ETS-Lindgren: PDM beyond CAD

ETS-Lindgren Background

ETS-Lindgren is a recognized leader in their field. Their area of expertise is the manufacturing and design of systems to control and detect electromagnetic energy emissions. If you have a cell phone, there’s a good chance ETS-Lindgren has had an impact on making it better. The technology they’ve developed is so advanced that some of their product chambers can give you a 3D view of what the cell phone antenna signal looks like.

Initially, all testing was conducted onsite in their state-of-the-art chambers. The need for building these chambers onsite emerged as they wanted the ability to run their own tests quickly for customers. ETS responded by providing this as a service to their customers in addition to the onsite testing. They do have a broad reach of products from antennas, amplifiers, filters, positioners, and more. The sizes of their chambers range from something small enough to wheel around in an office, all the way up to a large facility chamber you can put a jet aircraft in.

Engineering Project Management

ETS has grown up with the SOLIDWORKS brand, and like many customers, initially started controlling their documents and processes with SolidWorks PDM Workgroup. Their vault quickly became too large and sluggish for an entry level PDM system. In 2012, they took a leap towards moving their 400GB Workgroup Vault by migrating to SOLIDWORKS Enterprise PDM (now renamed as SOLIDWORKS PDM Professional).

This was also the first step towards providing a centralized vault for all of their worldwide locations. They worked towards setting up replication in countries like China, India, Finland, and many other US locations. Once they had a centralized depository of CAD, the next step was to control some of the Project Documentation and workflow. Check out this video to learn more about how GoEngineer solved their EPO (Engineering Project Order) issues.

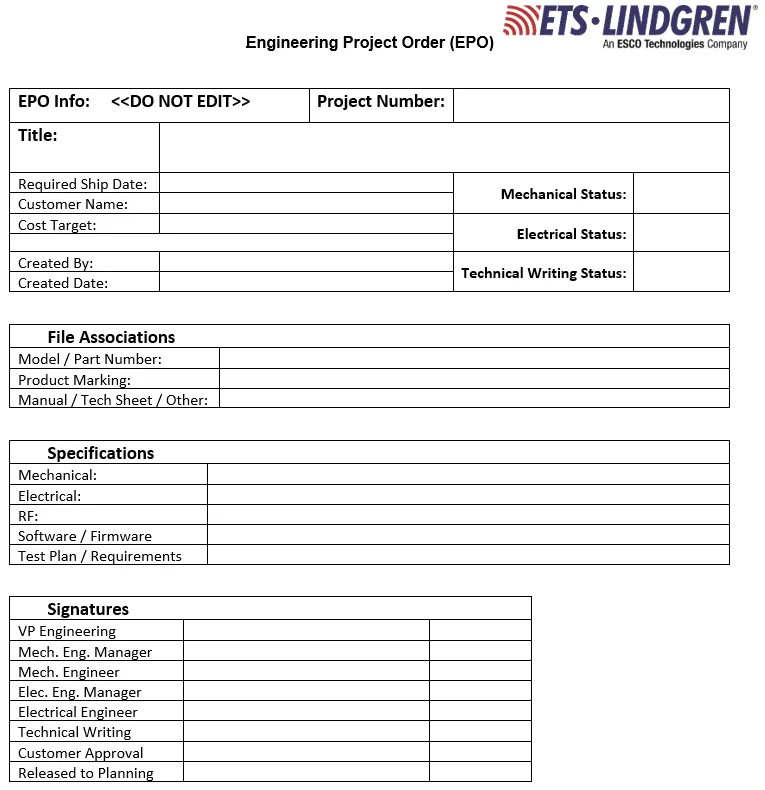

Engineer Project Order

ETS initially attempted to solve the EPO process by getting their IT department involved who developing a simple xml form. To begin, the Engineer would fill out a form, and then a little at a time, other team members would add notes. This was a step in the right direction, however, there wasn’t a version control on the form and anyone who had permissions was able to write over existing notes.

Scenarios like this are a perfect match for SOLIDWORKS PDM and a simple Microsoft Word Document. SOLIDWORKS PDM creates a history every time someone checks out the file, makes a modification, or checks the file in. This provides accountability, visibility into who makes each change, as well as provides a timestamp on those changes.

Building a Workflow

ETS projects get their start in three main department groups: Mechanical Engineering, Electrical Engineering, and Technical Documentation. The trick to this is that projects will usually differ on which department has tasks assigned to it. One of the tasks GoEngineer assisted ETS with was to make sure that the workflow supported this. For instance, some projects are dependent on the electrical team only, and so they only diverge through those workflow states. Some go through the mechanical department, then through electrical, and some need to go through all three departments. The workflow can start to look like a spiderweb, but is then very flexible, which allows for all scenarios.

PDM Templates for Automation

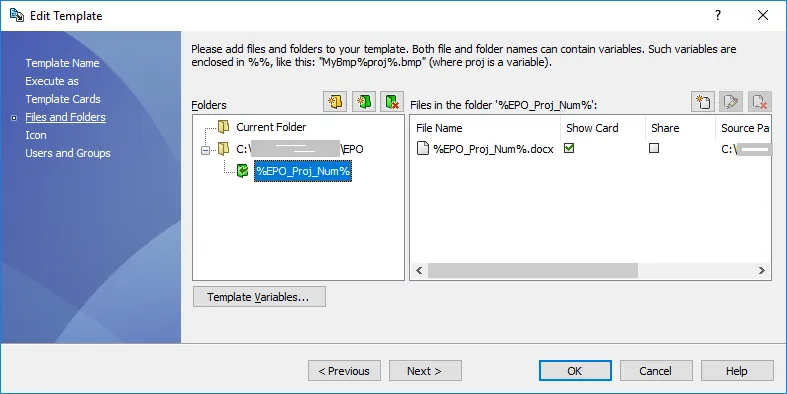

GoEngineer next used a PDM Template to allow the users to fill out a simple form which automatically copies the EPO word document from their Global Templates directory, grabs the Project Number and other variables, and then pastes them to the proper Vault Folder with the new EPO project number as the filename.

PDM Stretches its reach

Once ETS had been using the EPO system for some time and experiencing improvements, they added more PDM Viewer licenses to help aid with additional users having access to their projects and CAD documents. They’re also now evaluating new ways to integrate more document types that need to be controlled and use specific workflows.

PDM also has built-in custom reporting. For Engineering Project Orders, SOLIDWORKS PDM provides a report that lists key variables. This is so management can see which projects are falling behind or how long the typical project might take for the next customer. All data for these forms are completely searchable and helps to automate and make a better system for everyone involved in the project. Any document type that needs control from CAD, standard operating procedures, nonconformance reports, or Engineering Project Orders, can easily be handled with GoEngineer and SOLIDWORKS PDM.

About Steven Darcey

Steven Darcey is a SOLIDWORKS Elite Application Engineer and CATIA Specialist based out of Austin, Texas. In 2000, he earned his BS, Mechanical Engineering degree from the University of Arkansas at Little Rock and joined GoEngineer in 2015. In his free time, Steven enjoys wood working, family experiences, and anything electro-mechanical and nerdy.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.