Loading Fortus Material Canisters for Stratasys 3D Printers

FDM (Fused Deposition Modeling) thermoplastic filaments form the backbone of Stratasys' original core technology. FDM materials range from general purpose, like ABS, to composite-filled Nylon, to chemical-resistant Antero. Something all FDM materials have in common though, is that they are susceptible to moisture. Any moisture that infiltrates the filament strand will create bubbles when the material is pushed through the extruder, from that moisture boiling away as it's heated. Bubbles can cause print quality issues as well as clogged tips and failed prints. In short, moist filament can stall production and cost companies thousands of dollars in wasted material and machine downtime.

Stratasys takes moisture mitigation extremely seriously, especially on their Fortus line of industrial FDM 3D printers. These machines employ heat and airflow to actively dry the entire filament path, from the canister all the way to the print head.

As important as it is to dry the filament path, it is crucial to maintain a dry environment in the material canister itself. Fortus canisters are specifically designed to stay dry, employing several tactics in that effort, with a design as intuitive as it is effective. Here are the simple steps required to unbox a canister and insert it into the printer.

- Start by opening the box. Remove the steel material canister from its sealed mylar pouch.

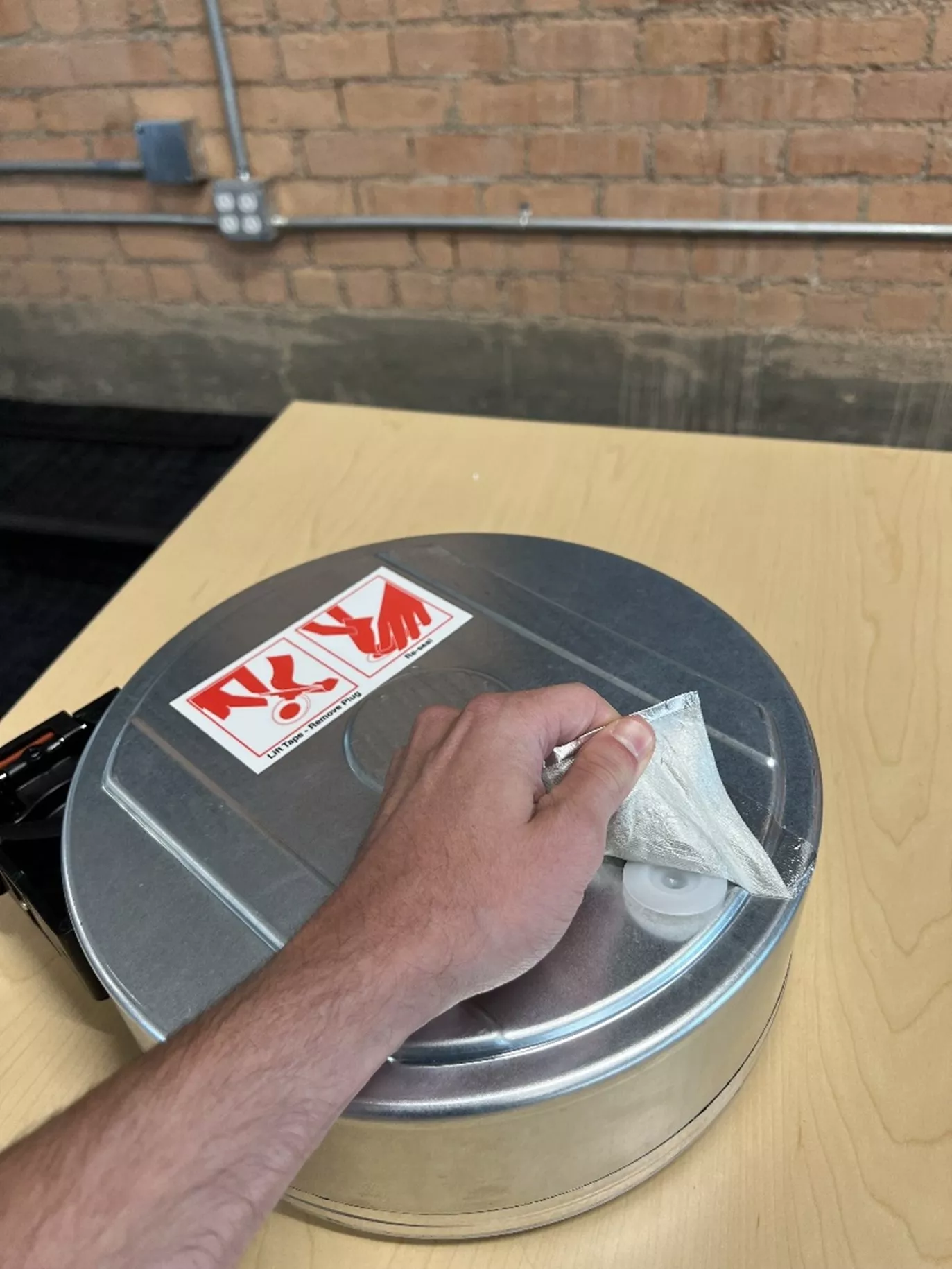

- The canister has an anti-rotation plug inserted during shipping to prevent cross-winding. Peel back the foil tape far enough to remove the plug, then reseal the opening. You can use the flat side of the plunger to flatten out the tape as best as possible. The rest of the operations are completed on the protruding canister snout.

