Enhancing EV Connector Design Using Abaqus FEA

Connectors are ubiquitous in our everyday lives, such as household electronics and appliances, industrial machinery, and electric vehicles. Product designers must control the mechanical forces developing during the plugging/unplugging process. A poor design will cause excessive wear, difficult usage, or even wider damage. In the case of EVs, many charge plugs conform to the North American SAE J1772 standard, specifying the dimensions, safety features, and communication protocols between the EV and the charging equipment.

To demonstrate a common and useful analysis in this space, I redesigned the connector feature of the SAE J1772 plug to securely lock through an application of pressure rather than lever depression, balancing usability against performance requirements. By optimizing the insertion and extraction forces, I could ensure the connector maintained the required level of strength and reliability while providing a satisfying and functional user experience.

The Solution

I built a model based on the SAE J1772 connector design and developed three additional designs. I ran the analysis using the dynamic solver, Abaqus/Explicit, to study the insertion extraction forces. From those runs, I extracted the normalized force magnitudes during insertion/extraction to evaluate and compare the performance of each design.

Simulation Outcome

Using Abaqus for this simulation, I calculated the forces required to insert and extract the plug from its socket. I identified one particular analysis that came very close to yielding and was able to come to a definitive conclusion about which of these designs was the best candidate for further testing.

