PostProcess Solutions

Support Removal and Surface Finishing for 3D Printed Parts

Now Serving US & Canada

Now Serving US & Canada

Eliminate Bottlenecks with PostProcess TechnologIES

Automate the support removal and surface finishing process with PostProcess Technologies. With solutions for all 3D printing technologies, a PostProcess Technologies solution improves the ease, consistency, and efficiency of finishing 3D printed parts.

don't miss this upcoming webinar!

January 26, 2023 at 7:00am PT

How It Works: Automated PolyJet Post-Processing

This webinar will showcase a demo of automated 3D post-processing focused on polyjet support removal. Attendees will get a close-up view of how software, hardware, and chemistry work together for transformative end part results. See the solutions running on the proprietary AUTOMAT3D® platform and engage in real-time Q&A.

See It Live - Don't Miss the Upcoming Events

Get up-close and personal with this technology during a Live Solution Experience (LSE) tour for post-printing. Streamed from the PostProcess labs, you'll be able to witness the unique blend of proprietary software, hardware, and chemistry at work, and engage in real-time Q&A. Register now:

FDM & PolyJet Support Removal and Surface Finishing: Live Solution Experience Tour

Resin Removal & Surface Finishing: Live Solution Experience Tour

Post Processing for Any 3D Printing Technology

Get predictable, consistent finishing on every job. PostProcess solutions have been tested to work across all materials and 3D printing technologies.

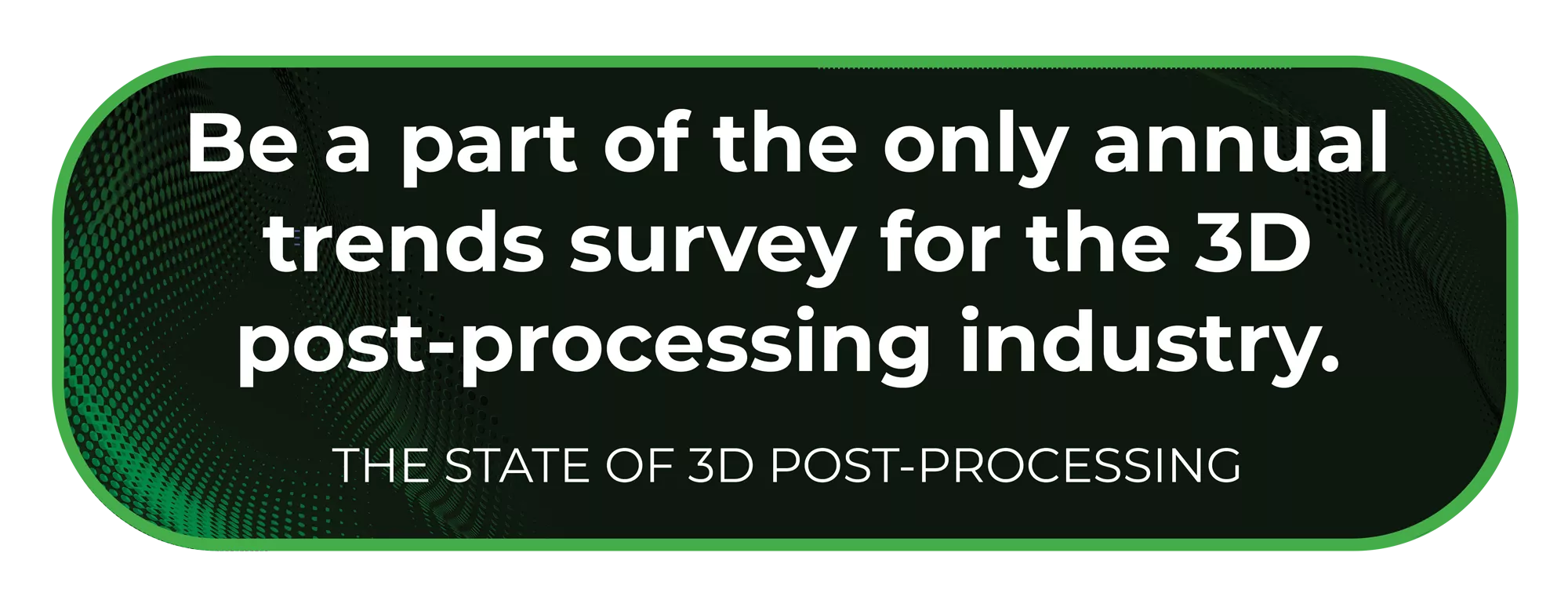

FDMProviding the fastest cycle times in the industry, PostProcess FDM post-printing solutions reduce processing times by at least 50% compared to traditional submersible tank systems. Controlled by AUTOMAT3D™ software, attended technician time is significantly reduced for both support removal and surface finishing to enable high volume production and decreases overall cycle time for your print operation. |

