SOLIDWORKS PDM vs 3DEXPERIENCE CLOUD PDM: Workflows, Licensing & More

Having a central location where all data is securely stored with history, shared, and approved can make the difference between an engineering design process that works and one that doesn’t. For SOLIDWORKS (and CATIA) users, Dassault Systèmes offers two first-party data management solutions: SOLIDWORKS PDM and the 3DEXPERIENCE Platform. Both solutions handle SOLIDWORKS files well, but each has its unique strengths. This article explains some technical differences between SOLIDWORKS PDM vs 3DEXPERIENCE CLOUD PDM to help you decide which product is right for you.

Table of Contents

- Hardware

- Software

- Licenses

- Search and Data Cards

- Versions vs Revisions

- Workflow/Lifecycle

- References

- Bill of Materials

- Preview, Review, & Markup

- Engineering Change Process

- Compare

- Conclusion

Hardware

Many companies use cloud initiatives for all their IT infrastructure. As a PDM solution, the 3DEXPERIENCE Platform is 100% cloud-based and accessed over secure web protocols. An engineer’s local CAD machine sends and receives CAD data directly from the Dassault Systèmes cloud, meaning there is no need to own and operate physical servers to house engineering data.

Not only does the responsibility of hardware maintenance, system security, data backups, and software updating fall onto Dassault Systèmes, but a cloud system will also alleviate any need to VPN into company servers when engineers are working remotely.

While the cloud-as-a-service business model that 3DEXPERIENCE shares with the likes of Amazon Web Services, Google Cloud, and Microsoft Azure has all these advantages, some companies need their data housed somewhere under their immediate physical control. 3DEXPERIENCE has a middle ground for that: you can run a private 3DEXPERIENCE cloud on your own servers. You won’t get the benefits of having someone else handle all that IT, but you will enjoy 3DEXPERIENCE’s improved accessibility of product data for both users and engineering tools.

SOLIDWORKS PDM is an on-premise software requiring a server to meet the operating system, memory, and processor requirements. In addition to the SOLIDWORKS software licenses, SOLIDWORKS PDM Professional also requires a license of Microsoft SQL Server Standard. While SOLIDWORKS PDM is typically operated from an on-site server, that doesn’t mean it can’t be run from a cloud server like AWS. That server would be attached to the local domain and would appear to the company as if it were on-premise. This isn’t truly “cloud-based", as access to that server is only available through the company domain, so users will still need VPN access.

Software

SOLIDWORKS PDM is built into Windows Explorer. Users can access all PDM functions right inside the familiar Explorer interface. That means the PDM database can be accessed from any Windows application, as the Save command for apps is leveraging Windows Explorer.

SOLIDWORKS PDM has full integrations into SOLIDWORKS CAD, SOLIDWORKS Inspection, Microsoft Office, DraftSight, Inventor, AutoCAD (2D), and others. Because it is Windows-based, it will only function on Windows devices.

SOLIDWORKS PDM Professional also has a Web2 interface that users may license for web access to the contents of the database. It works well for search/view/print/approve but is not an interface for modifying CAD files. For the Web2 application, any internet hosting would be an IT responsibility. It can also simply be set up as an intranet viewer.