Model Details

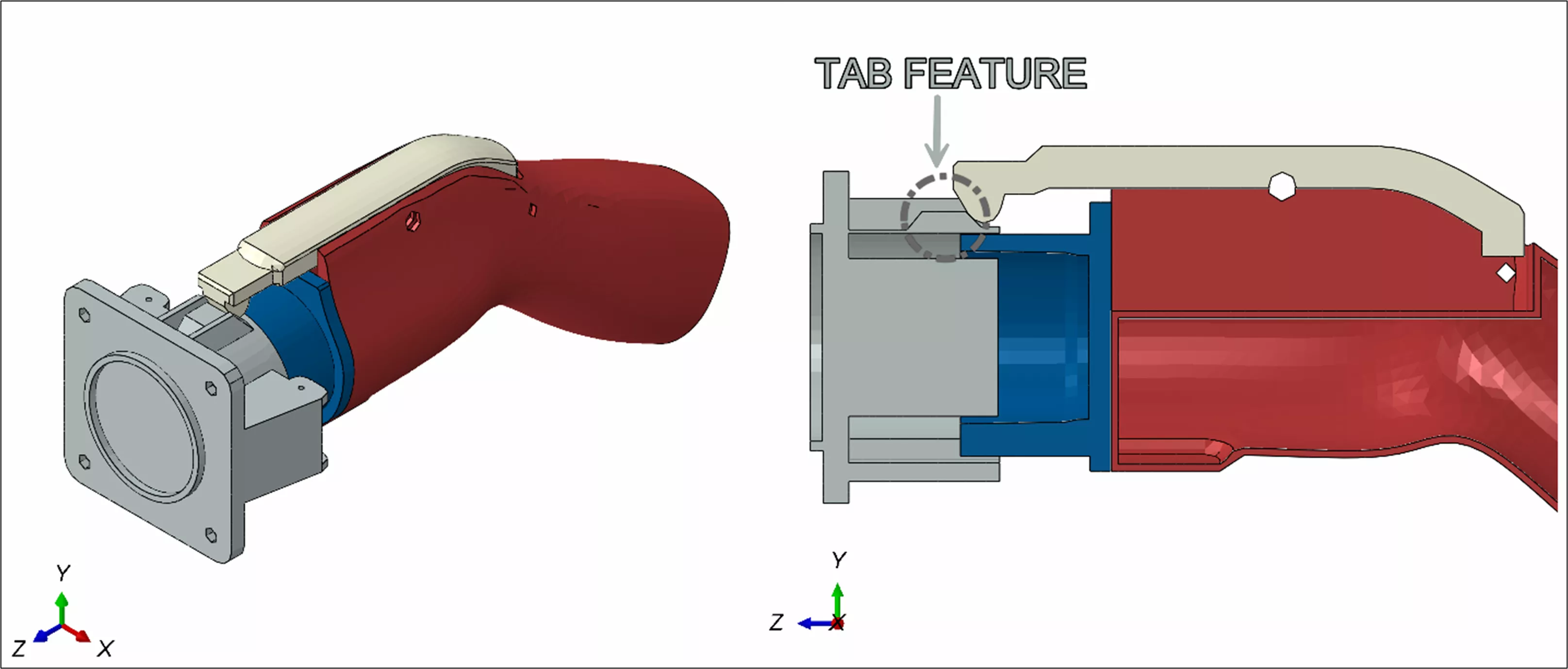

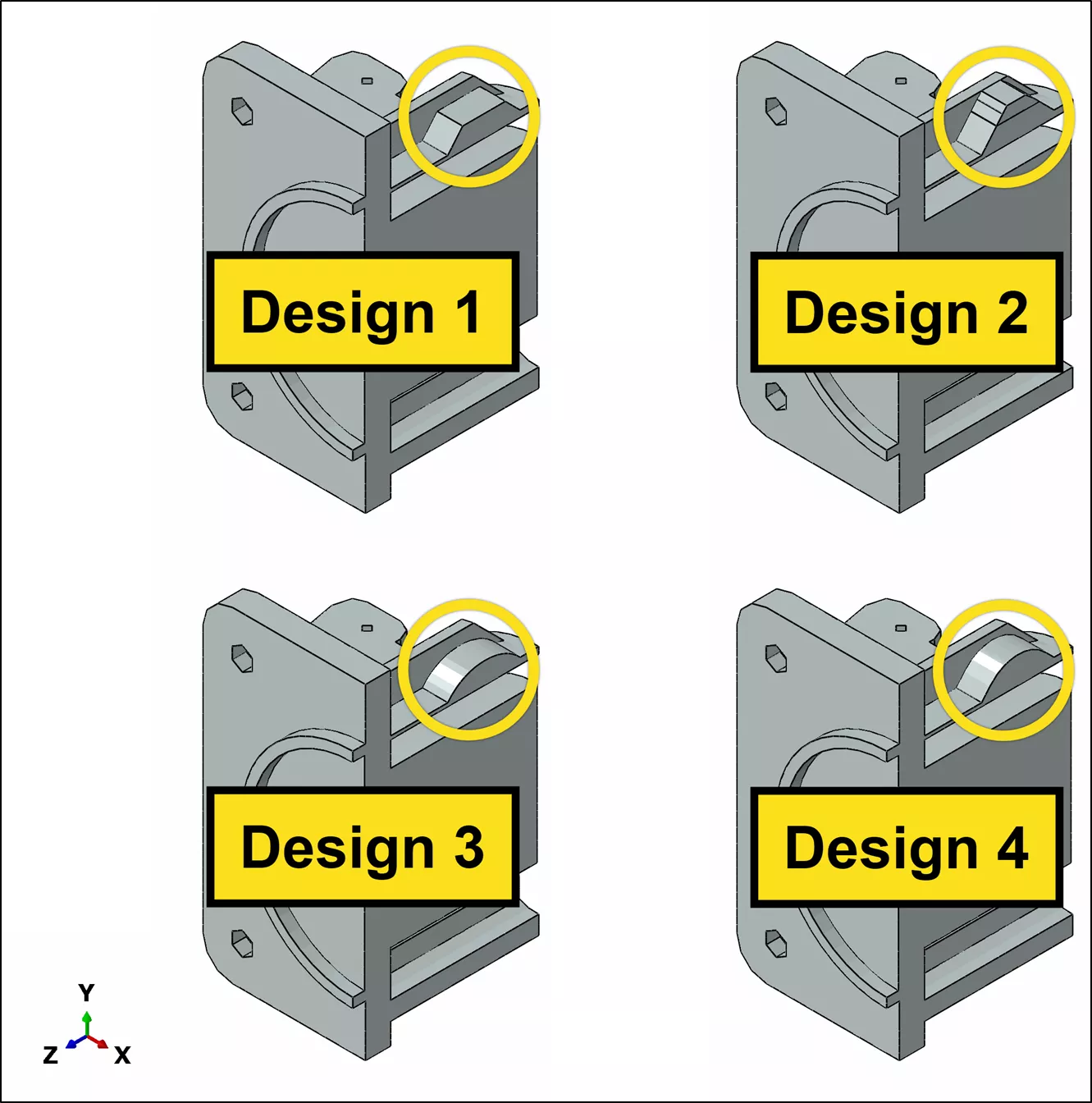

Looking at the initial design, it is evident that the feature needing adjustment is the tab that is part of the housing (shown below).

