Making Happily Ever After with 3D Printing

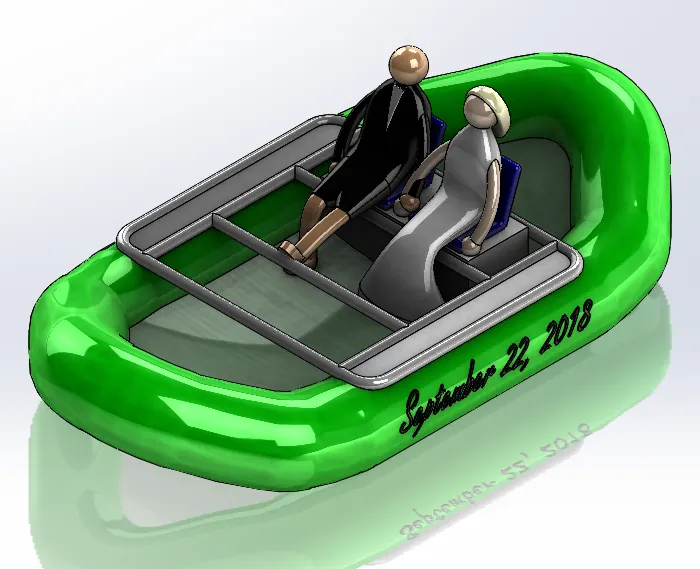

My significant other is really into whitewater rafting, and she has lots of friends who are riverboat guides. Because of this, weekend camping trips usually involve large inflatable boats, among other things.

I’ve been on a few river trips but I am not an official river person (yet), so I’m kind of the “plus one” on a camping trip.

One of the river dudes I know who owns a shop that sells only whitewater rafting gear proposed to his then-girlfriend on a—surprise, surprise—river trip. The marriage plan involved going back to the same river where he proposed and get married at the put-in point.

Project Manager

Before they got married, my significant other had told the betrothed that I would 3D print them a wedding cake topper. She gave me a three-week head start but it kind of got down to the wire.

I kept telling her “Yeah, yeah. I’ll get to that.” Six days before they were going to get married, I hadn’t done anything yet— the pressure was on!

So I figured I should start working on it.

Project Execution

It took half an hour to design the boat. No sweat. But the people on the boat are not industrially designed objects and very hard to model with industrial/mechanical design software. I spent probably another five hours trying to fine-tune the river people.

The groom is bald, so I made him bald in the model. His bride had blonde hair so I personalized that, too.

We printed it on the Stratasys J750 that has GrabCAD Print software onboard the machine. The type of material used is essentially photo-cured glass: VeroWhite, VeroBlack, VeroCyan, VeroMagenta, and VeroYellow.

The entire thing is one continuous print—it’s basically just one big piece. I built it out of multiple bodies (about 50) to aid with coloring, which is way easier if you have discrete bodies.

At first, I thought the arms were going to be too brittle, but as it turns out since they’re connected on both ends, they ended up rigid. I put a couple of little braces on the back of the people and in between the feet and the figures, just so they weren’t standalone.

They became one big, solid object rather than two brittle objects that might snap off. The two became one print so to speak.

Results

This whole thing was a complete surprise to Anthony and Anne, the groom and the bride, and when they saw it, they cried. (I think it was because they liked it.)

It was great to have a part in making someone’s day with 3D printing! For more design and 3D printing hacks, check out the projects below.

More Design & 3D Printing Hacks

3D Printed Redesign of Corvette C4 Gas Pedal Mount

3D Printed Trim Panel for Custom Shifters

A Modern Take on a Classic: 3D Printed Fender Telecaster

Creating a 3D Printed Race Medallion Hanger Using SOLIDWORKS

Designing a 3D Printed Storage Box Using Multi-Body Part Modeling in SOLIDWORKS

About Ryan Dark

Ryan has been in the GoEngineer technical support team since February 2008 where he most notably provides support for all FEA and CFD software offered by SolidWorks. His most recent accolade is the title of Elite Application Engineer awarded by SolidWorks Corp.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.