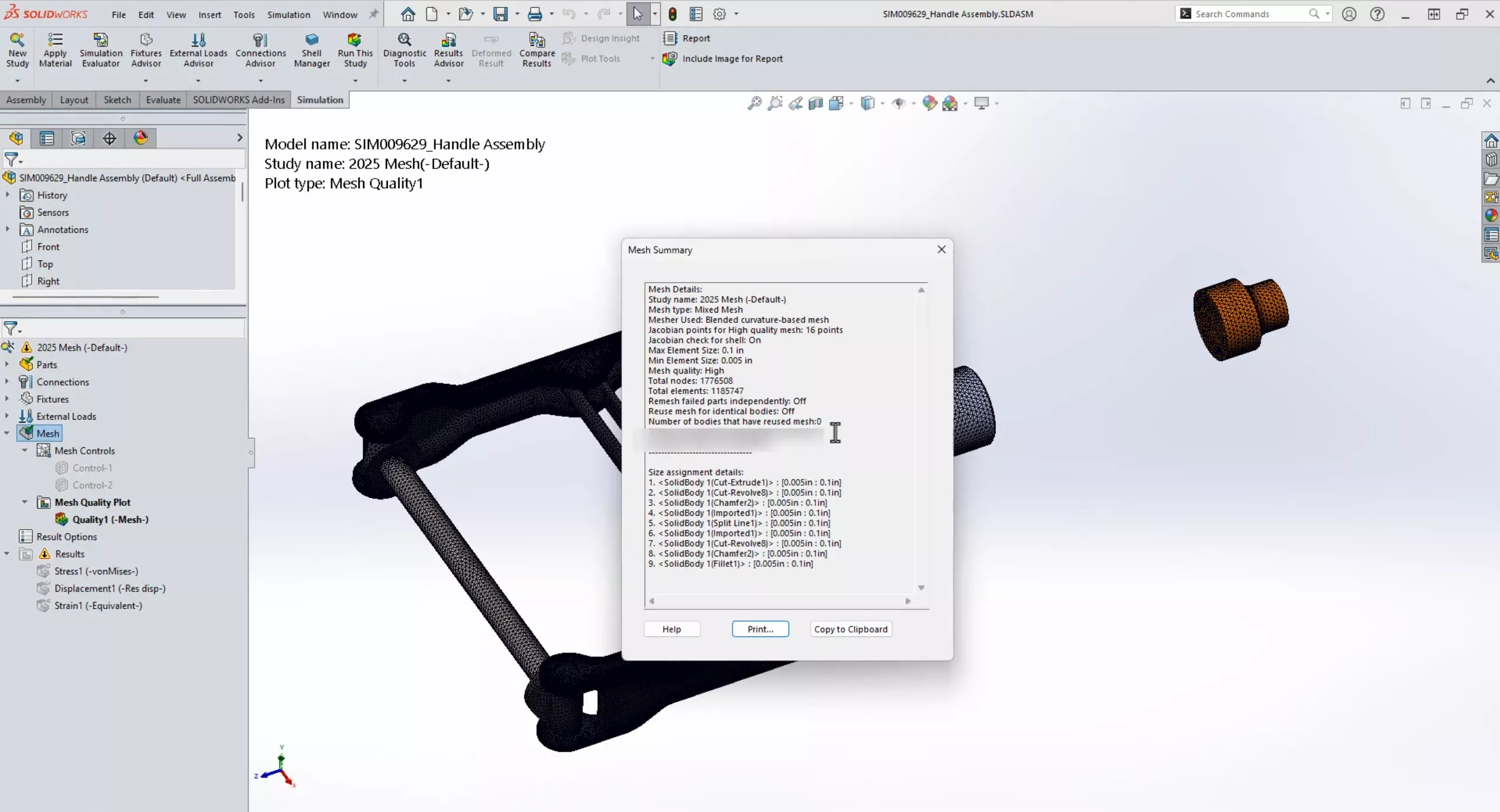

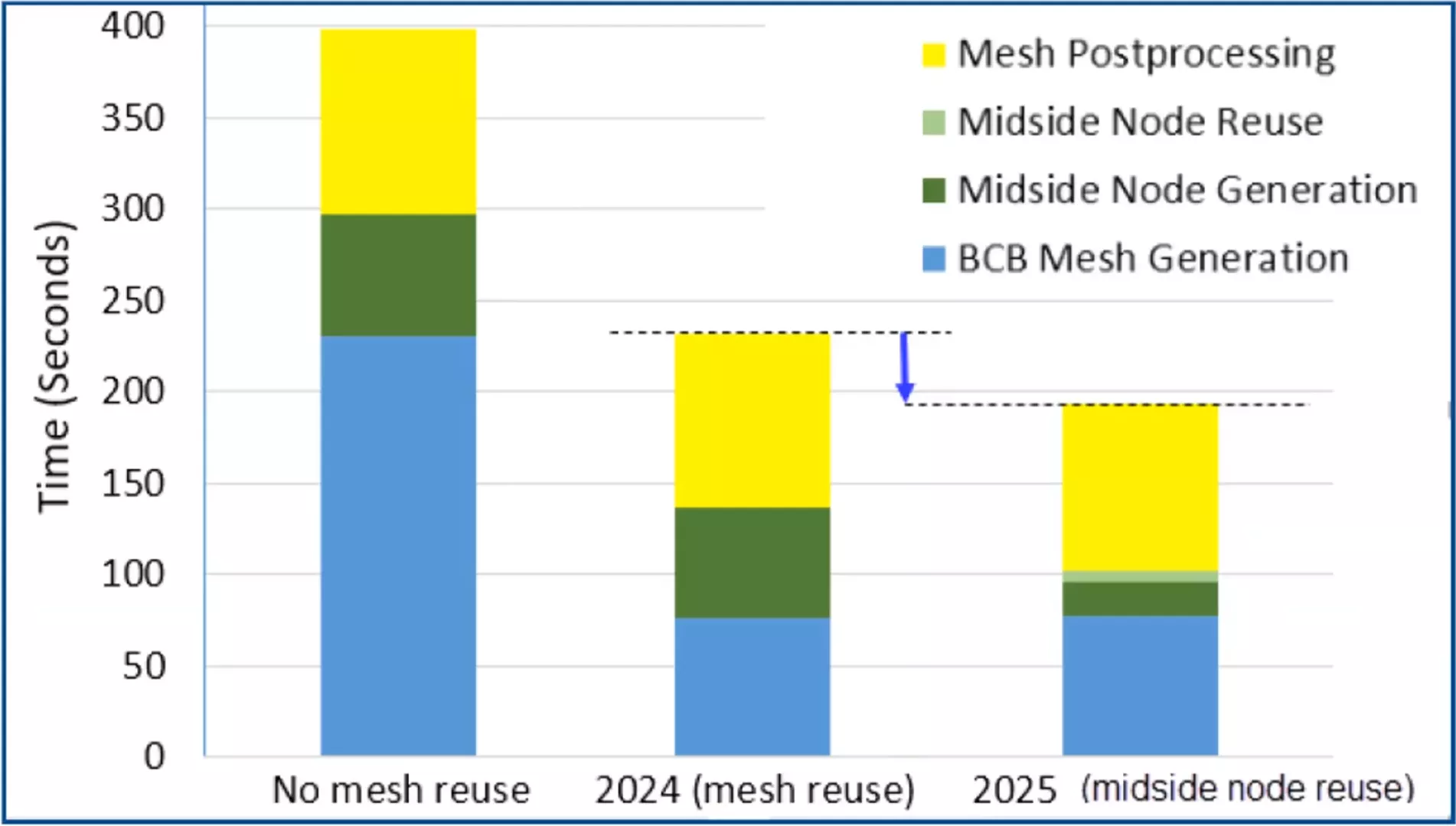

Total mesh time using blended curve-based measurement has been reduced for assemblies with multiple identical parts. Using the Performance Evaluation tool, we see that the assembly has many identical parts.

Now, in Simulation 2025, the blended curvature-based meshers create mid side nodes at the higher order element graph. Reuses the mid side node positions across repeated identical components, thus saving in meshing time.

The mesh performance improvement is more prominent for assemblies with many repeated parts that have curved surfaces and mesh with higher quality.

This graph shows for large assemblies in 2025, the total mesh time reduction has drastically been reduced when using the blended curvature mesher on assemblies with many identical parts compared to previous years.

Want to learn more? Check out what else is new in SOLIDWORKS 2025 below and tune in to our on-demand virtual What's New launch event.

SEE WHAT'S NEW

Watch the On-Demand Launch Event

Join our panel of expert engineers as they unveil the powerful new features of SOLIDWORKS 2025.

Related Articles

SOLIDWORKS Plastics 2025 - What's New

SOLIDWORKS 2025 Weldments - What's New

What's New in SOLIDWORKS 2025 Assemblies

SOLIDWORKS 2025 Drawings & MBD - What's New

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.