Simplified Configurations

One of the best methods for improving large assembly performance is to create simplified configurations of the individual components for use in your assembly. A simplified configuration is basically a less detailed, or stripped-down version of your model which reduces the amount of data that must be loaded into RAM. In this configuration features that generally create longer rebuild times, such as fillets and chamfers, are suppressed. These features, along with any other features that create unnecessary detail, usually do not affect fit, form, or function of your model. Some other features that may fall under this category are threads, cut/extruded text, patterns, holes, and extrudes that are not needed for placement purposes in your assembly.

Simplify Part Components at The Assembly Level Using Simplify Utility

Creating simplified configurations for complex parts should be a forethought part of the modeling process. However, most often this is an after thought once the assembly has already reached a point that performance is an issue.

This is where a handy tool called the Simplify Utility can help you create simplified derived configurations for each component while within the assembly level. The utility does this by determining an internal calculation of “insignificant volume” based on the size of a part or assembly. Features below the insignificant volume can be suppressed to a derived configuration.

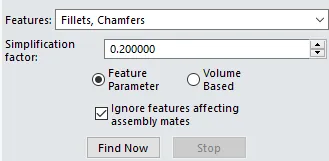

The following features are supported in assemblies:

- Chamfers

- Extrudes. Boss, boss-thin, cut, cut-thin. (Base extrudes and extrudes that are not Blind or Mid-Plane are not found.)

- Fillets. Simple, multi-radius, face (without the hold line parameter), variable radius. (Full round fillets are not found.)

- Holes (Simple and Hole Wizard)

- Revolves (Volume Based only)

NOTE: First make sure all components are fully resolved in the assembly.

Where to Find the Simplify Utility:

- Tools > Find/Modify > Simplify

Why Use Simplify Utility at the Assembly Level?

- Using the Simplify Utility at the assembly level will do the same thing it does at the part level without having to run it on each individual part and saving time in the process.

- Using the Simplify Utility in the assembly will also allow you to take advantage of the “Ignore features affecting mates” option.

Simplify Utility Task Pane

In the Simplify Task Pane you can:

1. Set which supported features will be suppressed.

2. Set the desired Simplification Factor.

- Simplification Factor: The value you enter to help SWX determine which features count as insignificant.

- Feature Parameter – Compares the primary or critical dimension of the feature to the cube root of the part or assembly’s volume, multiplied by the Simplification factor.)

- Volume Based – Compares the feature volume to the part or assembly volume multiplied by the Simplification Value.

3. Chose to “Ignore features affecting assembly mates” if desired (assemblies only)

- Click Find Now to display a list of features with insignificant volumes. Find Now can be ran again with different parameters to alter the search results.

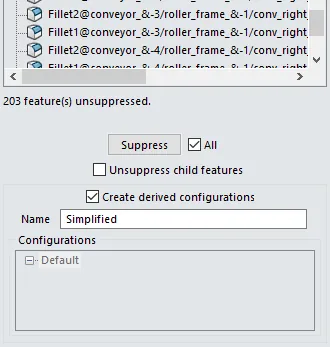

4. Chose to Create derived configurations

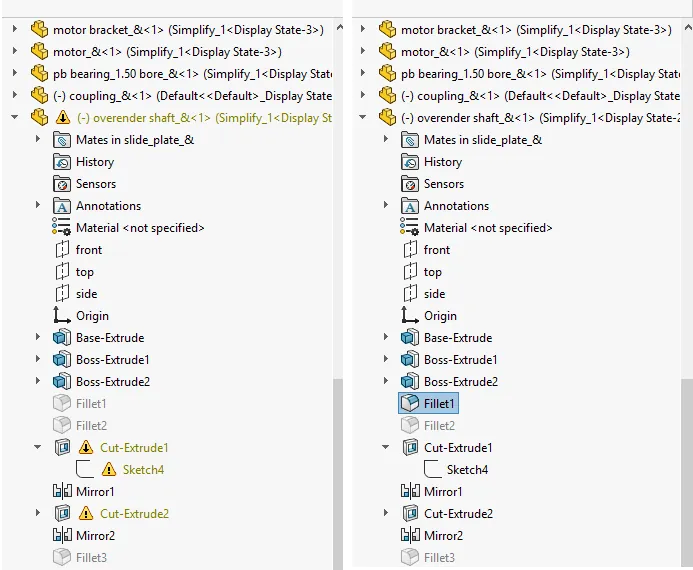

- Creates derived configurations (called Simplify_ ) of the simplified parts after you click Suppress or Unsuppress. The part or assembly is simplified by suppressing the features of insignificant volume. You can rename the configuration in the Name box.

- A derived configuration will also be made at the assembly level where the simplified component configurations will be active.

- When Create derived configurations is cleared, you can add the simplified features to a different configuration you select under Configurations. You can also rename a configuration here and it updates in the FeatureManager design tree. Configurations lists only the active configuration and its derived configurations.

5. Suppress the features individually or all at once.

- If the features are suppressed you can also use the tool to unsupress them individually or all at once, and chose to unsupress child features as well.