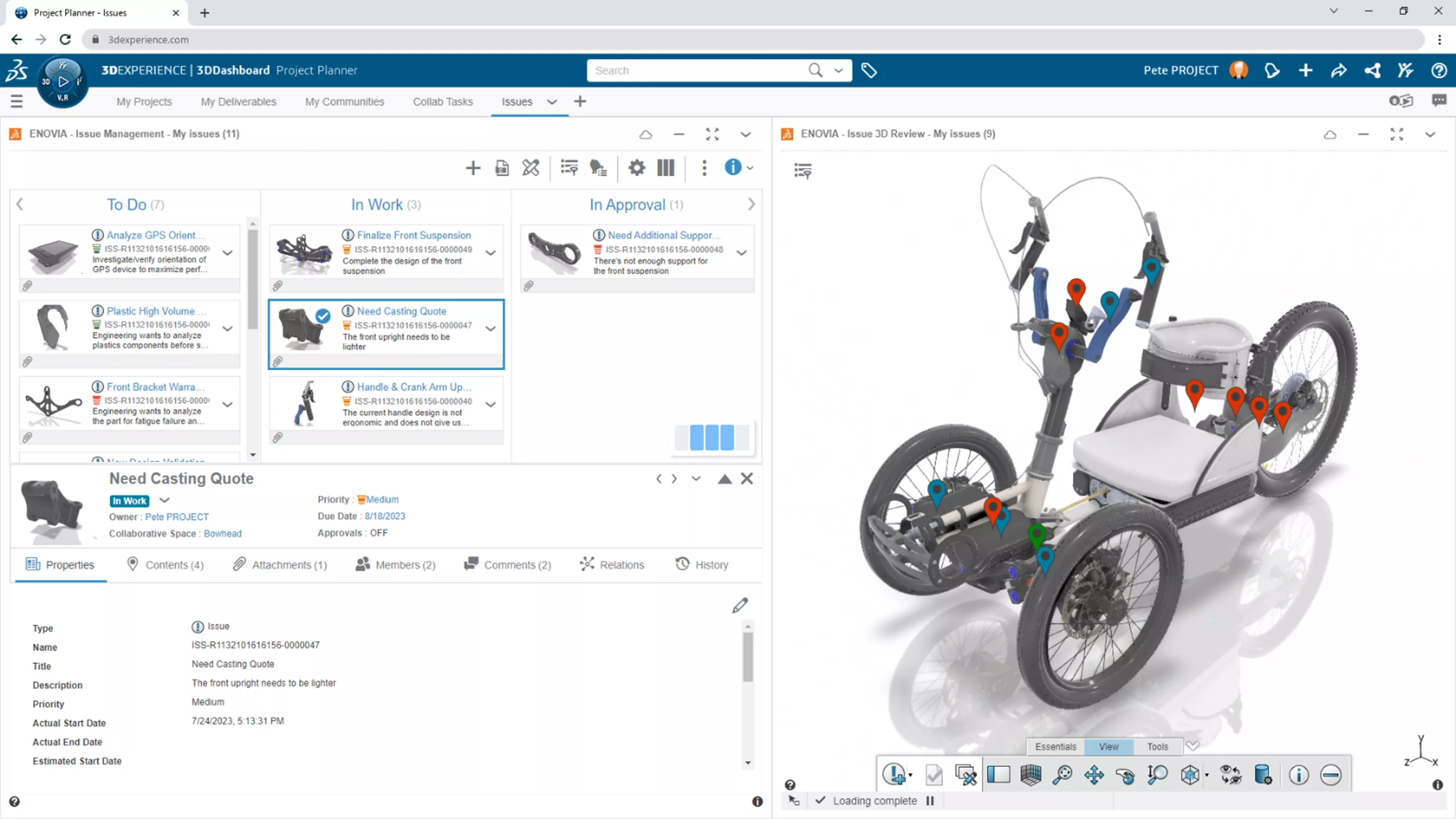

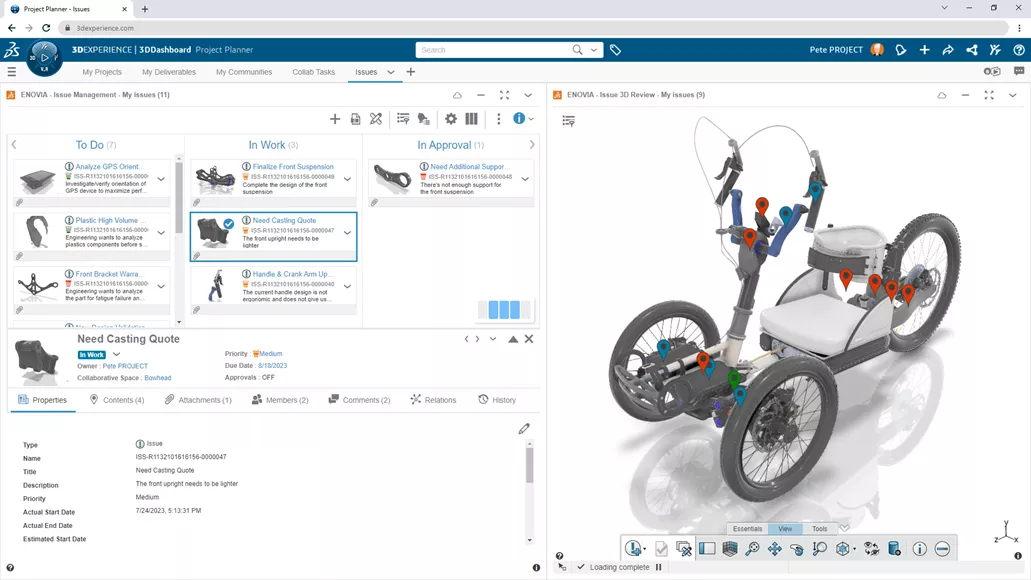

An Issue Management dashboard on the 3DEXPERIENCE Platform.

3DEXPERIENCE CLOUD PDM is primarily accessed via a web browser. All PDM functions, including those requiring 3D visualization, can be done with the 3DEXPERIENCE web apps. Web apps are often placed onto customizable, function-driven webpage layouts called dashboards. These dashboards are far more versatile than a Windows Explorer view of CAD files but may take some getting used to. You are not limited to just browser access, though. There is full integration into locally-installed and licensed apps like SOLIDWORKS CAD, DraftSight, Inventor, AutoCAD (2D), Microsoft Office, and more.

Licenses

3DEXPERIENCE is a true software-as-a-service (SaaS) product that uses named user licenses. This requires that a license be attached to each individual who is going to access the system. This license can be reassigned should the user no longer need access, with a 30-day cooldown period before it can be reassigned again. This named user methodology makes sense for a true cloud system. The license, accessed by web login, follows the user to whichever location or device they choose to use to access the system.

SOLIDWORKS PDM Professional uses a traditional network pool of licenses. There would need to be a license for each concurrent user. The license is consumed while the user is in the system, and when that user logs out, the license is returned to the pool for another user to consume. Licenses are typically housed on the same server as the PDM system, another reason SOLIDWORKS PDM requires a VPN.

Search and Data Cards

There are many similarities between the SOLIDWORKS PDM and 3DEXPERIENCE CLOUD PDM systems, which both have great search capabilities. Both searches rely on metadata collected on the files, so good data makes for good searches. In both systems, some of the data input, (e.g., names, dates, and revisions) can be automated, while other data, like descriptions, are manually entered.

