Understanding the Cost of Poor Quality Control in Manufacturing

Benjamin Franklin popularized the quote, “An ounce of prevention is worth a pound of cure”, which highlights the wisdom of planning in order to avoid problems. It is a very powerful message that speaks to the value of prevention, proper equipment, and the costs incurred by lack thereof.

Franklin’s message rings especially true in the quality control world. Most companies can relate to the cost, headache, and clean-up associated with rejected customer parts.

Quality issues that go unresolved throughout the production process can significantly impact a company's bottom line. Therefore, it's important to implement effective quality control processes and tools to reduce what can be a significant cost, including the following:

- Direct costs: Raw materials, labor, and overhead used to produce the rejected parts.

- Scrap costs: Disposing of the rejected parts.

- Rework costs: Retooling, Engineer remodeling, or remaking the rejected parts to meet quality standards.

- Inspection costs: Inspecting the parts to determine if they meet quality standards.

- Delays and lost production time: Rejected parts can cause delays in the production process and result in lost production time, negatively impacting the bottom line.

- Warranty, loss of customer trust, and reputation: Warranty repairs are a negative profit and if rejected parts are shipped to customers, it can result in customer complaints, loss of trust, and damage to the company's reputation.

What does a lack of proper quality control look like?

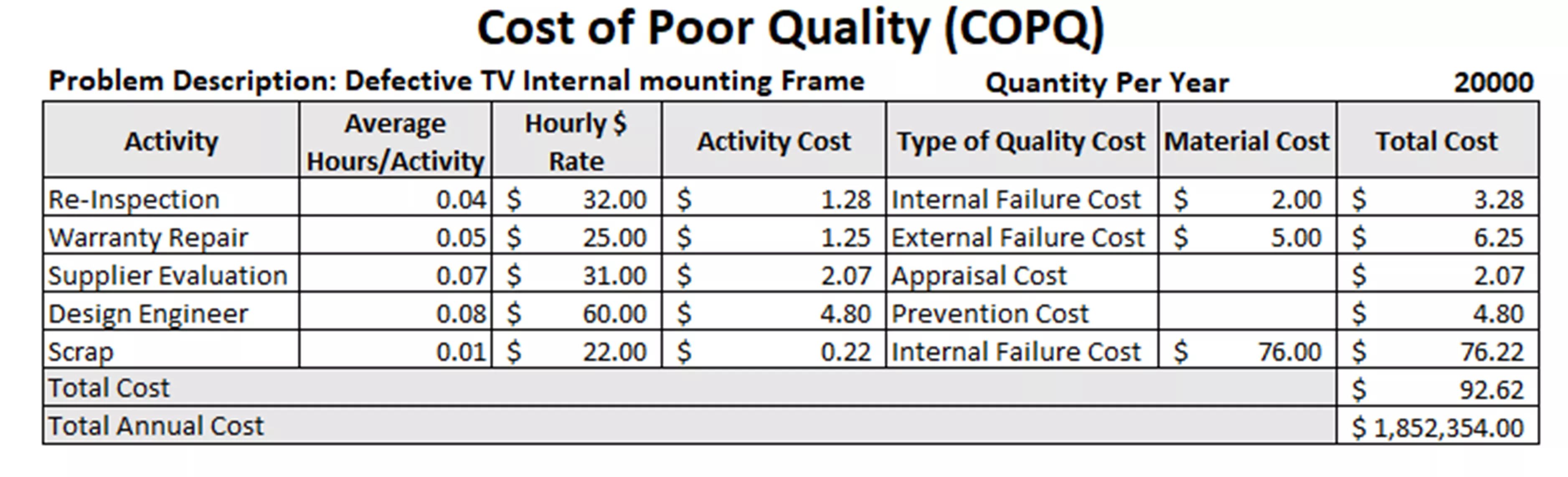

In this example, 20,000 defective TV Mounting Frames are allowed to reach the end customer. On top of the material cost of scrap and repair ($83 per unit; $1.66M overall) is an additional $9.62 ($192K overall) of labor spent to rework/repair and re-certify them. That's a total cost to the company of $1.85 million!

When you lay out the numbers, it’s pretty easy to justify prevention.

There is a principle that states the cost of preventing quality defects is lower than the cost of correcting defects, which in turn is cheaper than the cost of letting defects reach your customers: The 1-10-100 rule.

