SOLIDWORKS Simulation: Missing material data? No problem!

When setting up a structural simulation study, it never seems like you have ALL the information you need. Without exception, you’ll have to be content with making approximations and assumptions. Absent or unreliable material data is one key area that virtually all simulation users will need to question.

SOLIDWORKS MATERIAL DATABASE

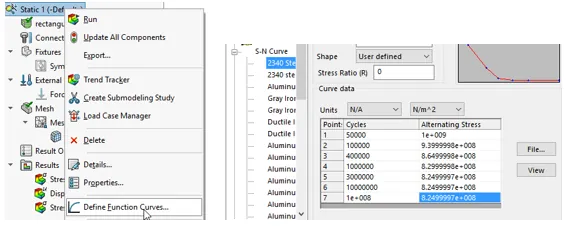

- The first place you might look for material data is in the SOLIDWORKS Material database. It houses roughly 500 materials and 100 material curves (as of 2016). Additionally, a few SN material curves used for fatigue analysis are stored under “Define Function Curves” (see below). The rest of the curves are available by clicking on a material with (SS) or (SN) in the name for nonlinear stress-strain and fatigue respectively.

SOLIDWORKS MATERIALS WEB PORTAL

- For your next step, you may look at the SOLIDWORKS Materials Web Portal included in SOLIDWORKS Simulation Professional (shown below). The portal has another roughly 1300 materials and 250 material curves (as of 2016).

MATWEB

- If you still can’t find what you’re looking for, you might check MatWeb. They have roughly 40,000 “static-ready” materials (as of 2016). The people at MatWeb even offer a SOLIDWORKS plug-in for a nominal fee. However, MatWeb does not offer any curves.

INTERNET SEARCH

- Still can’t find it? You may need to get out your shovel and do some digging on the internet. For example, if you’re looking for carbon fiber elastic properties, try searching for ‘carbon fiber material properties’ in your favorite search engine. At this stage, you’ll have to put your searching skills to the test. Sometimes you’ll strike gold at some material supplier website.

- Speaking of Material suppliers’ websites, have you tried picking up the phone and contacting your material supplier to see if they can provide you with the relevant properties? However, even if your material supplier does have some properties for you, you may need to consider that some materials can vary a lot from batch to batch.

BOOKS / TECHNICAL ARTICLES

- Still nothing? At some point you may need to put your shovel and phone away and get out your wallet to order a few books or technical articles. I have an “Atlas of Fatigue curves” on my desk and there are supposedly a few others you might find such as the “Atlas of Stress-Strain Curves”.

MATERIAL TESTING

- Keep your wallet out, because if you still can’t find what you’re looking for, you may need to consider paying for material testing. This may provide you with the most reliable material data, but since this can be expensive, I’d like you to first consider the alternative discussed below.

GENERIC PROPERTIES

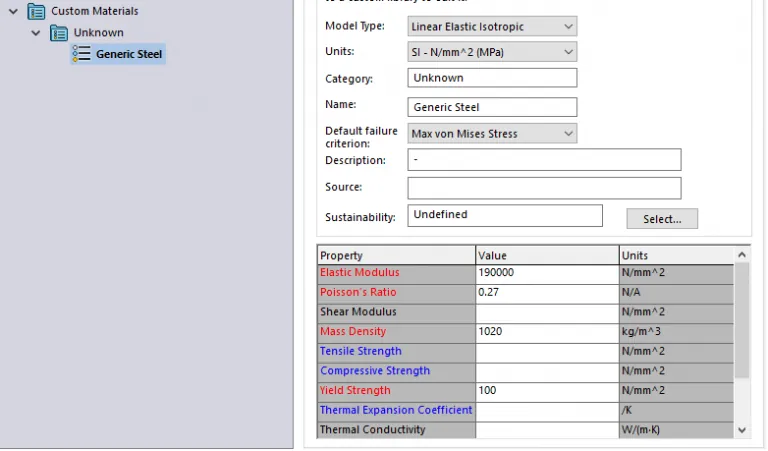

How precise do you need to know the properties of your material to obtain an acceptable accuracy level of your result of interest? If you are looking for approximate deflections on a steel part, you may be able to get away with entering simple generic properties such as the ones shown below:

If you browse through many of the steels in our database, almost all of them have an Elastic Modulus between 190-210 GPa. This means deflections in a linear static study would vary by about 10% depending on what steel you select. If this is acceptable, maybe try a steel that is on the conservative end of this spectrum (i.e., 190GPa). Don’t be misled, however, because even the elastic modulus can vary by more than 10% for some special classes of steel.

COMPLEX PROPERTIES

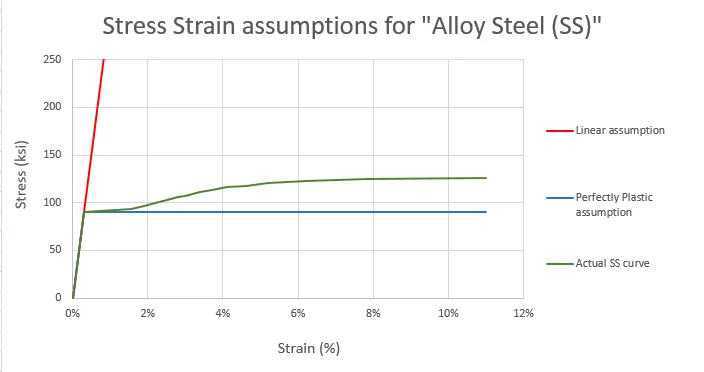

For more complex properties that you might need for a Nonlinear analysis, one of the easiest simplifications you can make for some materials is to use a “perfectly plastic” curve. This method only requires that an Elastic Modulus and Yield Strength are known. See the comparison shown below to see how similar the perfectly plastic assumption compares to the SS curve provided for “Alloy Steel (SS)” for strains under 2%.

There are more sophisticated methods for approximating stress-strain data if you also know the Ultimate Tensile Strength of the material.

You can use tools, like a fatigue calculator, for approximating S-N curve data. This website also has a few other tools. And, there are a few websites similar to this one that have tools to help you approximate material data.

MAKING SOUND DECISIONS

These recommendations can be helpful for certain classes of problems. But, they can also be potentially dangerous if you’re not conservative and careful with understanding the effects of these assumptions. This is why you should get out your textbook, browse through Wikipedia pages, view some YouTube videos, talk to your peers, etc. to make sure you understand some of the properties. This will allow you to make sound decisions about which simplifications to allow and which ones you’ll have to invest more time and energy to avoid.

At a bare minimum, a few of the properties you’ll likely deal with and need to understand on a regular basis are:

- Elastic Modulus (specifically Young’s Modulus)

- Poisson’s ratio

- Yield Strength

These properties are highlighted in red for Static studies for a reason.

About Shaun Bentley

Shaun Bentley is passionate about applied mathematics and engineering, which led him to pursue and understand real world applications of FEA, CFD, kinematics, dynamics, and 3D & 2D modeling. He teaches many simulation classes to both new and advanced users attending training at GoEngineer. Since 2006, Shaun has been working with simulation tools to solve real world engineering problems. With every new project, he seeks to find ways to push simulation to its uppermost limits, even going so far as to write bespoke code and macros. He has passed the Michigan FE exam and mentors or consults for virtually any industry that uses SOLIDWORKS, especially automotive and automated tools. He is a speed 3D modeling champion and one of the first Certified SOLIDWORKS Experts in Simulation in the world.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.