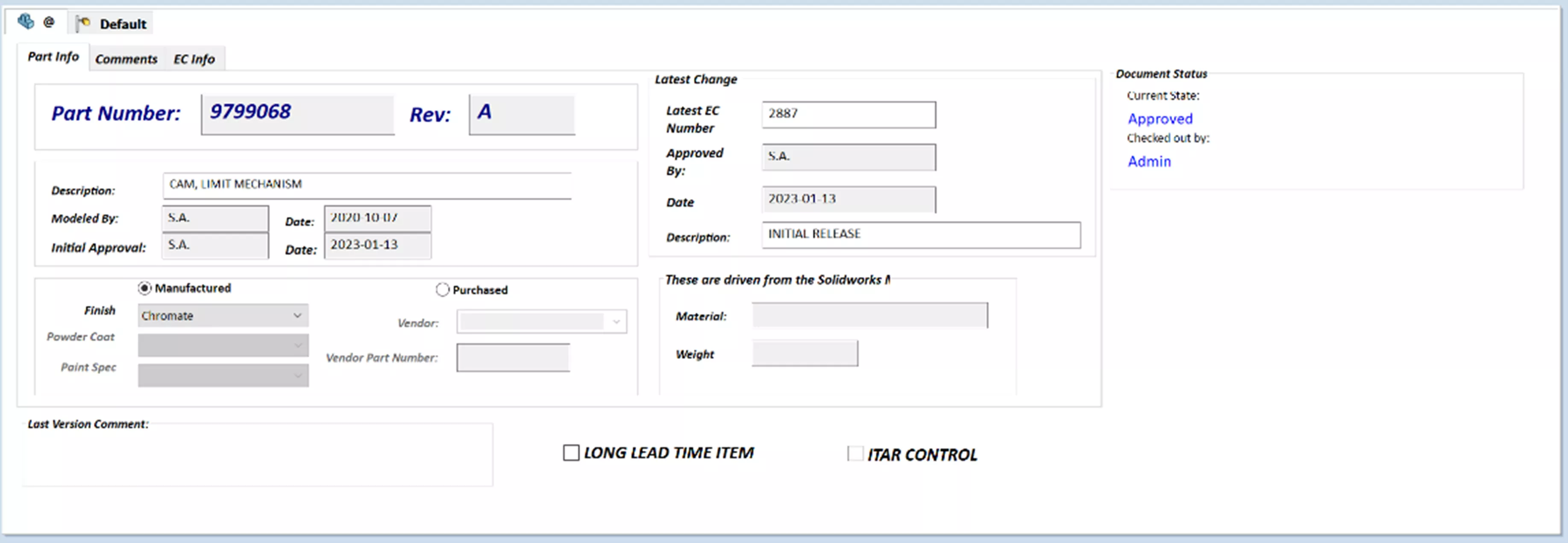

A significant difference between the two is how the data is displayed. In SOLIDWORKS PDM, there is a data card. The layout of this card is highly customizable.

Fields can be displayed in any order that makes it easy to read for the user. Different fonts, colors, bold, and italics can help highlight areas of concern.

Unique to SOLIDWORKS PDM is the ability to have dependent fields. In the example above, the “Powder Coat” and “Paint Spec” fields are greyed out because the part isn’t painted or powder-coated. One of those fields would light up if the Finish field were appropriately changed from “Chromate”. Fields can also be configured to Hide instead of grey out.

Another capability of SOLIDWORKS PDM is the ability to have drop-down lists with the capability to query other databases. For example, if there were an approved vendor list in an ERP system, SOLIDWORKS PDM could query that system every X minutes to update a vendor list in SOLIDWORKS PDM. This out-of-the-box functionality can be implemented right away.

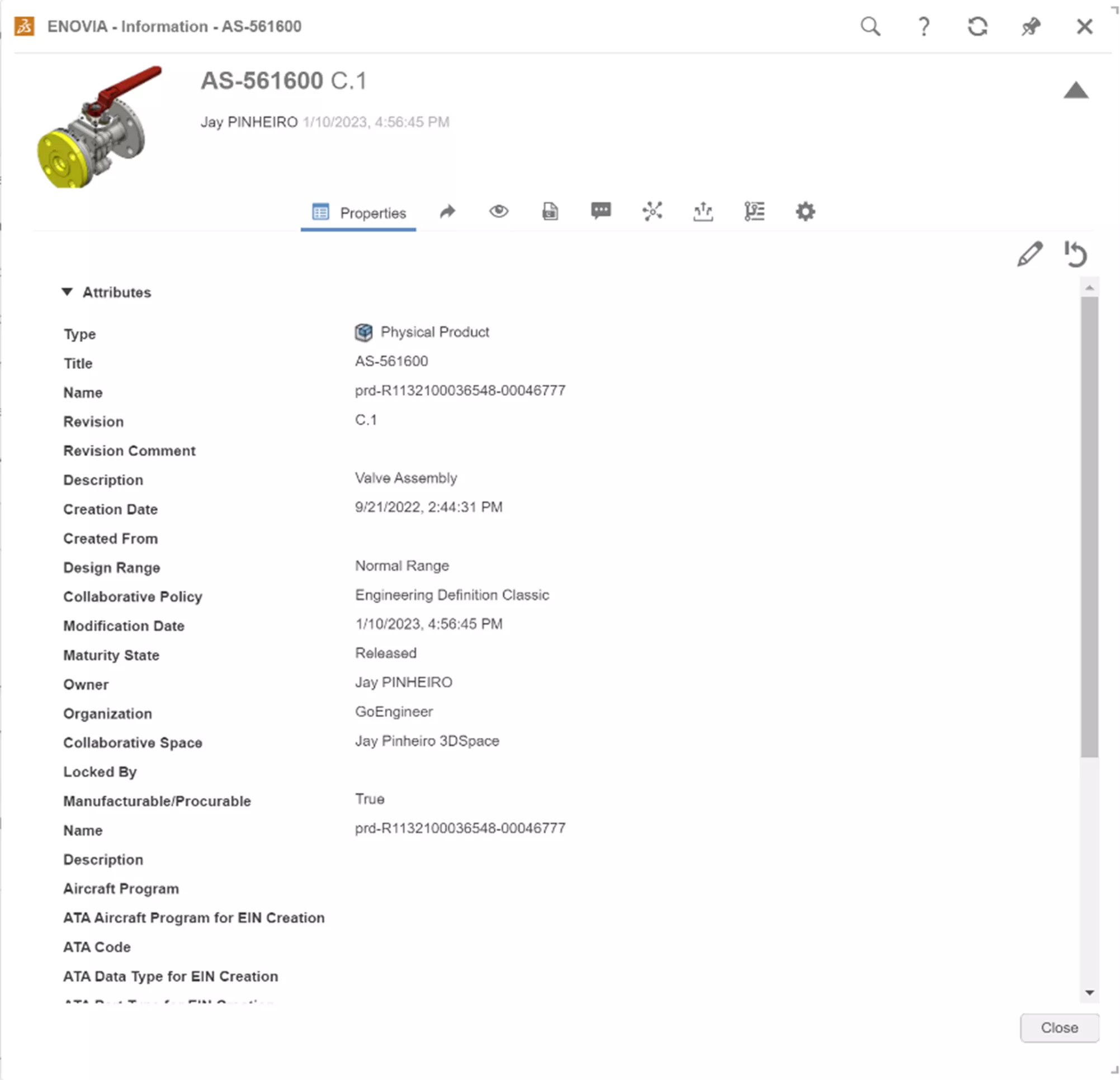

In the 3DEXPERIENCE Platform, the metadata is displayed in list form. This does create an easy-to-read interface but may require scrolling if there are many fields. Like SOLIDWORKS PDM, some of these fields, such as Revision and Creation Date, are automatically filled in, while some, like Description, require manual input.

