Choosing Analysis & Inspection Software: Creaform, Geomagic, & PolyWorks Considerations

When it comes to quality control or scanning parts to determine root cause analysis, there are a few different tools available to help get the job done, but which is the right one for you? In this article, we look at the pros and cons of the following three analysis and inspections solutions:

- Creaform VXinspect (Both the Analysis & Quality Control Packages)

- Geomagic Control X

- PolyWorks Inspector

Suggested Article >> Choosing a 3D Scanner: Light vs Lasers, Applications, & Considerations

Why Do You Need Inspection Software?

When creating a part, no matter the manufacturing process, you will slightly deviate from the perfect CAD file or drawing. To measure these deviations, traditional methods, like calipers and tape measures can be used, but they are limited to simple measurements and are highly dependent on the user wielding them.

Dedicated professional inspection software, however, ensures accurate and repeatable measurements. Detect defects early, improve efficiency with automation, and enable data-driven decision making. By leveraging such software, users can optimize the production processes, reduce costs, and maintain a competitive edge in the market.

Choosing an Inspection Software

Choosing an inspection software depends on several factors and should be prioritized in a way that’s unique to your organization. When evaluating different software, it's important to consider the unique standards or requirements of your industry, the learning curve of the software, the usefulness of automated tools, scalability as you develop more products, cost or return on investment, and integration with current MES or ERP systems.

