Design and Manufacture a Custom Hat Using LPBF & FDM 3D Printing Technology

Laser Powder Bed Fusion (LPBF) is a 3D printing technology that utilizes fiber optic lasers to micro-weld fine metal powder to generate a solid metal part. This method, used in many industries (e.g., oil & gas, nuclear, automotive, and aviation), allows manufacturers to produce parts for research and development. LPBF technology enables the production of field-ready parts, reducing lead times and supply chain issues. In this article, see how I created a custom hat using 316 Stainless Steel on an XM200G Xact Metal 3D printer and a custom press die to aid in the process. This project was completed in five hours, including printing the parts and assembly.

The Designing Process

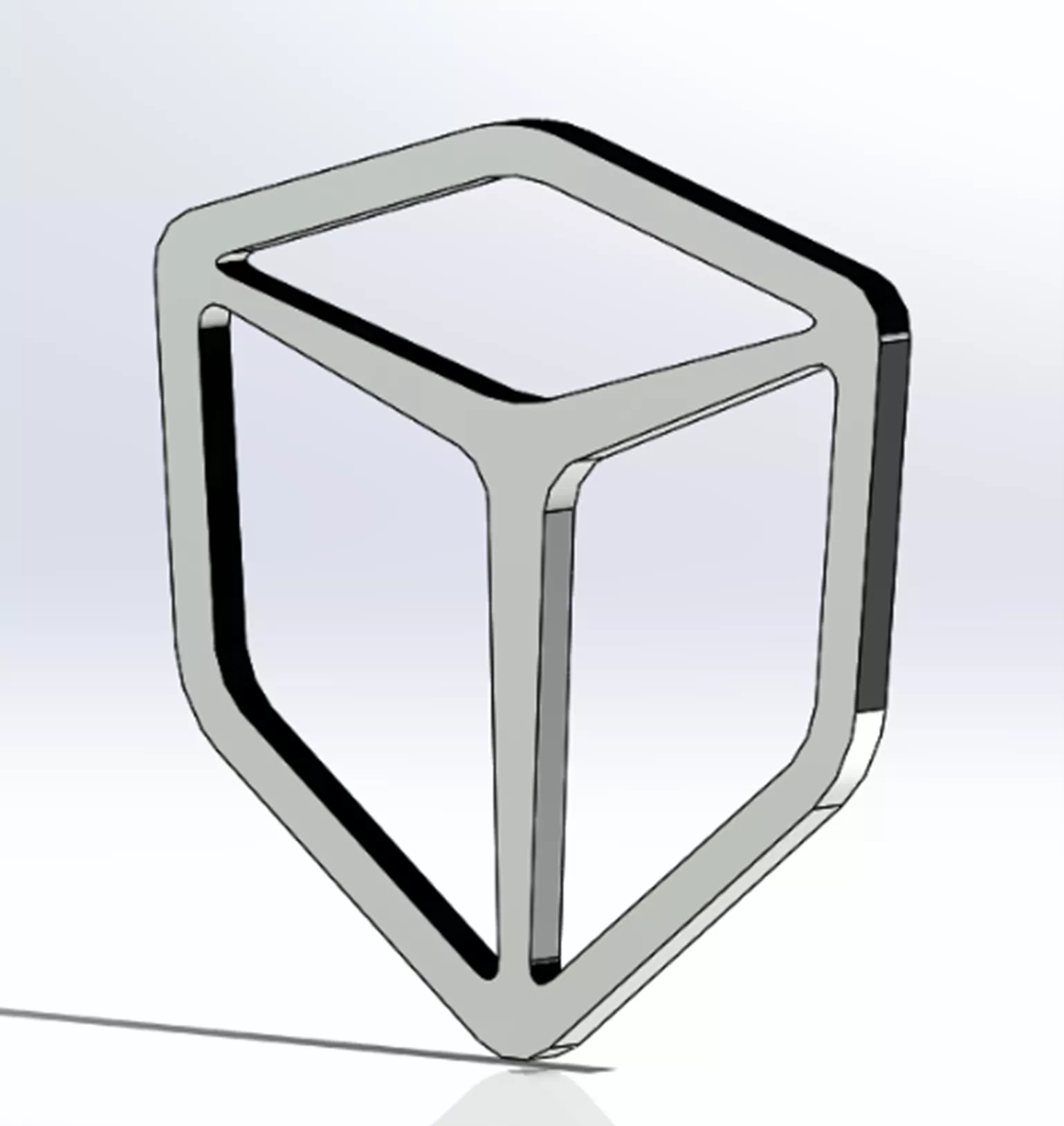

First, using SOLIDWORKS, I designed the GoEngineer logo in a single sketch and extruded the outline to two millimeters forming a solid digital part. (Figure 1)

Figure 1: Design Logo

When outlining the logo, it was important to be mindful of the size; the goal was for it to be placed on the front of the hat. I measured the front face with calipers and decided 50 millimeters (about 1.97 in) of width for this project. (Figure 2)

