Which Technology is Best for 3D Printing Miniatures?

3D printing technologies have come a long way, with a proven ability to provide small features with high-quality detail. This has led gaming communities like Dungeons & Dragons and War Hammer 40K players, to start adopting 3D printing to create personalized pieces.

- Suggested Article >> Gloomhaven 3D Printed Tool Organizer

These epic role-playing tabletop games typically include various terrains, unique structures, and small character pieces showcasing intense and intricate details. While many consider these board games fun and entertaining, the game pieces can be pricey, leading serious gamers to shell out hundreds (if not thousands) of dollars on miniatures and accessories.

Whether you're a gamer wanting to add some unique pieces or are in the production industry and need to produce hundreds or thousands of a single unit, choosing the correct 3D printing technology will help you get the highest quality of print necessary without breaking the bank.

Note: Although there are many different 3D Printing technologies, this article will focus solely on FDM and Resin-based equipment.

What’s the Difference Between, FDM, Programmable Photopolymerization, SLA & PolyJet?

Fused Deposition Modeling (FDM), is an additive manufacturing technology developed by Scott Crump, co-founder of Stratasys. FDM technology uses a continuous strand of filament of various thermoplastic materials, and fed to the heated extruder head to be extruded in thin layers (around 200 microns) driven by a computer-controlled coordinate system to create the desired model.

Resin 3D printers use a liquid-based composition of various thermoset epoxies and/or acrylics that, when exposed to UV light, rapidly convert to a solid polymer. Resin 3D printers also print layer by layer, but deliver parts with more detail thanks to a much higher layer resolution (about 50 microns).

The Origin One DLP resin 3D Printer (powered by Programmable Photopolymerization technology) uses a tightly synchronized print process with pneumatic controls to reduce pull forces during production, producing parts with exceptional surface quality.

Large stereolithography resin 3D printers, like the Neo 450 and 800, can build hundreds of miniature pieces in a single build. These resin technologies are particularly useful for prototyping parts intended to be painted (like miniatures and terrain), because the models can accept the same materials and processes as the end product.

PolyJet technology offers similar benefits with similar materials, but prints with even higher resolution (about 25 microns) and supports full-color printing without the need to paint. But that's a subject for another article.

Considerations

Print Quality

What are you trying to print and how much detail is needed? The scale of the object will also affect the amount of detail the printer is capable of. FDM machines typically have a bigger build volume, are easier to use, and come with a more entry-level price tag. While a properly tuned FDM printer can offer great detail, you will still see the layer lines and stepping from the inherent resolution of the technology.