The connector is made up of three main parts: the handle in red, the housing or insert in blue, and the latch in beige; the male side of the connector inserts into the female side socket housing, in grey. Note that some components in the CAD design have been removed or defeatured for this study to aid in the meshing process, as they do not contribute to the structural integrity of the design.

I focused my efforts on the tab feature, as I wanted to understand the insertion and extraction forces that build up during these operational events.

Materials

All components of the connector, as well as the socket housing, are modeled with aluminum alloy A6061 T-6. Aluminum 6061 is a relatively light material, making it easier to handle. Not only that, it makes the components cheaper and easier to transport and install. Moreover, Aluminum 6061 has great corrosion resistance, making it extremely durable under outdoor and harsh environmental conditions.

The FEA material model included elastic properties (elastic modulus and Poisson’s ratio), yield stress, and hardening behavior. However, for this analysis, none of the designs reached a stress above yield, and all stayed in the elastic regime; thus, it would have been sufficient to define a purely linear elastic material. Below is a table summarizing the material properties of Aluminum 6061:

| Property | Value | Units |

| Young’s Modulus | 68.9 | GPa |

| Yield Strength | 276 | MPa |

| Density | 2.7 | g/cm3 |

| Poisson's Ratio | 0.33 | - |

| Coefficient of Friction | 0.3 | - |

Interactions & Connections

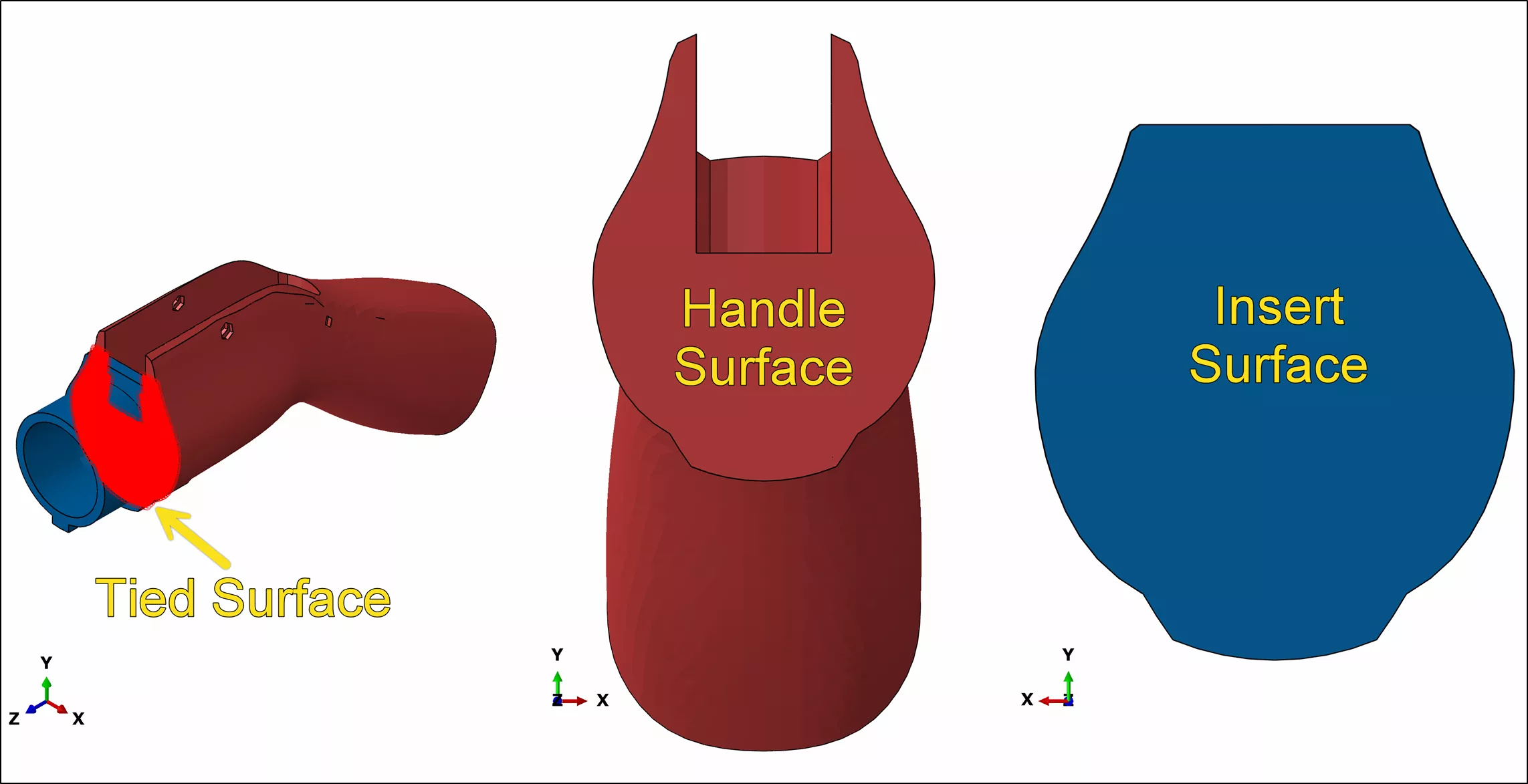

The connector, made up of three parts (as previously mentioned), has been defeatured quite a bit. This means that some of the components in the connector were removed, as they were deemed unnecessary in providing any significant structural integrity. This also makes the task of meshing a lot simpler and avoids producing any distorted elements. The insert (blue part) is tied to the handle (red part) as can be seen in the above figure.

In reality, the true connection between the two parts is a bolted connection, but again, that connection can be approximated or simplified with a tied connection instead. A more comprehensive model can be built down the line to study for example the deformation or contact pressure along the insert and handle surface.

