SOLIDWORKS PDM Professional and Flatter Files

by Steve Tietz, SOLIDWORKS Automation Engineer, Chart Air-X-Changers/Hammco and Scott Williams, Engineering Manager, Chart Air-X-Changers/Hammco

A few years ago, Chart Air-X-Changers/Hammco (formerly Harsco Air-X-Changers) was in the market for a PDM system.

We soon realized that in order to move forward with a new system, in addition to design control, the following issues needed to be addressed:

- Improve purchasing department control of deliverables both inside and outside the company

- Replace custom email notifications with automation to reduce IT burden

- Simplify QC’s distribution of customer operating manuals distribution

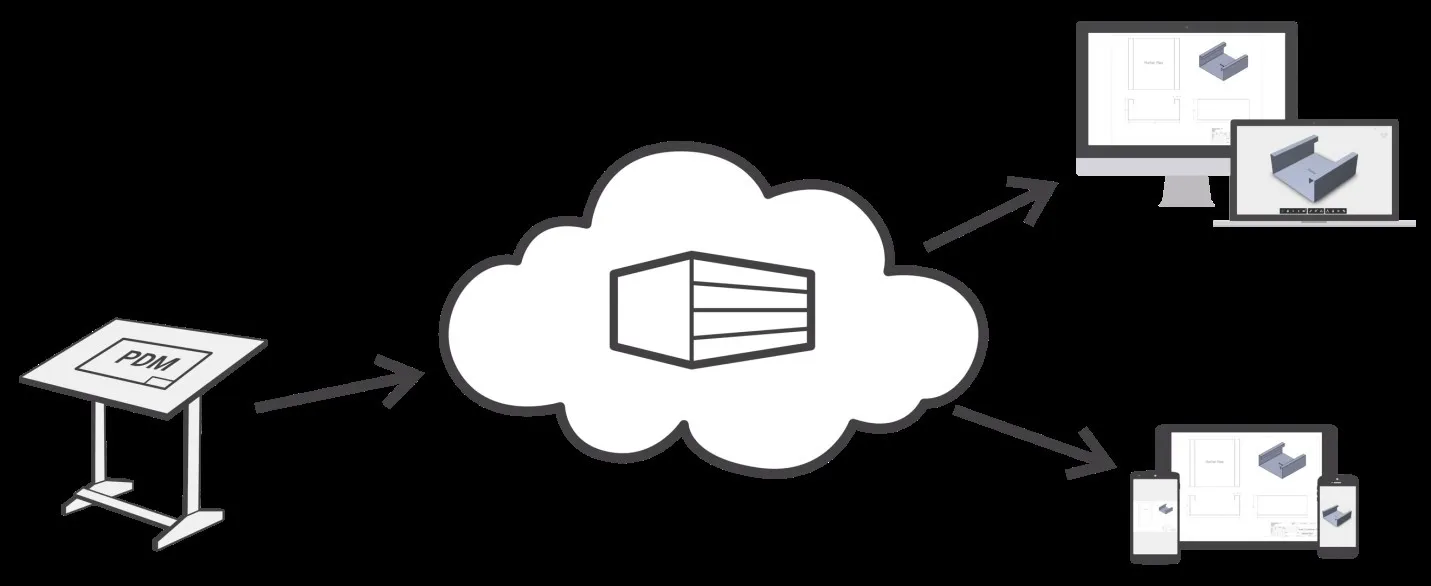

After a significant evaluation period, our company decided to implement SOLIDWORKS PDM Professional along with Flatter Files, a product that simplifies distribution and improves supply chain management.

Flatter Files addressed our issues—and many more—while providing tight integration with SOLIDWORKS PDM. Together these tools significantly increased our ROI.

