Stratasys VeroUltra White and Black Materials for Color 3D Printing

VeroUltra White and VeroUltra Black are the newest formulations of Vero opaque photopolymer resins compatible with Stratasys J-Series PolyJet 3D printers. In this article, we explore these new material developments and discover how they make Stratasys' best-in-class, highly professional, full-color models...even better.

The Stratasys J55 PolyJet 3D printer, found in our GoEngineer Additive Manufacturing Labs across the U.S., is a system we frequently use when producing customer benchmarks and orders for our 3D Printing Services department.

Since our clients come from a wide range of industries, from aerospace to medical devices, automotive to consumer products, and beyond, I find myself printing lots of unique and interesting geometries and model types.

Suggested Article >> Stratasys J55: Filling Big Shoes with a Small Footprint

What is a CMF prototype?

The CMF (Color, Material, Finish) prototype gives industrial designers and engineers the ability to effectively communicate the final look and feel of their products at any stage of the design process.

In the past, accurately simulating color, material, and finish on prototype models was a costly and time-consuming manual process that involved experienced model makers. With the advent of Stratasys’s J-Series PolyJet 3D printers, the rapid generation of CMF prototypes can be brought entirely in-house at tremendous cost and time savings. This allows companies to bring their products to market faster and more profitably with less risk.

The J-Series of Stratasys PolyJet 3D Printers leverages state-of-the-art additive manufacturing technology to bring your designs to life. By jetting microscopic droplets of multiple photopolymer materials simultaneously, these machines can create outstanding, high-fidelity, multi-material, full-color visual models.

The Challenge

After personally printing many models since its release last year, I noticed that as spectacular as the full-color printed models were, there was still a limit to the amount of realism I could produce. Specifically, when printing parts that required crisp color separation, like labels and text on packaging, simulated cloth, or models with complex organic appearances such as figured wood grain or marble.

Another area of concern when printing models with thin features such as simulated injection molded components, light and color could bleed through the thin walls and color accuracy would be compromised.

These limitations stemmed from the translucent nature of the Vero resins that the machine was capable of printing. The J55 has five model material channels and one support material channel that allows the printer to print six materials at the same time. There are different material loading schemes possible depending on what end results you are after.

For example, you have a “Full-Color with Clear” material scheme and a “Digital ABS” material scheme. The ideal material scheme for high-fidelity, full-color printing is “CMKY”, or having White, Cyan, Magenta, Black, and Yellow model resins loaded in addition to the support material.

To achieve different opaque colors, the loaded CMKY resins are printed together in the appropriate ratios on top of a white base shell layer. If the feature being printed was thin (>6mm), color accuracy would be compromised as the older VeroPureWhite resin base layer was itself 6% translucent, thus allowing color and light to bleed through the thin areas of the model.

The Solution

With the recent release of the new opaque VeroUltra White and Black PolyJet resins, the issues outlined above are now a thing of the past! By increasing the opacity of the white resin from 96% to >99%, printed models now display superior color fidelity, separation, contrast, and brightness.

Another improvement was in a reformulation of the white color itself. The original VeroPureWhite resin displayed a “cool” white color that had a very slight blueish tint when compared to the new VeroUltra White which is a warmer white. While I never really minded the appearance of the older VeroPureWhite resin, when placed side by side, I much prefer the color of the new opaque VeroUltra White.

