Understanding the DriveWorks Generation Queue

Whether in your DriveWorks training or first projects, you have experimented with capturing and releasing models to your specifications. Since the models are released inside the specification, the generation of those models is linked to the specification, right? Well, no.

Specification Flow versus Generation Queue

When you release documents (e.g., Word quotes, Excel spreadsheets, etc.), those documents are generated right when they are released. However, when models are released, they are placed into a generation queue to be generated by a user or by Autopilot. Using this generation queue frees up the specification to perform other tasks and not have to wait until the models are done generating, which may take a while, depending on the size and complexity of the models. Therefore, once the models are released, the Specification Flow and the Generation Queue are separate.

There are a few caveats to this. The main one is that the generation queue is separate from the specification, meaning all rules, variables, and generation tasks are evaluated at the time of release. Therefore, if the variables change after the models are released, those changes are not reflected in the generated model.

Connect Generation Data with the Specification: Case Study

What if we want data from SOLIDWORKS to be part of our specification? For example, what if we wanted to report the overall mass of the generated assembly in our quote document? This is not something we can simply calculate from inside the specification, and we will need to rely on data available in SOLIDWORKS. Therefore, we will use SOLIDWORKS to calculate the mass properties, and then we will need to use that data in our specification somehow.

Exporting the Mass Properties

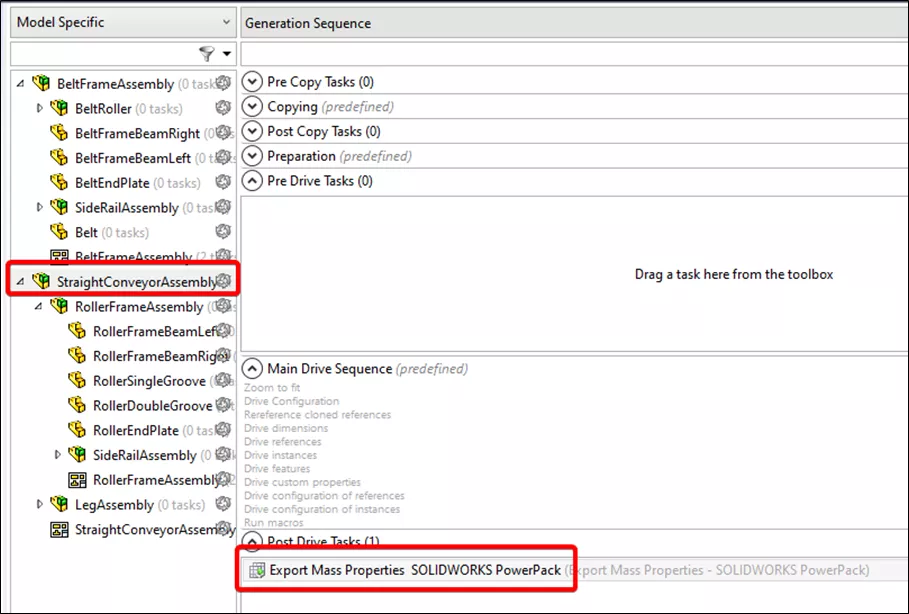

Using the Straight Conveyor assembly from the DriveWorks Pro training as our case study, I will first need to export the Mass Properties of the assembly using the Export Mass Properties Generation Task from the SOLIDWORKS Powerpack.

