Backspin is Important to Your Basketball Free Throw! A SOLIDWORKS Simulation Study

A free throw in basketball is a shot about precision and consistency. Error margins are tight, so players implement techniques to improve their chances. One vital technique is to put backspin on the ball. In this article, we will run a motion and aerodynamic analysis using SOLIDWORKS Motion and SOLIDWORKS Flow Simulation to look at why backspin is important by comparing it to a shot without spin. We will look at two important factors along the way:

- Bounce mechanics

- Knuckleball mechanics

Related Article: SOLIDWORKS Motion: A Tip for Handling Performance "Hogs"

Setup

Using SOLIDWORKS, we can accurately position the ball at the free-throw line (figure 1) and reliably shoot a free throw the same way every time, varying only one parameter at a time. This way, we can answer specific questions without too many confounding variables.

Figure 1 – SOLIDWORKS CAD setup at the free-throw line

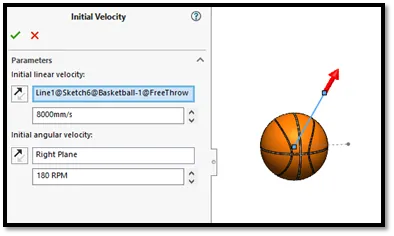

In this test, we varied the speed of the basketball while holding the angle constant, and we tested with 3 RPS (revolutions per second) of spin (figure 2). Then we also did the same test without spin.

Figure 2 - Initial Velocity and Rotation are setup in SOLIDWORKS Motion

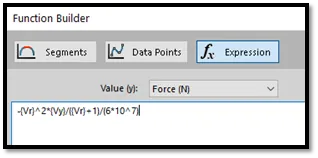

We included drag forces on the ball, which will affect its natural parabolic path and give us more accurate results. Figure 3 shows an example equation of the Y-component of the drag force.

Figure 3 - Drag force Y-component depends on velocities

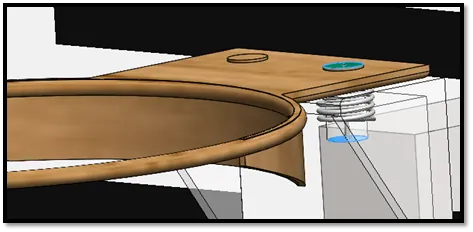

Springs were included on the hoop (figure 4) to mimic the deflection that occurs when the basketball hits the front of the rim.

Figure 4 - Springs on the basketball hoop for more accurate bounce mechanics

With this setup in mind, we are now ready to run our tests.

Related Article: Beating COVID-19 with a Snorkel

Bounce Mechanics

One of the most telling results we got was when we shot the ball at around 7.78 m/s and it hit the front of the rim. See if you can spot the difference in performance between the exact same shot without spin (left) and with spin (right) in animation shown below.

Figure 5 - Shot at 7.78m/s to hit the front of the rim at the same spot. Left : No Spin; Right : 3RPS spin

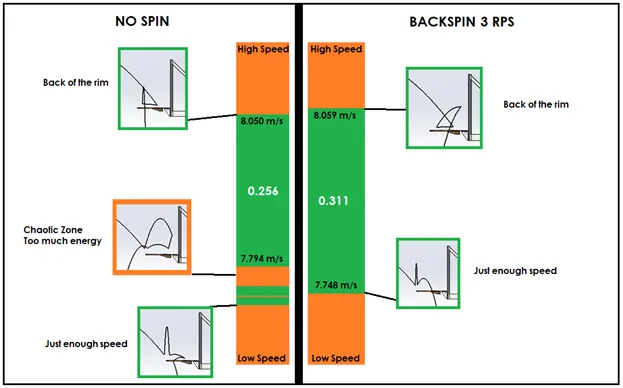

The backspin slows the ball down when it contacts the hoop. We tested with many speeds and summarized the results in Figure 6.

Figure 6 - Summary of shots at varying speeds. Orange zones are missed shots.

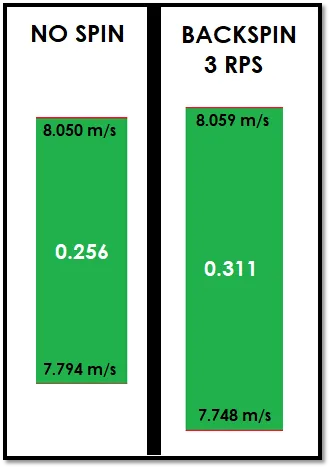

As you can see in this figure, we can potentially make shots by undershooting with no spin, but there is an unreliable zone where the ball has too much energy and tends to bounce out. If we look at the reliable region, our margin for error looks a lot bigger when the spin is added. See the comparison of these regions in Figure 7.