Figure 2: Hat with Calipers

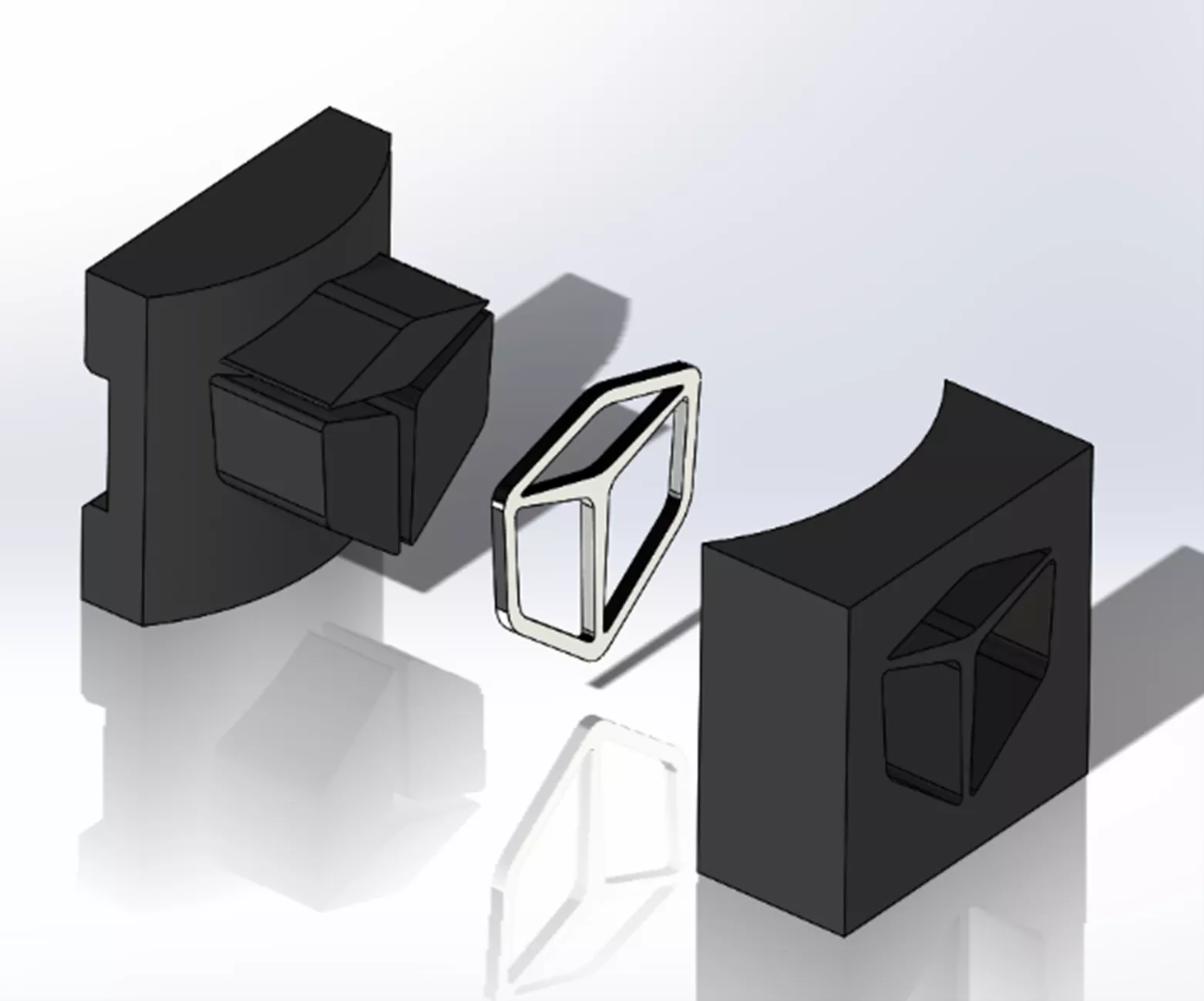

With this information and my part designed, I started working on the press die. The main function of a press die is to mold the shape to the natural curve of the hat. This is a two-part assembly where the logo is placed inside the die to control the bending. (Figure 3)