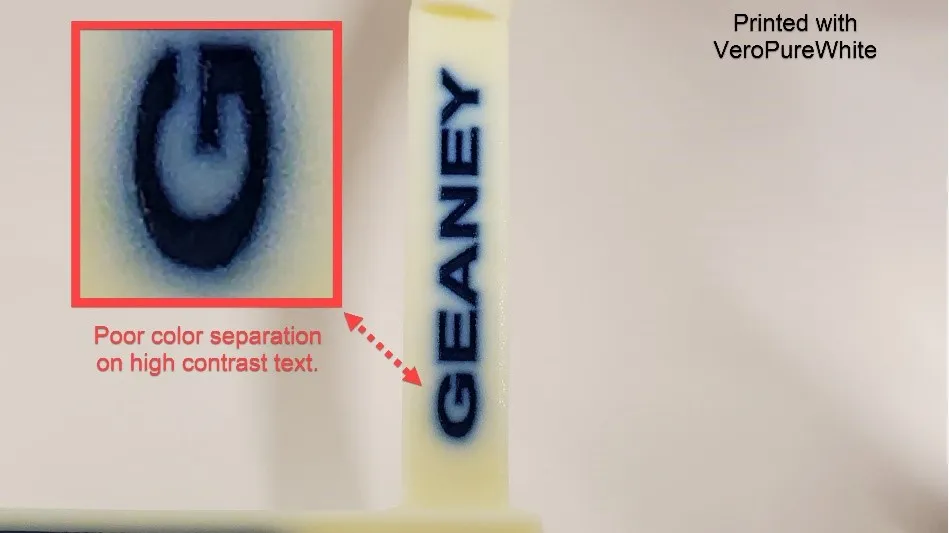

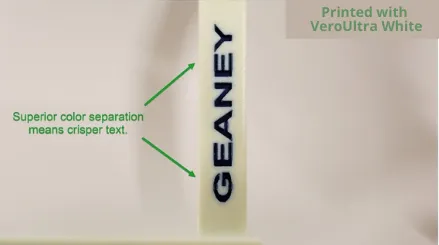

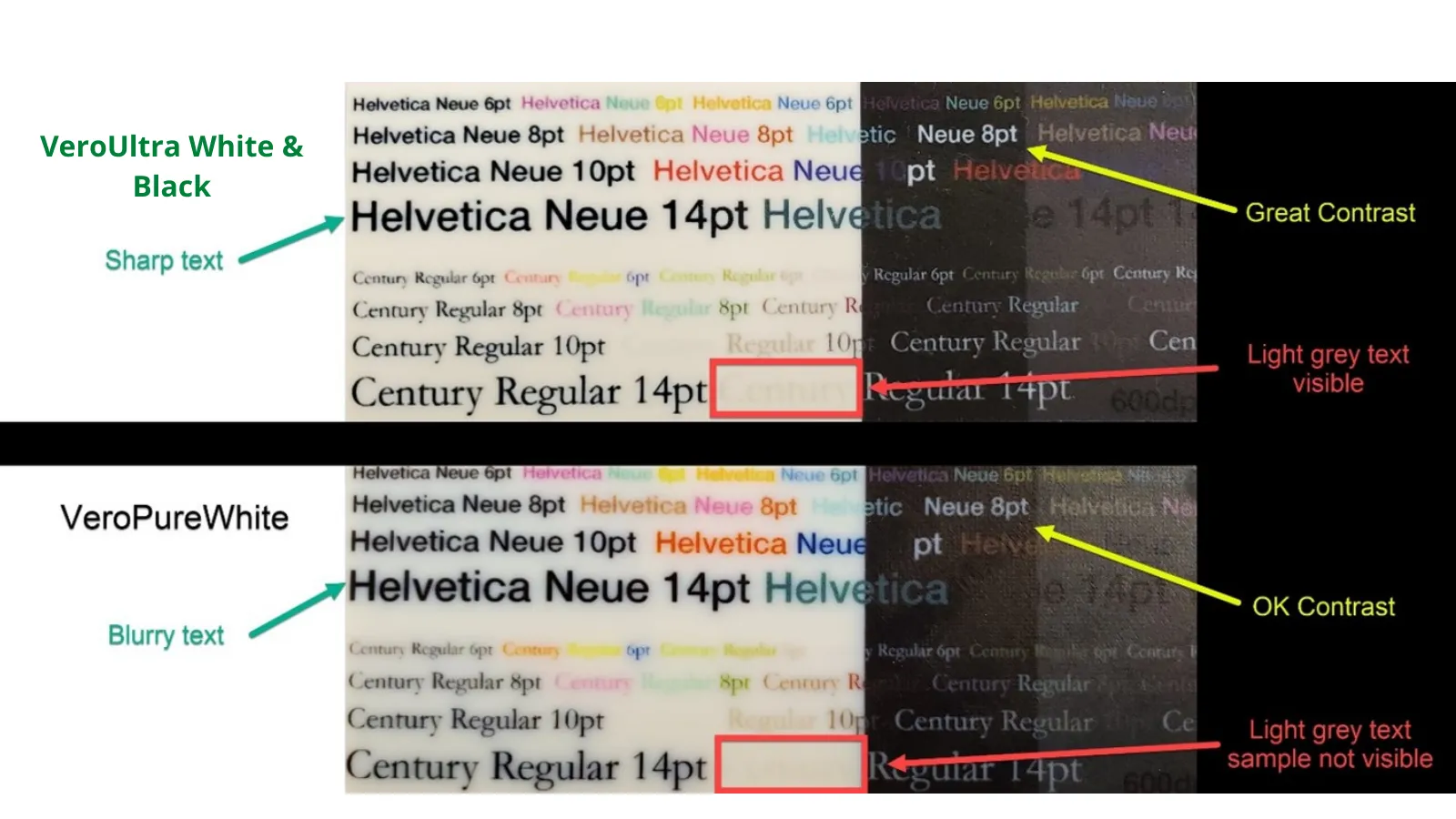

An issue caused by the translucent nature of the resins was poor color separation. For example, if printing dark blue text on a light-colored background, the text could appear blurry around the edges where the two colors intersect. The new opaque VeroUltra White resin creates a model with text that is crisp with better contrast and color separation.

