Modeling and 3D Printing a GoEngineer Clock

Recently, we received our Stratasys F120 3D printer. We’ve been eager to get off some cool prints that showcase its 3D Printing capabilities. One of the ideas that I’ve had is to print the components for a frameless wall clock. I had one in college and thought it would be great to do a custom, GoEngineer-themed clock for the office.

Let’s get modeling!

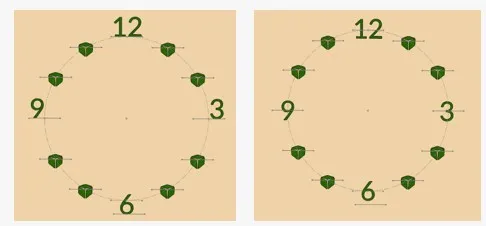

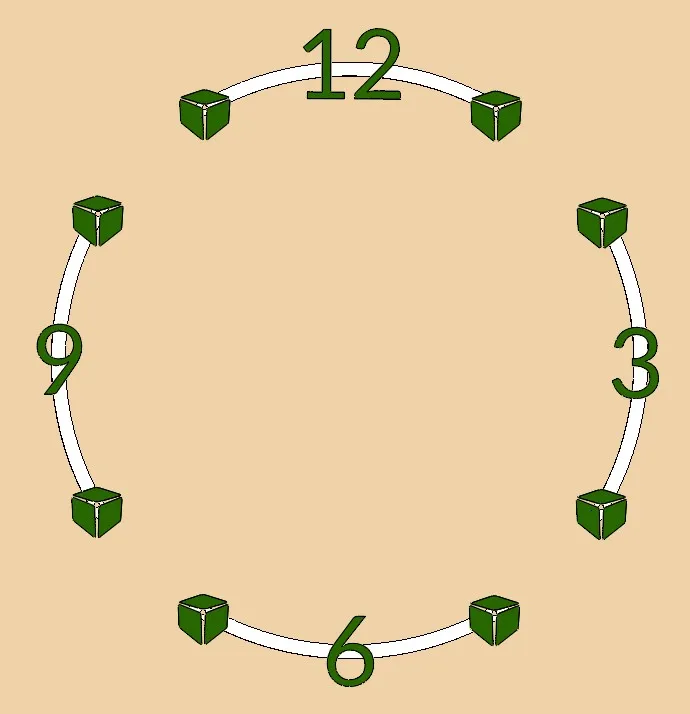

I modeled my design as a multi-bodied part. The only challenge I ran into was how to get the circular pattern correct with the GoEngineer Logo. The feature’s circular pattern and curve-driven pattern didn’t quite get the results that I wanted. With those two options off the table, I ended up using a sketch-driven pattern to get the position and orientation precisely where I needed them. A little Move Body action helped me locate the numbers correctly.

After that, I decided to connect the numbers and icons in such a way that the clock would be four pieces. This would make the final assembly and mounting easier.

A few iterations later…

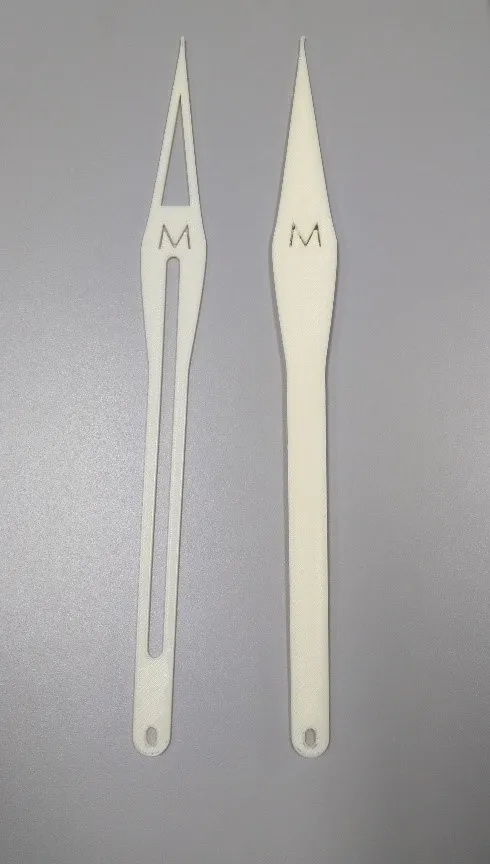

I continued on to model the hour and minute hands.

The minute hand proved to be tricky because the clock does not support as much weight on the minute hand shaft as it does on the hour hand shaft. Since my first version of the minute hand was too heavy, I went through a few iterations to get an acceptable size and weight. I light-weighted the design by:

- decreasing the thickness from 0.125 inches to 0.035 inches

- creating some openings in and slimming the profile

- changing the print settings in GrabCad from high density to low density

I decided to mark the hands H and M for hour and minute to test the gap capabilities of the printer. The smallest gap in these profiles is 0.018 inches, which doesn’t even seem to be the lower limit.

The finished product

Once I printed all the models, it was time to apply the GoEngineer colors.

Currently, we only have the ivory colored ASA material for our printer; so I bought some green and gray acrylic paint along with the clock mechanism from Hobby Lobby. I mounted the finished product in the AE room (that’s where the application engineers hang out). Now we have a reminder that every time is GO TIME!

About Jared Trotter

Jared Trotter is an Application Engineer and CSWE at GoEngineer. He holds a Bachelor’s Degree in Biomedical Engineering from Mississippi State University. Previously, Jared worked as a design engineer with Hol-Mac in Bay Springs, MS and worked on curriculum development with the Engineering is Elementary program at the Museum of Science in Boston, MA.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.