Figure 3: Press Die

The Printing Process

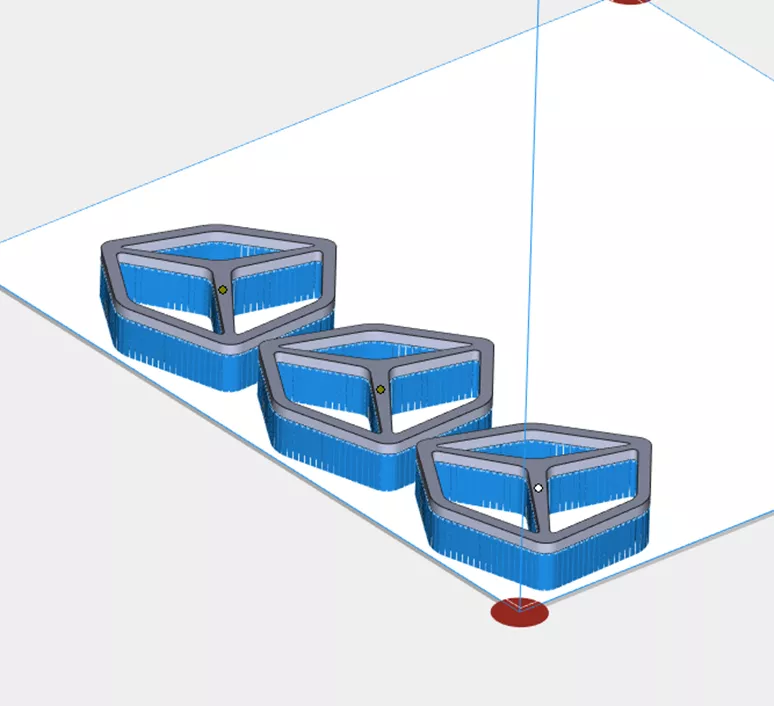

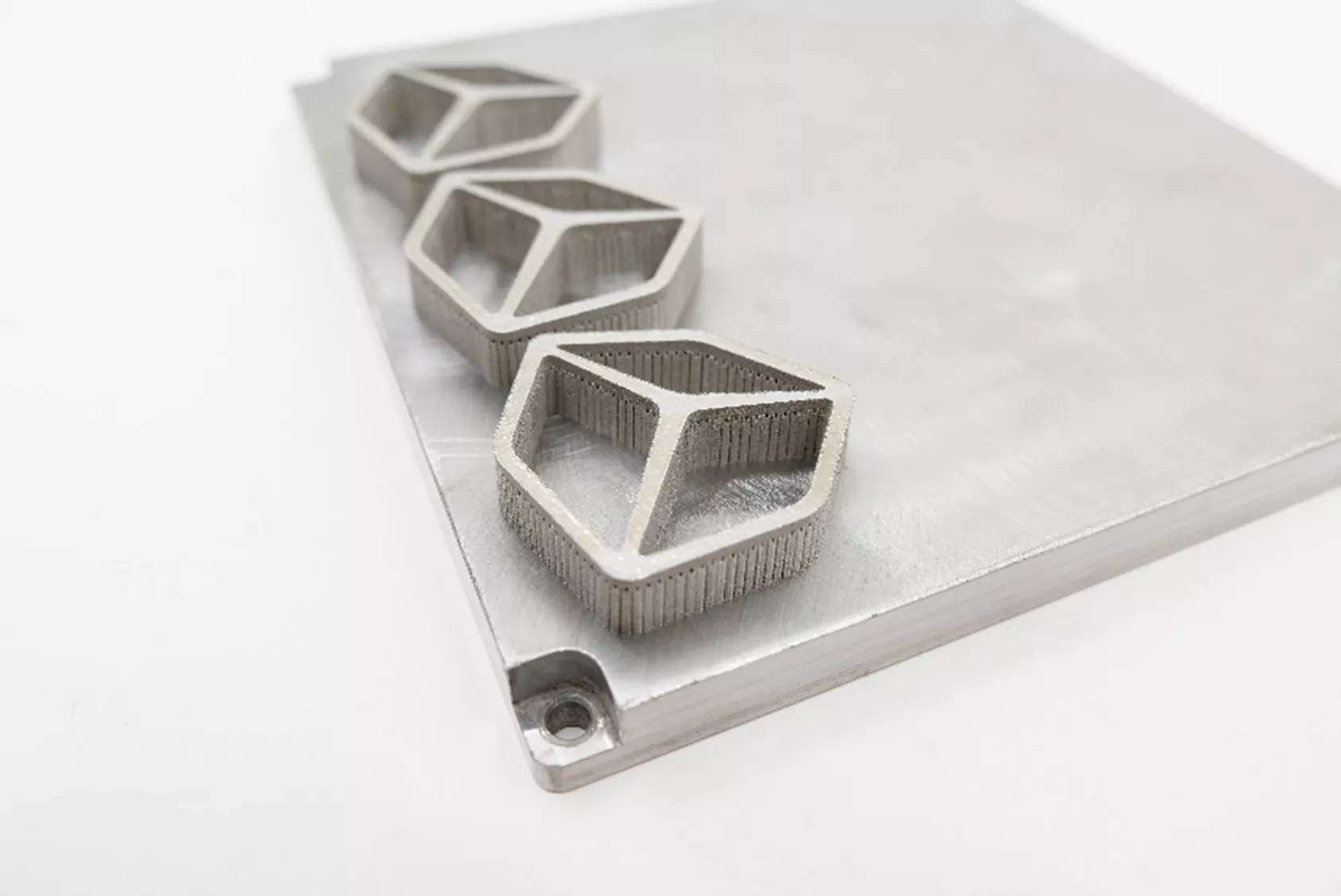

After designing, I exported the logo as a STEP file to Materialise Magics and supported it with a grid pattern (Figure 4), which prepares it for our LBPF 3D printer. 316 Stainless Steel material was used in this process due to its ease of printing and ductile nature.

