SOLIDWORKS Simulation Standard vs 3DEXPERIENCE Structural Designer

Are you a SOLIDWORKS user ready to jump into simulation and start doing static analysis? There used to only be one tool for the job: SOLIDWORKS Simulation. Now there is a second option: 3DEXPERIENCE Structural Designer. So which should you choose? In this article, we’ll compare and contrast so you can make the right choice.

SOLIDWORKS Simulation Standard

If you need the following capabilities, SOLIDWORKS Simulation Standard is the choice for you:

- Large Displacement

- Mixed Meshing

- Design Studies

Large Displacement

For most engineering problems, a structure’s initial shape closely resembles its final shape.

If this is not the case, then special techniques must be used to find the correct solution. SOLIDWORKS Simulation has a Large Displacement option to address this.

Large Displacement disabled (left) and enabled (right)

The meter stick in the above animation shows the problem with assuming that deformations are small. When large displacement is not used, the points on the meter stick displace horizontally and it appears as though it doubles its length rather than bending on a natural curved path.

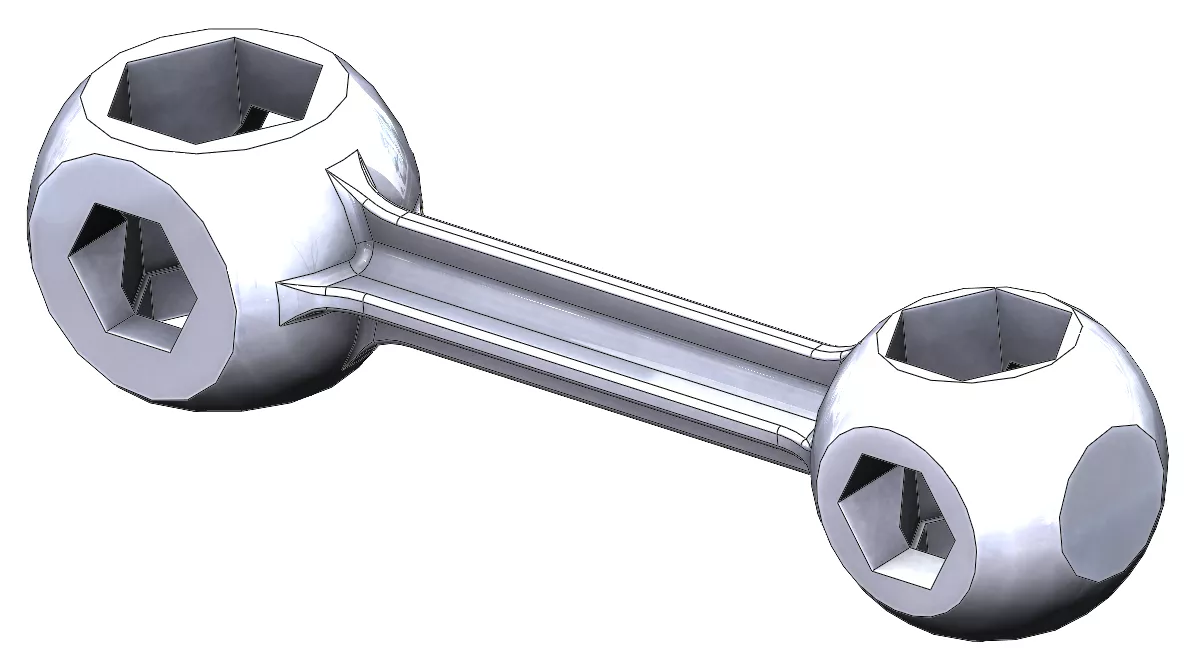

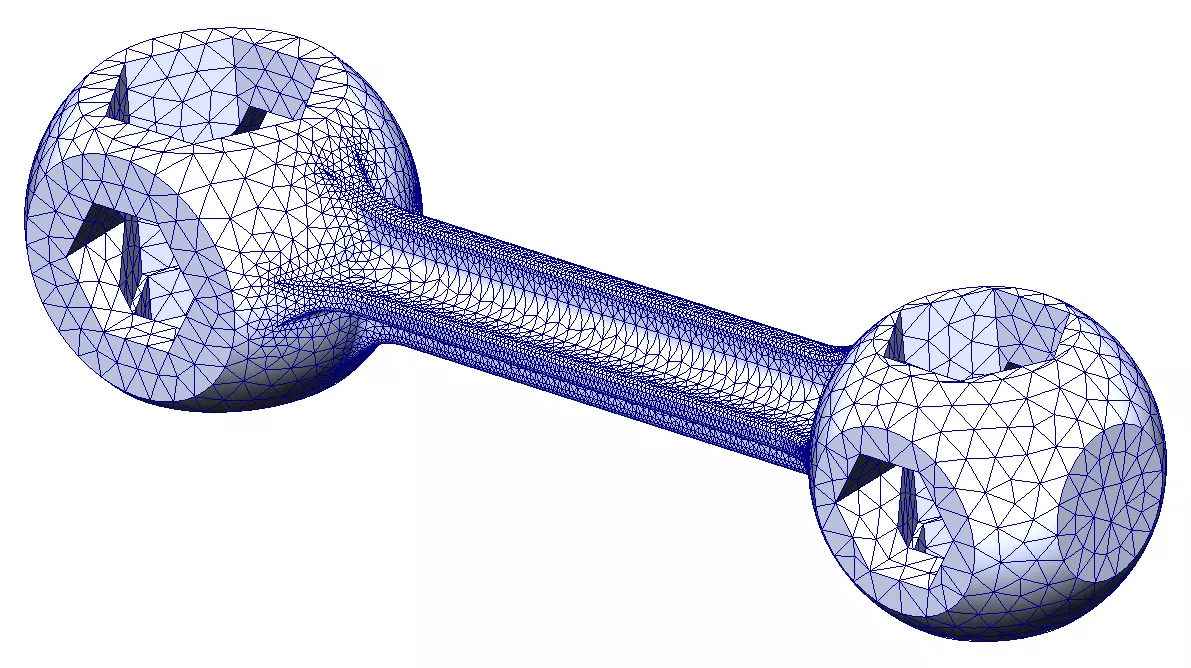

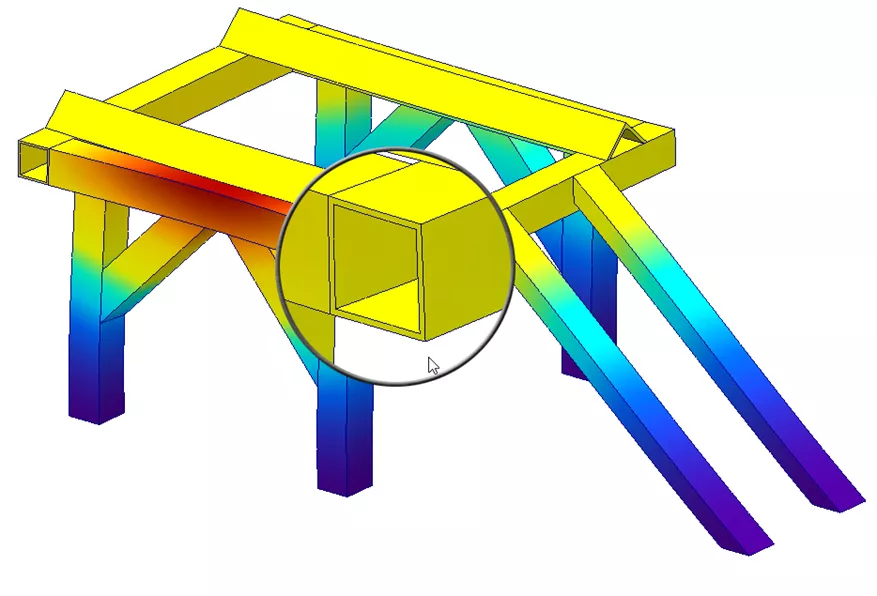

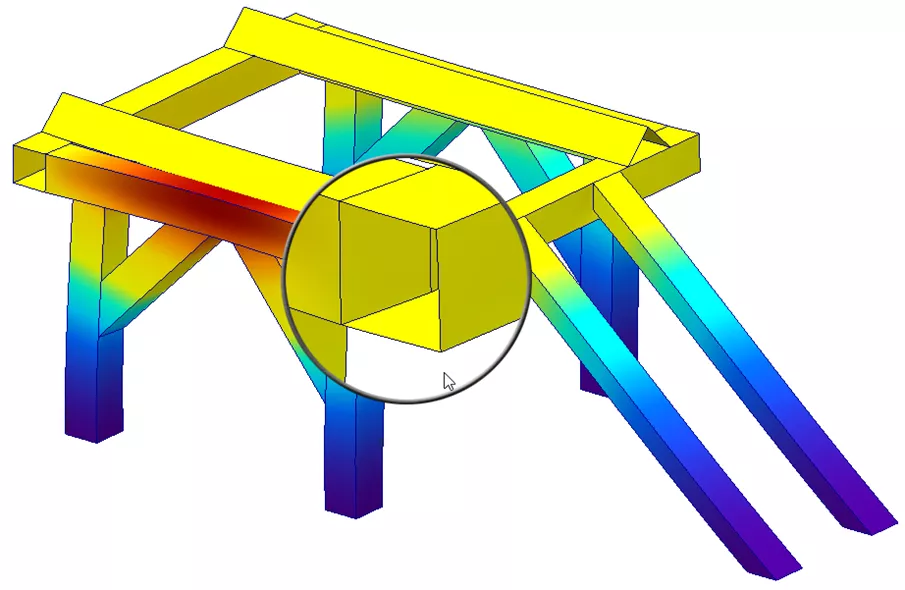

Mixed Meshing

In FEA, part volumes are split into simple shapes called elements. The collection of these elements is called a mesh.

