Optimizing Your Workstation Budget for Design & Engineering Applications: Flow Simulation

This article is part four of a five-part blog series that provides guidance on how to optimize your workstation purchase for different CAD workflows. This blog covers flow simulation—often referred to as CFD (Computational Fluid Dynamics).

In all, the series covers the following workflows:

- Basic/advanced CAD

- Rendering and visualization

- Structural and plastics simulation

- CFD simulation

- eDrawings Pro VR

In each, we discuss components of a workstation that are important to that particular workflow and come up with some sample configurations to help optimize your spending budget.

Workflow: Flow Simulation (CFD)

SOLIDWORKS Flow Simulation and 3DEXPERIENCE FLUIDS are powerful parametric flow simulation tools that simulate fluid flow, heat transfer, and fluid forces in real-world conditions. Engineers and analysts can efficiently determine the effects of liquid and gas flow early in the design process. The primary algorithm used is the Finite Volume Method (FVM) although additional algorithms might be used depending on the type of analysis.

Although similar, we’ve chosen to address workstation requirements for flow simulations separate from structures, owing to differences in computational methods between the two simulation product families. While it depends on model size and type of analysis, FVM-based models tend to more efficiently parallelize than those of structure models, leading to subtle differences in CPU and GPU recommendations.

How Many Cores Do I Need?

The solver portion of FVM-based models is quite parallelizable, meaning more processor cores can be used to reduce time-to-solution. Further, because the time spent in the solver increases geometrically with the problem size, the importance of additional cores grows as model size increases (although there is a point of diminishing returns depending on the model size). Flow simulation configurations should include a minimum of 12 processor cores.

When selecting CPU specifications, keep in mind that performance and efficiency increase with each generation of CPU, so it’s important to note the generation of the processor. Because CPU performance is critical to simulation workflows, Intel 12th or 13th Gen i7 or i9 processors, Intel Xeon W-3400 or Intel Xeon W-2400 Workstation Processors, or AMD Ryzen™ Threadripper™ PRO Processors are recommended.

How Much Memory?

Another important component when configuring hardware for flow simulation workloads is system memory. Memory requirements for simulation solutions are directly proportional to the number of cells used in the model; larger meshes and more complex simulations require more RAM.

At a minimum, consider 32 GB or 64 GB for medium and larger models. FVM solvers also tax memory bandwidth, thus if the workstation architecture supports multiple memory channels that feature should be considered for larger model sizes.

What about the GPU?

While CPU and memory performance dominate the configuration choices for flow simulation, the GPU choice is still important. We recommend an NVIDIA RTX™ A4000 or higher.

Selecting a workstation configuration that the hardware vendor tests and validates for your specific application is critical. Dell and GoEngineer have worked closely with SOLIDWORKS to create prepackaged hardware configurations that are specific to a workflow; these configurations are a thoroughly tested combination of hardware and software specifically chosen to eliminate incompatibility or performance issues.

To summarize, component suggestions for flow simulation workflows:

| Component | Suggestions |

|---|---|

| CPU |

12ᵗʰ or 13th Gen Intel® Core™ i7, or i9

Intel Xeon W-3400 or Intel Xeon W-2400 Workstation Processors AMD Ryzen™ Threadripper™ PRO Processors |

| GPU | NVIDIA RTX™ A4000 and above. (Increase VRAM for larger models) |

| RAM | Minimum 32 GB; 64 GB suggested |

| Storage | SSD with NVMe interface |

| Packaging | Mobile and Tower |

| Application Testing & Validation | Select specific workflows at the www.dell.com/goengineer portal. |

Flow Simulation Workstation Recommendations

Flow simulation models traditionally required desktops or tower configurations. However, the Dell Precision 7780 mobile workstation is a viable platform for running moderately-sized models in the field or at home. It supports up to 128 GB of RAM and up to 24 cores (eight performance, 16 efficiency cores when configured with the Intel Core i9 processor).