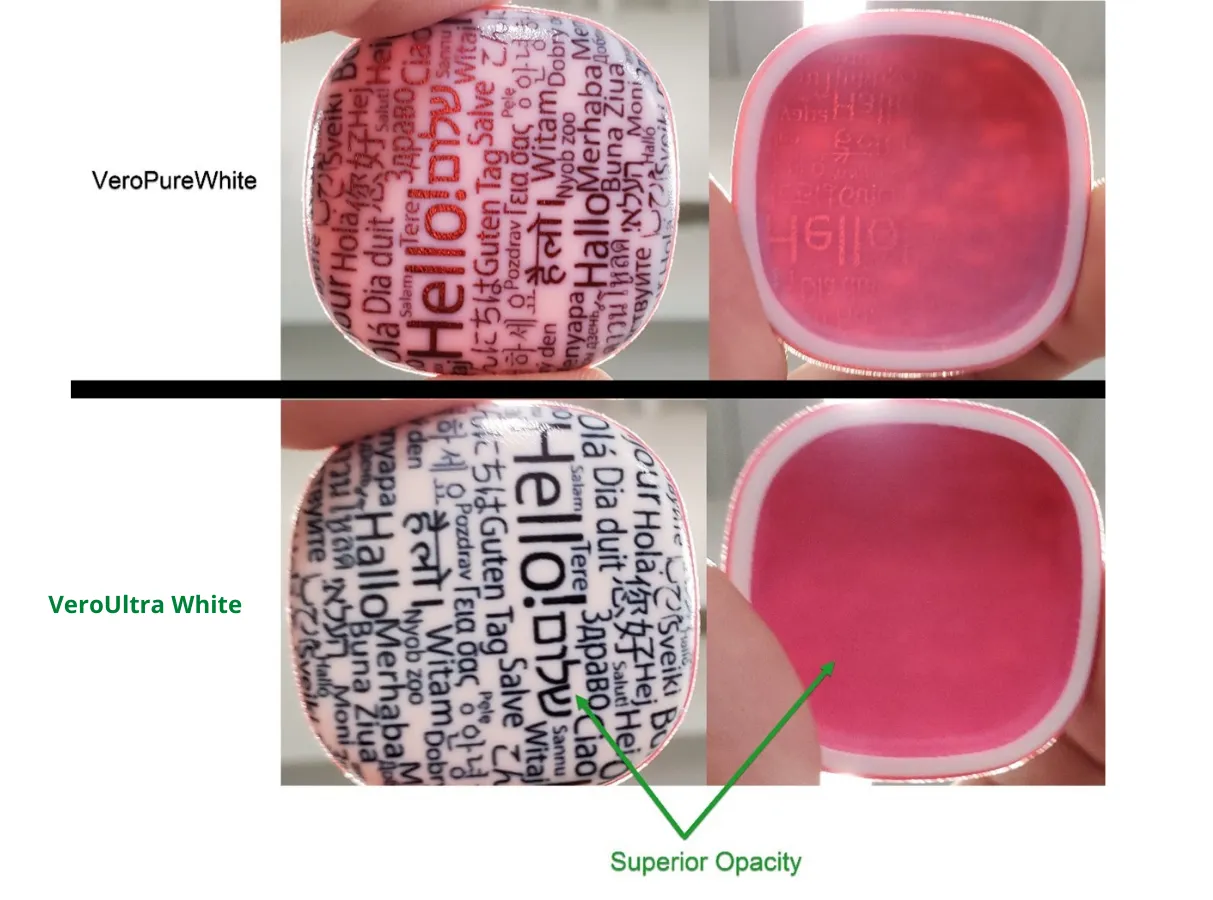

VeroPureWhite VeroUltra White & Black

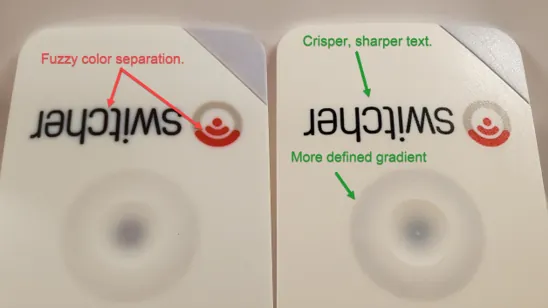

Upon examining the two printed housings above, the quality of the subtle gradient in the center circle is more clearly defined on the example printed with VeroUltra White as opposed to that printed with the older VeroPureWhite. The text and logo on the VeroPureWhite example appear blurry when compared to the VeroUltra example.