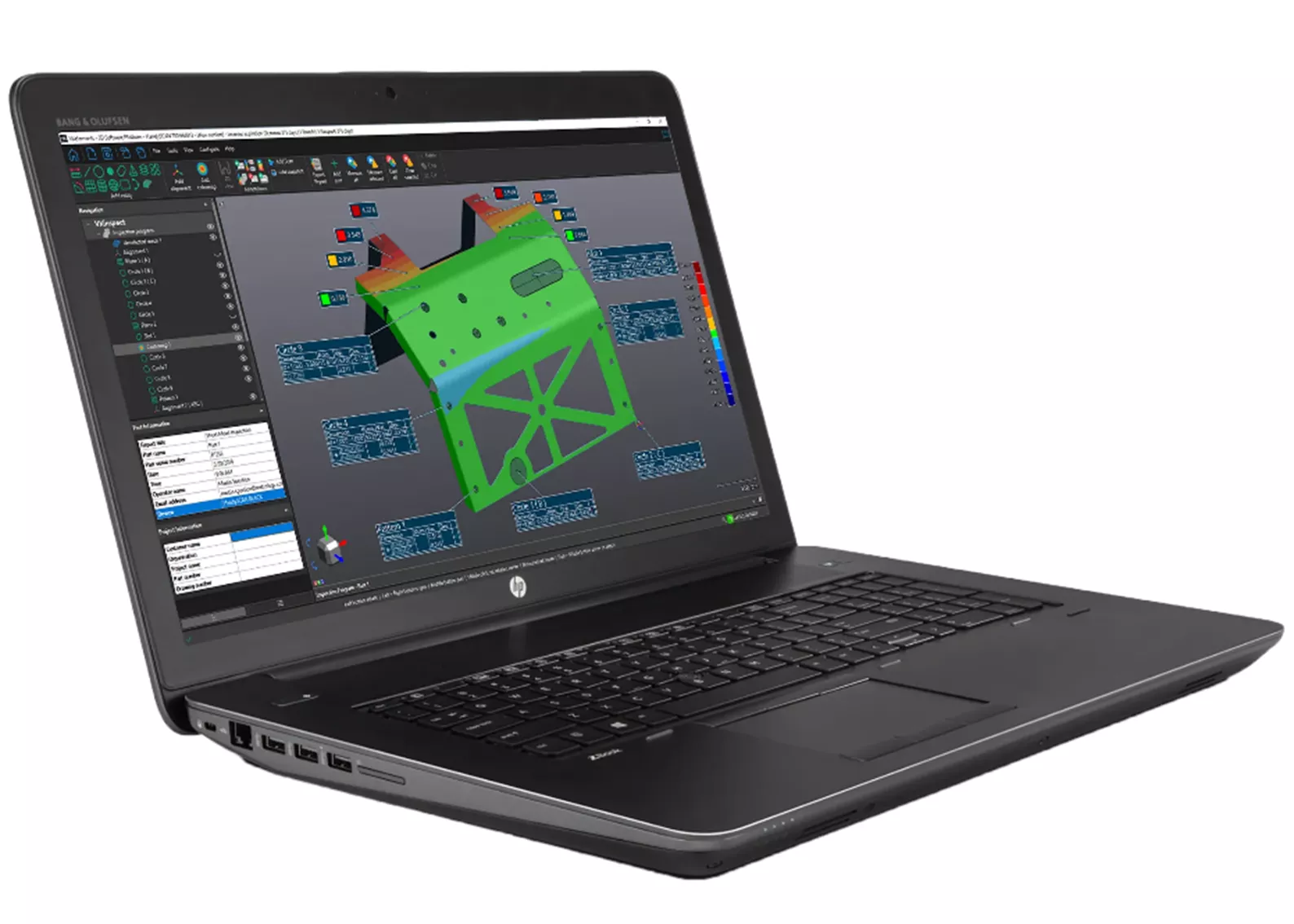

Creaform VXinspect

If you've used a Creaform 3D scanner, you will be familiar with the scan acquision module: VXscan. However, VXinspect can be used to perform analyses and create inspection reports with numerous 3D scanner brands on the market.

There are two versions of Creaform VXinspect: VXinspect Analysis and VXinspect Quality Control.

VXinspect Analysis is a simple but comprehensive tool for analyzing defects with 3D colormaps and extracting measurements from a single part at a time.

VXinspect Quality Control is a more robust version of the inspection software and allows for the analyis of parts with GD&T and can inspect multiple parts at once.

Both software packages are incredibly user-friendly and have a low learning curve. Additionally, of the three software solutions we discuss in this article, VXinpsect is the most budget friendly. However, compared to other softwares, the inspection capabilities are a little more limited, with no integration to other MES or QC systems, no ability to use statistical process controls, and limited automated reporting.

VXinspect is ideal for those new to QC, are budget conscious, don’t require a high volume of parts inspected, or have no need for integration with other systems.

