What is Titanium Assistant? Stratasys Neo Companion Software

Titanium Assistant software complements the operation of the Stratasys Neo ® line of SL 3D printers . While not fundamentally required to operate a Neo, it is a companion program that I rely on as a daily user. It excels at workflow optimization and efficiency and allows any number of Neo's to be monitored remotely. Titanium Assistant empowers Stratasys Neo operators to control three crucial aspects of the printing process from their local computer: file preparation, queue management, and machine management.

File Preparation

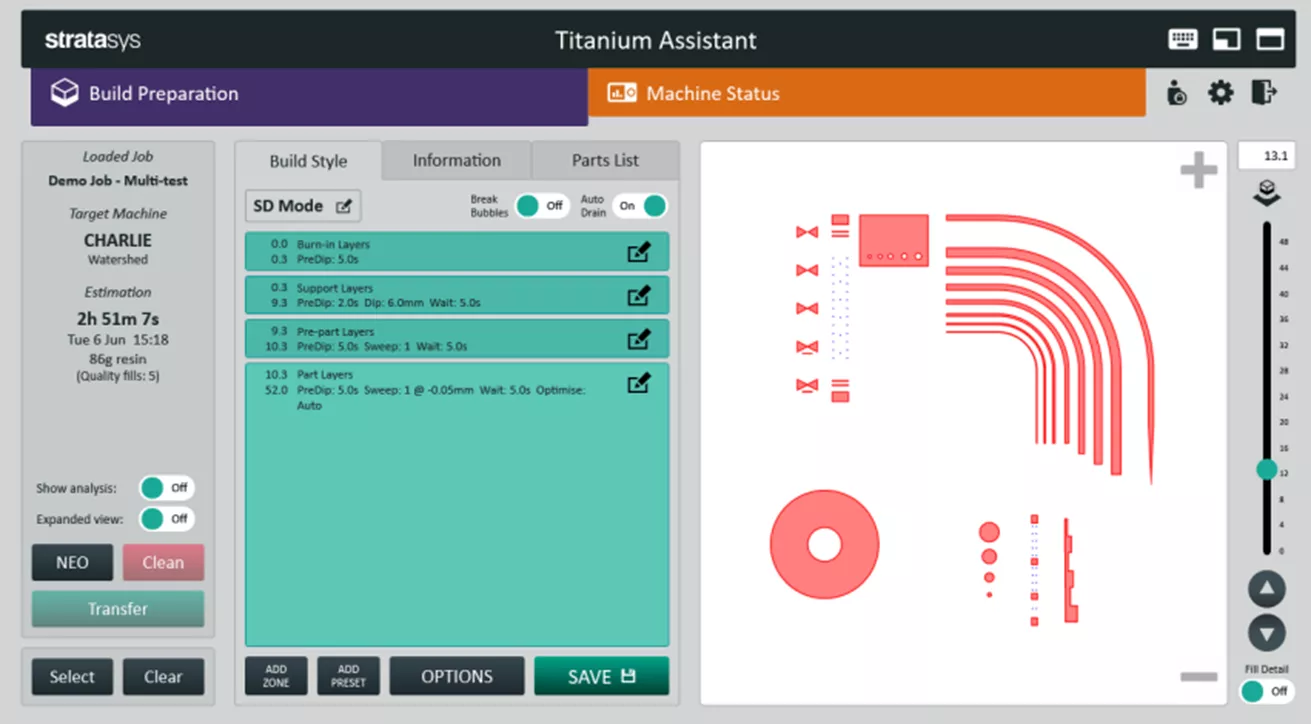

Once the build layout, support generation, and slicing are done (using Materialise Magics software ), the slice files are opened in Titanium Assistant. From there, slice previews, material use estimates, and print time estimates are immediately available.

Every Stratasys Neo is dedicated to a single SL material, and the validated print parameters are established during machine installation. There are many reasons a user may want to tweak those parameters on a part-by-part, section-by-section, or even layer-by-layer basis, and Titanium Assistant facilitates those changes.

They can also be saved so that, when similar part requirements arise, those modified settings are easily accessible. Users can also toggle between print modes and enable or disable certain operations during a build.

When changes are made, the software automatically updates print time and material use estimates. It also validates that slices are printable in a given mode or layer thickness.