|

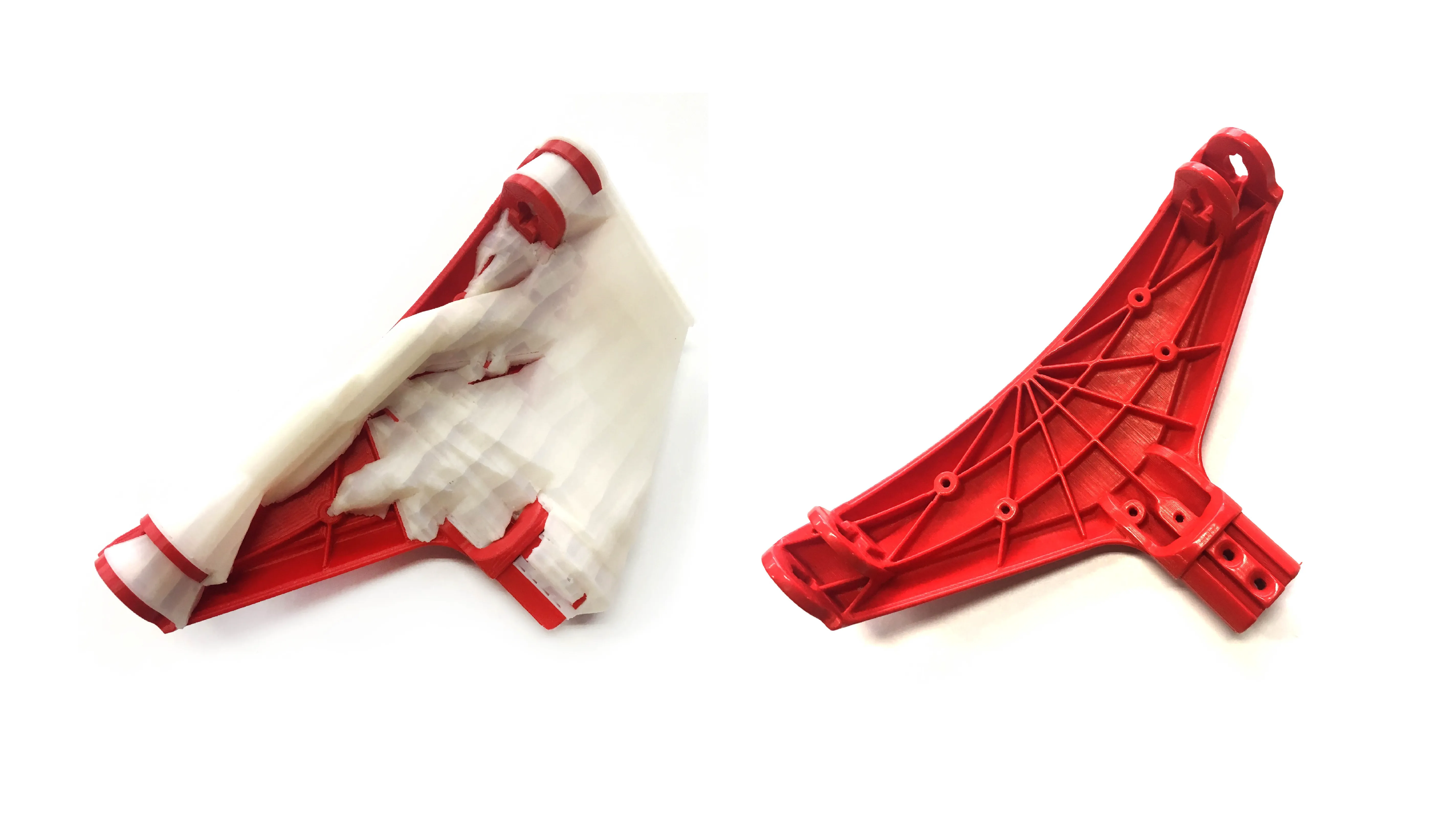

MetalPostProcess automates surface finishing for additive manufactured metal parts with unique, patent-pending technologies. Ensuring every printed part meets your desired Roughness Average (Ra) while maintaining dimensional consistency and fine-feature detail. Data-driven solutions deliver repeatable automation in batches to align with your print quantities with significantly reduced operator attendance time. |