Purchasing Department Streamlined

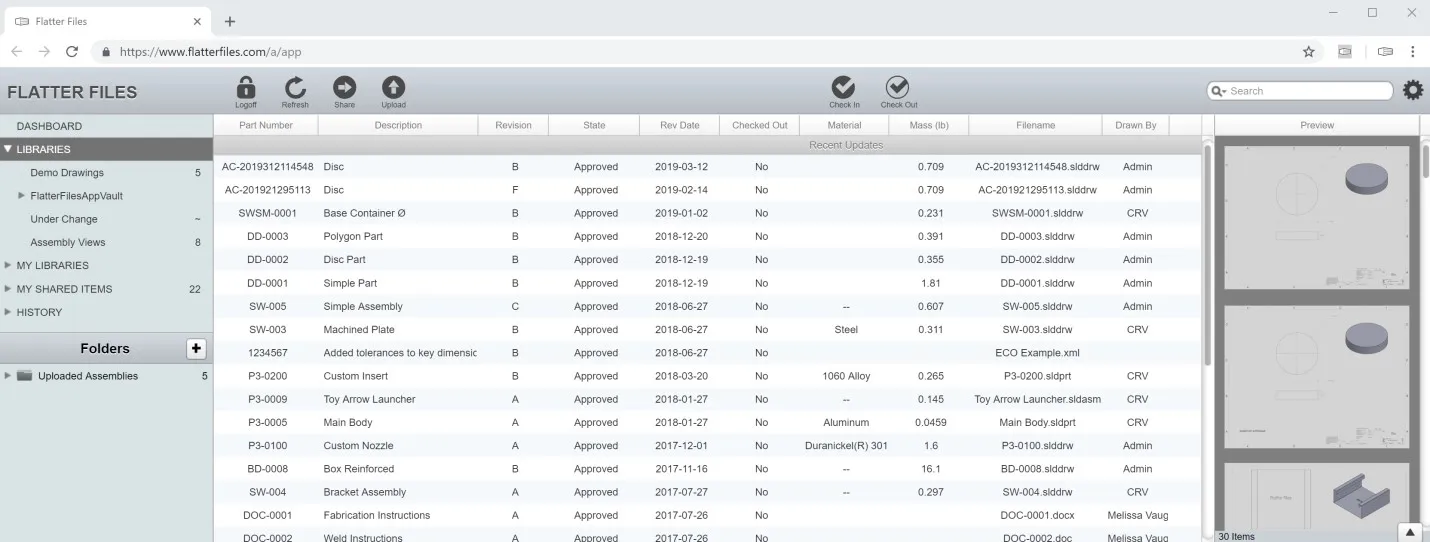

Flatter Files also allows our purchasing department to enable the software to automatically share drawings with external vendors instead of manually managing revisions and 3D exports.

Because Flatter Files automatically emails internal and external users when a new version is created, purchasing doesn’t have to notify a vendor regarding each change.

In addition, a vendor can download corresponding 3D models for import into their CAD or CAM systems. When a vendor needs a different/unique 3D export, the purchasing department can simply right-click on the shared item to add another 3D model.

This automation also frees up time in the design department and saves the cost of an additional license of SOLIDWORKS or PDM.

Reducing the IT Burden

Our IT department no longer has to maintain custom programs that automatically email people since it is now taken care of by Flatter Files.

Flatter Files also eliminates the management of custom programs for creating PDFs, and it automates upgrades to each new release of SOLIDWORKS.

Our IT team no longer needs to install every new upgrade to each computer. All content is simply accessed in the web browser via Flatter Files and all updates are instantly delivered to all users.

Flatter Files’ user accounts are also implemented into the company’s active directory, so disabling a user account simultaneously disables access to Flatter Files. This keeps our IP secure when someone leaves the company—this kind of security is priceless.

Simplifying the Process for Quality Control

Distributing customer operating manuals was a long-standing problem for our quality control department. The manuals were too large to attach to an email, so QC resorted to printing hard copies, mailing out CDs, or managing them on an FTP site.

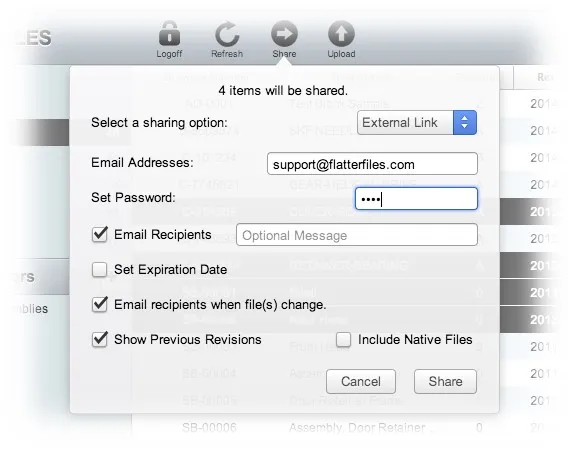

With the Flatter Files sharing feature, the quality control department can deliver the operating manual to the customer via email. Plus, the sharing system tracks if the customer actually logged in and viewed, printed, or downloaded the manual at any point—information not available with simple email attachments.

Access and Communication

Users now have 24/7 access to the latest design PDFs because the Flatter Files system automatically notifies them of new revisions. For example, while a CAD designer is actively working on an engineering change, Flatter Files will notify the viewer that the drawing they are seeing is about to change.

As soon as design revisions are completed and placed in the PDM vault, Flatter Files automatically sends email notifications to users inside and outside the company.

If someone wants to be sure they have not missed an email notification regarding a change, they can still check if they have the latest revision by quickly scanning it at a workstation because Flatter Files barcode stamps every document.

This saves lots of rework by preventing work on out-of-date drawings.

Flatter Files also provides a 3D model view via a single click directly from the drawing view, which facilitates communication better than a simple 2D print. Such capabilities far exceed our previous procedure of placing a PDF in a folder.

Ease of Use

If needed, training on Flatter Files is easily done in-house over lunch. In many cases, new employees figure it out themselves. All that is typically needed is to show users how to login to the system with the same credentials as they use to login to the desktop computer and point them to the search function within Flatter Files.

Payback

One of the clearest advantages of adding Flatter Files is its capacity for unlimited viewers. Thus, as our company grows, we do not have to purchase more seats or manage upgrades on existing seats, which saves us time and money.

Flatter Files has also leveraged our investment in PDM while making our business processes more efficient, more employee-driven, and more reliable. The ROI has far exceeded our expectations, and we have been able to improve our customers’ experience in ways simply not possible without Flatter Files.

About Steve Tietz and Scott Williams

Steven Tietz

Steve is a SOLIDWORKS Automation Engineer for Chart Air-X-Changers/Hammco (formerly Harsco Air-X-Changers), creating and maintaining multiple automated 3D smart model templates. He also administers SOLIDWORKS PDM Professional and Flatter Files for multiple offices with over 20 years of experience using, training, and teaching on SOLIDWORKS design software.

Scott Williams

Scott is the Engineering Manager for Chart Air-X-Changers/Hammco (formerly Harsco Air-X-Changers) and has over 28 years of experience in Solid Modeling technologies and engineering system development. He has spent the last 5 years working with the team at Harsco, GoEngineer and Flatter Files to develop a state of the art file distribution system to better serve Harsco and their customers.

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.