- On the snout is a removable filament cap and a thumbwheel door, which seal the filament path and thumb wheel respectively. Both components have thick gaskets and are designed to be opened and closed for the life of the canister to keep moisture from getting in during storage. Remove the filament cap to expose the filament lead, and place the cap underneath the filament drive wheel door for storage.

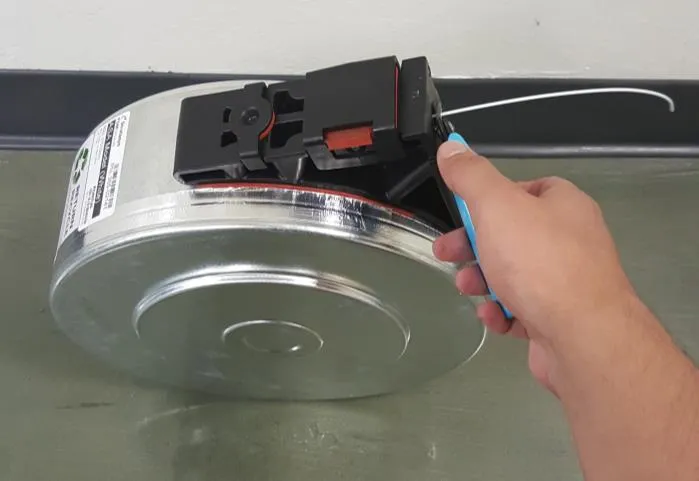

- Open the filament drive wheel door and roll the rubber wheel down with your thumb to begin driving the filament out of the canister. Note: Never move the cartridge with the door open, you want to make sure the door is closed whenever moving a canister.

ROLL WHEEL DOWN - Pull out about a foot of material to make sure the material comes out freely.

- Push about 6 inches of material back into the canister. This will reduce the tension and will reduce the risk of the filament falling all the way back into the cartridge. Close the door so the filament is locked in place and then cut it flush.

PUSH IN 6" - Slide the canister into the desired material bay.

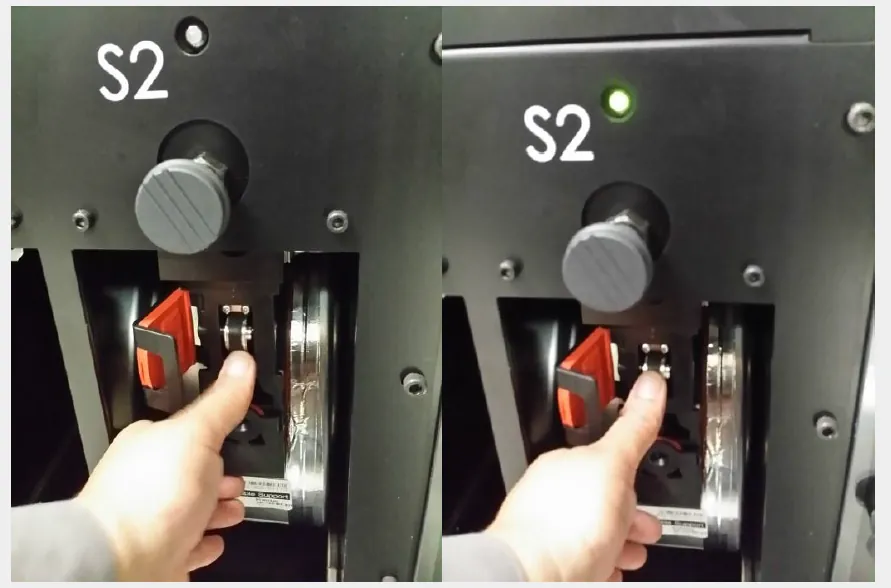

- Pull out the drive block handle and drop it into place to lock the cartridge.

PULL OUT AND DROP DOWN - Open the material drive wheel door and use your thumb to roll down the rubber wheel. This will push the filament up into the drive block sensor. Once the sensor is triggered the light above will start flashing green specifying that the material is ready to load.

- The inside of the door has a rectangle-shaped orange sponge. This sponge acts as a brake and keeps the filament locked in place while the door is closed. At this point, we want the material to come out freely so we need to peel off the brake pad. The sponge has double-sided tape so it is easy to store by sticking it underneath the filament cover.

- We can now close the door and load material from the machine main panel.

Pulling out a foot of material and pushing back 6 inches of material into the canister helped us reduce the risk of losing the filament inside the cartridge. Without doing this trick, you can load material, but the wheel will be more difficult to spin downwards and the filament will have a natural tendency to want to drop back into the cartridge. This trick helped us make a small task just a bit easier.

Editor's Note: This article was originally published in June 2016 and has been updated for accuracy and comprehensiveness.

More 3D Printing Tutorials

Stratasys Slicer Updates for FDM: GrabCAD Print & Insight

Stratasys Industrial 3D Printer Maintenance Tips: Fortus Edition

5 123 Series Maintenance Tips for New Users

Fortus Tip and Build Sheet Combinations: 3D Printing Tutorials

About GoEngineer

GoEngineer delivers software, technology, and expertise that enable companies to unlock design innovation and deliver better products faster. With more than 40 years of experience and tens of thousands of customers in high tech, medical, machine design, energy and other industries, GoEngineer provides best-in-class design solutions from SOLIDWORKS CAD, Stratasys 3D printing, Creaform & Artec 3D scanning, CAMWorks, PLM, and more

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.