VeroPureWhite VeroUltra White & Black

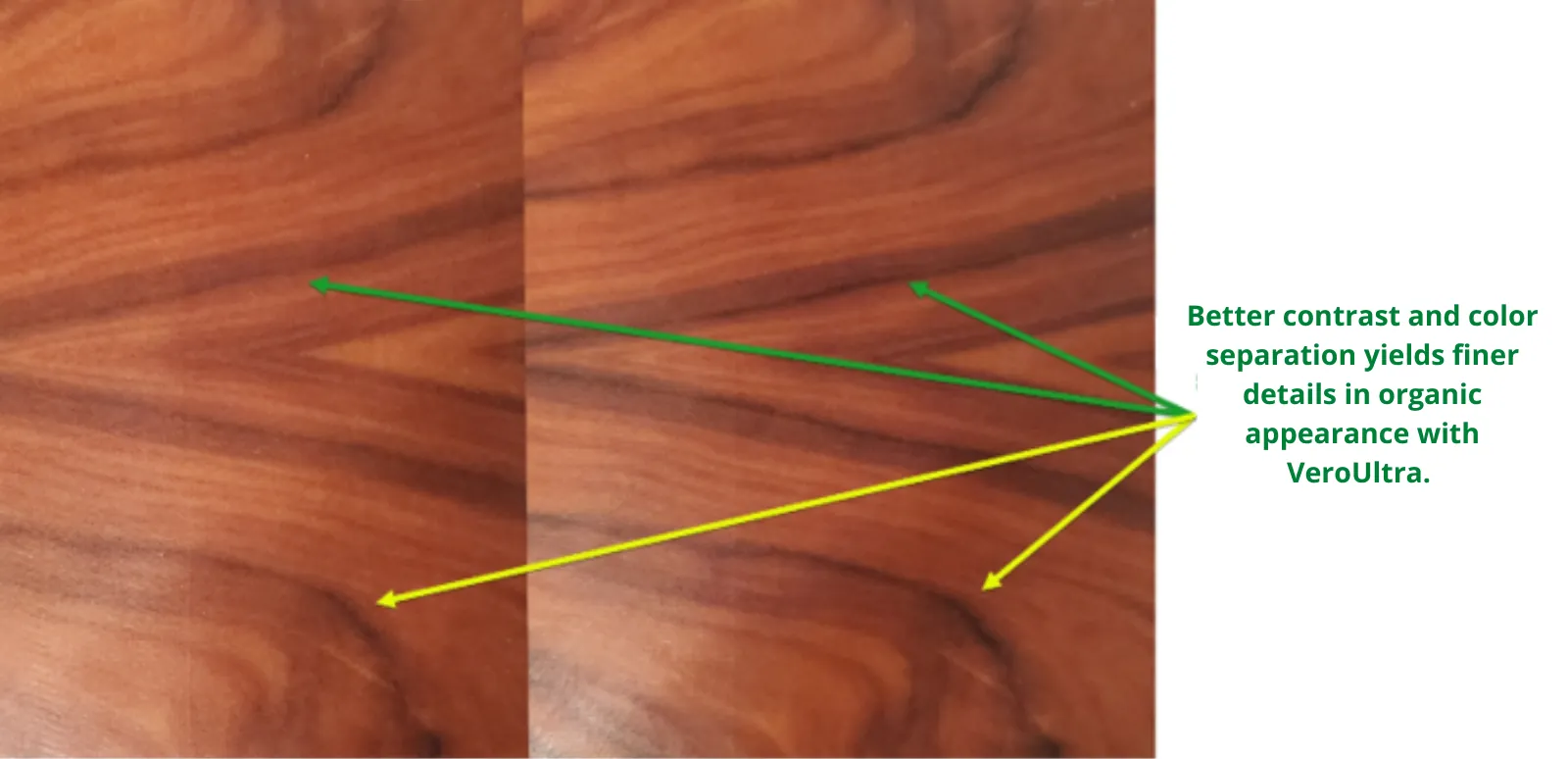

Another example of color separation issues with the older VeroPureWhite resin was when printing an organic appearance such as wood grain. The subtle differences in the grains’ color would wash together giving the model a somewhat bland appearance. The higher contrast afforded by the new opaque VeroUltra White and Black resins adds depth and realism to the figured wood grain.