Cost: $

Ease of use: 5/5

Advanced Capabilities: 1/5

Learning Curve: 5/5

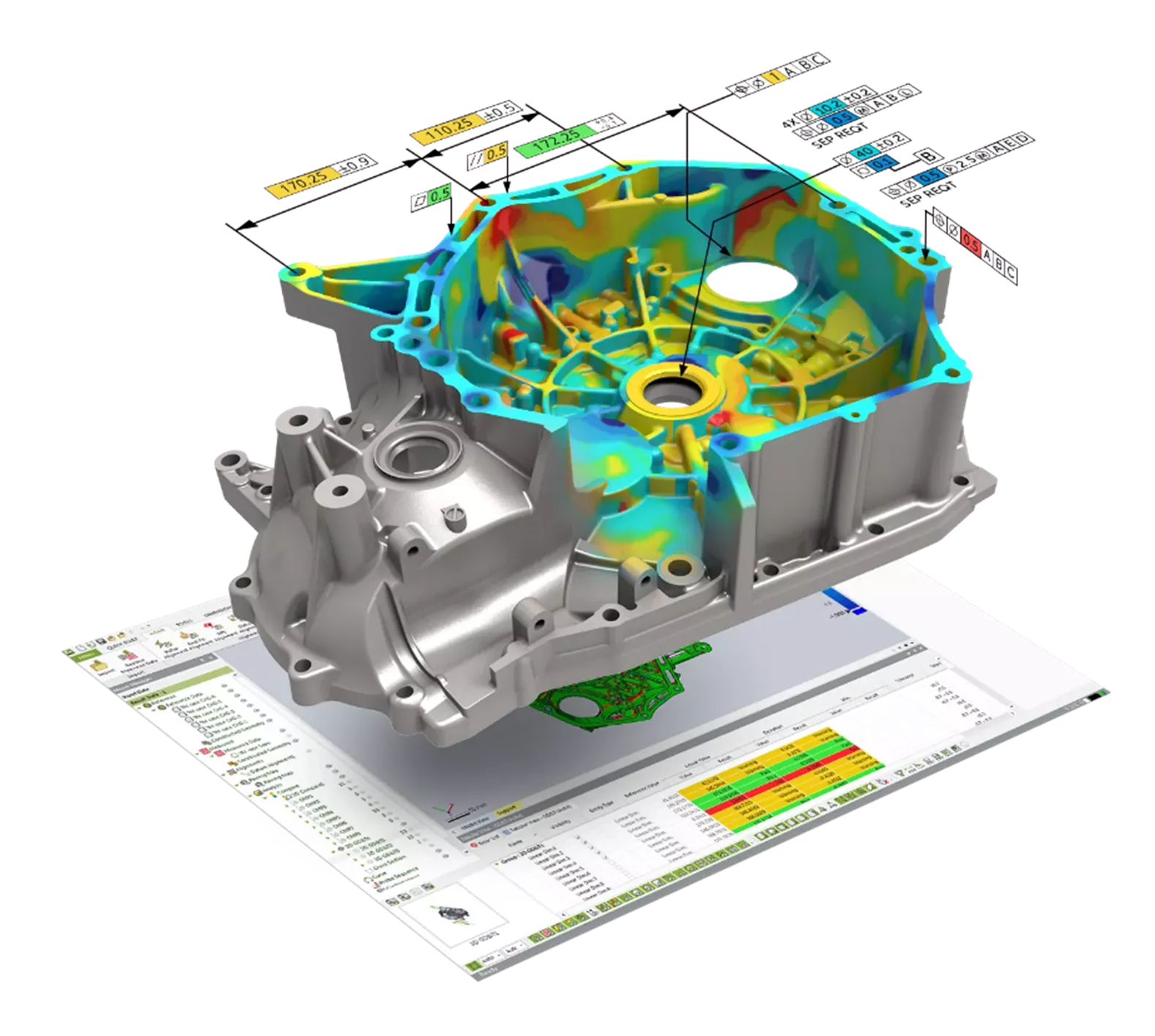

Geomagic Control X

Geomagic Control X is a powerful metrology and quality inspection software developed by Oqton, designed to streamline the inspection and measurement processes for industrial manufacturing. Compared to VXinspect, Geomagic Control X is more advanced, allowing users to import 3D scan data from various sources, such as coordinate measuring machines (CMMs), laser scanners, and other 3D measurement devices.

What sets Geomagic Control X apart from the pack is the ease of use of automatic alignment and other efficient and automated tools that make inspections a breeze. Geomagic Control X also supports numerous file formats, making it compatible with different hardware systems. Advanced tools for airfoils, corrosion, and dents, make Geomagic Control X great for aerospace and pipeline applications.

Geomagic Control X is built on a CAD kernel, so it behaves like the CAD package you already know. Batch inspection and scan process designers are available to help scale your inspections up without increasing workload. Finally, reports are highly customizable in order to suit your needs and whatever reporting standards you employ.

Geomagic Control X does have a higher price point, a slightly steeper learning cuve, and has some limitations in statistical process control and integration with MES and ERP systems. Overall, it is an ideal choice for anyone serious about metrology who needs advanced capabilities without breaking the bank.

Geomagic Control X, although less intuitive than VxInspect, allows users to scale and grow their inspection capability and integrate multiple measurement systems into one software while benefitting from advanced tools for specific applications.