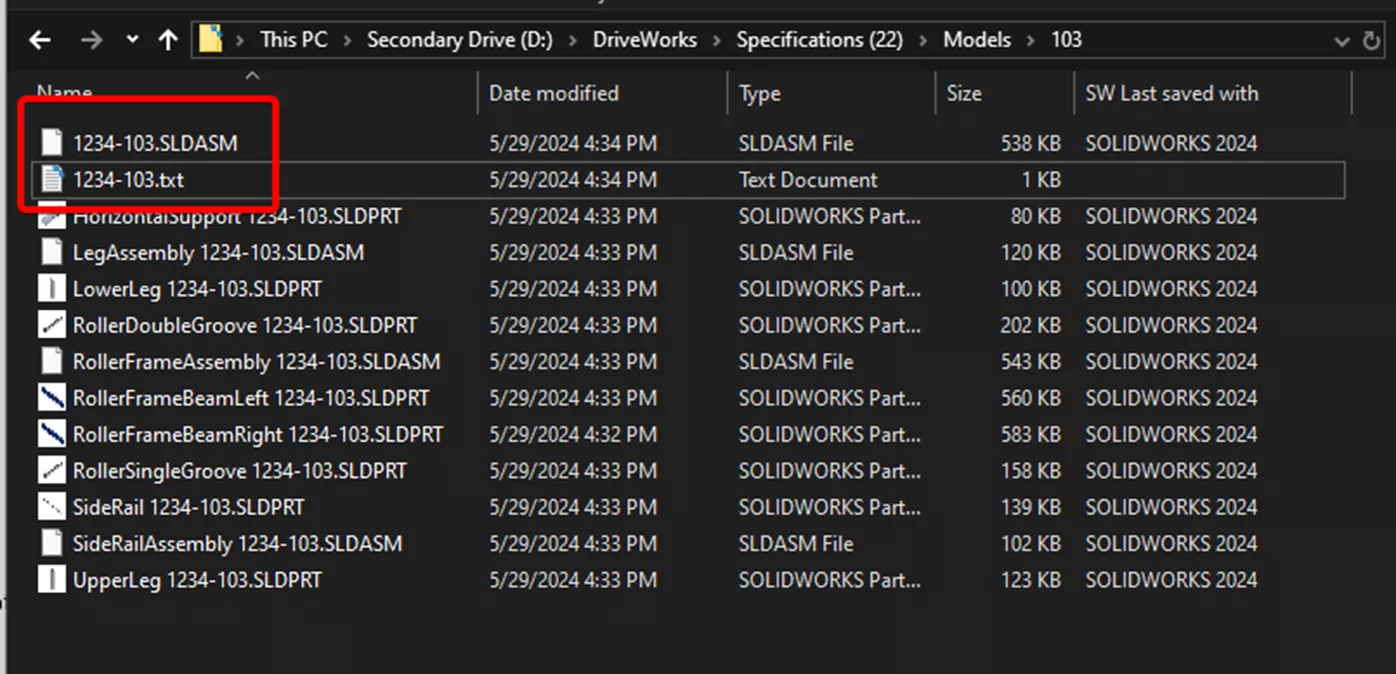

Now that I added the generation task to export the Mass Properties, a text file is created in the same folder as the assembly after generation is complete.

