DriveWorks CPQ - Enhancing Collaboration Between Sales and Engineering

Communication between departments can be challenging, whether due to struggling to communicate in a timely matter or difficulty conveying design requirements. That’s why many organizations are adopting CPQ solutions.

What is CPQ?

CPQ stands for configure, price, and quote. The power at your fingertips with such a system is that one person can configure an item, get an accurate price, and send out a quote from a single tool.

According to studies conducted by PwC, organizations that adopt a CPQ solution can see their sales cycle time reduced by up to 60% and revenues increased by nearly 15%. In part, these numbers are fueled by reducing bottlenecks and making communication between departments more efficient. Here, we'll explore how we can use DriveWorks as a CPQ solution for manufacturing and look at an example from Air Handling Systems.

Configure

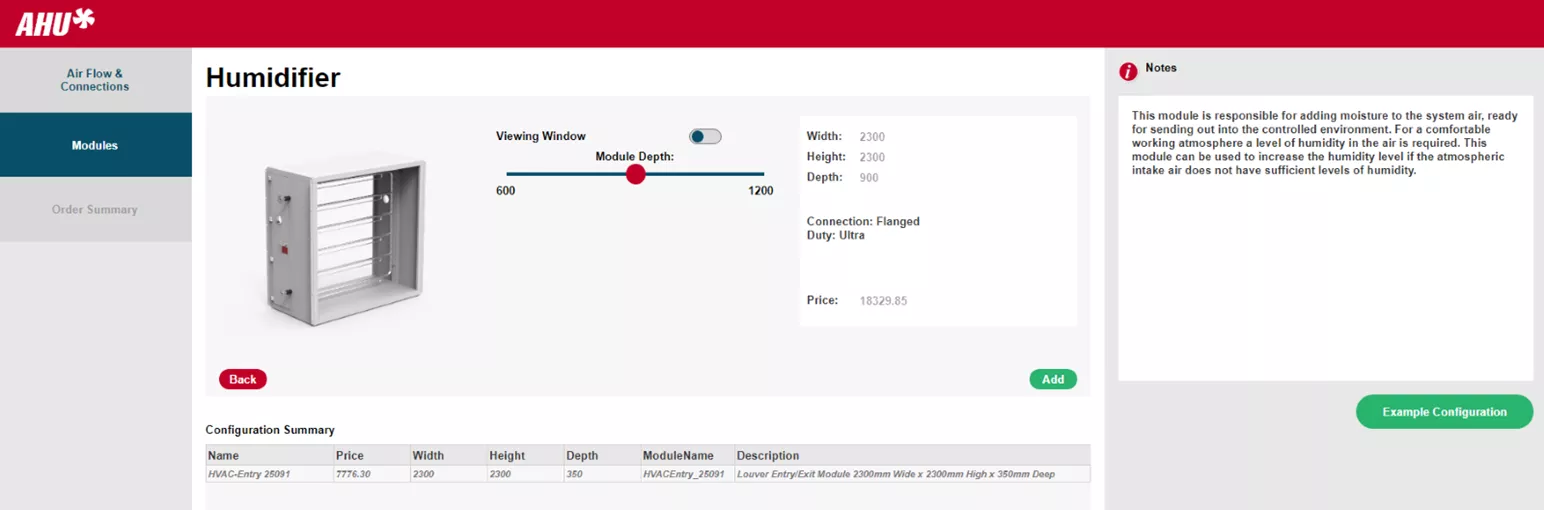

One of the biggest advantages for sales when adopting a CPQ solution is that all of the engineering requirements (i.e., what is and isn’t possible or available) get programmed into the tool. This eliminates the added step of confirming with the engineering team. In essence, if you can specify it in DriveWorks, you can sell it to your customers. Let’s look at an example from DriveWorks Live.

In this example, we’re configuring an HVAC unit and, specifically, which humidifier to include. I’ve chosen a depth of 900cm for the module, but I can see that I could go anywhere from 600cm to 1200cm. For a sales engineer talking with a customer, the main benefit is that if our customer asks for a depth of 1500cm, we already know it's impossible and that we should look at other options.

Conversely, if a customer wants 700cm but they’ve told us others have said that’s impossible, we can assure them that our system will meet their requirements with room to spare.

Price

As a former pre-sales Applications Engineer, my role was to help sales teams scope out the needs of our customers and curate an accurate set of line items. While we had a sufficient system, it would have been more efficient had Sales had the ammunition to conduct discovery calls and create quotes without needing an engineer involved.

