3DEXPERIENCE SIMULATION: Better Industrial Equipment Design

Finite element analysis software has helped many companies improve product design and shorten design cycle times. Currently a $12.7 billion industry, this field is expected to grow to around $26 billion, which constitutes a CAGR of 13% in the next five years [1]. The primary drivers that contribute to this growth, are the increasing demands to reduce production and prototyping costs, and technological advancements in fields like automotive, aerospace, telecommunications, and healthcare.

In this article, we introduce a few topics related to simulation in the Industrial Equipment segment, a chief contributor to this growth.

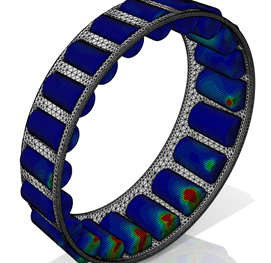

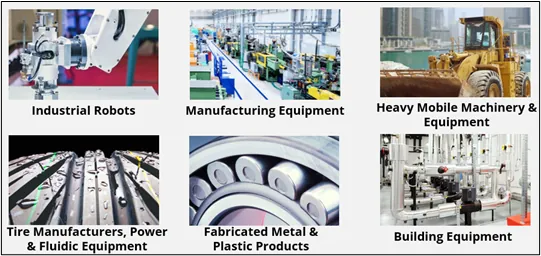

Industrial Equipment Landscape

Figure 1. Industrial Equipment segments

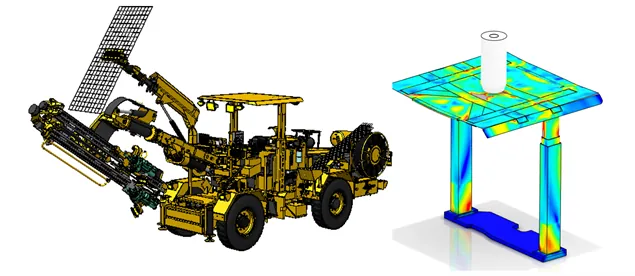

The Industrial Equipment segment is comprised of six major fields described in Figure 1. It is typically characterized by heavy machinery and moving equipment that undergo cyclic structural loading and vibrations. This requires sophisticated simulation technology to ensure product performance and reduce prototypes. An example of a company in this segment that has adopted SOLIDWORKS Simulation, for these tests is ABCO Automation.

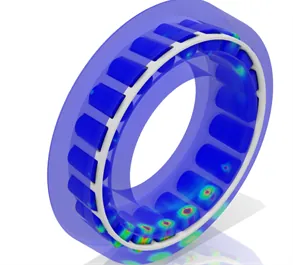

Figure 2. ABCO Automation

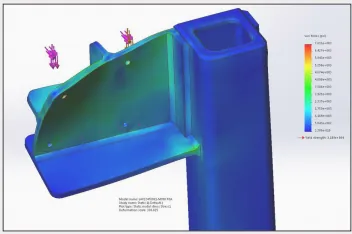

ABCO Automation designs and builds custom turnkey factory automation systems for manufacturers across the globe. Success really depends on the company’s ability to develop high-quality automation equipment such as the one pictured in Figure 2. They used SOLIDWORKS Simulation to determine the stress and deflection performance on a robot mount assembled to a similar frame.

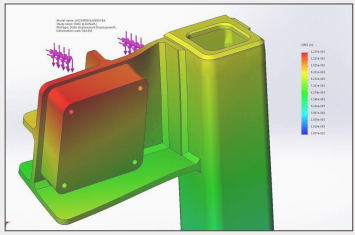

Figure 3. Robot Mount from ABCO Automation

By using SOLIDWORKS Simulation, they were able to ensure that the mount did not deform excessively. They were also able to determine the appropriate bolt specifications to avoid thread pullout during operation. Besides static loading conditions, these structures also have moving components that induce shock and vibration loads that requires powerful analysis programs like SIMULIA.

