Concept to Production 3D Printing: How it Works

There's no doubt that 3D printing has changed the way products are developed, tested, and manufactured, but do we fully understand how a part goes from concept to production? In this article, we'll look at how a company can utilize 3D printing, from prototyping to design validation and even tooling. While this is a hypothetical story, it is a scenario we've seen repeatedly in the real world, and if you develop products, it's likely relatable.

ABC Medical Devices launched a professional thermometer specifically for use in a hospital setting. This device met all of the standards and regulations and was a significant success for the company. Over time, the company started receiving feedback from customers saying they weren't happy with a few features, so they began investigating further.

The most common complaint was that the shape of the grip made it difficult to handle. Because of this, some users had dropped and broken them and needed a replacement. In addition, some customers said the poorly designed handle caused fatigue because they had to hold it tighter.

Prototyping

As more and more users shared this feedback, the company knew it was time to work on a new version of the thermometer. So, they tasked their designers to come up with a unique solution that would solve this problem. They started by sketching several versions of the new and improved grip, and the team chose the top three designs.

They submitted the three designs to their Stratasys FDM F370 3D Printer and printed them in ASA which was perfect for form & fit testing. Their 3D printer made the parts overnight, and the team held a design review meeting the next day.

Testing

Each team member held the parts during this meeting and compared them to the original before casting their vote on the best iteration. One stood out as the clear winner, but they wanted additional feedback from actual end-users.

Validating

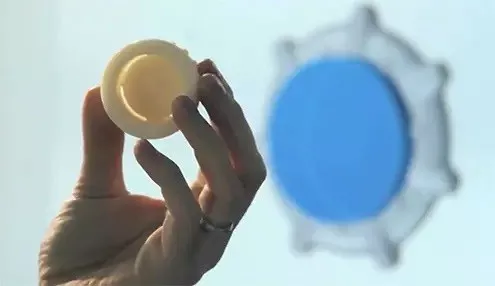

They printed the three grips using PC-ABS, the same material the actual production parts are made from, and brought them to a local hospital. The nurses passed the parts back and forth, and to the company's surprise, they couldn't pick a clear winner. Instead, they wanted a version that combined features from two of them.

The designer took that feedback, made the adjustments in CAD, and reprinted them the next day. So when the nurses held the new design, they knew it was the winner. This was further validated by sharing the parts with other nurses who also chose the same version.

Inspecting

The company knew what to do, and the manufacturing process began. A major part of producing an end-use part is inspecting the components for accuracy using a 3D scanner or CMM machine that compares the geometry of physical objects to the exact specs of the design.

To perform the inspection, the part is first placed onto a fixture (or holder that positions the part precisely), and the baseline measurements are taken. To avoid the usual wait for initial production parts to arrive, they used 3D printed fixtures and an accurate 3D printed replica of the final part. By taking care of this step ahead of time, they were ready to inspect and assemble the product within moments of the components hitting the dock.

The company also printed assembly fixtures to hold the individual components in place during the assembly process. These fixtures led to faster assembly times and reduced the potential for errors and fatigue for the assembly workers.

In this example, 3D printers were used for prototyping, testing, part validation, and tooling. If you take the 3D printer out of the equation, the development process would have been longer, more costly, and the end-user may not have been satisfied.

3D printing is a truly transformative solution that can significantly impact your workflow, but it's critical to choose the right partner. That's why GoEngineer has built a team of passionate, knowledgeable, and creative professionals who all share a common goal: to help you identify challenges, find the right solution, and get the most out of it now and in the future.

3D Printing as a Service

GoEngineer offers comprehensive 3D printing services across multiple U.S. labs, equipped with cutting-edge Stratasys FDM, PolyJet, Stereolithography, and SAF technologies for 3D printed prototypes or production parts. Request your quote online today!

More 3D Printing News

Ultimate Guide to Fused Deposition Modeling - What is it?

3D Printing In-house and Outsourcing: Why a Hybrid Approach Works

Stratasys Introduces Composite Ready FDM, New Materials, and More at Manufacturing Event

3D Scanning for Automotive: Applications, Hardware, & Software

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.