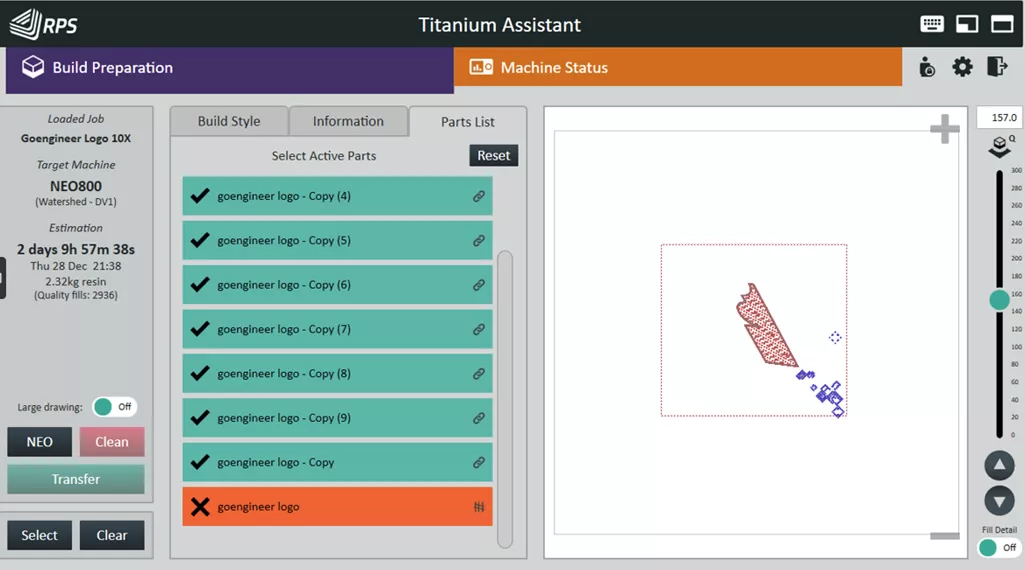

A favorite feature of Titanium Assistant is the ability to remotely disable the printing of individual parts mid-build, for example, a service bureau needing to expedite a specific job. A user may start a build with parts from many different customers (remember, the Neo 800 build tray is a whopping 800 x 800 mm) and determine halfway through that one of those customer deadlines is at risk of not being met. That user can disable less-critical parts so that the machine only spends time printing what needs to get out the door ASAP.

Queue Management

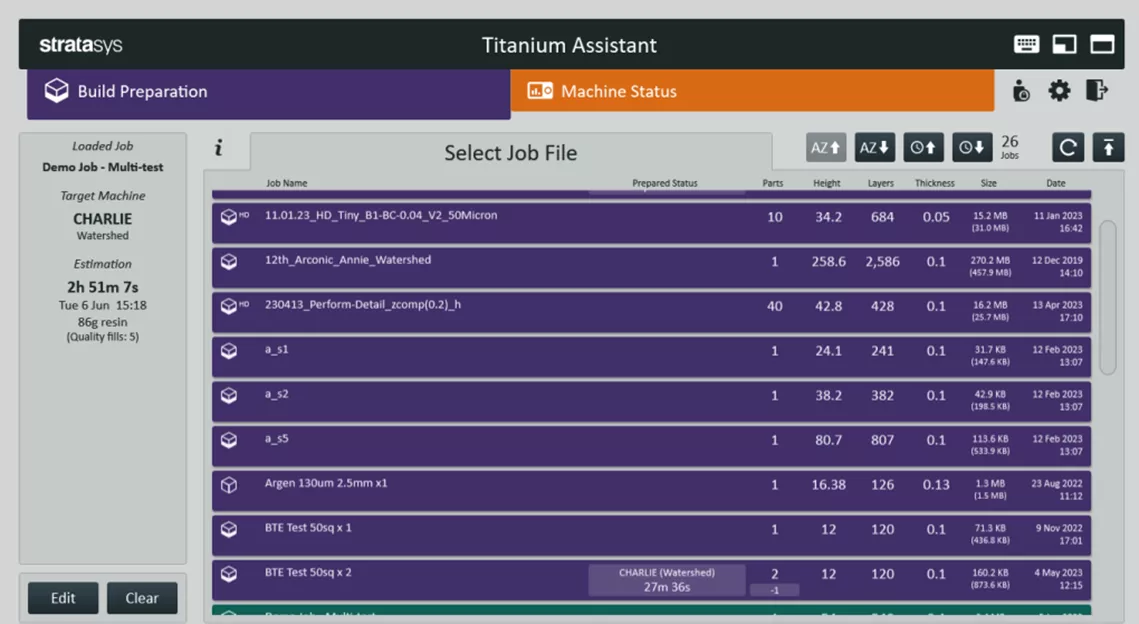

3D Printing service bureaus often have a few week's worth of builds in the queue. Titanium Assistant provides an at-a-glance view of what is in the queue to be printed, associated print times, and material use. That information can be used to optimize production schedules and maximize machine utilization.