3DEXPERIENCE SIMULAtion

3DEXPERIENCE SIMULATION offers a portfolio of high-end analysis programs from Dassault Systèmes deployed on the 3DEXPERIENCE platform. This portfolio boasts structural analysis (FEA), fluid dynamics (CFD), and electromagnetic analysis technology to tackle the most comprehensive multi-physics analysis problems.

This is especially significant in the industrial equipment industry because of the dynamic nature of the loading conditions experience by these components. For instance, the roof crush analysis is a standard test performed on heavy machinery to ensure operator safety.

Figure 4. Roof Crush Test

Using the Explicit Analysis solver from Abaqus on the 3DEXPERIENCE platform, these tests can be set up and simulated with a high degree of realism and accuracy. An important aspect of the 3DEXPERIENCE platform is the ability to leverage cloud computing to simulate resource intensive problems like these.

With the cloud solve capability, users can access up to 192 cores on Dassault’s Cloud Service directly from the simulation user interface. The access to cloud infrastructure to solve design and simulation challenges is another key contributor to the large-scale adoption of these analysis tools by several industries [3].

Figure 5. Roof Crush Test Simulation

MULTI-PHYSICS SIMULATION

Figure 6. Heat Exchanger Thermal Performance Simulation

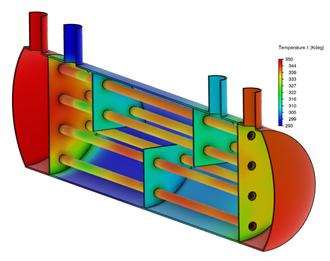

Electronic components, cooling, and lubrication systems are some of the most common problems that are simulated in the Industrial Equipment segment with Computational Fluid Dynamics (CFD).

CFD software is used to study the fluid flow and thermal performance of these products and the 3DEXPERIENCE platform accomplishes this with Fluid Dynamics Engineer.

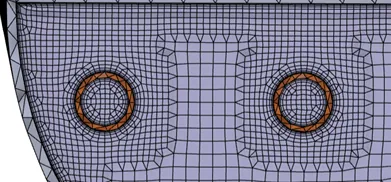

The ability to tackle problems that require detailed meshing capabilities enables users to simulate a wide range of applications. Figure 6 shows a common shell and tube heat exchanger that has several pipes and a few baffles. The pipes offer a large surface area, and the baffles increase the dwell time of the flow to ensure optimal heat exchange efficiency.

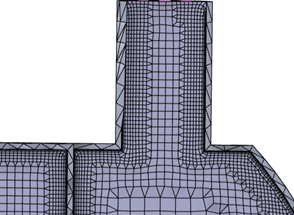

To estimate this efficiency accurately requires a fine mesh across the solid and fluid components which is easy to accomplish with the hex-dominant body-fitted mesher available with the program.

Figure 7. Heat Exchanger Mesh

Large complex meshes drive up solve times making the case again to leverage cloud computing resources on the 3DEXPERIENCE platform to solve these problems in a timely fashion. For instance, this analysis has 6,000,000 elements and took 30 minutes to solve with the compute cores available on the cloud.

Related Articles

DELMIAworks: A Turnkey Application for Real-World Manufacturers

Getting Started with 3DEXPERIENCE: Setup, Dashboards, Connectors, & More

The 3DEXPERIENCE Platform for Educators Explained

References

[1] https://www.marketsandmarkets.com/Market-Reports/simulation-software-market-263646018.html

[2] STRESS AND DEFLECTION ANALYSIS of an EXISTING ROBOT MOUNT from goabco.com

About Arun Thiraviam

Arunachalam Thiraviam is a Simulation Product Specialist with GoEngineer. He is involved in educating and assisting customers with studying the quality of product design through FEA, CFD and Injection Molding analysis. He has a Master’s Degree in Mechanical Engineering from North Carolina State University where he was involved with studying the Dynamics of floating Vertical Axis Wind Turbines. Besides engineering, he plays the guitar and writes music in his free time.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.