PolyWorks Inspector Overview

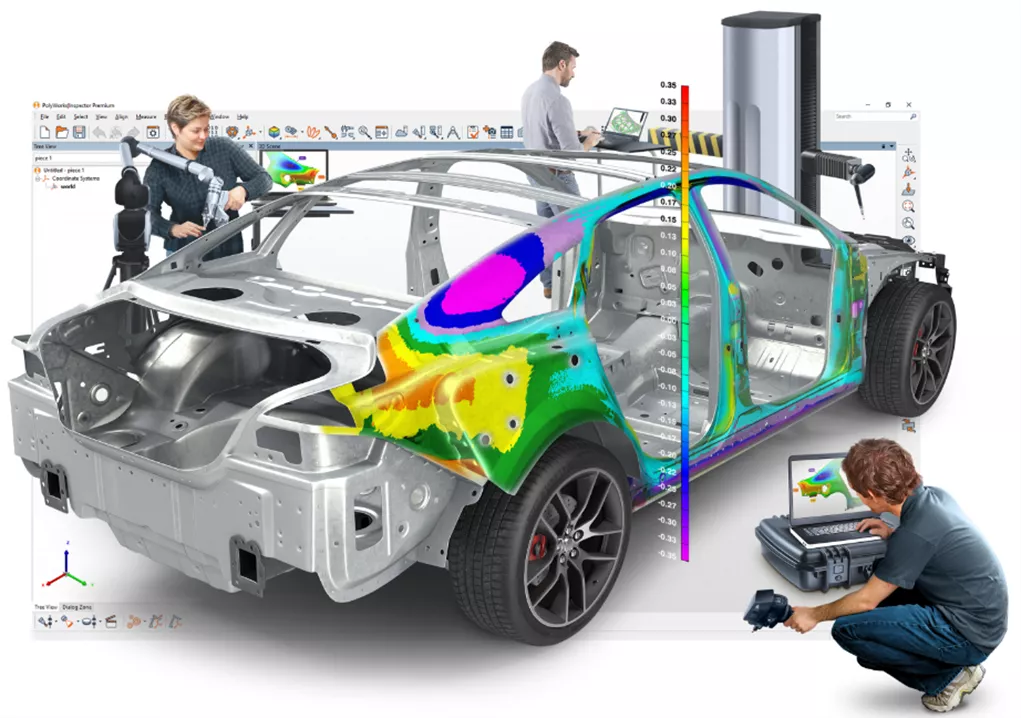

PolyWorks Inspector is a premium metrology and inspection package ideal for high-volume inspections, manufacturing line quality control, and advanced reporting - all wrapped up in a clean and easy-to-use interface. The biggest difference between PolyWorks and other inspection software (like Geomagic Control X and Creaform VXinspect) is that it can act as a measurement technologies hub.

- Suggested Article >> Choosing Analysis & Inspection Software: Creaform, Geomagic, & PolyWorks Considerations

PolyWorks Inspector is used to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, and guide assembly building through real-time measurements. Oversee the quality of assembled products by using portable metrology devices (like 3D scanners), digital gauges, visual inspections, and CMMs - all in one universal hub.

What Makes PolyWorks Inspector Unique?

As previously mentioned, PolyWorkst acts as a hub for all your measurement equipment, meaning you can bring in 3D scanning data, probe measurements from CMMs, digital gauges, and even visual inspections performed by the operator. Having all of this metrology reading in one convenient location allows for cross-collaboration when working on parts that require a variety of different measurements.

Additionally, PolyWorks allows users to extract meaningful information from their measured 3D data, automate the inspection process when more than one piece is measured, and structure the presentation of measurement results in customized reports.

Another advantage of PolyWorks Inspector is the macro scripting and Statistical Process Control (SPC) functionality. Add or create macro scripts to your measurement workflows to apply proprietary techniques, provide special feedback, or interconnect with other systems in your organization to promote cross-departmental collaboration. You can also evaluate the repeatability and predictability of your manufacturing processes with multipiece statistics automatically calculated for object dimensions and surface deviations.

What’s New with PolyWorks Inspector 2024?

