SOLIDWORKS Simulation Volumetric Interference

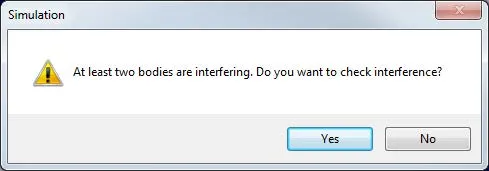

As a SOLIDWORKS Simulation technical support specialist, I see many very complicated assemblies on which customers are attempting to perform a SOLIDWORKS Simulation; that, at times, will not mesh because of a phenomenon called volumetric interferences. Many times these customers see the following error messages:

SOLIDWORKS Simulation has a built-in tool to detect where in an assembly the volumetric interferences are occurring.

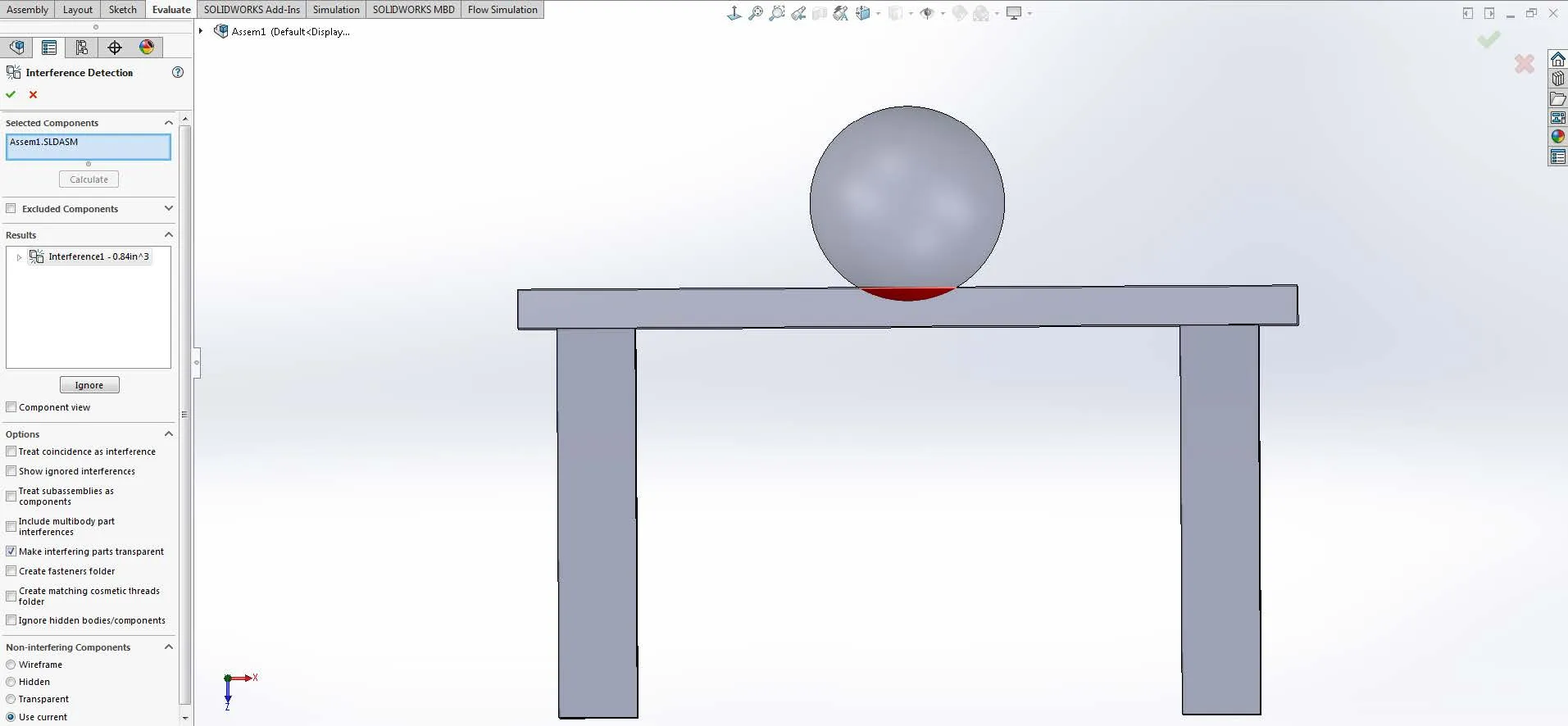

To access this tool please perform the following. Click Tools > Evaluate > Interference Detection > Calculate.

The interference in the assembly will show up as line items that the user can click and see in red exactly where there are interferences in an assembly file.

Below is an example of a volumetric interference of a ball sitting on a tabletop.

Obviously, in real life, this situation would not happen, and I cannot say that if you have volumetric interferences in your model your simulation will not mesh or run.

I can say that, if it does, while these interferences still exist in the assembly your results will not be accurate because SOLIDWORKS Simulation is meant to model real-life situations and the results of those situations.

When assemblies contain volumetric interferences they automatically cannot represent real life because in real life objects do not take up the same space at the same time. The one exception to this rule is the shrink fit contact set that uses volumetric interferences to calculate the normal forces exerted as an object is pressed into a slightly larger object. The smaller object will shrink while the larger object expands.

It is always best to find all the volumetric interferences in a model and make the necessary changes to the model before running a simulation on an assembly. If you ever run into this error message, or even if you don’t, but your model still will not mesh. The first thing you should check is if there are any volumetric interferences in your assembly by using the interference detection tool and make the necessary changes to the assembly to “clean it up” in order to remove all of these interferences. Afterward, try meshing the model again to see if the interferences were the problem.

Learn More About SOLIDWORKS Simulation

What Determines the Default Mesh Size in SOLIDWORKS Simulation?

Why Use Hex Elements in Your FEA?

Introduction to Validation Equations in SOLIDWORKS Simulation

SOLIDWORKS Simulation Results Export Options

SOLIDWORKS Simulation Gauss Points, Nodal, and Element Stress

About Taran Packer

Taran is a SOLIDWORKS Simulation Technical Support Specialist at GoEngineer. He has a Bachelor’s degree in Biomedical Engineering from the University of Utah. Taran enjoys learning about different tools in SOLIDWORKS Simulation, Flow Simulation, and Plastics.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.