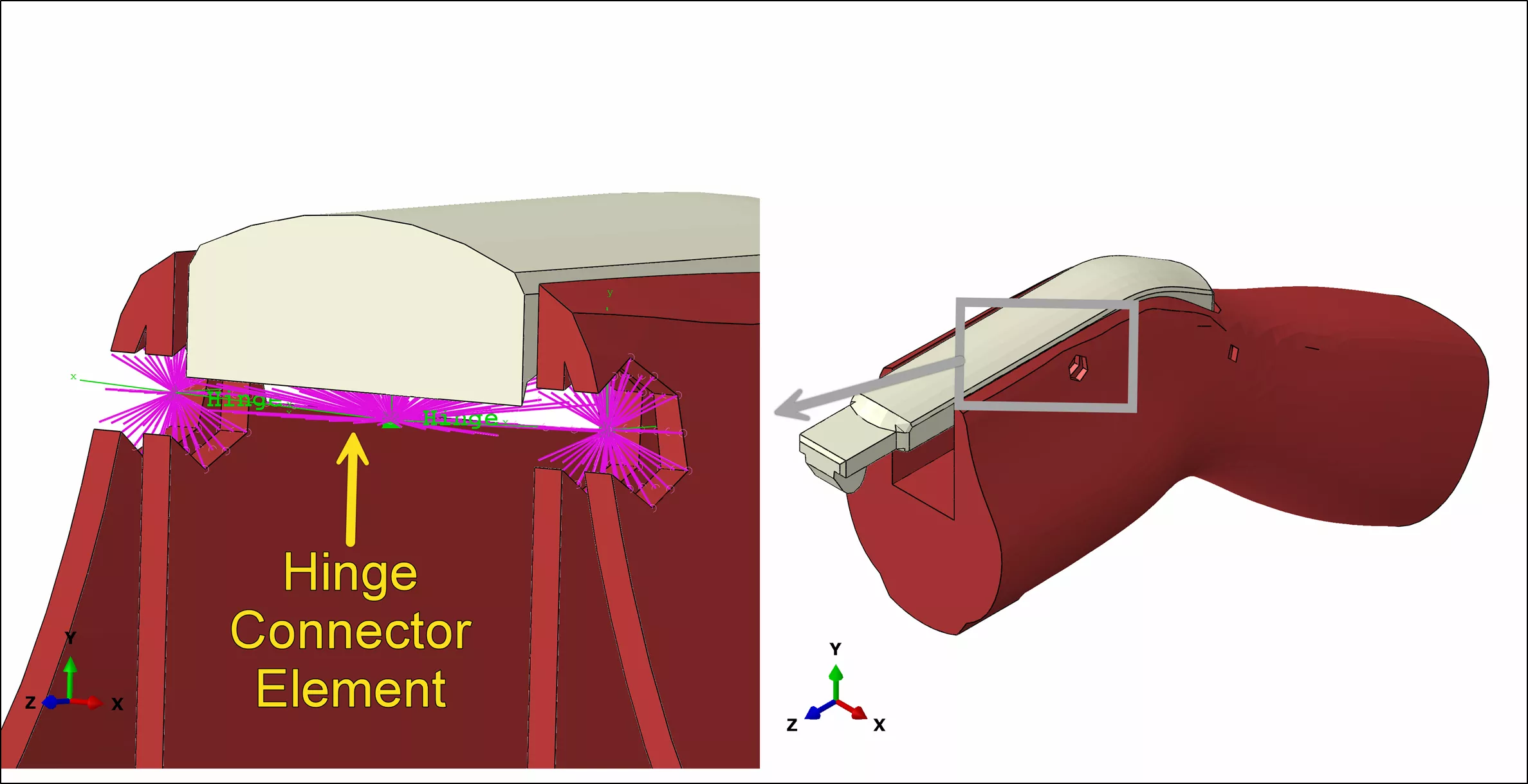

As for the connection between the latch (beige part) and the handle, a hinge connector element has been modeled instead of explicitly modeling the pin going through the handle and the latch. By defining a hinge connector, we are essentially modeling the kinematic relationship between the two parts, and forcing the latch to pivot about where the pin would have been.

Additional behavior can be modeled, such as elasticity, reference angle (to introduce initial stiffness), and much more. A stiffness value, which will not be reported, has been defined for the hinge connector and remains constant for all additional designs. See the figure above for more details on how the connector has been defined. Note that the purple lines are kinematic couplings.

The assembly includes contact interactions wherever components are not rigidly tied to each other via a general contact domain. For such contact interfaces, the coefficient of friction was 0.3.