Figure 7 - Side-by-side comparison of shot margin. More than 20% larger when spin is added

According to this test, adding backspin will increase our margin of error by a little more than 20%.

Related Article: Cybertruck Simulation: Deal or Dud?

Knuckleball Mechanics

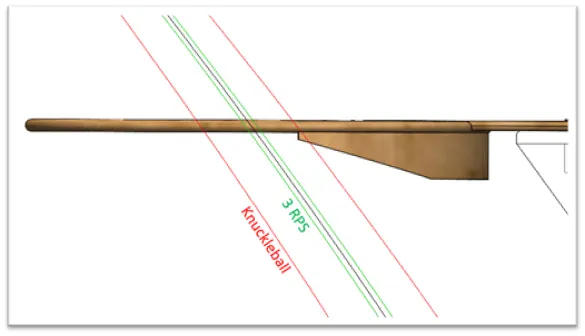

Another factor that can make a big difference between a shot without spin versus one with spin is aerodynamics. Since basketball shots must be both consistent and precise, the knuckleball effect (as seen in baseball) can influence the error margins significantly on a shot with no spin. Figure 8 shows the same two shots going through the air with lift forces plotted beneath them.

Figure 8 - Shot aerodynamics and lift forces. Left : No spin; Right : 3RPS spin

The lift force on the shot with spin (right) has a stable average lift force which swings up and down roughly in-sync with the rotation of the ball.

In contrast, the average lift force on the shot with no spin (left) shifts upward in this animation.

This upward shift is difficult to predict and could have shifted downward or even not at all if the initial conditions had been slightly different. The shift depends on a few factors, but primarily in this case, the position of the seams has the biggest impact.

The animation below shows how a slight change of angle can have a big impact on the lift force direction.

Figure 9 - Knuckleball effect: Slight change in initial angle can lead to big differences in lift

But what does this mean for our shot? If the lift force points up in the beginning of our shot and then switches in the middle, it pulls the shot off away from its average path (figure 10).

Figure 10 - Knuckleball effect on the flight path of the ball. Average path shown in blue.

Compare this to a shot with the average lift being relatively constant and where the fluctuations quickly cancel themselves out along the way (figure 11).

Figure 11 - Ball with 3RPS spin. Average path shown in blue.

If we zoom in and look at how far away from the average path these shots get, the difference is clear (figure 12).

Figure 12 - Knuckleball can push the ball far away from its mean path (large red margin) compared to having spin

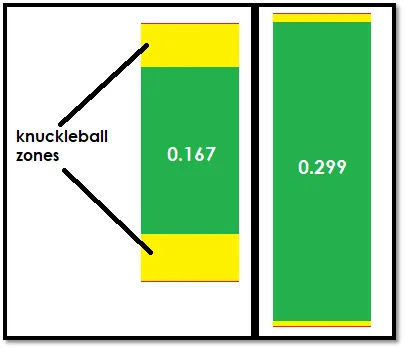

And the effect this has on our error margins creates a compelling argument for adding spin to your free throws (figure 13).

Figure 13 - Error margins updated to include these knuckleball zones. Consistent zone almost 80% larger

Looking at the consistent zones, this represents almost an 80% improvement.

Related Article: Is a Bolt Stiff Like an Engine or Flexible Like Your Hands?

Conclusion

Setting up virtual experiments in SOLIDWORKS Motion and SOLIDWORKS Flow Simulation is often a lot easier, faster, and more consistent than setting up real physical experiments or prototypes. Fortunately, in basketball, there are a lot of “experimenters” already out there on the field to test these theories and their overall conclusion is the same: backspin helps.

To learn more about how SOLIDWORKS Motion or SOLIDWORKS Flow Simulation can help you on running your virtual experiments, please contact our support or schedule a session with one of our engineers.

Blooper Bonus Shots

Figure 14 - A couple funny shots that did not make it into the error margin chart

About Shaun Bentley

Shaun Bentley is passionate about applied mathematics and engineering, which led him to pursue and understand real world applications of FEA, CFD, kinematics, dynamics, and 3D & 2D modeling. He teaches many simulation classes to both new and advanced users attending training at GoEngineer. Since 2006, Shaun has been working with simulation tools to solve real world engineering problems. With every new project, he seeks to find ways to push simulation to its uppermost limits, even going so far as to write bespoke code and macros. He has passed the Michigan FE exam and mentors or consults for virtually any industry that uses SOLIDWORKS, especially automotive and automated tools. He is a speed 3D modeling champion and one of the first Certified SOLIDWORKS Experts in Simulation in the world.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.