Cost: $$

Ease of use: 3/5

Advanced Capabilities: 3/5

Learning Curve: 3/5

Suggested Video >> Introduction to Geomagic Control X

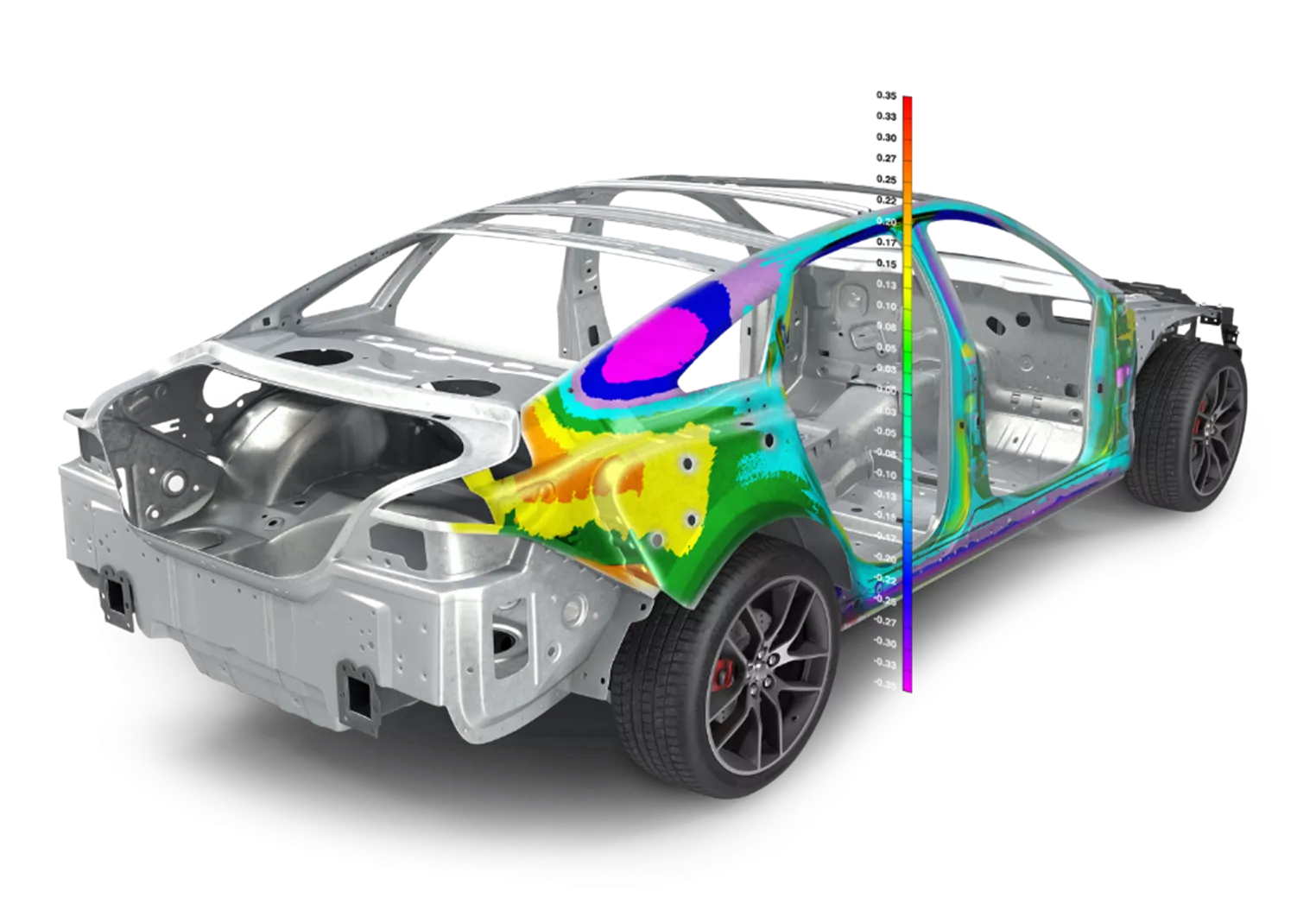

PolyWorks Inspector

PolyWorks Inspector is a comprehensive 3D metrology software developed by InnovMetric. It is designed to address the needs of quality control and inspection processes in various industries, including automotive, aerospace, and manufacturing. It offers a wide range of features and functionalities that set it apart from other inspection software tools including real-time inspection. With real-time inspection, measurements and inspections can be performed directly on the shop floor during the production process. This feature enhances efficiency by reducing the need for additional measurement setups and allows for immediate feedback on the quality of parts being manufactured.

When combined with a CMM, users benefit from smart collision avoidance to speed up the programming step without sacrificing machine safety. However, the main benefit of PolyWorks Inspector is the extensive automation and scripting capabilities. Users can create automated inspection processes, develop customized workflows, and streamline repetitive tasks. The software also supports integration with external systems and databases, facilitating seamless data exchange and workflow optimization along with being a universal data hub for metrology equipment.

Furthermore, PolyWorks Inspector offers a collaborative environment that enables teams to work together on inspection projects. Multiple users can access and share inspection data, collaborate on analysis and reporting, and improve productivity by working in a synchronized manner.

The drawback to this software is the price point and the learning curve, which can be improved through training. This software is ideal for those with existing metrology equipment that need the ability to collaborate and keep all their inspections in one place. Automotive, aerospace, or manufacturing industry professionals will find this software ideal for their QC department.

Cost: $$$$

Ease of use: 4/5

Advanced Capabilities: 5/5

Learning Curve: 1/5

As you can see, there is much to consider when choosing analysis and inspection software. If you need further help or have questions about any of the solutions mentioned in this article, contact us.

Related Articles

3D Scanning for Automotive: Applications, Hardware, & Software

Creaform Releases HandySCAN BLACK|Elite Limited 3D Scanner

Artec Micro Desktop 3D Scanner: Full Function Freedom

The GoEngineer Trifecta: Creaform, Geomagic & Stratasys

3D Technology and Archaeology: Enabling Artifacts to Virtually & Literally Travel the World

About Sam Cheney

Sam Cheney is an Application Engineer specializing in 3D Scanning and Additive Manufacturing based out of Dallas, TX. He is a Certified Stratasys Applications Engineer and co-leads the 3D Scanning Services team. Originally from the UK, Sam holds a Master's Degree in Mechanical Engineering with a specialization in 3D Printing from The University of Sheffield. Alongside working with commercial 3D printers & scanners, Sam trains others and teaches courses for Geomagic products & VXelements software. He is also an avid consumer 3D printer user and uses his Creality Ender3 to create art and functional parts for projects in his everyday life.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.