Boundary Conditions

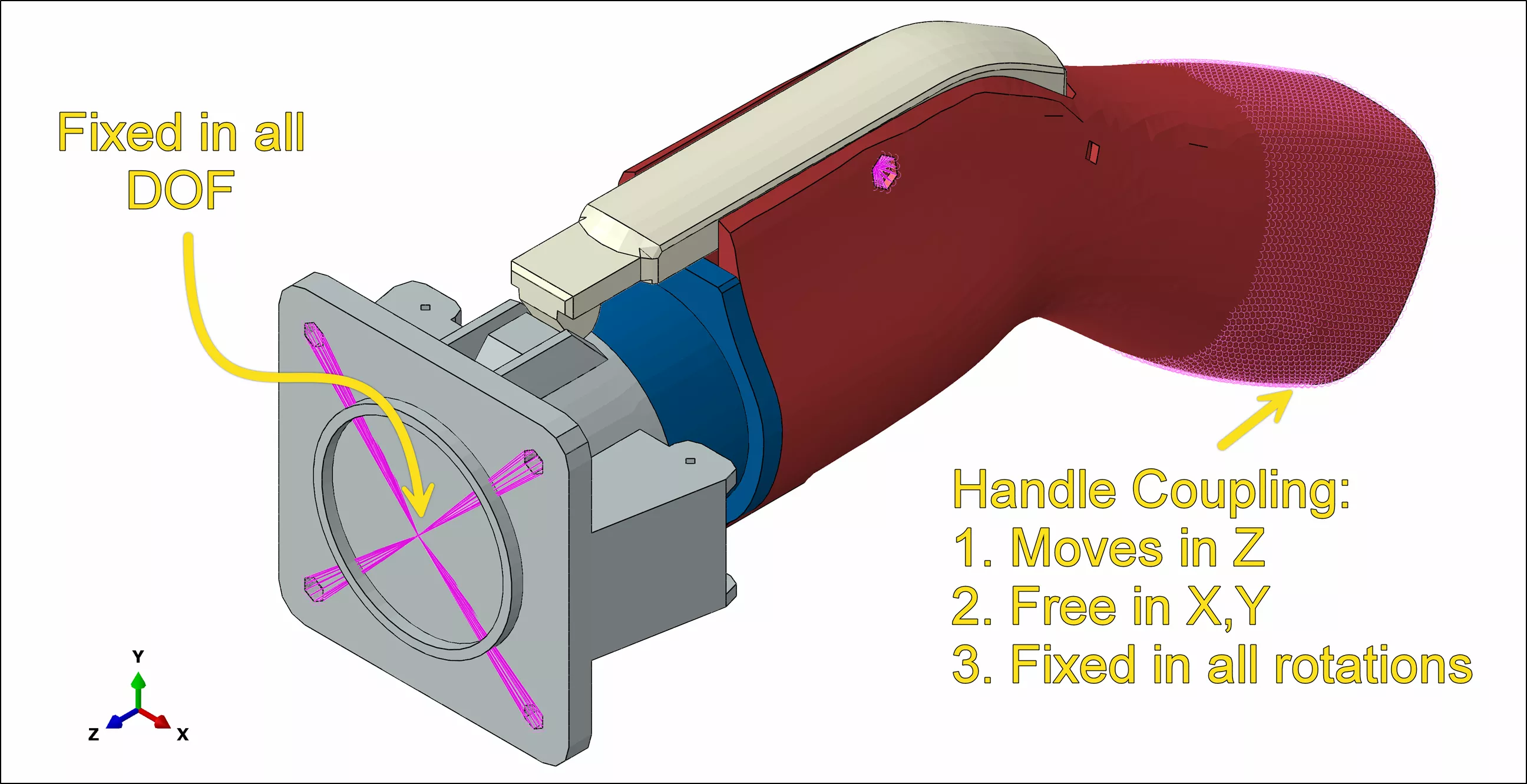

The socket housing, into which the plug will press, is fixed in all degrees of freedom from four corner holes. This is done by coupling together the four holes and fixing their reference node in order to simulate a fixed bolted connection.

As for the plug, a coupling has been created on the handle part, covering the handprint as a user would grab it. A displacement is then defined on the reference node of the handle coupling in the Z direction. The handle cannot pivot about X, Y, or Z axis but is free to move in Y and X. This is done to avoid any unwanted wiggle or pivot during insertion. Besides, in reality, the handle is grabbed firmly and inserted without any rotations but with a relatively straight motion in Z. See the figure below for more details on boundary conditions.

Analysis

The simulation is a two-step process. The first step is inserting the connector into the housing socket. The second step is extracting that connector by the same amount.

Because this event happens fairly quickly and must be treated as dynamic, Abaqus/Explicit is used. Having said that, the same dynamic solver, Abaqus/Explicit, can be used to model this as if the insertion and extraction were to happen fairly slowly, with inertial effects being negligible as opposed to the internal energy of the system. In other words, this could have been modeled as a quasi-static analysis.

In addition to the first design, three more designs for the socket housing will be studied. Though numbered two to four, they are in no particular order.

In the first and second designs, the tab feature has well-defined flat facets. For the first design, the top facet is a lot longer in depth (Z direction) and shorter in height (Y direction) than the second design, but the sloped facets on both sides, for both designs, are at equal angles with respect to the base.

As for designs 3 and 4, the edges of the top facet for design 1 and design 2 have been filleted with a radius of 10mm to produce designs 3 and 4, respectively. By rounding off the edges of the top facet, I would expect the insertion and extraction process of the connector to be very fluid. The roundness and smoothness might also improve the lifespan of the connector, as it avoids contacting any sharp features during its use.

However, a separate fatigue study would need to be performed to assess and confirm the aforementioned hypothesis.