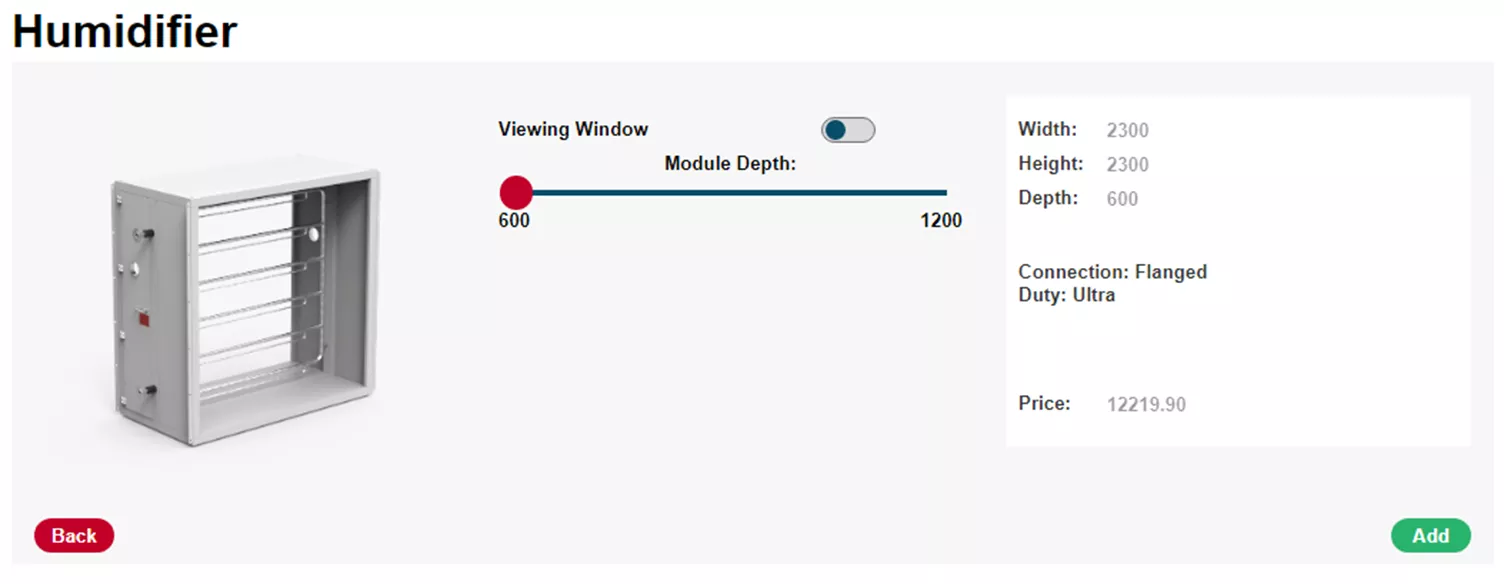

In our HVAC example, we can see pricing listed for the individual humidifier we're adding to our design.

Of course, that price changes based on the size the person configuring the unit asks for. With the depth of the unit down to just 600cm, the price of the humidifier has dropped considerably.

An important point to note, is that these prices are calculated using internal rules and requirements. They can be derived from external systems, like ERP, or calculated using logic added to the DriveWorks tool itself. This way, you know the values are correct without checking with engineering or procurement about the proper configuration or pricing.

Quote

Our final obstacle involves creating a quote and getting it into the hands of the customer. Every organization creates quotes differently and on different templates, but what if you could remove the speed bump between the configuration and pricing and immediately have a quote ready to go?

