New Creaform 3D Scanner Updates for 2020

Creaform recently introduced some hardware and software updates in a few of their product lines including the Go!SCAN, HandySCAN, and VXelements software. We'll go over the details of the Creaform 3D Scanner updates for 2020 here.

Related >> Creaform Releases New HandySCAN 3D SILVER Series 3D Scanners

Go!SCAN Spark

The Go!SCAN Spark is the new and only 3D scanner in this category. It replaced the Go!SCAN20 and Go!SCAN50. It’s been completely redesigned and has received updates to the cameras and other hardware. The Go!SCAN Spark is a white light scanner with 99 stripes allowing you to capture geometry or texture and tracks off of natural features eliminating the need for target stickers.

Volumetric accuracy

One of the major updates is volumetric accuracy (now just under 0.002in per running foot for X, Y, or Z), resolution is now just under 0.004in, and the capture rate increased to 1.5M per sec. The new ergonomic design and updated hardware help you get faster and more accurate scans which make it a great option for reverse engineering.

HandySCAN

The HandySCAN lineup is now made up of three scanners: HandySCAN 307, HandySCAN Black, and the HandySCAN Black Elite.

The HandySCAN 307 looks a lot like its predecessor, the HandySCAN 700, but it now has black housing.

The HandySCAN Black and HandySCAN Black Elite are essentially identical in appearance, however, there have been some major updates in hardware and 3D scanning capability. In the chart below, you can see a breakdown of these differences.

In the video clip below, we took the HandySCAN Black Elite outside to scan the wheel of a Chevy Monte Carlo (a reflective surface in natural daylight).

In the video clip above, it took me just a minute and a half to collect very accurate data and perform a complete 3D scan.

VXelements 7.0

There have also been some updates that will help you obtain fast, accurate, and clean 3D scan data.

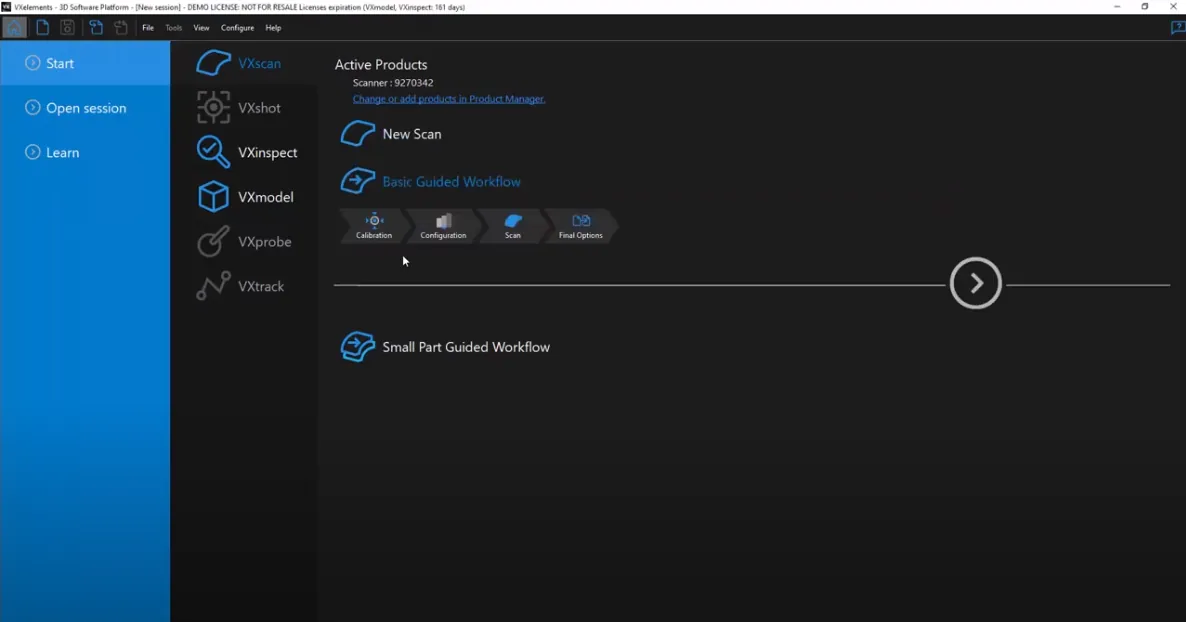

One of the cool new features in VXelements 7.0 is the Guided Workflow , designed for new users or users who have had minimal 3D scanning experience. The Guided Workflow takes you step-by-step through the entire process from calibration to finalizing a scan. It’s very quick and easy to follow.

There’s also a workflow for parts that require multiple scans. For example, small parts usually require a top and a bottom scan. For this, the process works the same, only this time, the workflow is going to include aligning the scans, merging them together, and then finalizing.

In version 7.0, the calibration button and the configuration button are in a window on the right-hand side. There are also some new features on the main toolbar with the scan button on the upper left-hand corner. The remove background tool is also new. See how that works in the video below.

Optimize Volumetric Accuracy helps tighten the tolerance of all your targets. Fill Positioning Targets just fills the holes behind targets, and Optimize Accuracy of Boundaries helps give you cleaner boundaries. The new Reduce Noise tool helps you specify how much noise to remove from your scan (if you have any at all).

Auto-Decimate is a tool that recalculates your mesh, giving you big triangles for the flat areas and smaller triangles for the curved areas, resulting in a higher quality mesh.

That wraps what’s new for the Creaform 3D Scanning product line. For more information about these 3D Scanners, contact us .

About William Huertas

William is an Applications Engineer for GoEngineer. He graduated from CSU Los Angeles with a Bachelor’s and Master’s degree in Industrial Technology. His expertise lies in 3D printing, 3D scanning, and reverse engineering applications. Using the latest technology, he enjoys helping customers improve their design and manufacturing process.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.