Results

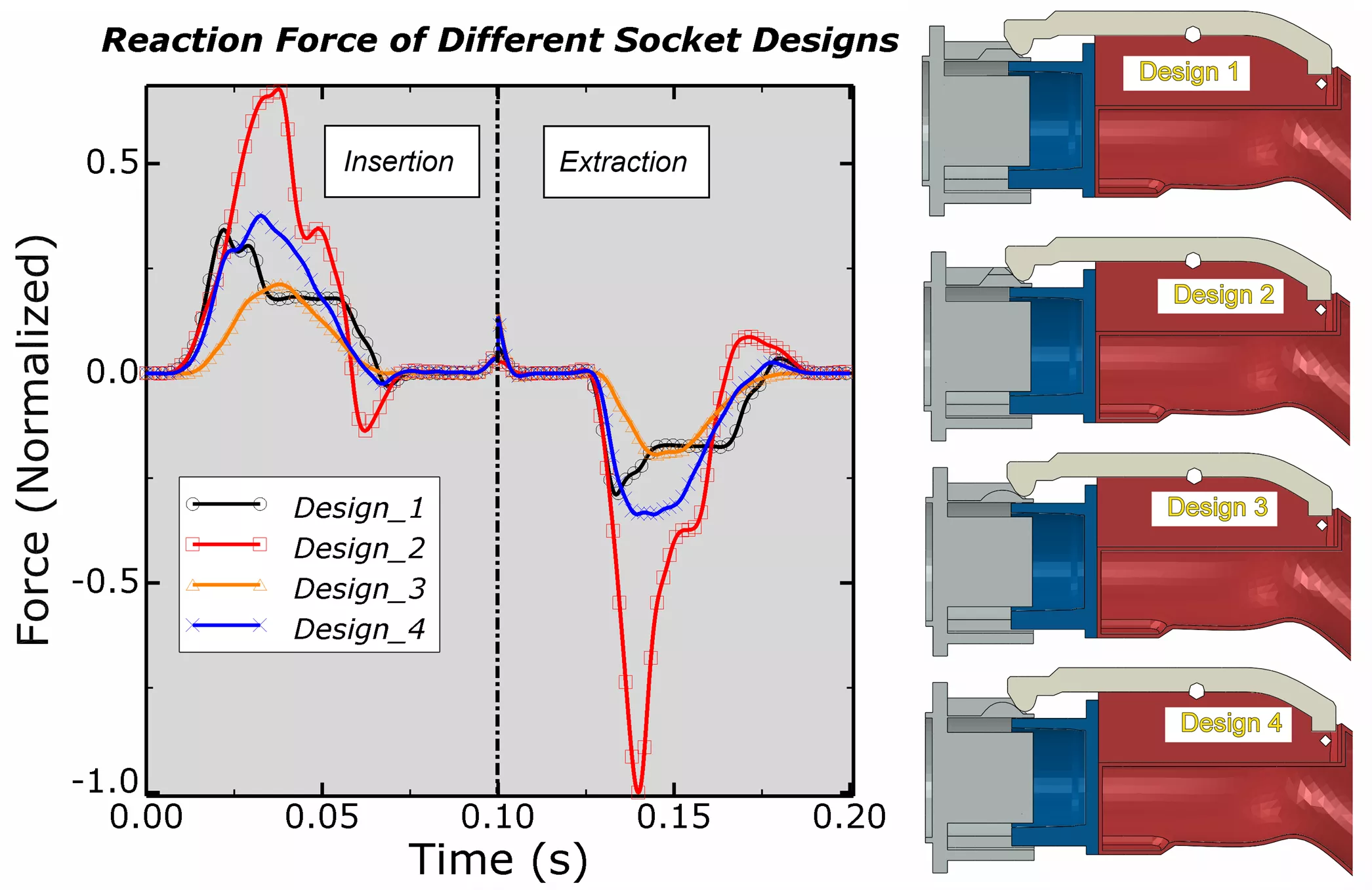

After running the analysis for all four designs, the results are summarized in the plot below. This plot reports the normalized force of insertion and extraction as a function of time.

During insertion (left of the vertical dashed line), the force gradually increases, reaches a peak, and then stabilizes. Design 2 (shown in red) had the highest peak force, meaning it required the most effort to insert, and during the extraction phase (right of the vertical dashed line), the force peaks again, having the highest magnitude of all the designs. This means that pulling the connector out of the socket requires the most effort, even more than that exerted during insertion.

Design 3 (orange line) has a significantly lower peak force, demonstrating improved ease of use during insertion and extraction. Having said that, things might feel a little flimsy, and the latching mechanism can easily come off. Design 4, showing comparative peak force magnitudes to the first design, does seem to perform the best. Let’s now move on to each design for a more in-depth look.