Printing Volume & Time

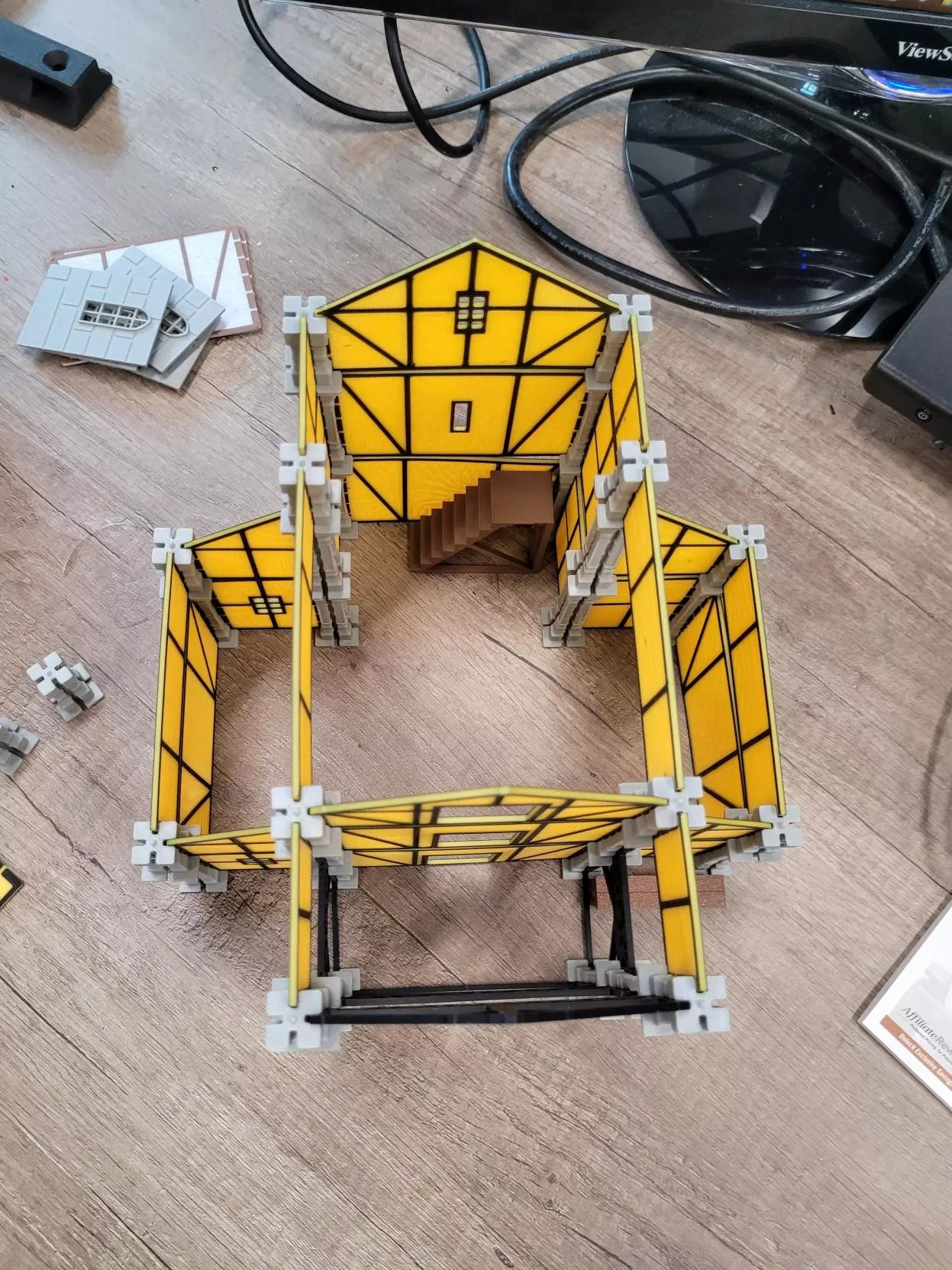

If you don’t need high-quality details with small features, such as large trees or building structures, you can save money going with FDM.

Resin printers often have smaller build bays than FDM, but they typically print at nearly the same speed, regardless of the number of parts —decreasing the overall price-per-part when printing multiple miniature characters at once. And, large Stereolithography printers can produce hundreds of parts on a single build tray.

Material Types & Costs

PLA and ABS are two commonly used FDM materials due to their useability and affordability. Consumer FDM filament spools of PLA or ABS can be purchased for as low as $20 for a 1kg spool, up to $100/kg or more for production quality material.

General purpose consumer resin is found to be about $50 for a 1L bottle, ranging to $100/L for professional grade materials. However, resin printers often have other associated costs that must be addressed, such as replacing a resin tank, having a large supply of Isopropyl alcohol, as well as UV lamps and other protective equipment.

Working Process

Both FDM and resin technologies require support structures to ensure part quality, which must be removed after printing. FDM supports may be removed by hand and discarded, but some support materials are dissolvable in water or detergent for hands-free removal. This process is similar for resin technologies, which rely on scaffold structures made of the same model material; carefully remove as much as possible by hand and with tools, then soak the parts in an ultrasonic cleaning solution tank that disolves the remaining support material.

Which Technology is Best for Printing Miniatures?

For large parts, FDM printers are very capable of producing impressive detail when build parameters are properly established. If you are new to 3D printing, you may want to consider an FDM machine like a MakerBot Method because of the lower cost and ease-of-use. For commercial/industrial purposes, Stratasys offers a host of large reliable and precise printers.

For next-level detail, large volumes, and fine-tuned models, DLP and Stereolithography resin technologies deliver every time.

Or, if you simply want to take your next game night to the next level, contact our 3D Printing Services department. They'll print your parts for you, so you can focus on game strategy and leave the rest to us.

3D Printing as a Service

GoEngineer offers comprehensive 3D printing services across multiple U.S. labs, equipped with cutting-edge Stratasys FDM, PolyJet, Stereolithography, and SAF technologies for 3D printed prototypes or production parts. Request your quote online today!

Related Articles

The Perfect 3D Printed Desk Organizer: From Render to Reality

Design and Manufacture a Custom Hat Using LPBF & FDM 3D Printing Technology

FDM 3D Printed Tool Organizers & Assembly Aids

A Modern Take on a Classic: 3D Printed Fender Telecaster

About Ryck Hoopes

Ryck Hoopes is a Hardware Application Engineer at GoEngineer. With a background in domestic and international manufacturing, he brings extensive knowledge of R&D, quality control, and supply chain management. Having worked in Aerospace, Healthcare, Marine, and Consumer Goods industries, Ryck is well versed in common challenges many companies face today. When he’s not working, Ryck enjoys mountain biking, snowboarding, and spending time with his friends and family in the mountains. He also coaches little league football, baseball, and snowboarding.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.