SOLIDWORKS Simulation offers multiple element types to help solve larger-scale structures. The default is the solid element which can be used to mesh solid bodies.

These solid tetrahedral elements are an excellent choice for thick parts, where they produce very accurate results. However, for thin parts, a different kind of element does better while remaining computationally efficient – the shell element. The shell element spatially represents the flat surface of a thin body and numerically represents its thickness.

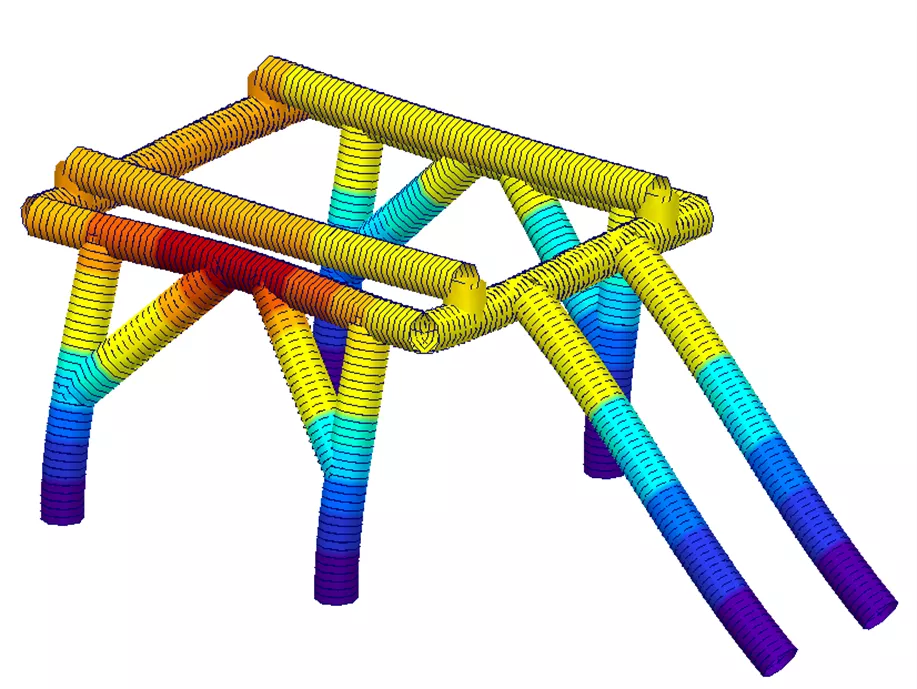

As structures get larger, a further abstraction can be made to reduce the computational overhead with beam elements. The length of the part is represented spatially and the whole shape of the cross section is numerically represented. This element applies well to long, slender geometry with fairly uniform cross-sections.

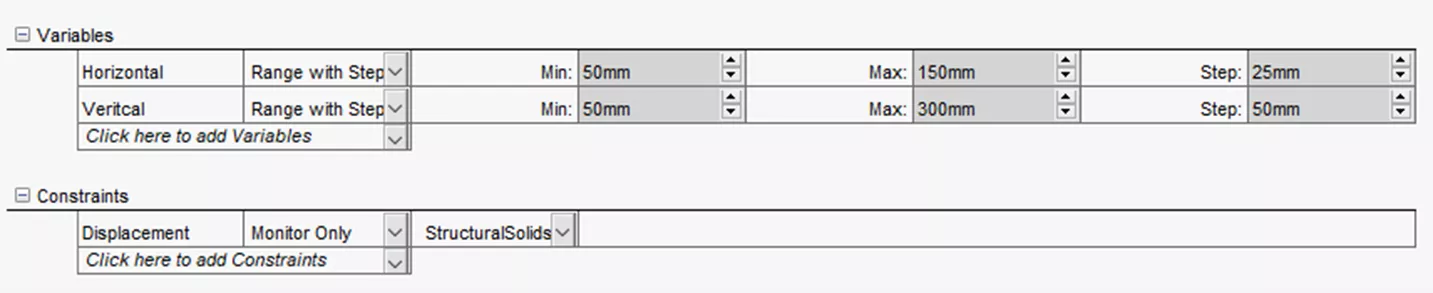

Design Study

Since SOLIDWORKS Simulation exists within the SOLIDWORKS CAD environment, users can change their model directly and re-run their simulation in seconds.