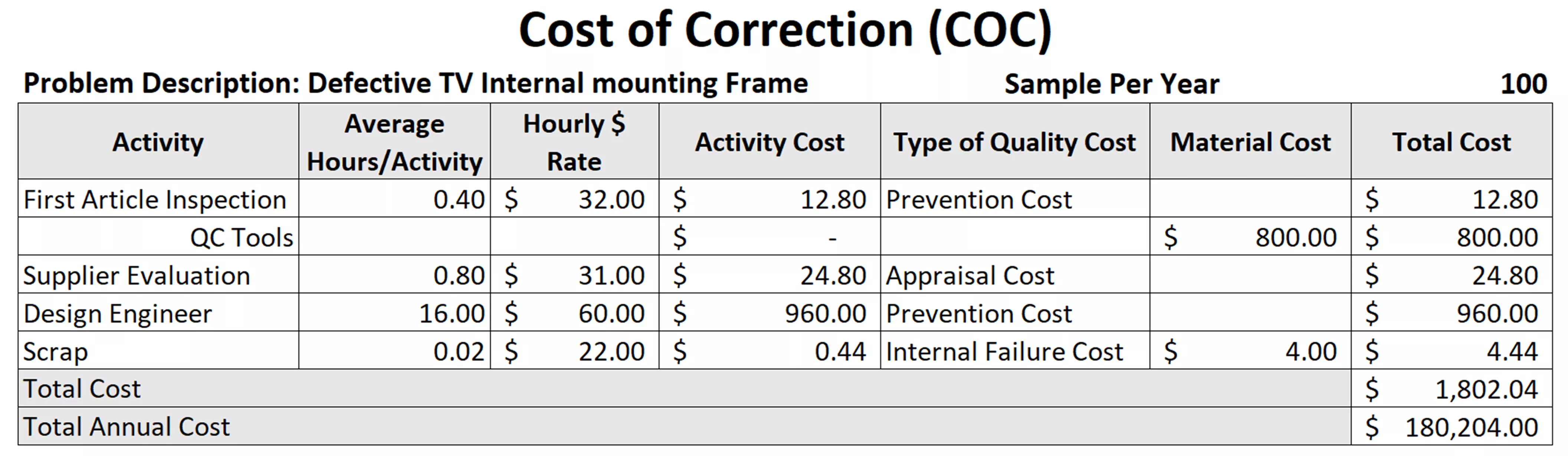

Referring to our example, had the issue been identified with an adequate first article inspection, the defect would have been caught early and the company would have seen significant savings.

As you can see in this counter-example, the issue was captured in the first run of production during the FAI (First Article Inspection). This company implemented 3D scanning to accurately and reliably capture high-resolution 3D measurements in a faster workflow to report the first article parts. The total annual cost to the company now is 180K, including the new inspection system. That’s 10X the cost savings by implementing preventative measures.

Suggested Article >> Why Choose 3D Scanning for Inspection

The Solution

The devil is in the details. A company needs to be diligent in its QC implementation and processes. Consider your company’s current process and equipment and ask:

Is your company:

- Documenting standard operational procedures?

- Properly managing part flow throughout the production?

- Holding scheduled equipment tests?

- Identifying and/or documenting non-conformity cases?

- Ensuring managers and employees are properly trained?

- Using current technology to minimize waste and take the guesswork out of the job?

Using a 3D scanner for inspection speeds up the production process by quickly and accurately collecting data up to 1.3 million measurements per second. Metrology-grade 3D scanners are regulated by a set standard for inspection tools, ensuring that the data extracted by the scanner is accurate and highly repeatable. As a result, you have a reliable tool that provides precise measurements, independent of the operator.

Featured Item: Creaform HandySCAN 3D Scanner

Suggested Article >> Choosing Analysis & Inspection Software: Creaform, Geomagic, & PolyWorks Considerations

If you're thinking about implementing 3D scanning for inspection, but are unsure where to start or need help determining what scanner is the best fit for your company's needs, contact us.

Related Articles

Choosing a 3D Scanner: Light vs Lasers, Applications, & Considerations

3D Technology and Archaeology: Enabling Artifacts to Virtually & Literally Travel the World

3D Scanning for Automotive: Applications, Hardware, & Software

USA Luge Teams Up with GoEngineer for 3D Scanning Services

About Bob Renella

Bob is a Manufacturing Solutions Application Engineer Manager at GoEngineer.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.