VeroPureWhite VeroUltra White

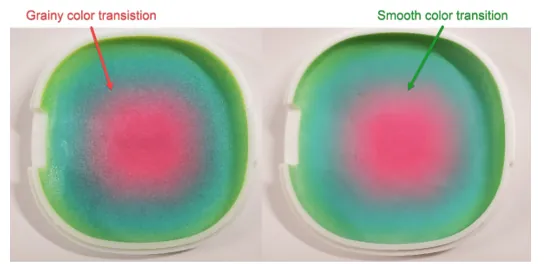

The pebble printed with the old VeroPureWhite displays a grainy transition between the colors while the model created with new VeroUltra White resin facilitates a much smoother color transition.

The “Hello” Pebble printed with the older VeroPureWhite resin allows plenty of light to seep through the surface causing both the text and color to be visible from the opposite side, while on the part printed with the >99% opaque VeroUltra White blocks the light’s transmission through the thin shell.

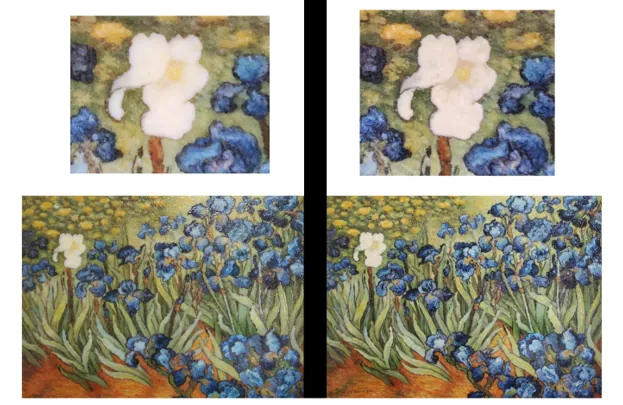

VeroPureWhite VeroUltra White & Black

In this example, we examine a model printed from a color 3D scan of a painting. While both examples look good, the part printed using the new opaque VeroUltra White and Black resin is slightly more vibrant overall, with better contrast, and a superior representation of the painting’s subtle gradients in shading.

In the text examples above, the older VeroPureWhite printed tile yields text with less-than-optimal blurry edges while the new VeroUltra White printed tile displays crisp text with good color separation and more vibrant colors.

Conclusion

After having a chance to print a plethora of parts with the new opaque VeroUltra White and Black resins, it has become clear that they greatly enhance the full-color printing capabilities of the Stratasys J-Series PolyJet machines. The new resins allow for the improved simulation of injection-molded thin parts, overall superior color accuracy, better separation between colors, and a 4x reduction in graininess (according to the ISO-ICE 13660 standard).

VeroUltra Availability

The new VeroUltra White and Black resins are available now for the Stratasys J750/J735, J850/J735, and J55/35 series 3D printers.

To run the VeroUltra resins on the Stratasys J55/35 it is required to use GrabCAD Print software version 1.54 and up.

To upgrade the J750/735 and J850/835 series printers to run the VeroUltra resins requires an on-site visit by a CSE to install an update to the machine’s firmware. The upgrade is bundled into the initial order of the new material at no additional cost if the machine is under warranty or service contract.

Have Questions?

For more information about Stratasys PolyJet 3D printers, materials, or any of the other Additive Manufacturing solutions found in GoEngineer’s Manufacturing Technology portfolio, please contact us.

More 3D Printing News

Meet the Stratasys J35 Pro 3D Printer

Stratasys J55 3D Printer: Created for Your Workspace

Take a Look Inside the Stratasys J850 Pro Mult-Material PolyJet 3D Printer

About Richard Cromwell

Richard Cromwell is an Additive Manufacturing Applications Engineer based out of Auburn Hills, MI, having recently joined the team in February 2020. He is a Certified Stratasys Applications Engineer and holds a degree in Technological Science with a specialization in CAD from Oakland Community College in Auburn Hills. Before delving fully into his passion for additive manufacturing and 3D CAD modeling, Richard honed his mechanical design, CAM, and custom fabrication skills while working for over a decade as a renowned craftsman creating custom retrofit piano actions for many of the world’s most prized musical instruments.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.