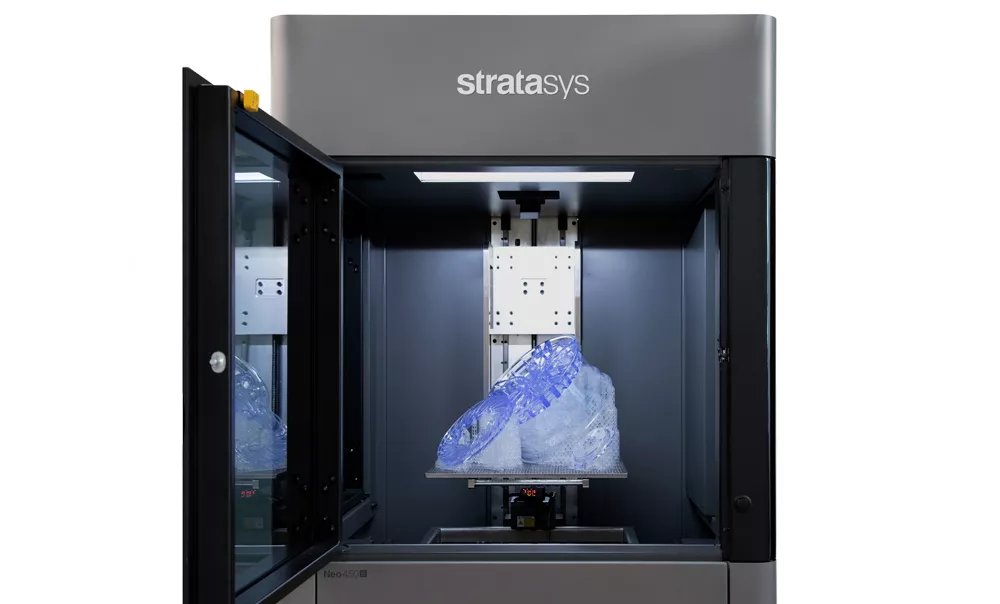

Stratasys FDM 3D Printers

Functional Prototypes, Tools and Production Parts

Now Serving US & Canada

Now Serving US & Canada

FDM Meets the Demands of Production

Stratasys FDM (Fused-Deposition-Modeling) 3D Printers streamline processes from design through manufacturing, reducing costs and eliminating traditional barriers along the way. With FDM, designers can create an idea, and test it the same day. Industries can cut lead times and costs, products turn out better, and get to market faster. Breakthrough designs, process innovations, just-in-time manufacturing — whatever you can imagine, FDM can make it happen.

FDM Applications

Shorten the design process for new concepts with reliable FDM 3D printing.

