DELMIAworks: A Turnkey Application for Real-World Manufacturers

DELMIAWorks for ERP Manufacturing

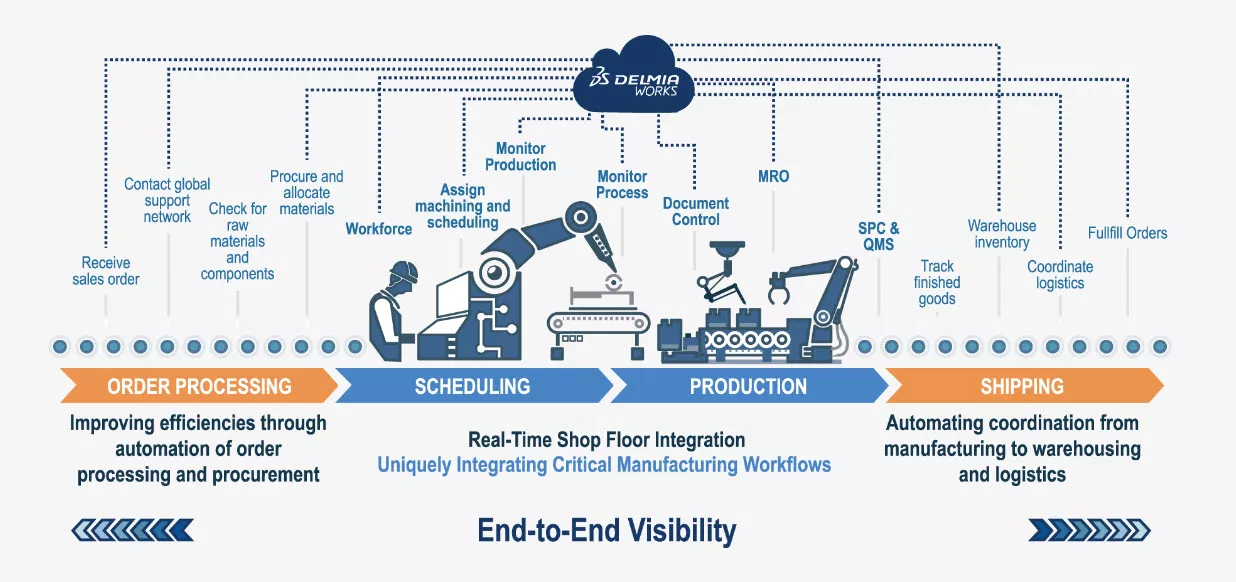

DELMIAworks is a robust ERP (Enterprise Resource Planning) system built to help manufacturing companies improve their end-to-end-production processes. In one, collaborative environment, all sales, production, resource planning, manufacturing tracking, and inventory management can be leveraged throughout the business. Some of the software solutions that manage this data are:

- Manufacturing Software

- Warehouse Management

- Enterprise Resource Planning

- Manufacturing Execution System

- Quality Management

- Supply Chain Management

- Workflow Software

- Electronic Data Interchange

- Customer Relationship Management

- eCommerce and Web Portals

With all of these tools and more at your fingertips, DELMIAworks truly is a “front door to back dock” solution.

How does DELMIAWorks Work?

From the time a sale comes through the front door to the moment it leaves the back dock, every single piece of data is captured and shared in a real-time ecosystem. Once a customer’s sales information has been gathered, then components, packaging, and raw materials can be ordered, tracked, and delivered on time.

After a manufacturing center receives materials and is ready to start producing parts, intelligent tools and intuitive dashboards display what machines are up and running, what is next in line for production, as well as material and tooling changeover information.

Are pick tickets required? Do any shipments require special documents to be included? DELMIAworks has the ability to automate "back dock" information like pick tickets, packing slips, labels, bill of lading, inventory lots and locations.

DELMIAWOrks Manufacturing Solutions

Below, we’ve highlighted three manufacturers who turned to DELMIAworks to streamline their production process. Each of these companies had a unique situation, but paired with the right tools, were able get back to business in no time.

Ditching a Manual Sales Process

This manufacturer used spreadsheets for pricing information, production scheduling, and inventory management; all updated manually. Quotes were also generated by hand and were stored in a standard file directory. Because of this manual process, they had difficulty predicting proper pricing and tracking costs which led to quote errors and inaccuracies. These issues caused them to incur penalties, lose repeat business, and it ultimately hurt their profitability.

The Solution

By leveraging DELMIAworks’ fully integrated customer resource management solution and integrating the sales quoting functionality, this manufacturer was able to solve the many issues within their sales process. Utilizing the Capable to Promise tool and being able to see historical cost and pricing information associated with customers, opportunities, and purchase orders was transformative to their organization.

Overcoming Poor Capacity Planning

This manufacturer was losing business because they were setting unachievable delivery dates. They were struggling with the accuracy of their production planning (i.e., the fact that it varies) and the lack of communication within the recording process from those involved.

They also faced machine downtime and couldn’t accurately account for it from a planning standpoint. After several weeks recording and documenting every instance of machine downtime as well as the cause, the five main factors were:

- Tooling and auxiliary equipment delays

- Excessive machine setup time

- Unplanned machine maintenance

- Raw material delays

- Machine operator errors

The Solution

After reviewing their findings, they used the DELMIAworks Bill of Manufacturing tool to capture everything from raw materials and packaging, as well as tooling intelligence to determine if running certain parts at the same time on different machines would cause issues.

The Real Time production display connected their machines to the database so everyone in the production shop could see in real-time what was next on the line and the Capable to Promise tool flags found conflicts in the production schedule to determine accurate deliverability of parts.

Lastly, they used DELMIAwork’ Runs the Best to track the efficiency of each of their machining centers, offering insight into whether a given machine is or isn’t performing at its best, and why.

Developing Better Business Intelligence

This manufacturer’s decision makers weren’t getting the right data at the right time and decisions were being made by “gut feel”. They lacked a central repository for data and received hand-calculated reports from their various department heads.

The Solution

Smart Page is a Business Intelligence reporting tool inside of DELMIAworks that allows multiple dashboards. This system allowed them to have a sales pipeline, a customer service viewpoint, and vendor performance to track delivery. Smart Page is configurable but doesn’t require an ERP license, so they stationed television screens around their building to display in real-time any changes in manufacturing, production, and sales.

If your company is familiar with the challenges these manufacturers faced, if you’d like to further improve your business process, or are interested in learning more about DELMIAworks please contact us.

Editor's Note: This article was originally published in April 2021 and has been updated for accuracy and comprehensiveness.

Related Articles

What's New SOLIDWORKS 2022: 3DEXPERIENCE

Getting Started with 3DEXPERIENCE: Setup, Dashboards, Connectors & More

Best Workstations for SOLIDWORKS: Hardware Configurations

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.