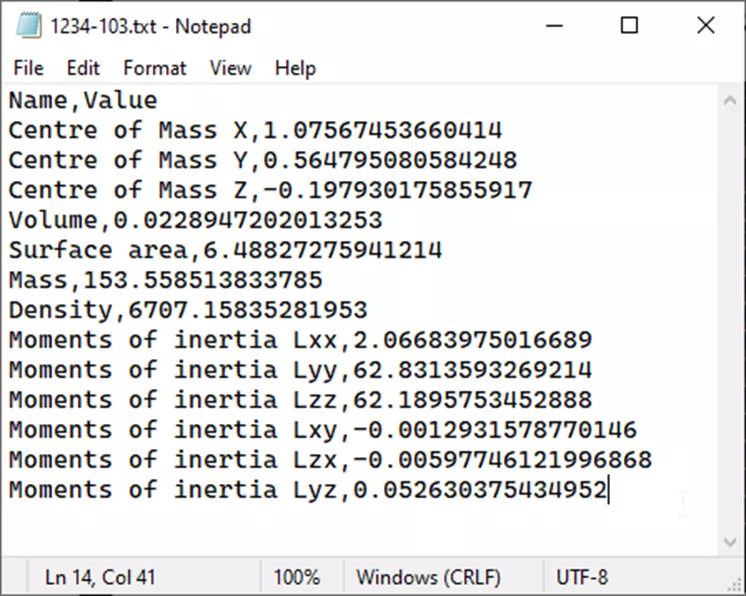

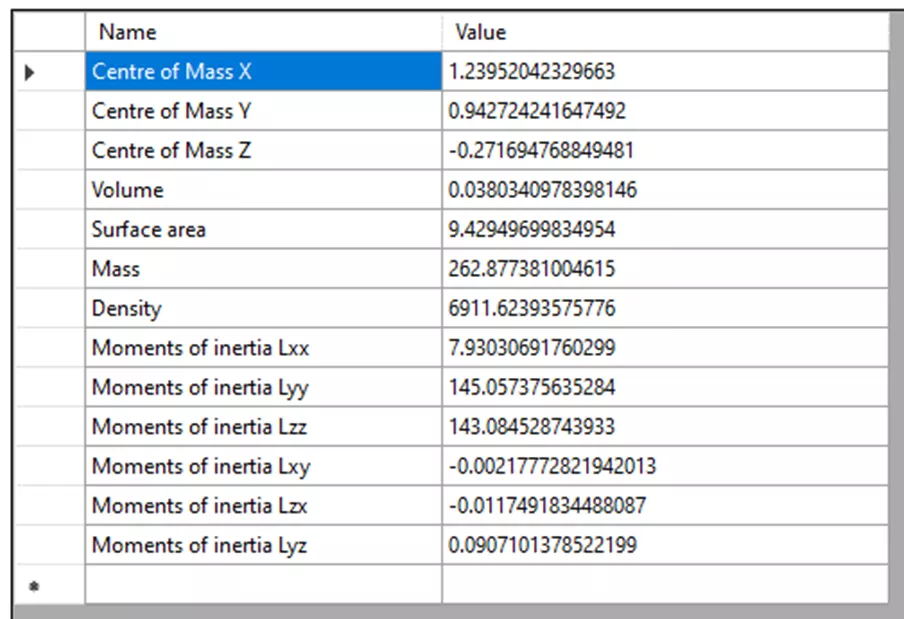

The data inside the Text file looks like this:

Read Data Into the Specification

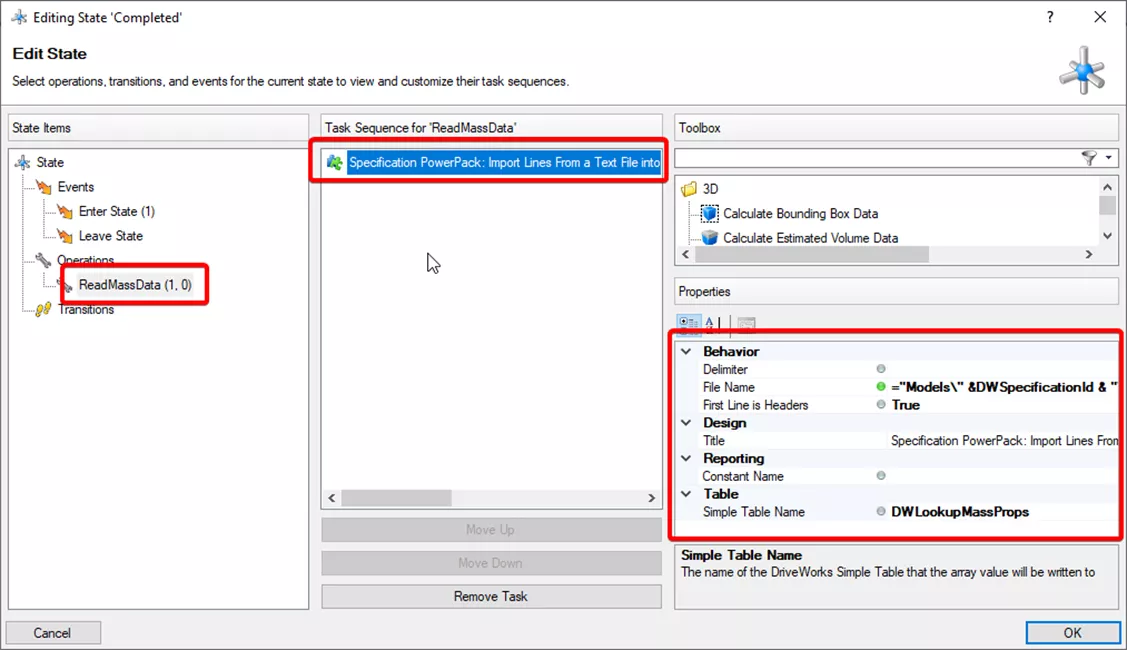

Now that I have my data exported as a text file, I need a way to read the data back into the specification so I can use it in my documents. To do this, I will use the Import Lines From A Text File Into An Existing Simple Table Specification Task from the Specification Powerpack.

I placed the task in a new operation called “ReadMassData” in my Specification Flow so that I can trigger the importing of the data after the generation is complete. The operation needs to be placed on the state the Specification Flow will be in when the models are done generating.

Now, after waiting for the models to finish generating, I can run the operation manually from Specification Explorer. I must then edit the specification and review the table in Test Mode to confirm the data has successfully been imported.