|

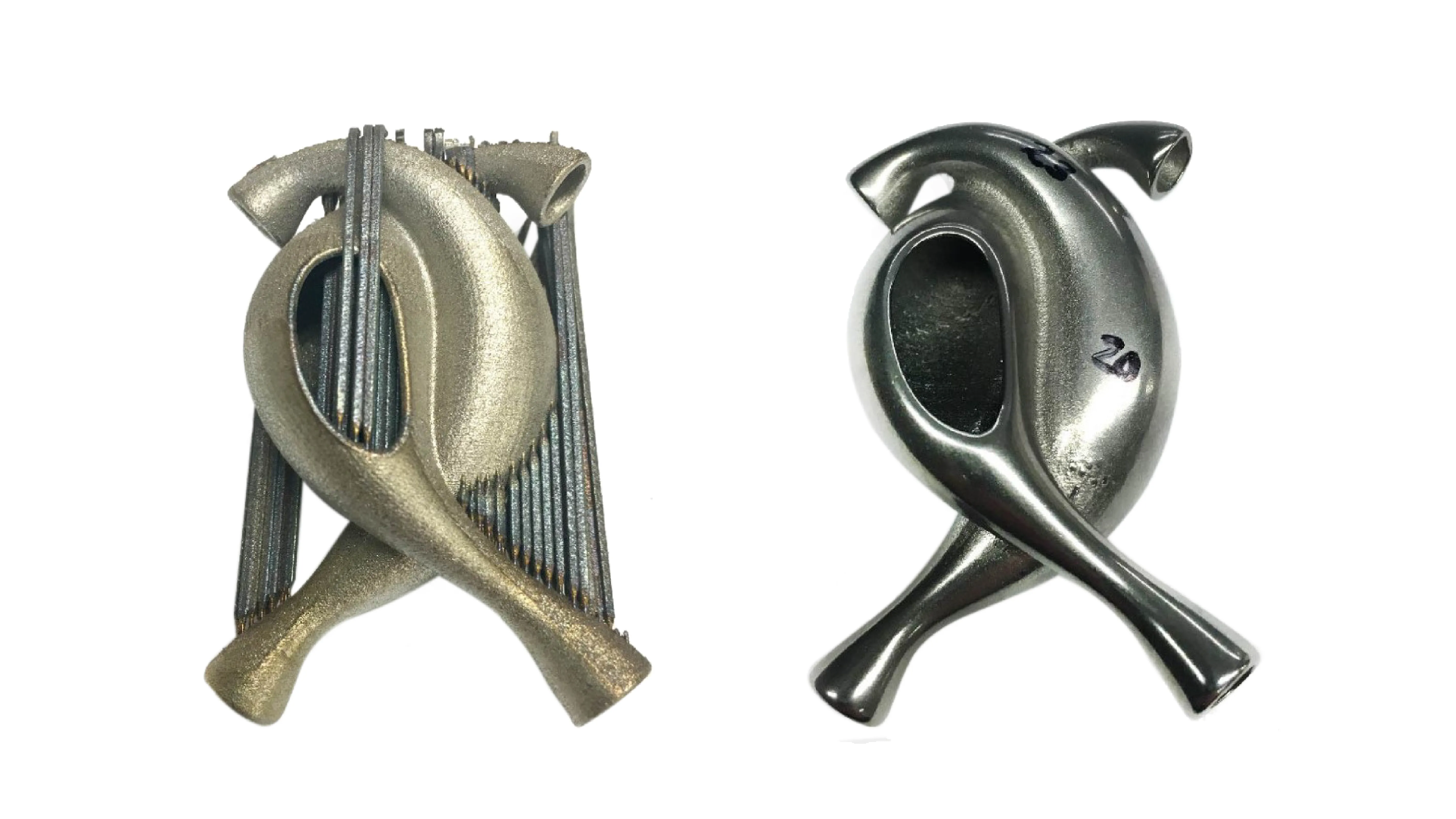

SAF, MJF and SLSDelivering replicable, high-quality uniformity for every part, surface finishing and powder removal solutions incorporate advanced, additive-specific technology for SAF, MJF and SLS. The PostProcess proprietary software platform provides an unprecedented level of process insight and control, ensuring uniform media and detergent exposure and motion control for predictable, consistent surface finishing. |

|

POLYJETPostProcess Technologies' PolyJet solutions perform thorough support removal with less part warpage and breakage. Software-driven submersible technology has proven to increase throughput by over 30% compared to traditional manual water blasting, along with a dramatic reduction in attended technician time of over 80%. Pair with surface finishing solutions for a complete post-print workflow to achieve consistent results even for the most delicate geometries. |

|

SLA, P3, DLP, & CLIPThe PostProcess comprehensive software, hardware, and chemistry solution reduces SLA, P3, DLP, and CLIP resin removal steps by 50% or greater. As the fastest resin removal system on the market, field-tested on thousands of trays, these solutions are proven to clean multiple full trays in under 10 minutes consistently. |

|

“

Toro performance standards require a degree of precision that can only be achieved through an automated solution. PostProcess delivers an unprecedented level of precision that is paving the way for the digital manufacturing revolution, and Toro is excited to be a part of it.

”

![]()

Solutions

-

-

Demi 430

- Function:

Support Removal - Features:

Patent Pending AUTOMAT3D Platform -

Envelope:

14″ L x 14″ W x 14″ H

-

-

Demi 830

- Function:

Support Removal - Features :

Designed for High Volume Use -

Envelope:

18" H × 18" W × 18" L

-

-

Demi 910

- Function:

Support Removal - Features :

Carbon Resin Removal -

Envelope:

18 L ″ x 18 W ″ x 25" H

-

-

Demi 4100

- Function:

Support Removal - Features :

SLA Resin Removal -

Envelope:

35 L ″ x 35 W ″ x 25 H ″

-

-

Base

- Function:

Support Removal - Features :

Evenly Treated Parts -

Envelope:

40 L ″ x 27.5 W ″ x 26 H ″

-

-

vorsa 500

- Watch Video

- Function:

Support Removal - Features :

FDM Support Removal -

Envelope:

16″ L x 16″ W x 14.5″ H

-

-

Demi X 520

- Watch Video

- Function:

Support Removal - Features :

Axial Flow Technology -

Envelope:

14” L x 14” W x 15” H

-

-

Demi X 520 Dental

- Watch Video

- Function:

Support Removal - Features :

Dental Resin Removal -

Envelope:

14” L x 14” W x 15” H

-

-

Rador

- Function:

Surface Finish - Features:

Produces Desired Roughness Avg. -

Envelope:

21.4″ L x 8.8″ W x 13″ H

“Before, it might take an operator an hour and a half or two hours to clean a tray of parts coming off our PolyJet. Now with the PostProcess machine, operator time is down to less than 10 minutes.”

![]()

Hybrid Solutions

HYBRID DECI DUO

Envelope:

19″ L x 27.5″ W x 26″ H

HYBRID DECI DUO

Features:

15″ D x 18″ H

DECI DUO

With the Hybrid DECI Duo, support removal, powder removal, and surface finishing of 3D printed parts are automated in a single multi-functioning system and designed with a space-saving footprint that optimizes production floor space. The patent-pending software, user-friendly hardware, and additive-formulated consumables work collectively to deliver exacting support removal and surface finishing while increasing the throughput of your production. The Hybrid DECI Duo has been engineered for the most advanced 3D print materials such as resins, thermoplastics, and metals, and offer fast cycle times for even the most complex parts.

Additional 3D Printing Resources

AWARD WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

3D Printing Courses

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training and 3D printing courses. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

3D PrintING SERVICES

No matter the size, quantity, or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing Services to help your organization produce the best parts and prototypes available on the market.

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services