Economic Change in Manufacturing Demands a New Approach by Leveraging 3D Printing

As the global manufacturing market shifts with increased demand for personalized products and on-demand production, 3D printing finds an ever-growing range of applications.

3D printing is the process of creating a 3D object from a digital file. Since its inception with Stereolithography and FDM (Fused Deposition Modeling) in the 1980s, 3D printing has evolved into a whole portfolio of technologies, becoming ever more accessible and affordable for businesses of all sizes.

Affordable Prototypes & Production Parts

Creating a new product with traditional manufacturing can be a lengthy and expensive process requiring specialized tools and equipment. If a new product requires custom tooling, iterations can add weeks to a product delivery date and increase labor costs.

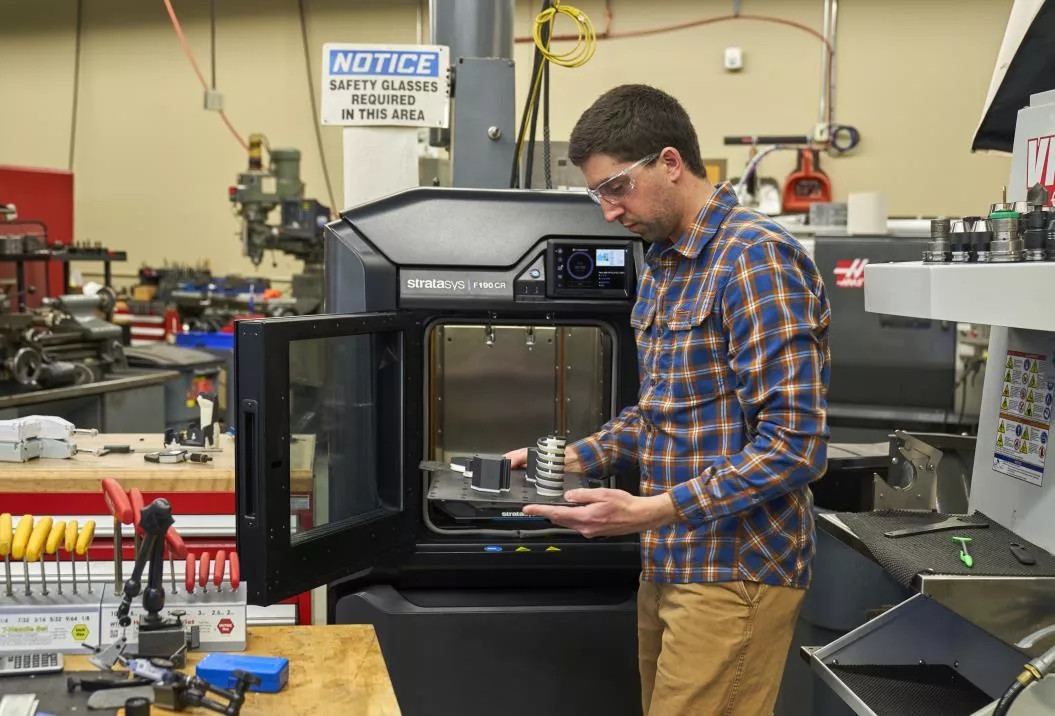

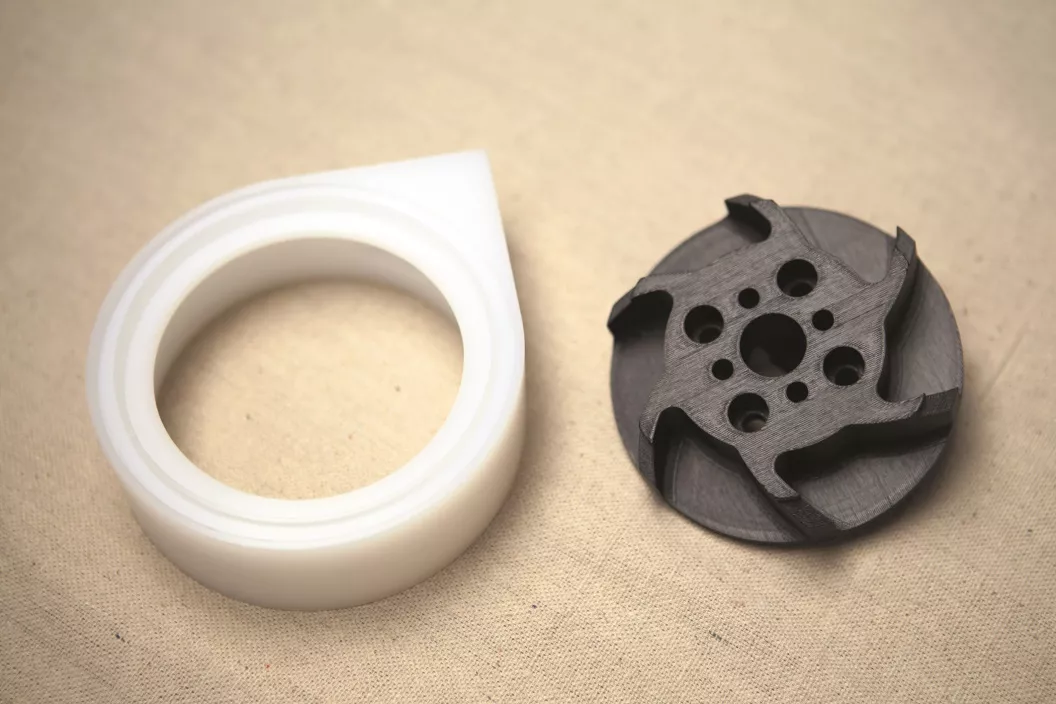

One main advantage of 3D printing is the ability to create complex and customized parts quickly and efficiently. 3D printing provides a cheaper, expedited workflow for manufacturing with the ability to go from digital CAD file to final product in hand within a matter of hours or days, rather than weeks or months.

A designer can then test a prototype, perform fit-and-function, and visualize the final product. If needed, they can quickly make changes to the CAD and reassess with another 3D print.

This reduced turnaround time and simplified workflow allows 3D printers to produce small batches of products at a lower cost than traditional manufacturing methods, making it possible to cater to niche markets and respond quickly to changing demands.

Sustainability

As a rule, 3D printing produces very little material waste. Compared to traditional subtractive manufacturing, additive manufacturing processes consume nearly the exact amount of material needed for a specific object. That material, however, is almost never reusable or recyclable. Powderbed Fusion technologies, however (like the Stratasys H350 SAF machine) can notably use excess material from previous builds with a ratio of 70% used to 30% fresh powder, bringing sustainable manufacturing to a whole new level.