SOLIDWORKS PDM and 3DEXPERIENCE have powerful search capabilities once data is collected. Both can perform multiple-criteria searches with logical (AND, OR, NOT) criteria. The SOLIDWORKS method is to create the proper search criteria so that it returns a small number of results.

The 3DEXPERIENCE method has a modern, browser-like feel to it and will produce the best results if you start with a broad search term and then filter from there. 3DEXPERIENCE uses what are called 6W tags to filter. The 6 W’s are Who, What, When, Where, Why, and hoW. Within a few clicks, you can dial in your search results to a manageable number and start working. Users may find the 6W tags a quicker path to find their file than learning the nuances of SOLIDWORKS PDM search.

Versions vs. Revisions

While the topic of versions and revisions may seem obvious, the terms should be defined. Document revisions are stamped with a Revision piece of metadata (A, B, C,…) and usually approval names and dates. But it is a combination of “Revision” and “Workflow (Lifecycle) State” that truly designates whether a document is ready for production. If a user is instructed to revise a document, a “Rev A/Released” document could become a “Rev B/In Process” document. That document would be working its way toward “Rev B/Released”. Both systems are very similar here and keep a history of all released revisions, so at any point in time, an older revision can be viewed or opened.

Versions are document states that lie between revisions, and SOLIDWORKS and 3DEXPERIENCE are quite different here. The on-premise SOLIDWORKS PDM will create a new version as a snapshot in time, anytime a document is checked in. There are some exceptions, but this is most typical. There is an actual file sitting in the archive server that represents that version. While it may seem advantageous to have all these versions, the versions in between revisions are rarely used.

The 3DEXPERIENCE Platform doesn’t have that same concept of versions. When a document is saved to the Platform, it may be, for example, a “Rev A/ In Work” document. When changes are made, and the file is resaved to the Platform, that file is overwritten and is still “Rev A/In Work”. That happens for all subsequent saves to the Platform. When the document is released, it will become a “Rev A/Released” document and will be protected from any overwriting. As the document continues to mature, Rev A and Rev B will both be part of the historical record. If there is a desire to have an “in-between rev” document, the Platform offers a "major.minor" revision scheme (for example: A.1, A.2, ...), where the minor component is incremented as new revisions are created from in-work content.

Workflows/Lifecycle

SOLIDWORKS DPM and 3DEXPERIENCE offer two different approaches to how a document moves from its inception, through review, and on to approval.

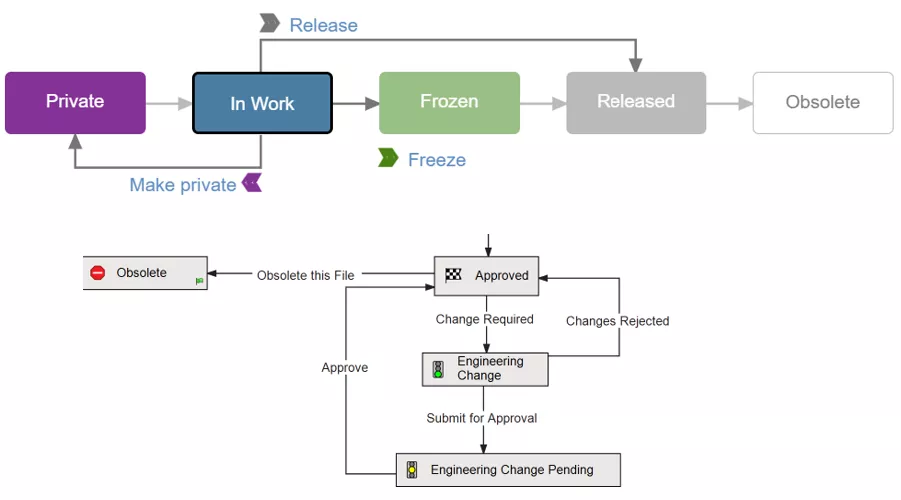

SOLIDWORKS PDM Professional can create multiple workflows to govern the release and change of any document. When a document is first checked in, it is classified and sent to the proper workflow. As the document moves through the states of the workflow, the read/write permissions, visibility, and metadata all change. Workflows look like simple flow charts but are the real foundation of SOLIDWORKS PDM’s document control. They can be complex and involve contributors from all over an organization for approvals.

The goal is to meet document control requirements but not bottleneck the process. See the simple example above. They can be configured with a couple of different options; multiple paths to approval, depending on the document. However, take caution trying to incorporate too many approval paths for any one document type, or the result could be an overly complex process.

At first, the 3DEXPERIENCE Platform seems to have a simplistic approval process, but that is not really the case. While it is true that out-of-the-box, the default document lifecycle has five stages (see above), we can supplement this with what is known as routes.

Routes go in between the Frozen and Released states of the process and can add levels of parallel or serial approval - or a combination of the two. With the ability to add routes to the lifecycle, the 3DEXPERIENCE Platform can accommodate a large number of complex approval processes. Routes are also simpler to build than SOLIDWORKS PDM workflows and require much less testing before enacting. On top of all that, the Platform allows for ad-hoc approvers to be added to the process at any time - something that is not truly possible with SOLIDWORKS PDM. If the approval of a document is truly a single-person approval, routes are not needed.

References

SOLIDWORKS PDM and 3DEXPERIENCE CLOUD PDM keep track of upstream and downstream CAD references. It is a quick process to query a document and find the parents or children. Both systems can find all levels of references as well, so in other words, you can start at a top-level assembly and dig through references down to the smallest part in a subassembly, or vice versa.