Now that I know my data is getting imported successfully, I am going to modify the operation to release an Excel document that contains this mass data to mimic using this data in a quote or other document.

Trigger the Operation when Generation is Complete

Once the mass properties export from SOLIDWORKS is complete, and the importing of the data back into the specification works, some human interaction is still required. There are a couple of ways to accomplish this.

One way is using a triggered action document, which tells Autopilot to monitor for a particular file, and when that file is created, Autopilot will trigger an operation or transition. This is a viable option, but it does require Autopilot to be running.

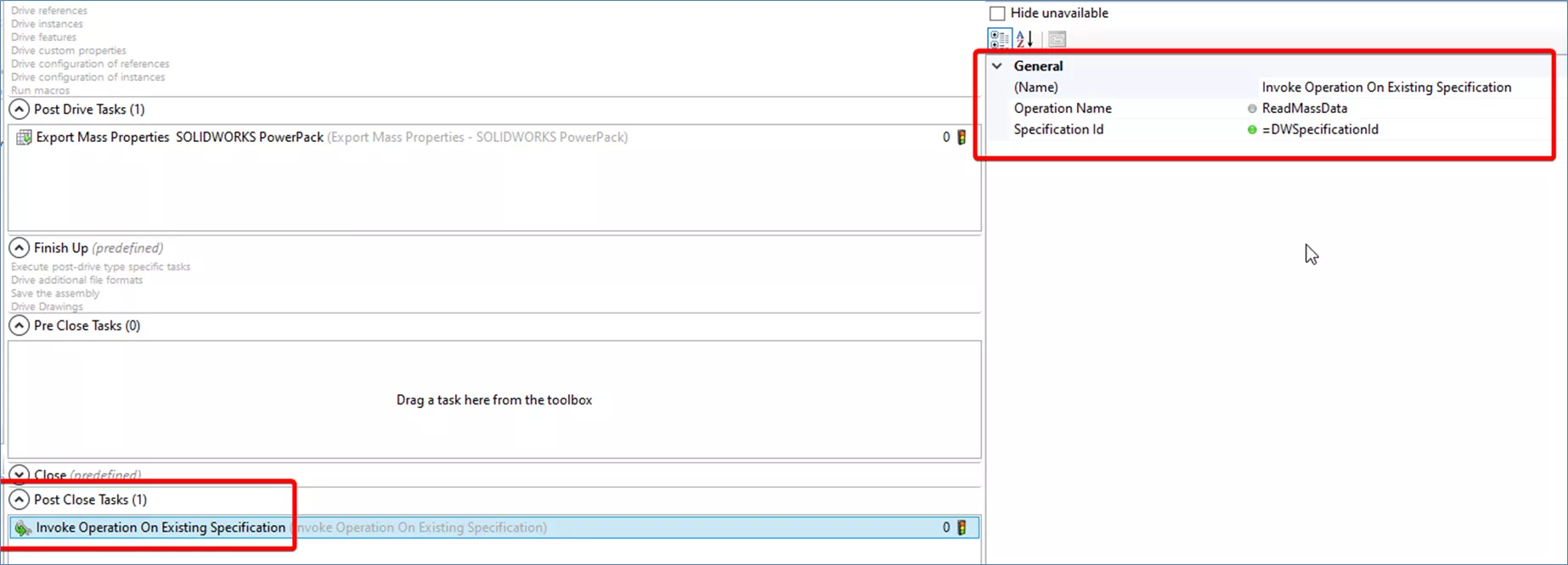

A simpler option, generation actions, can trigger an operation or transition in a specification. All I have to do is add the generation task to invoke the right operation for the right specification. I added the Invoke Operation on Existing Specification generation task on the same assembly on Post Close.

Now I have automatically been able to export data from SOLIDWORKS and import it back into the specification so it can be used in other documents.

Summary

These concepts of exporting data from SOLIDWORKS with generation tasks and using operations or transitions to import that data can help automate ways to coordinate the Generation Queue and the Specification Flow to help bring data from SOLIDWORKS back into the Specification for use in other documents.

Learn More About DriveWorks

Compare DriveWorks Packages: Features in DriveWorksXpress, Solo & Pro

DriveWorks Test Mode: Generate (On Demand) vs Generate (Queued Using Model Insight)

DriveWorks CPQ - Enhancing Collaboration Between Sales and Engineering

About Isaac Smith

Isaac Smith is a SOLIDWORKS Technical Support Engineer at GoEngineer.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.