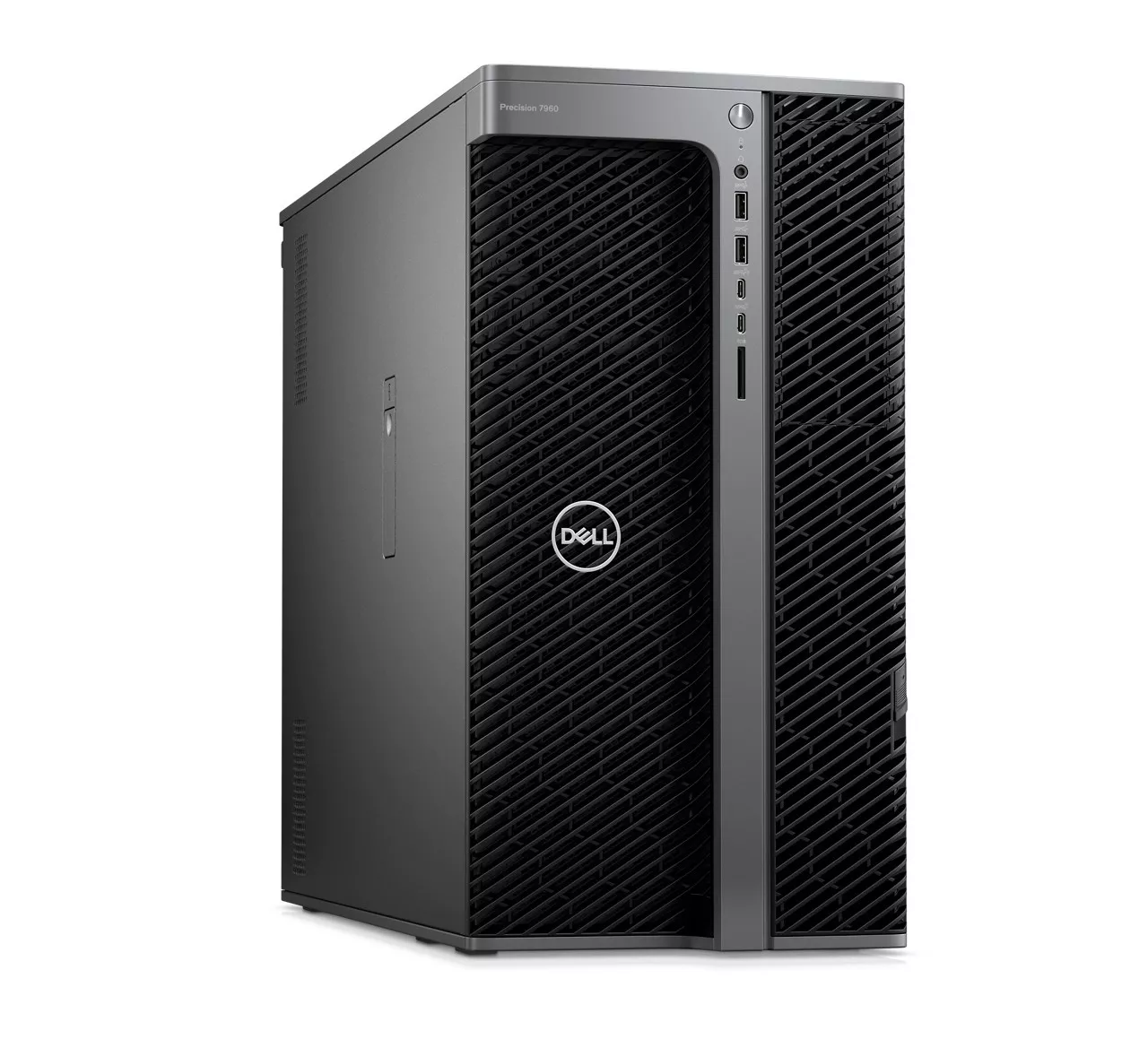

The Precision 7960 and Precision 7865 towers are ideal solutions for larger models. The Precision 7960 supports Intel Xeon processors with up to 56 cores and up to 4 TB of memory. The Precision 7865 supports the AMD Ryzen Threadripper PRO CPU with up to 64 cores and up to 1 TB of ECC memory utilizing Dell Reliable Memory Technology (RMT) Pro.

While CPU and memory dominate the component choices, GPU choice is still important. The Precision 7960 Tower supports up to four NVIDIA RTX 6000-class graphics cards—highlighting the power, cooling, and expandability capabilities of the platform.

Dell offers a curated lineup of Precision workstations with NVIDIA RTX GPUs that provide a full range of options for flow simulation workflows. Along with flexibility for scaling memory, storage, and graphics to support higher complexity designs, these workstations are tested and validated with SOLIDWORKS applications.

These workflow-based configurations, along with additional learning resources (and an additional discount!), can be viewed at the dell.com/goengineer portal. The portal simplifies the selection of an optimized, tested, and validated solution that maximizes every budget dollar.

Related Articles

Best Docking Stations for SOLIDWORKS

How the GoEngineer Simulation Team Is Expanding Customer Capabilities

Computational Fluid Dynamics (CFD): Applications & Solutions

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.