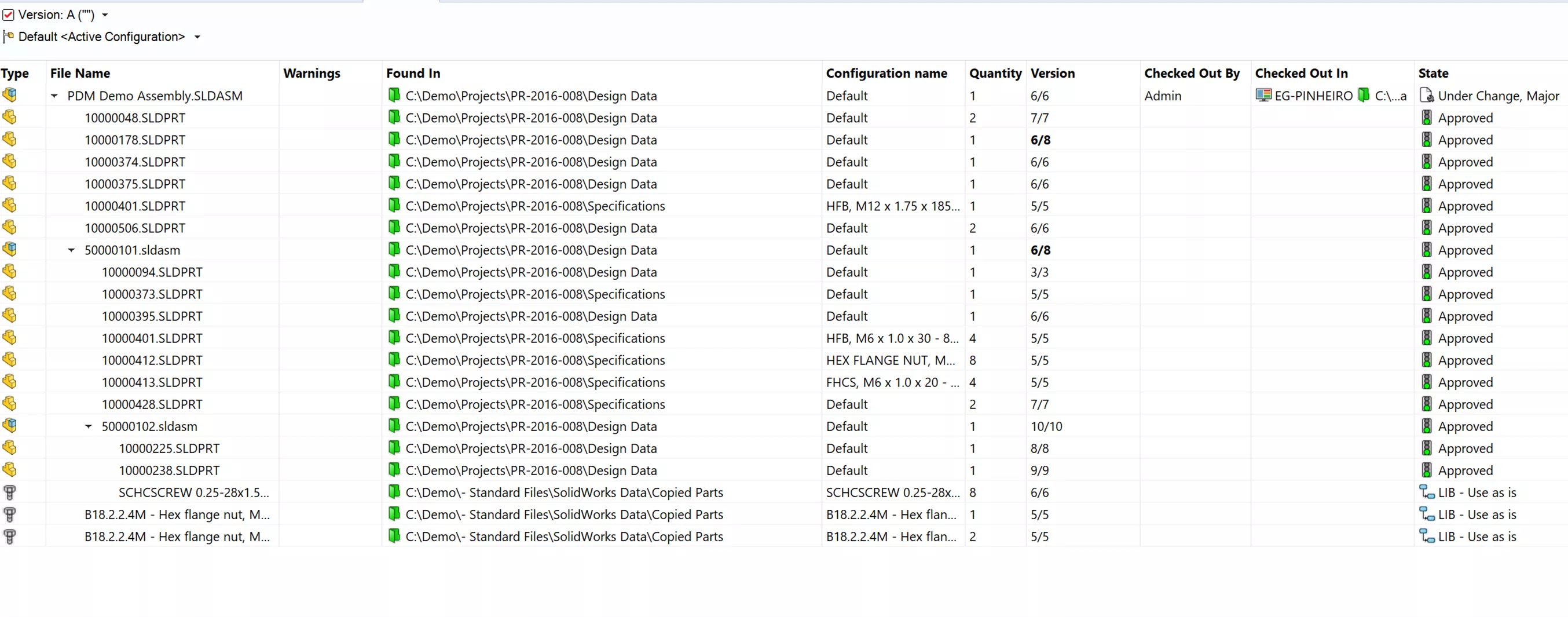

SOLIDWORKS PDM, by default, displays referential information in something like a spreadsheet with entries that can expand or collapse. At the top are quick pull-downs to change the list to show the information for an older version or a different configuration.

SOLIDWORKS PDM also has an option to use Treehouse to display referential data and relationships. This tool is available to all SOLIDWORKS users, and SOLIDWORKS PDM leverages it to give us a more graphical alternative to the spreadsheet view.

