Sip Puff Bite

For my senior design capstone class, my team worked on the advanced navigation for the Portable Accessible Docking System (PADS), which is part of the Technology Recreation Access Independence Lifestyle Sports (TRAILS) program whose goal is the revolution of rehabilitation of tetraplegics (those with a partial or total loss of use of all four limbs and torso). Our part in this multiyear project was to redesign motor nodes and create a control system for boats to be used by tetraplegic patients and clinicians.

Reviving an Idea

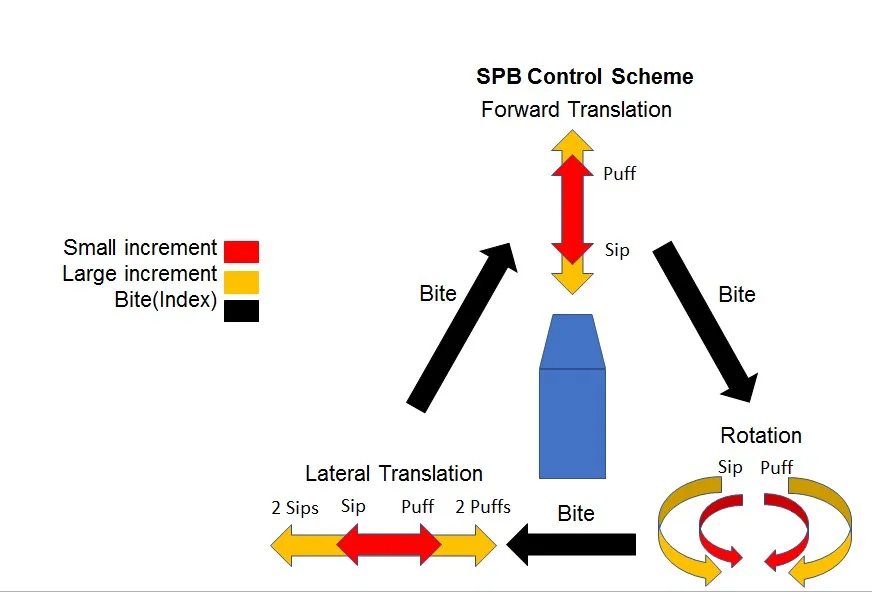

We were to use a device known as the sip ’n’ puff (SP) as the control system for the patients. The SP converts changes in pressure from breathing in and out of a straw to inputs that are used to create strings of characters assigned to boat commands. To effectively control the boat in open water and in docking maneuvers the character strings needed to be at least five characters long. We knew that multiple five-character-long strings would be too hard to remember and would not allow for dynamic control of the boat, so we needed to devise an alternate method.

Another engineer working for the TRAILS program had tried to create a soft bite switch, but the project never came to fruition. We decided to revive this idea and design and build a bite piece whose input could act as an indexing mechanism to alternate between menus. Thus, the sip ’n’ puff control sequence became Sip Puff Bite (SPB).

These menus further broke up the boat control and decreased the input commands to about 2 to 3 characters.

I needed to design a light and comfortable headset to facilitate a patient’s use of the bite piece and sip and puff straw. I found a commercial product on which I could add specially designed parts to mount the bite piece and straw onto.

The 3D Models, Prototypes, and Molds

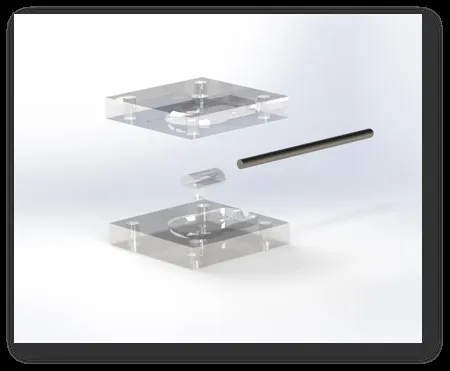

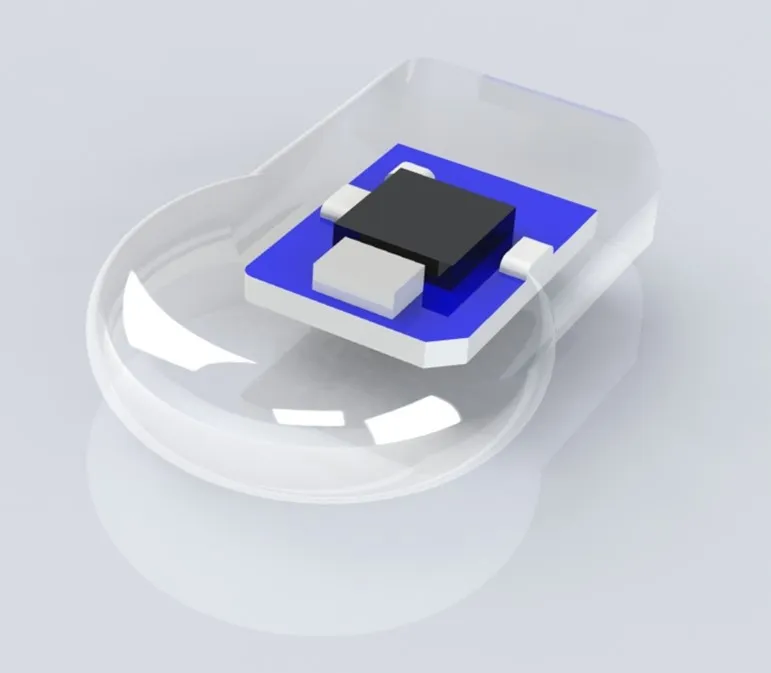

I worked with The Hitchcock Research Group Laboratory (HRG) to design the bite piece. The HRG specializes in soft silicone pressure sensors to measure forces and pressures for various body parts. The lab creates silicone-encased sensors by injection molding. Using SOLIDWORKS, I rapidly designed the overall geometry of the bite piece and then used 3D printing to refine the design and print prototypes until I decided on a final design. I modeled the molds using SOLIDWORKS Mold Tools.

The next step was choosing the material. The silicone needed to cure at 150° C for at least an hour, which meant the material had to be heat resistant. Metal would not work, as the molds were small, with intricate details, and the time constraint would not allow for machining such a complex part. With help from HRG, I found The Center for Medical Intervention (CMI), an institute that could 3D print with Form Labs High-Temp resin, a temperature-resistant material.

Form Labs High-Temp resin withstands 200° C, and so was perfect for our purposes. I had to have the CMI 3D print a couple of revisions of the molds because the HRG and I had to design the molding process because this was a new untested design. With the final molds and the help of CMI, we created the bite piece we had designed.

Setting Sail

I designed and 3D printed specific mounting points to integrate the custom bite piece into the commercial headset. I showed the assembled prototype at my Senior Design Day. When the control system is coded the control system will be tested on a trial population of patients to refine the controls as well as get feedback.

The TRAILS program plans on showcasing the PADS at medical conferences next year, with the final goal of having multiple PADS for use in programs around the country.

About Nathen Blas

Nathen Blas is a SOLIDWORKS Technical Support Engineer based out of our Headquarters in Salt Lake City, Utah. He earned his Bachelor’s degree in Mechanical Engineering at the University of Utah in 2018 and joined the GoEngineer family that same year.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.