Figure 4: 316 Stainless Steel Build

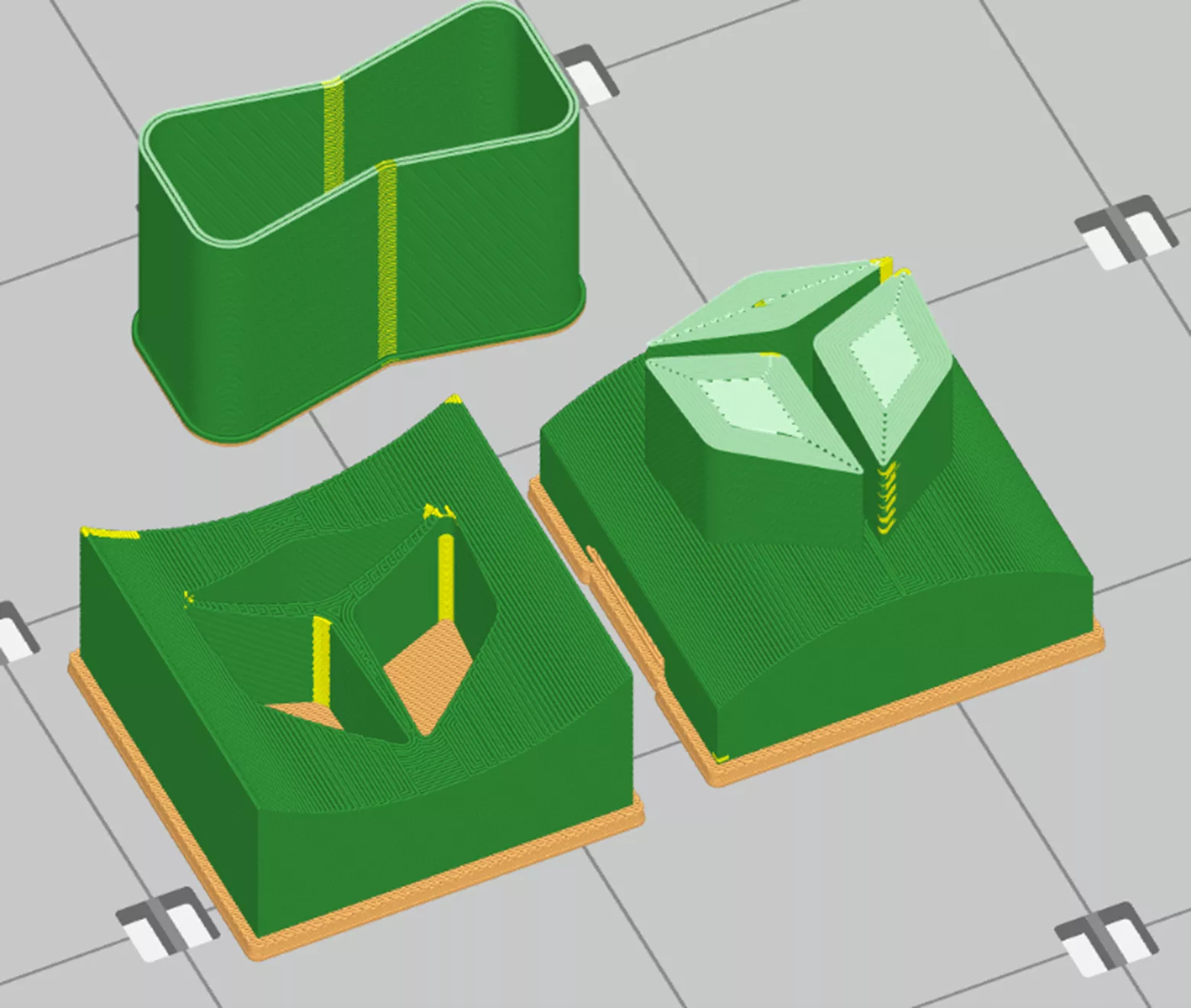

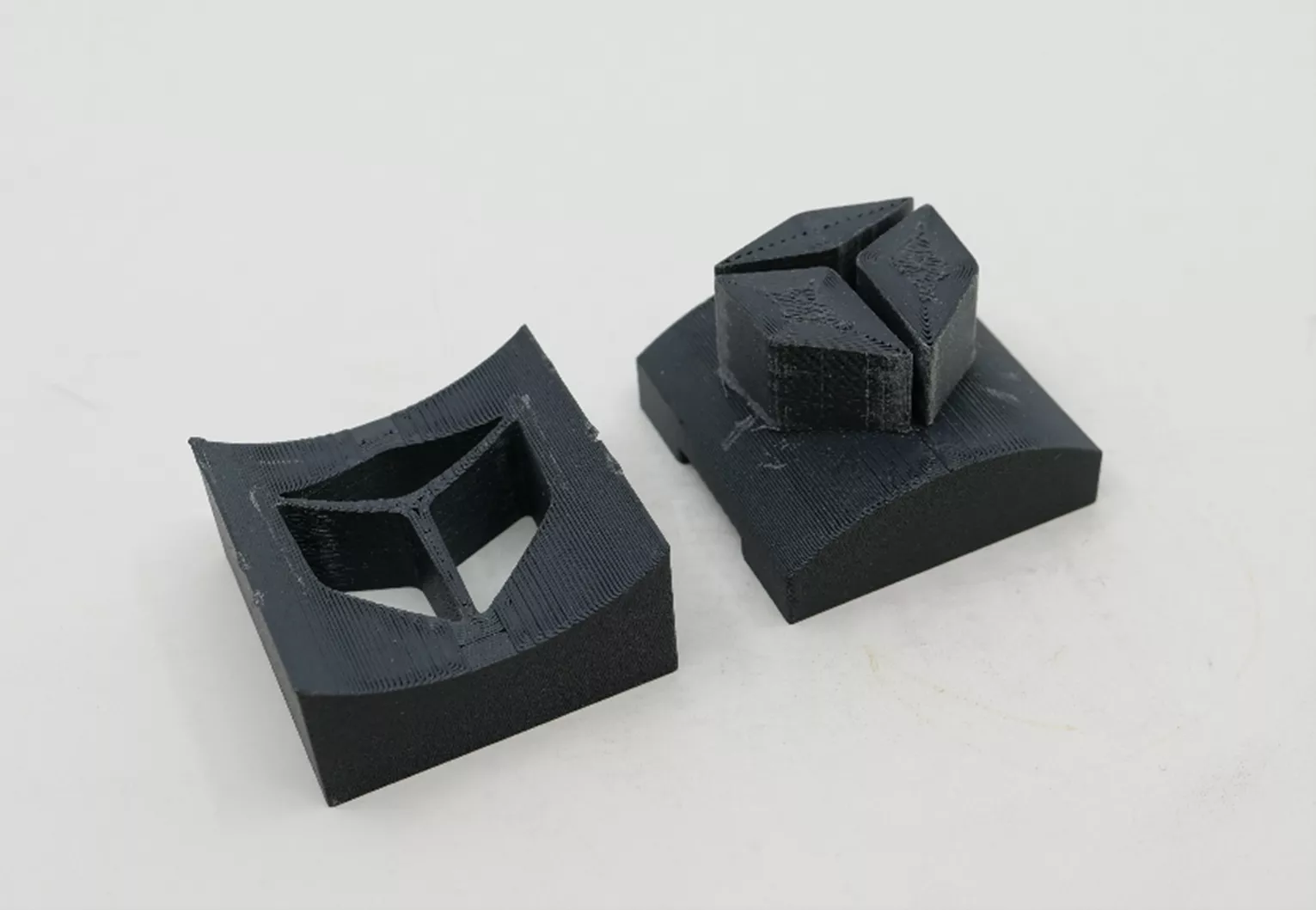

The press die was printed on a Stratasys F370 with ABS-CF10 material. ABS-CF10 is a great replacement for fixtures and jigs in the manufacturing area. For maximum strength, I used a thick wall and assigned it as a solid body. (Figure 5)

Figure 5: ABS-CF10 Parts

After the parts were printed, they were removed, cleaned, and prepared to be utilized.

Figure 6: Hat Logo in 316 Stainless Steel

Figure 7: Press Die in ABS-CF10

The Manufacturing Process

The press die was clamped in a vise and slowly tightened, forcing the metal print to form the contour of the press die and therefore forming a curved part. This step is critical and ensures the part mates correctly with the front of the hat.

Figure 8: Assembled Part and Die

After the part was formed, the logo was fabric glued to the front - completing the project.

I hope you found this article insightful. Check out more from the 3D printing team at GoEngineer below.

3D Printing as a Service

GoEngineer offers comprehensive 3D printing services across multiple U.S. labs, equipped with cutting-edge Stratasys FDM, PolyJet, Stereolithography, and SAF technologies for 3D printed prototypes or production parts. Request your quote online today!

Related Articles

FDM 3D Printed Tool Organizers & Assembly Aids

A Modern Take on a Classic: 3D Printed Fender Telecaster

3D Printed Redesign of Corvette C4 Gas Pedal Mount

Tips for Adding Fasteners to 3D Printed Parts

About Benjamin Davenport

Benjamin Davenport is an Additive Manufacturing Application Engineer at GoEngineer.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.