Design changes and analysis of each change can even be automated using a table within a Design Study.

With the push of a few buttons, you can test 30 different design iterations and examine trends to identify the best design.

3DEXPERIENCE Structural Designer

Structural Designer has a lot of overlap with SOLIDWORKS Simulation, but here are some of the features that will make it the better choice for you:

- Contact efficiency

- Buckling analysis

- Frequency analysis

- Thermal analysis

Contact Efficiency

3DEXPERIENCE Structural Designer uses the world-leading Abaqus solver to handle the complex numerical task of resolving contact. Abaqus can be multiple times faster than SOLIDWORKS Simulation on problems that require components to be able to engage, disengage, or slide relative to one another, such as in the pliers example below.

Abaqus shows its contact analysis efficiency in this challenging example involving a pin and neighboring contacting bodies.

In our test, using SOLIDWORKS, this model with around 300,000 degrees of freedom took ten minutes to solve on our 16-core machine. Using Abaqus and only four CPU cores, it only took five minutes. Even better, it only took two minutes using Abaqus with eight. That’s five times faster with half the cores!

| Application | Cores Available | Solve Time |

| SOLIDWORKS Simulation | 16 | 10 min |

| Structural Designer (powered by Abaqus) | 4 | 5 min |

| Structural Designer (powered by Abaqus) | 8 | 2 min |

Buckling

Long, slender components in compression can become unstable. 3DEXPERIENCE Structural Designer can help users identify buckling safety factors to avoid this often catastrophic mode of failure.

Frequency

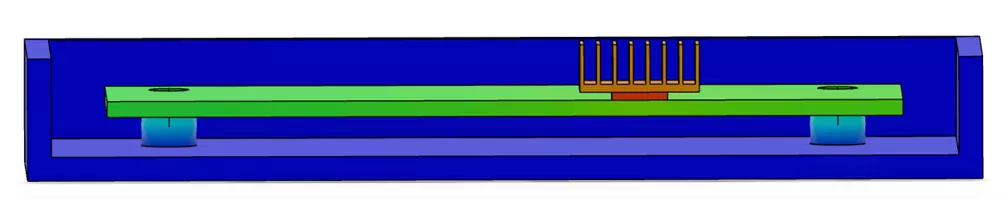

Many structures are subjected to dynamic loading. Sometimes loads are periodic, like in the case of a motor. Sometimes loads are pulse-like, for example in the case of a drop test. Understanding the modes and natural frequencies under which a design will vibrate allows designers to make better decisions about where to place sensitive components such as in the electronics enclosure below.

Thermal

Heat loading can be applied in this analysis type to assess how hot a design gets and examine the primary heat pathways. Designers can use this information to decide whether adding heat flow pathways may be necessary.

Summary

SOLIDWORKS Simulation is a powerful structural analysis tool with direct CAD integration that makes it easy to examine how the design matches with performance. If users are running SOLIDWORKS today and only need static structural analysis, this option is often preferred over 3DEXPERIENCE Structural Designer.

On the other hand, if users do not want to consider an upgrade to SOLIDWORKS Simulation Professional, Structural Designer is a great alternative that gives users access to these Simulation Professional features such as buckling, frequency, and thermal analysis.

Have questions about SOLIDWORKS Simulation or 3DEXPERIENCE Structural Designer? Please feel free to contact us.

SIMULATION IS IMPORTANT.

It’s common knowledge that simulation helps us design faster, better, and at lower cost… but knowing and doing are two different things. Learn more with our Smarter with Simulation campaign.

Related Articles

Comparing All SOLIDWORKS Simulation Packages: Basic to Advanced

SOLIDWORKS Simulation 2025 - What's New

Structural FEA for Beginners: 5 Stages of Simulation-Driven Design

3DEXPERIENCE Platform Beam Analysis

FEA Materials Are Make-or-Break: Introducing the 3DEXPERIENCE Material Calibration App

About Shaun Bentley

Shaun Bentley is passionate about applied mathematics and engineering, which led him to pursue and understand real world applications of FEA, CFD, kinematics, dynamics, and 3D & 2D modeling. He teaches many simulation classes to both new and advanced users attending training at GoEngineer. Since 2006, Shaun has been working with simulation tools to solve real world engineering problems. With every new project, he seeks to find ways to push simulation to its uppermost limits, even going so far as to write bespoke code and macros. He has passed the Michigan FE exam and mentors or consults for virtually any industry that uses SOLIDWORKS, especially automotive and automated tools. He is a speed 3D modeling champion and one of the first Certified SOLIDWORKS Experts in Simulation in the world.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.