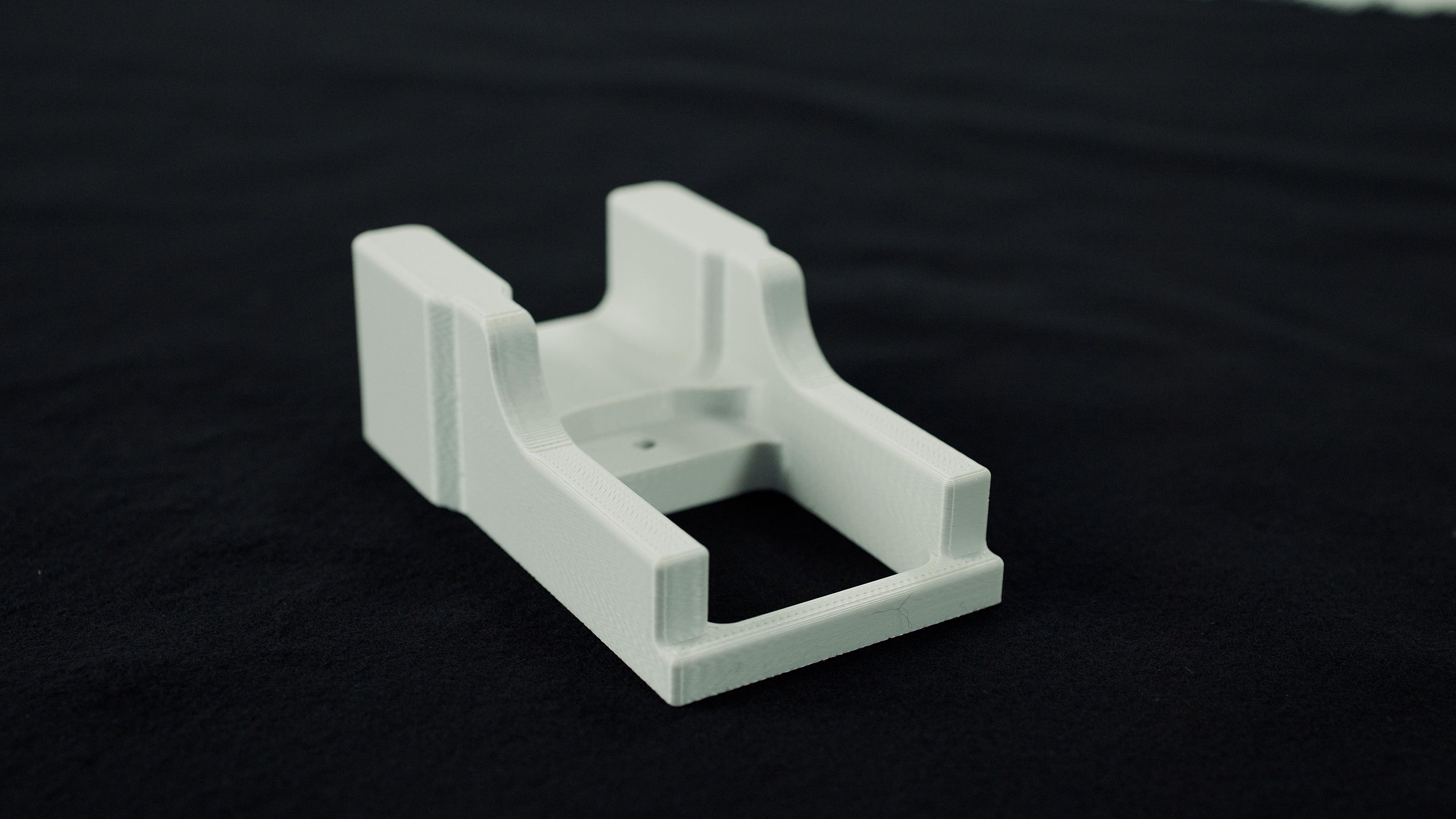

Concept Models

Durable materials and simple print setup make prototyping in FDM fast and efficient.

Functional Prototypes

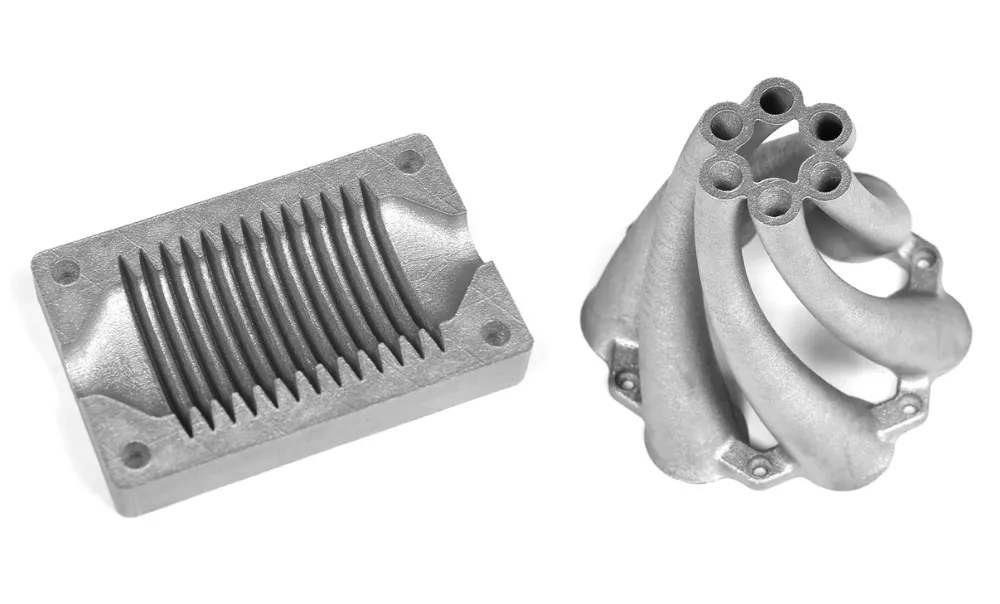

3D print molds and dies with unique geometries in a fraction of the time and cost as traditional methods.