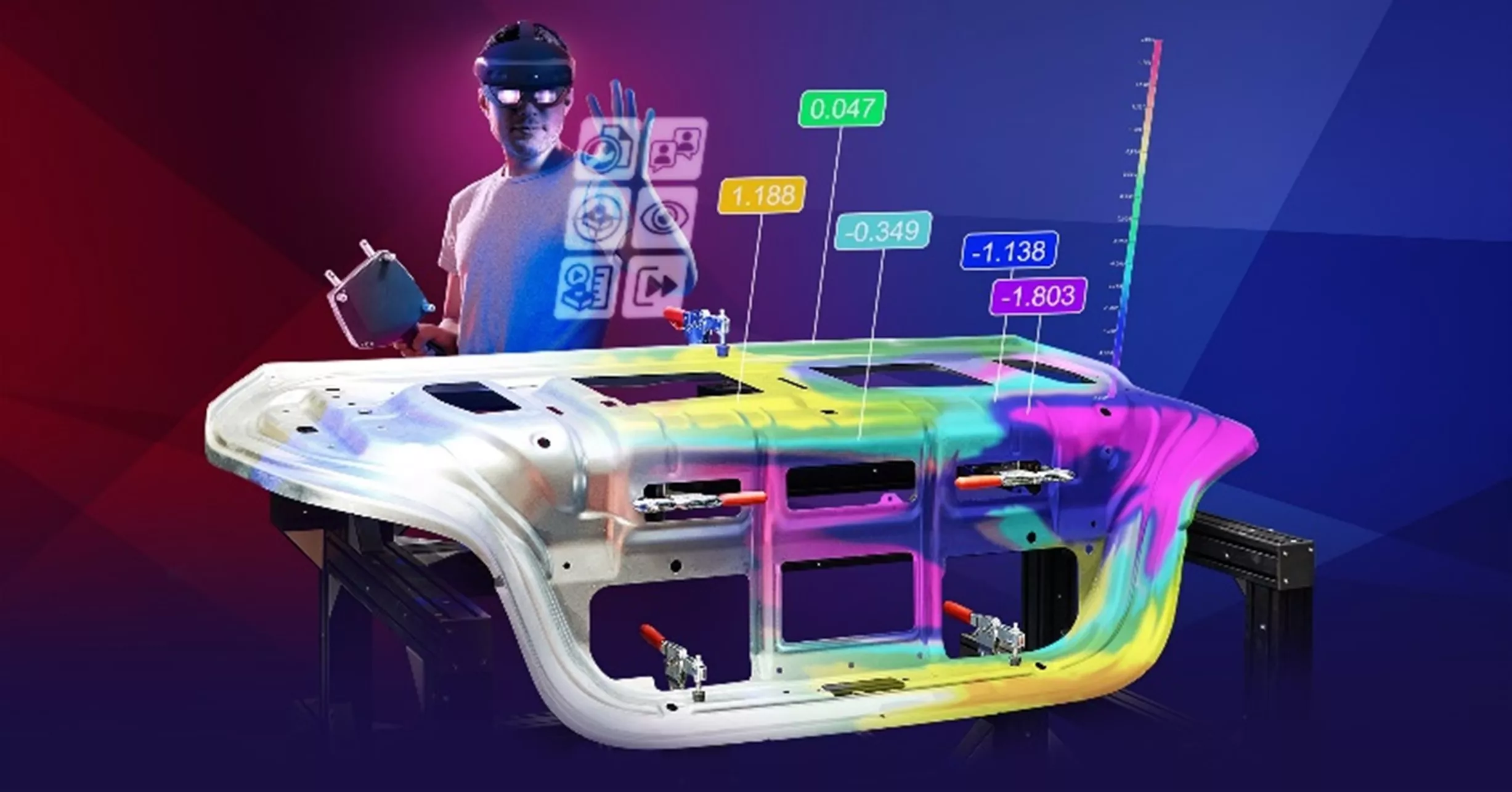

PolyWorks Inspector 2024 has seen the addition of mixed reality technology, providing visual guidance, scan quality information, and measurement feedback to operators without encumbering their hands. Additional improvements have been made, including a search function to filter large projects quickly, faster feature creation on inspections without CAD references, and a noise reduction filter for tactile CMM scanning.

Since PolyWorks is a universal hub for almost all 3D scanners, there are plenty of options to choose from, however, a metrology-grade scanner is recommended.

- Suggested Article >> Choosing a 3D Scanner: Light vs Lasers, Applications, & Considerations

The MetraSCAN Black Elite is great for larger parts and, for parts up to 10 feet, the HandySCAN Black Elite (or Black Elite Limited, for those who need even more accuracy). Both of these scanners are made by Creaform and come with ISO 17025 accreditation for reliable and accurate data acquisition.

For an even more thorough hardware setup, pair the MetraSCAN with the HandyPROBE – a wireless touch probe that delivers all the benefits of a CMM without the large footprint, hefty price tag, and facility requirements that come with a fixed gantry system.

Computer Requirements for PolyWorks Inspector

While you could use a lower-powered PC to open and do basic programming with the software, to get the most out of this advanced tool, the recommended computer requirements are:

- CPU: Quad-core CPU

- RAM: 32 GB

- Graphics card: Professional NVIDIA RTX*** / Quadro series graphics card equipped with at least 2 GB of memory

- Operating system: 64-bit Windows 11 or 10, Professional Edition

- Input device: Two-button mouse with wheel

Is PolyWorks for Me?

If you have a QC department, multiple measurement tools, or need deeper manufacturing quality analysis (SPC, FAI, inspections with MBD references) then PolyWorks might be the solution for you. To determine if PolyWorks is the right fit for your organization, contact us to talk to one of our Application Engineers.

Related Articles

New Creaform HandySCAN Max Elite & Other Updates

3D Scanning for Automotive: Applications, Hardware, & Software

Creaform Releases HandySCAN BLACK|Elite Limited 3D Scanner

Scan-to-Print Workflow: Tips to Optimize 3D Printed Food Models

About Sam Cheney

Sam Cheney is an Application Engineer specializing in 3D Scanning and Additive Manufacturing based out of Dallas, TX. He is a Certified Stratasys Applications Engineer and co-leads the 3D Scanning Services team. Originally from the UK, Sam holds a Master's Degree in Mechanical Engineering with a specialization in 3D Printing from The University of Sheffield. Alongside working with commercial 3D printers & scanners, Sam trains others and teaches courses for Geomagic products & VXelements software. He is also an avid consumer 3D printer user and uses his Creality Ender3 to create art and functional parts for projects in his everyday life.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.