What Do You Know About SOLIDWORKS CAM? Let’s Test It!

What is SOLIDWORKS CAM?

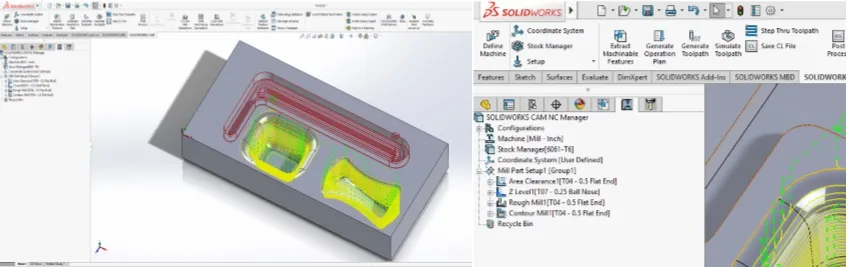

SOLIDWORKS CAM is a 2.5-axis milling and turning solution that is powered by CAMWorks, a SOLIDWORKS Gold-level solution partner in CAM since 1998. SOLIDWORKS CAM allows users to program in either part or assembly environments. In addition, SOLIDWORKS CAM is also able to work with configurations of components to expedite the programming process. Simply activate the add-in in SOLIDWORKS 2017 and start programming.

CAMWorks Testing

We decided to test out SOLIDWORKS CAM this week and found some exciting results. Having been familiar with CAMWorks and the general SOLIDWORKS workflow of sorts, grasping the new CAM tool was a breeze. As you will see below, I tested out basic capabilities; considering its 2.5 axis, it handles quite a bit. The lower center pocket is drafted and has both rounds and fillets while the lower right pocket has a compound surface feature that varies in x y and z. Neither of these proved to be a problem; 2 minutes of programming tops!

Lastly, to lean on the software a little bit, we decided to go to town on a custom wheel with complex 3D milling. The picture on the left shows the machine in action! About two hours later the finished product rolled out and all was well!

For those looking for a new but established and affordable cam tool (included in all packages of SOLIDWORKS 2017 {beta} and 2018) SOLIDWORKS CAM will absolutely be your best go-to option. Full integration in SOLIDWORKS makes editing and re-writing tool paths a walk in the park. You won’t even break a sweat!

About Adam Hughes

Adam Hughes is an Applications Engineer based in Santa Ana, California and is SOLIDWORKS Elite Certified. Adam enjoys teaching where his students range from those in high school, to college undergrads to mechanical engineers with 20 years experience.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.