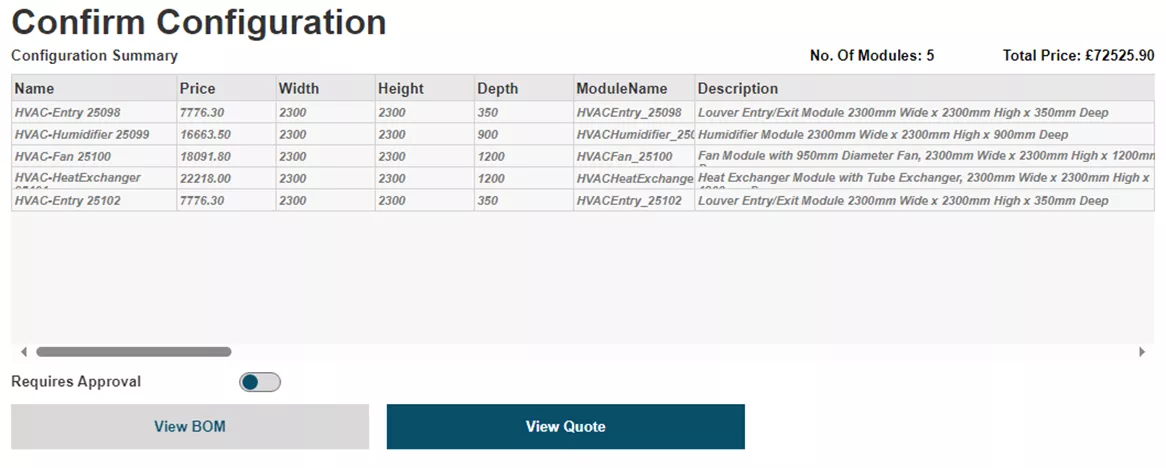

We've added a few more modules to our HVAC unit and confirmed that everything is correct. Instead of telling a customer, “I’ll have a quote over to you by the end of the day”, you can view the quote instantly.

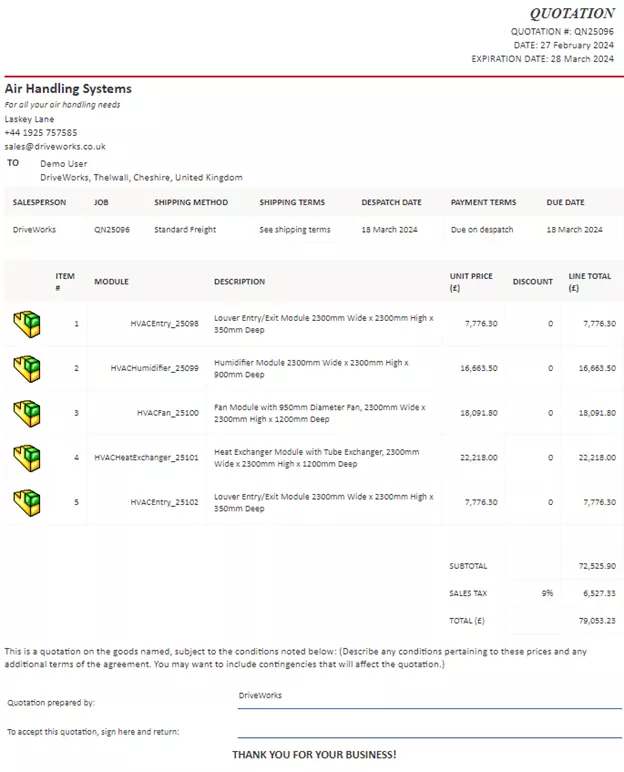

Even better, when the order is confirmed, the customer receives an email with a cover letter, quote, bill of materials, and the drawings within a few minutes.

This document is formatted specifically for our example HVAC distributor, but you could easily swap out the logos and specific details to match any organization.

Finally, remember that hurdle we keep going over – sales and engineering communicating effectively? Well, once we’ve configured our model, gathered accurate pricing, and created the quote for our customers, the designs are automatically passed to engineering, and they can begin working on whatever CAD models and assets they need for fabrication and assembly.

5 Bottlenecks that Impact Revenue

& How to Fix them

Manufacturing bottlenecks directly impact revenue. By implementing a digital transformation, you can minimize their impact and maximize your profit. Find out how introducing DriveWorks automation improves your processes.

CPQ Streamlines Communication

Every organization could stand to improve its communication. Whether sending emails, messages, or calling colleagues, involving multiple people in every step of a process is a recipe for a bottleneck. That’s where a CPQ solution built for manufacturing thrives.

When you introduce DriveWorks as a CPQ solution, you are implementing a full-service solution to configure accurate designs, provide timely pricing, and generate formatted quotes all in one place.

Related Articles

Everything New in DriveWorks 21: Rules, Integration, 3D Previews & More

Everything You Need to Know about DriveWorks Pro

Everything You Need to Know About DriveWorks Solo

Everything You Need to Know about DriveWorksXpress

About Nick Sweeney

Nick Sweeney is a Marketing Specialist with GoEngineer with a focus on software solutions. Nick graduated from The Ohio State University in 2018, completing internships with CATI (now GoEngineer) and DriveWorks Ltd. Before joining the Marketing team, Nick spent 3 years in pre-sales with CATI, giving product demonstrations, leading technical discussions, and creating technical content.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.