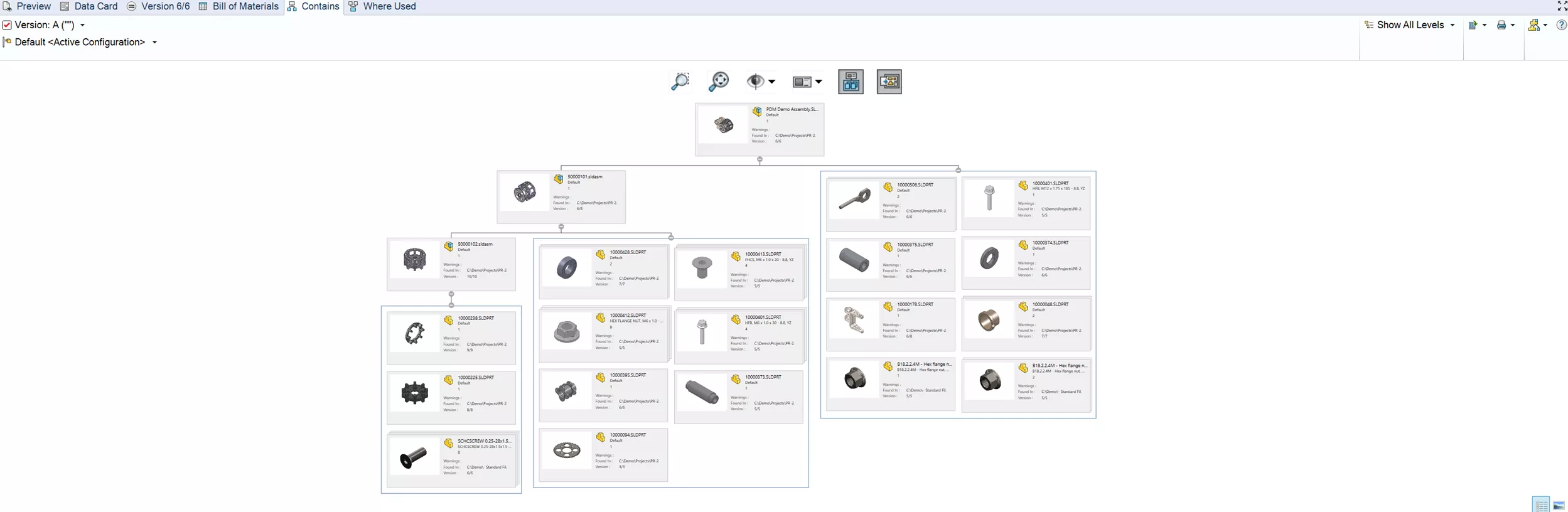

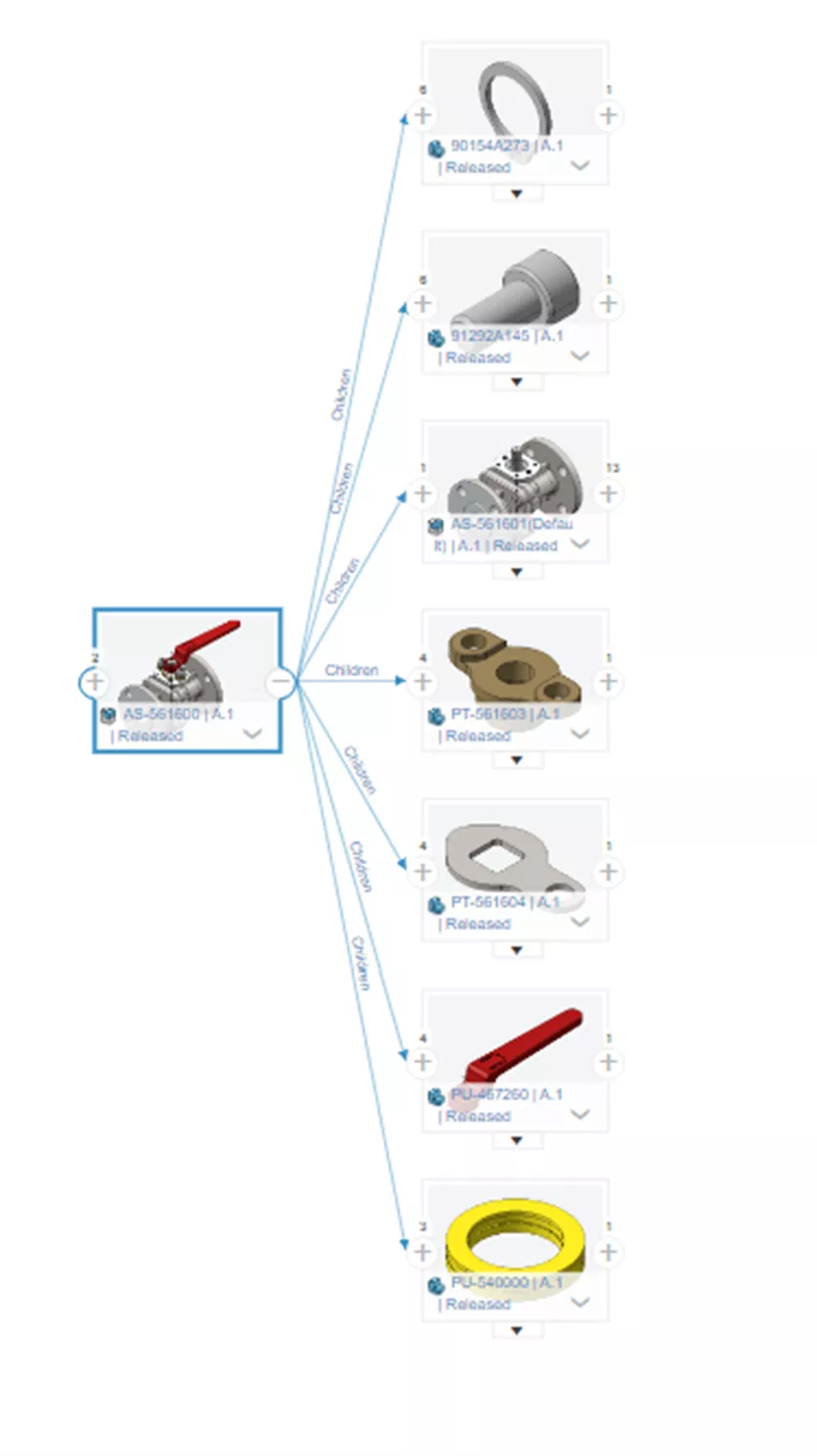

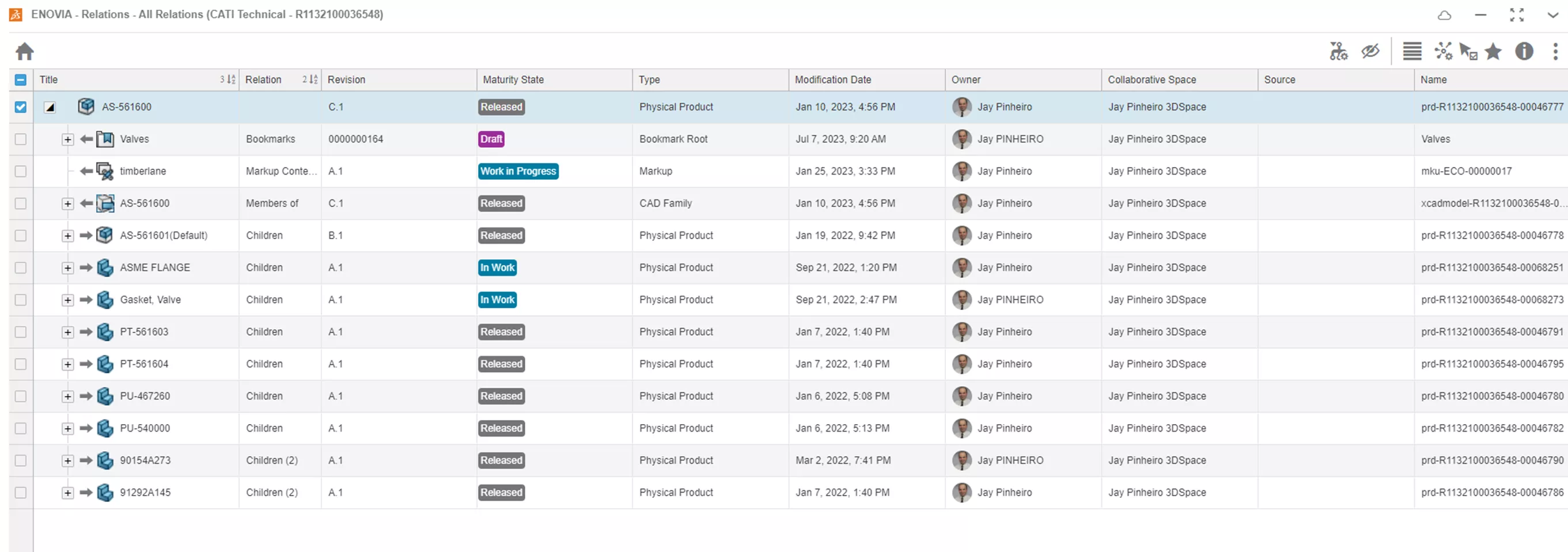

3DEXPERIENCE, by default, displays references graphically like Treehouse, but vertically. This is an expandable tree that allows for traverse upstream and downstream references.