The H350 uses SAF (Selective Absorption Fusion) technology to produce a high volume of parts with the repeatability and accuracy typically reserved for injection molding. With the H350, users can print parts on the build tray in both the X&Y plane and vertically in the Z direction, providing a full volume of nested parts. Leveraging a full build volume to print hundreds of parts has a significant impact and drastically reduces the cost per part.

Additionally, 3D printing also enables manufacturers to produce objects with fewer assembly steps, reducing the need for additional components, transportation and assembly energy costs, and storage space.

Finally, the H350 uses PA 11 and PA 12 material which is useful in manufacturing. With the large volume builds it's the perfect fit for and use production in the automotive industry.

Conclusion

In conclusion, the economic changes in manufacturing demand a new approach, and 3D printing technology is a vital part of that approach. Its ability to create complex and customized objects quickly and efficiently, with fewer material wastes and lower energy costs makes it a sustainable and cost-effective alternative to traditional manufacturing methods.

3D Printing as a Service

GoEngineer offers comprehensive 3D printing services across multiple U.S. labs, equipped with cutting-edge Stratasys FDM, PolyJet, Stereolithography, and SAF technologies for 3D printed prototypes or production parts. Request your quote online today!

More 3D Printing News

Concept to Production 3D Printing: How it Works

Meet the F3300 3D Printer from Stratasys

Scan-to-Print Workflow: Tips to Optimize 3D Printed Food Models

GoEngineer 3D Printing Services: Stronger than Ever

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.