Molds and Patterns

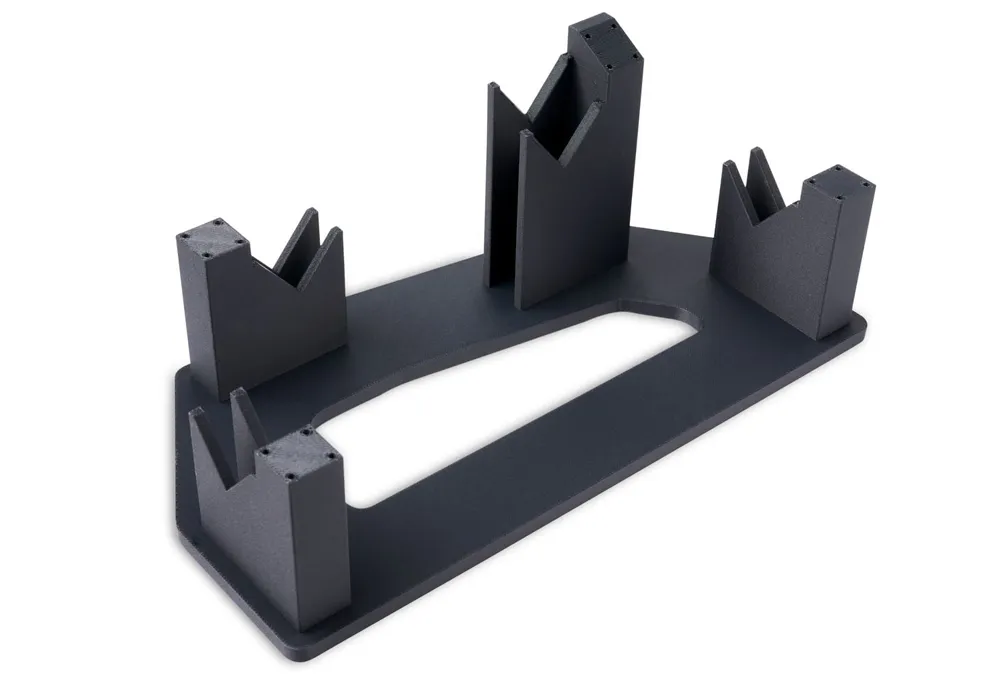

Create jigs and fixtures faster, and cheaper, without compromising on quality.

Jigs and Fixtures

3D printing production parts can slash lead times by up to 83% by eliminating tooling and other traditional manufacturing constraints.

Production Parts

BUYER'S GUIDE TO 3D PRINTING

This guide will help you understand the questions you’ll need to ask as well as provide insight into the technologies, materials and services available to you.

Industries that utilize FDM 3D Printing

FDM 3D Printers

-

-

F170

- Technology:

FDM - Build Envelope:

10″ x 10″ x 10″ -

Materials:

ASA, ABS-CF10, ABS-M30, PLA, FDM TPU 92

-

-

F190CR

- Technology:

FDM - Build Envelope:

12″ x 10″ x 12″ -

Materials:

ABS-M30, ASA, FDM TPU 92A, ABS-CF10, FDM Nylon-CF10

-

-

F370

- Technology:

FDM - Build Envelope:

14″ x 10″ x 14″ -

Materials:

ASA, ABS-CF10, ABS-M30, PLA, FDM TPU 92A, PC-ABS, Diran, ABS ESD7

-

-

F370CR

- Technology:

FDM - Build Envelope:

14″ x 10″ x 14″ -

Materials:

ABS-M30, ASA, FDM TPU 92A, ABS-ESD7™, PC-ABS™, Diran™ 410MF07, ABS-CF10, FDM Nylon-CF10

-

-

Fortus 450mc

- Technology:

FDM - Build Envelope:

16″ x 14″ x 16″ -

Materials:

ASA, ABS-M30, PC-ABS, ABS-ESD7, ABS-M30i, PC, PC-ISO, Nylon 12, Nylon 12CF, ST-130, Antero 800NA, ULTEM 1010 resin, ULTEM 9085 resin

FDM MATERIALS

* Material needs specialized upgrades to 3D Printer to operate

ASA

Acrylonitrile styrene acrylate

– New Standard material for all-purpose prototyping

– UV-stabilized for outdoor production parts

– Superior aesthetics and 10 color options

– All-around average mechanical performance

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

ABS-M30

Acrylonitrile Butadiene styrene

– High performing ABS blend 25-70% stronger than standard

– Versatile, well-understood material

– Available in a biocompatible version

• ABS-M30i | ISO 10993 USP Class VI (can only print in Fortus machines)

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

PLA

Polylactic acid

– Low-cost material option for fast-draft part iterations

– Low melt temperature = fast print speeds

– Available in multiple colors and translucent blends

– Breakaway support material only

Potential applications:

– Low-cost iterations

– Conceptual prototypes

FDM TPU 92A

Polyurethane

– Resilient & flexible thermoplastic

– High abrasion resistance and elongation

– Excellent toughness and tear resistance

– Perfect for large and/or complex elastomer parts

– Compatible with soluble support material

Potential applications:

– Hoses, tubes, air ducts

– Protective covers

– Seals

– Vibration dampeners

– Prototype and end-use parts

ABS-CF10

Acrylonitrile Butadiene styrene

– Combines standard ABS material with 10% carbon fiber by weight

– 50% stiffer than standard ABS 3D printing material

– 15% stronger than standard ABS 3D printing material

– Exclusive to the F123 Series

Potential applications:

– Tooling

– Jigs and fixtures

– Production and assembly

– Drill guides

PC-ABS

Polycarbonate + Acrylonitrile Butadiene styrene

– Blended material that shares properties with ABS and PC

– Highest impact strength of Stratasys FDM materials

– Good toughness, durability, and heat resistance

– Available on the F123 platform

Potential applications:

– Conceptual models

– Functional prototypes

– Manufacturing tools

– Production parts

Diran

Mineral-filled Polyamide

– Nylon12 with 7% mineral fill

– Smooth, lubricious surface

– Low scratch & Mar characteristics

– Good flexibility and Strength characteristics

– Resistance to hydrocarbon-based chemicals

Potential applications:

– Tooling

– Jigs & fixtures

ABS-ESD7

Acrylonitrile Butadiene styrene

– Static-dissipative material based on ABS-M30

– Prevents build-up of static electricity

– Electrical Properties:

• Volume Resistivity: 3.0×109 – 4.0×1010 ohm-cm

• Surface resistance: 106 – 109 ohms

Potential applications:

– End-use components

– Electronic products

– Industrial equipment

– Jigs & fixtures

PC

Polycarbonate

– Material known for its superior strength and durability

– Stable material that will not change shape over time

– Available in a biocompatible version

• PC-ISO | ISO 10993 USP Class VI | F900 only

– Great material for use on the shop floor

Potential applications:

– Demanding prototypes

– Tooling & fixtures

– Metal bending patterns

– Composite patterns

– Medical production parts

Nylon 12

Polyamide

– Composite material

– Moderate chemical resistance

Potential applications:

– High-fatigue endurance

– Repetitive snap fits

– Friction-fit inserts

Nylon 12CF

Polyamide + Chopped Carbon Fiber

– Composite material with 35% chopped carbon fiber reinforcement

– Highest flexural strength and stiffness-to-weight ratio FDM material

– Moderate chemical resistance

– Static dissipative qualities

Potential applications:

– Metal component replacement

– Production parts

– Tooling

Nylon CF10

Polyamide + Chopped Carbon Fiber

– Replace machined jigs and fixtures quickly

– Upgraded, lightweight, convenient designs made possible by FDM Nylon-CF10’s high strength-to-weight ratio

– Soluble support for geometrically complex designs

Potential applications:

–

Metal forming dies

– Press brakes

– End effectors and more

ST-130

Soluble Model Material

– Engineered and tested specifically for sacrificial tooling applications

– High compressive strength

– Triangle fill pattern to optimize process speed | Build & dissolution

– Capable of Autoclave cure

Potential applications:

– Temporary pattern for hollow composite parts

Antero 800NA

Polyetherketoneketone

– Pekk-based super material

– Strong mechanical properties

– Excellent chemical resistance

– Minimal outgassing and dimensional stability

Potential applications:

– Everything aerospace

– Production parts

– Advanced functional prototypes

Antero 840CN03

Polyetherketoneketone + Carbon Nanotubes

– Pekk-based super material

– Electrostatic dissipative

– Ultra-low outgassing

– Electrical properties:

• Volume Resistance: 104 – 109 ohm

– Outgassing properties:

• Total Mass Loss (TML): 0.41-0.45 %

• Water Vapor Recovered (WVR): 0.15 – 0.17 %

• Collected Volatile Condensable Materials (CVCM): <0.01 – 0.01%

Potential applications:

– Production parts

– Advanced functional prototypes

ULTEM 1010

Polyetherimide

– Excellent strength & thermal stability

– Highest heat resistance of any FDM material 421˚F

– Flame, smoke, and toxicity rating

• 14 CFR/FAR 25.853 | ASTM F814/E662

– Available in general purpose or biocompatible grade

• ULTEM 1010CG | NSF51| ISO10993 Class VI

Potential applications:

– Advanced functional prototypes

– Production parts

– Manufacturing tools and patterns

ULTEM 9085

Polyetherimide

– Flame-retardant, high performing material

– High thermal & chemical resistance

– Flame, Smoke, and Toxicity rating

• 14 CFR/FAR 25.853 | ASTM F814/E662

– Fungus resistant

• MIL-STD-810G

– Available in general purpose or certified grade

• Raw & filament analysis | lot number traceability

Potential applications:

– Advanced functional prototypes

– Production parts

– Manufacturing tools and patterns

PPSF/PPSU

Polyphenylsulfone

– Built for demanding applications

– Excellent chemical resistance

– Good heat resistance and mechanical strength

– Suitable choice for “under the hood” scenarios

– Sterilizable

– Steam | ETO | Plasma | Chemical | Radiation

Potential applications:

– Concept models

– Functional prototypes

– Production parts

– Manufacturing tools

Nylon 6

Polyamide

– New standard material for all-purpose prototyping

– Fills the niche between Nylon 12 and Nylon 12CF

– Excellent combination of strength and toughness

– Good choice for production floor environment

Potential applications:

– Production tooling

– End-use parts

– Tough prototypes

FDM Hips

High-impact polystyrene

– High impact resistance

– General use

– Low cost

Potential applications:

– Jigs and Fixtures

– Manufacturing Aids

– Functional Prototypes

Kimya PC-FR

Polycarbonate (PC) - Flame Retardant

– Flame-resistent material

– Electrical insulator

– Good dimensional stability

Potential applications:

– Passenger and commercial rail

– Electrical

– Replacement of obsolete parts

VICTREX AM 200

PEEK

– PEEK-Based copolymer

– Wear resistant

– Heat resistant

– Chemical resistant

– Soluble support compatible

Potential applications:

– End-use parts

– Jigs & fixtures

– Functional prototyping

– Manufacturing aids

Want to Learn More About Fused Deposition Modeling (FDM)?

Check out GoEngineer's NEW Fused Deposition Modeling (FDM) 3D Printing page! Here you will find:

- An Extensive History of Fused Deposition Modeling

- Fused Deposition Modeling Uses and Materials

- Advantages and Disadvantages of FDM 3D Printing

and much more!

ADDITIONAL 3D PRINTERS

POLYJET

3D print realistic prototypes and models with full-color elements, labels, and true-to-life textures in one operation. PolyJet 3D PrintersMETAL

3D print functional metal parts and prototypes for industrial, commercial and private applications. Metal 3D PrintersSAF

Selective Absorption Fusion™ SAF™ technology that delivers functional, production grade parts with optimum consistency. Production SAF 3D PrintersP3

Programmable PhotoPolymerization P3™ technology delivers industry leading accuracy, consistency, and details. Production P3 3D PrintersStereolithography

Open-system Stereolithography (SL) technology delivers dependable, scalable fabrication at unprecedented speeds. Open-system Stereolithography 3D PrintersAdditional 3D Printing Resources

AWARD WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services