Another option is to use a datagrid format that looks like a spreadsheet. Once again, this will let you traverse through the structure of an entire assembly.

So, both products have quite similar functionality here. The slight nuances between them come down to personal preference.

Bill of Materials

Since both systems keep track of references, it can make sense to export the CAD Bill of Materials, or engineering BOM, to the ERP system to begin the process of making a true manufacturing BOM. The debate about where the engineering BOM stops and the manufacturing BOM takes over is a topic for another day. Either way, the CAD BOM is a good starting point for the MBOM.

SOLIDWORKS PDM Professional can export the CAD BOM to the ERP system via an XML file. XML is a common translator file when connecting two software systems. The approval of an assembly is usually the trigger to create that XML. Once approved, the XML gets generated and placed into a folder that the ERP is listening to to consume it.

If the ERP system is capable of consuming that XML, the out-of-the-box functionality might be all that is required. Depending on how much manipulation of the data needs to be done, there may be a need for a custom API program to bridge the two. GoEngineer has a long history of successfully integrated PDM and ERP systems.

With the 3DEXPERIENCE Platform, the Manufacturing Items Engineer role is full EBOM-to-MBOM functionality within the system. However, users can manually export BOMs to CSV format for off-platform purposes with the Product Release Engineer role. Surprisingly, the request to automate such an export is not as common as you might think, so while that particular functionality is not available as a simple role purchase, this might not be as big of a deal breaker as it may appear.

Preview, Review, & Markup

SOLIDWORKS PDM has two main viewing applications. One is an embedded version of eDrawings, compatible with 3D models of many types. The other is a document viewer for approximately 250 different non-CAD file types. The preview is interactive for most file types and allows, for example, scrolling through Word, PowerPoint, and PDF documents.

The 3DEXPERIENCE Platform has four viewers: 3DMarkup, 3DPlay, 3DNavigate, and Issue 3D Review. They have a nearly identical 3D viewport experience but have different tools for what to do in there, as the names would suggest. 3DPlay can also open many non-CAD file types, like Microsoft Office documents, videos, PDFs, etc.

In an ideal world, review or markup of a document would happen within the system rather than with a third-party electronic markup tool or paper and red pen. Let's go through the details of SOLIDWORKS PDM Professional markup methodology.

SOLIDWORKS PDM Professional unlocks eDrawings Pro’s markup capability, meaning a native SOLIDWORKS drawing can be opened in eDrawings and annotated very much like a red marker on a piece of paper.

But how does that markup get back into the system?

The user doing the markup would need to open the native SOLIDWORKS file, mark it up, and save/check in the .SLD file (yes, you can save a .SLD* from eDrawings). That means the user would need to have the proper workflow permissions to write to the SOLIDWORKS file, which is not always the case. If the document has never been released and is going towards its first approval, then maybe the user can write to the file. But that is not consistently the case throughout the change process, during which the user will most likely not have that write access. The markups in the eDrawings need to be saved as an eDrawing file (which is a brand new document in the system) and attached to the original CAD document.

SOLIDWORKS PDM allows you to create a reference between the two but is not a step a casual user will be confident doing. Both eDrawings and SOLIDWORKS have efficient markup capabilities but work best with write access to the original files.