Figure 1: Animation of Design 1

See here the first design in action. The animation consists of four sub-videos. The top two show the insertion and extraction process without stress contours, illustrating the overall connector movement and the latch sliding across the tab feature. The bottom left animation mirrors the top left but includes the von Mises stress contour plot overlaid. The top limit for the color legend is set to the yield stress of the material, which was Aluminum 6061 alloy of σy = 276 MPa.

Additionally, the normalized reaction force from the plug is plotted against the time, measured in seconds. The normalized force was computed from the peak force measured in all designs, regardless if it was during insertion or extraction.

Figure 2: Animation of Design 2

As for the second design, the tab height was increased in an effort to make the latch more secure and less flimsy when it is being inserted or extracted. Here, the latch rotates significantly, causing the connector to experience a lot of force before fully inserting into the housing socket. Because of the shape of the latch, as it is not quite symmetric, the connector experiences a larger force during extraction. In fact, if you notice the value of the peak force during extraction, you will realize this is the highest force value experienced by the connector in all designs. I might have overshot the force value and will need to dial it down.

Figure 3: Animation of Design 3

For the third design, the tab feature of the first design is replaced with a rounder and smoother feature by filleting the top edges. This might help with extending the overall lifespan of the connector by avoiding contacting any sharp features.

Looking at the reaction force plot, it can be deduced that the peak force is about 66.6% of that of the first design. This means I undershot and got a value below the force of the original design, which won’t do. Please note that the spike seen in the center of the plot is artificial, a side effect of signal filtering.

Figure 4: Animation of Design 4

Moving on to the fourth design, the top edges from the second design were filleted by the same radius as that of the third design. The only difference is that the tab feature in the fourth design is higher than the rounded one in the third design.

In the reaction plot, the peak insertion and extraction forces are a bit higher than that of the original design, but what is important is that the tab feature is now round and can contribute to the longevity of the connector. Like the previous plot, the center spike is artificial due to signal filtering. Going back to the first plot reported in the results section, which summarizes and overlays the reaction force of all four designs, Design 4 performed the best according to the peak force magnitudes as well as the roundness and smoothness of the tab feature.

Thus, Design 4 is deemed appropriate for now, but further analysis would need to be done to fully quantify the performance of such design. Mesh can be refined on the two contacting surfaces of the latch and the tab to look at the contact pressure more closely.

Conclusion

The testing of the EV connector’s locking feature showed meaningful insights into the mechanical forces involved during the insertion and extraction process. Multiple designs were developed to demonstrate that both the tab feature shape and smoothness have a critical impact on the connector’s ease of use and longevity. The fourth design, with the rounded tab edges, showed the most balanced performance, displaying satisfactory peak force values with improved durability.

While, for the purposes of this example comparative analysis, we’ve shown normalized force values, there is great value in obtaining absolute force magnitudes. By further fine-tuning the models (the exact right material data, fewer simplifications in the assembly and loading, etc.), we’d be able to estimate real insertion and extraction forces accurately. This could further increase the efficacy of the design recommendations and enable decision-making with true full-context, end-goal results in mind.

With that said, further detailed analysis, such as mesh refinement or fatigue studies, must be done to finally optimize and validate the design robustness for long-term use. With the hard work of the initial analysis done, these tasks can be completed in relatively short order with a modest expectation of passing results for our design of choice.

Ready to get started with Abaqus? Read our Abaqus buying guide or contact us to talk to GoEngineer's simulation experts to find the right tool for you! If you’re not ready to use Abaqus yourself, you can still take full advantage of its benefits through FEA consulting from GoEngineer.

Related Articles

Understanding Abaqus General Contact

How to Run Abaqus Simulations on the Cloud with the 3DEXPERIENCE Platform

Abaqus - Modeling Arbitrary Shaped Beam Cross Sections

Abaqus FEA: Powerful Finite Element Modeling

About Bilal Abdul Halim

Bilal Abdul Halim is an Application Engineer at GoEngineer specializing in Abaqus. Bilal holds a Bachelor’s degree in Mechanical Engineering and a Master's degree in Experimental Fluid Mechanics where he studied the effects of corona discharge on viscous oil using particle image velocimetry. When not at work, Bilal is usually playing ping pong or trying different restaurants.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.