Machine Management

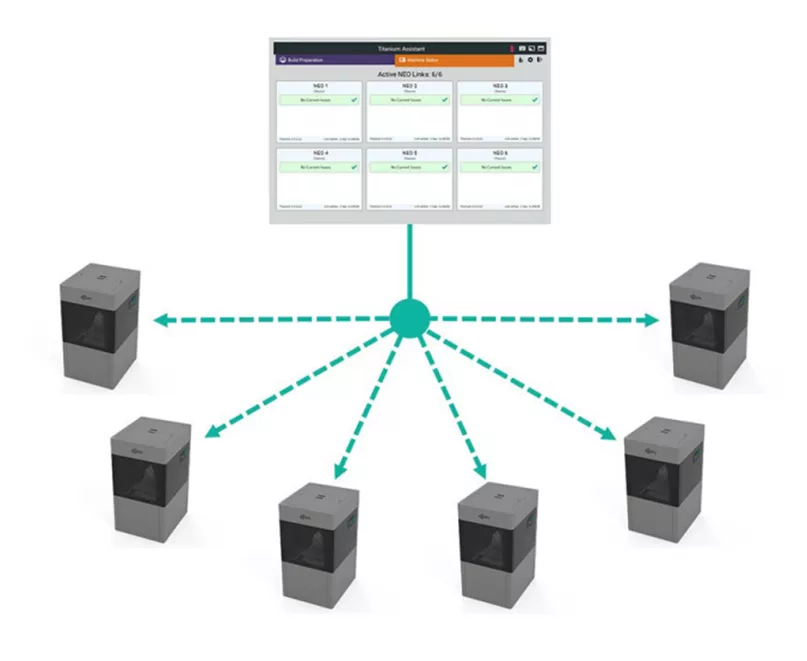

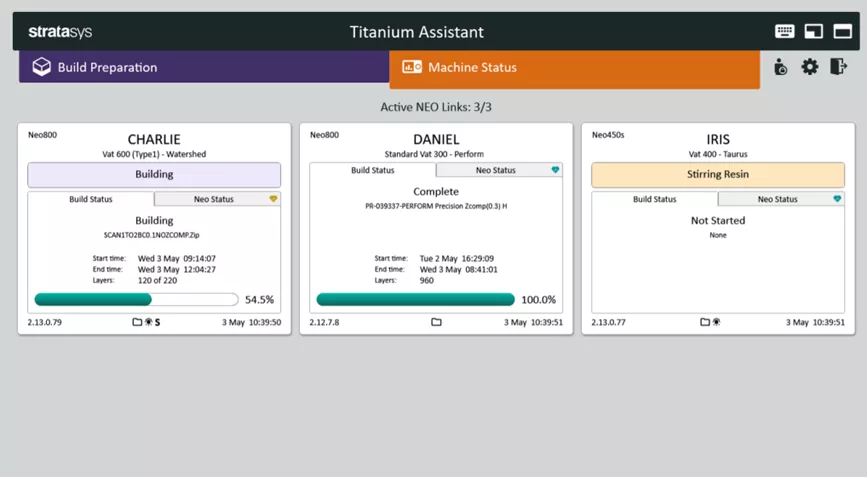

Titanium Assistant can also communicate with one or many Neo machines on a network. Simply put, users can remotely prep builds on their own computers and send those build files and print parameters directly to the machine(s).

Additionally, Titanium Assistant can monitor the status of ongoing builds remotely. If a pause or notification occurs mid-build, users can rapidly respond remotely to resolve issues, without needing to wait until they can physically be present with the machine.

If, like me, you're focused on optimizing workflows and improving productivity, consider incorporating Stratasys Titanium Assistant and Neo Stereolithography printers into your organization's additive manufacturing arsenal. To learn more, contact us at GoEngineer.

3D Printing as a Service

GoEngineer offers comprehensive 3D printing services across multiple U.S. labs, equipped with cutting-edge Stratasys FDM, PolyJet, Stereolithography, and SAF technologies for 3D printed prototypes or production parts. Request your quote online today!

More 3D Printing News

Exploring Stereolithography 3D Printing: Precision, Innovation, & Real-World Applications

Concept to Production 3D Printing: How it Works

3D Printing In-house and Outsourcing: Why a Hybrid Approach Works

Experts in Additive: 3D Printing with GoEngineer

About Simon Pinter

Simon Pinter is a Manufacturing Solutions Application Engineer at GoEngineer

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.