Stratasys J55: Filling Big Shoes with a Small Footprint

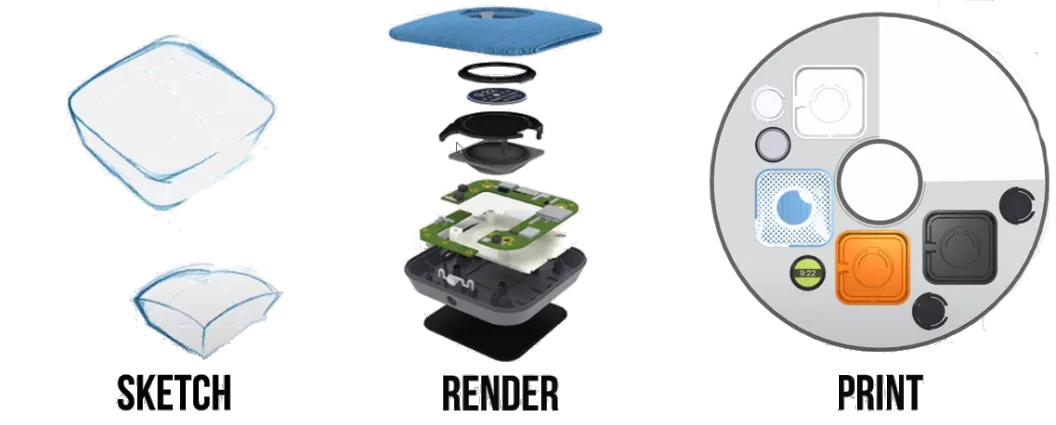

Earlier this year, Stratasys announced their new full-color J55 PolyJet 3D printer. The J55 is uniquely positioned for designers who want color accuracy and variety. If you’re a designer, you may be familiar with 3D rendering tools, such as SOLIDWORKS Visualize, which lets you turn 3D CAD models into something that visually communicates the design to customers, decision-makers, and stakeholders.

However, when you are looking at a picture through a monitor, it’s not possible to communicate non-visual information, like how a product feels to the touch, how much it weighs, how it fits in - or works with - other objects or pieces.

Historically, creating high fidelity parts early in the design process has been expensive (which is why we rely on rendering), but the J55 changes that. This 3D printer allows us to create high fidelity CMF models early in the process, gather feedback from prospective users or other stakeholders, and design a product that meets your end goal without a hefty prototyping price tag.

Digital Manufacturing for the Everyday Design Firm

Currently, the top of the line PolyJet system is the Stratasys J850, an enterprise-level machine that allows you to have seven different materials loaded at a time to create high fidelity and high-quality parts. However, it can be cost-prohibitive for small design firms employing five to twenty designers that take on five to fifteen projects a year.

There’s also the F123 Series of FDM printers from Stratasys, like the F370. These print thermoplastics that let you prototype fit and function, but lack the color capabilities for branding and aesthetics. The J55 bridges that gap, combining high-end PolyJet functionality with the small footprint and office-friendliness of the F123 Series.

Additive Manufacturing vs. Conventional Manufacturing

Communication is key in the design process. There are a lot of moving parts: different people with different ideas, markets that you’re trying to hit, and markets that you’re trying to understand. Communication, therefore, needs to be concise, clear, and timely. These goals are hard to hit if you’re dealing with subpar prototypes and lacking information.

Realistically, conventional manufacturing methods like CNC machining and urethane casting can take weeks or months to develop prototypes. Additive manufacturing changes the way prototypes are developed. Say, for example, you want your design to be bigger; just scale it up in your software, hit print, and now you have a second iteration of that part within minutes or hours. Rapid prototyping allows for quick iterations, resulting in better products that hit the market faster than ever before.

More and more companies are shifting away from outsourcing and bringing 3D printing in-house. Outsourcing risks confidentiality, meaning any time you send a design out to a manufacturing partner, you risk bleeding your intellectual property. Bringing manufacturing in-house and keeping it in-house is a great hedge against that.

If your “in-house” isn’t a large space, the J55 is a small machine that fits nicely in tight spaces, it’s odorless, nearly silent (53 decibels operating), safe to use, and doesn’t require special ventilation or sound isolation.

What’s Unique About the J55?

The prototyping process with the Stratasys J55 is a little bit different than what you might typically see. Oftentimes there is card stock and hot glue involved, but with the J55 it’s purely digital. There will be some sketching and rendering in CAD, but after you’ve laid out your colors and textures onto the model all you have to do is hit print.

Colors

The J55 has a color space of nearly 500K unique colors as well as Pantone validated colors.

Vivid Translucent

There are three core color materials: cyan, magenta, and yellow. These color materials are all very vivid, translucent materials that, when mixed with opaque materials like black and white, produce solid colors, but on their own are translucent which allows us to produce specific CMY and RGBs hues. The last core material is a colorless clear material – perfect for simulating acrylic or glass and expanding the translucency range of other material combinations.

In addition to the core materials is the support material, which allows you to build complex geometry like overhangs and undercuts. The support material will get washed away with an electric pressure washer or post-processing machine.

Unique Build Platform

The J55 has a very unique build platform. If you’re familiar with 3D printing or 3D CAD in general, then you know we typically think in X, Y, and Z linear space. When we talk about dimensions of the build volume we think in terms of length and width and height. With the J55 that doesn’t apply because the build platform is round.

With other PolyJet 3D printers, we’re used to a rectilinear build tray with the printhead sweeping back and forth across it. But this is reversed with the J55; the print head stays stationary and the table moves underneath it. This turntable design is more compact, allowing a large build area without compromising speed, accuracy, or ease of maintenance.

Additional Included Tech

-

Intuitive Touch Panel - Like the F123 Series and those in the J8 series, the J55 employs a touchscreen that allows you to operate the printer without a standalone computer.

-

UV LED Lamp - The J55 uses a long-life energy efficient UV lamp.

-

12 Material Bays - 5 model materials, one support material, and each of those have up to 2 cartridges. As a cartridge is depleted, the system switches over to the next cartridge allowing you to print overnight and over a weekend without running out of material.

- ProAero Air Extractor - If you’ve been in a lab with a PolyJet machine, you may have noticed a very faint crayon-like smell (very faint, not dangerous). In a lab, this may not be bothersome, but for a system that is intended to exist in your office, next to you, the J55 has a filtered air system that is completely silent to capture those odors.

If you're interested in checking out the J55 3D printer, please contact us.

Related 3D Printing News

The Big Reveal! Stratasys Unvels 3 NEW 3D Printers

New Stratasys J55 3D Printer: Created for Your Workspace

3D Printing with the F123 Series: Hardware, Software, and Materials

COVID-19: 3D Printing World Responds Quickly to Aid in Battle

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.