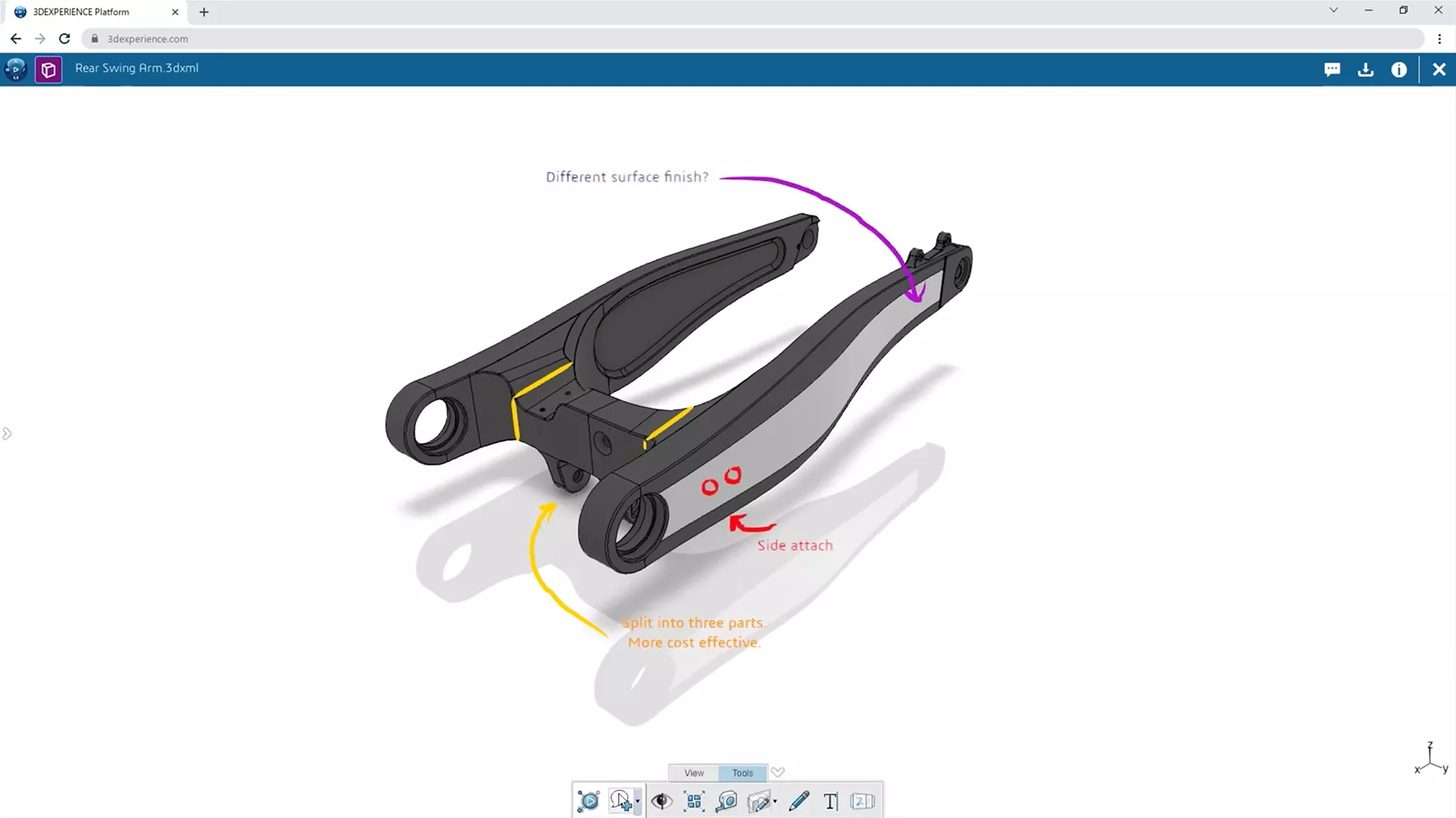

In the 3DEXPERIENCE Platform, markup capabilities might seem similar to SOLIDWORKS, but the workflow to incorporate those markups in the design/change process is much more straightforward to accomplish.

Opening a CAD file in 3DMarkup offers the capability to redline documents as well as zoom/rotate to an area of interest, add text, add shapes, or freehand markups. This super simple workflow automatically links the markup file to the CAD file without needing any special write permissions, allowing non-engineering people to be part of the design and review process.

Engineering Change Process

While this topic may often be referred to as an ECN process, it is more appropriate to refer to it as the engineering change process, as an EC document may go through different stages in its life – request (ECR), order (ECO), or notice (ECN). These three terms often get interchanged, but this conversation will be about the overarching engineering change process.

The EC document will govern the change of a CAD document, but it is its own document. SOLIDWORKS PDM Professional is a document-centric software, so an EC document must be created in its own software (the EC document is most often a Word or Excel document).

SOLIDWORKS PDM can take data card information and write it into such documents, but the layout of the form is controlled by Office. While this may seem advantageous, it is difficult to protect that document from any user editing. It is also not possible (without custom automation) to take information from the in-work CAD document and have it populate in the EC document. This would be a relatively common practice as the part number, description, and revision of the CAD file would most likely be written into the EC document. SOLIDWORKS PDM does a great job routing the EC document through its approval, but not at making an EC.

The 3DEXPERIENCE Platform's process for engineering change can be implemented in many forms, but for the sake of this discussion, the pieces that make up a change will be issues, markups, and change actions.

Any user can document an “issue” to describe a problem or potential change. That issue references the original CAD object and is assigned to another user to review.

The issue can be supplemented with a markup to help convey the problem with 3D annotations shown on the CAD geometry. The connection between the markup and the CAD geometry will be shown in the reference tree.

From the markup, a user can start the change process, which will also automatically reference the original CAD document in the newly created change action. The approval of the change action (i.e., changing its status to “In Work”) gives the assigned engineer authority to make the changes in CAD.

All of this is done with out-of-the-box functionality available to all 3DEXPERIENCE CAD users. All the forms involved are built into the system and do not require a third-party app like Office to get the job done.

All the reference-building between the different items is automatic. If that seems like too much, change actions do not require issues and markups.; they can be directly created to keep the process simple.

Compare

SOLIDWORKS PDM is a document management system and does a great job controlling file access. It doesn’t know about the contents of the file other than the metadata that it is controlling and the file references.

So, SOLIDWORKS PDM can compare BOMs between different revisions, as the BOM data is part of the SOLIDWORKS PDM database but cannot compare any geometry. To compare geometry, we rely on the SOLIDWORKS Compare utility. This utility will graphically show changes between different revisions.

SOLIDWORKS PDM has access to the different revisions to hand the Compare tool, but since Compare is a SOLIDWORKS function, the user needs access to a full CAD machine to compare geometry. The same is true for drawings, for which there is a Compare utility as well.

The 3DEXPERIENCE Platform is different. As CAD models are saved to the platform, it extracts a 3D Shape. That is a 3D object, viewable through 3DEXPERIENCE’s local and web apps (such as 3DPlay or Issue 3D Review), that can be used for geometry investigations without any need to use a full desktop CAD application. The 3DEXPERIENCE Platform has its own 3D Shape-based compare tool that any Platform user can use - no CAD licensing or software necessary. This tool allows any user to overlay two different revisions and easily see the changes incorporated.

Conclusion

SOLIDWORKS PDM and 3DEXPERIENCE CLOUD PDM are highly capable data management tools, each with its own advantages:

- With cloud initiatives, 3DEXPERIENCE has the advantage, as it was built from the ground up to be a SaaS and cloud tool. With ITAR or DoD work, the local infrastructure of SOLIDWORKS PDM is the simpler option. (An on-premise version of 3DEXPERIENCE does exist, but requires special implementation.)

- 3DEXPERIENCE has a more versatile, capable, and accessible web implementation. SOLIDWORKS PDM offers good Web2 functionality but is still primarily an on-premise tool.

- Metadata capabilities are similar in both systems, but SOLIDWORKS PDM data cards offers more formatting options than the 3DEXPERIENCE Platform.

- 3DEXPERIENCE implements a better CAD markup system, with easy CAD referencing and accessibility for non-CAD users and across teams.

- 3DEXPERIENCE is much better equipped out-of-the-box to manage engineering changes, whereas SOLIDWORKS PDM requires extensive configuration and testing.

I hope this article provided some insights into SOLIDWORKS PDM vs 3DEXPERIENCE CLOUD PDM, but we’re only scratching the surface here. Contact us any time – we’re happy to go over both solutions as they relate to your company’s particular needs. Whichever your choice, data management improves both the quality of life and productivity of CAD users.

Related Articles

Getting Started with 3DEXPERIENCE: Setup, Dashboards, Connectors & More

How to Import SOLIDWORKS Parts Into 3DEXPEREINCE

SOLIDWORKS vs 3DEXPERIENCE SOLIDWORKS: What's the Difference?

About Jay Pinheiro

Jay Pinheiro is a Software Strategic Solutions Manager at GoEngineer.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.